Patents

Literature

288results about How to "There will be no stuck phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

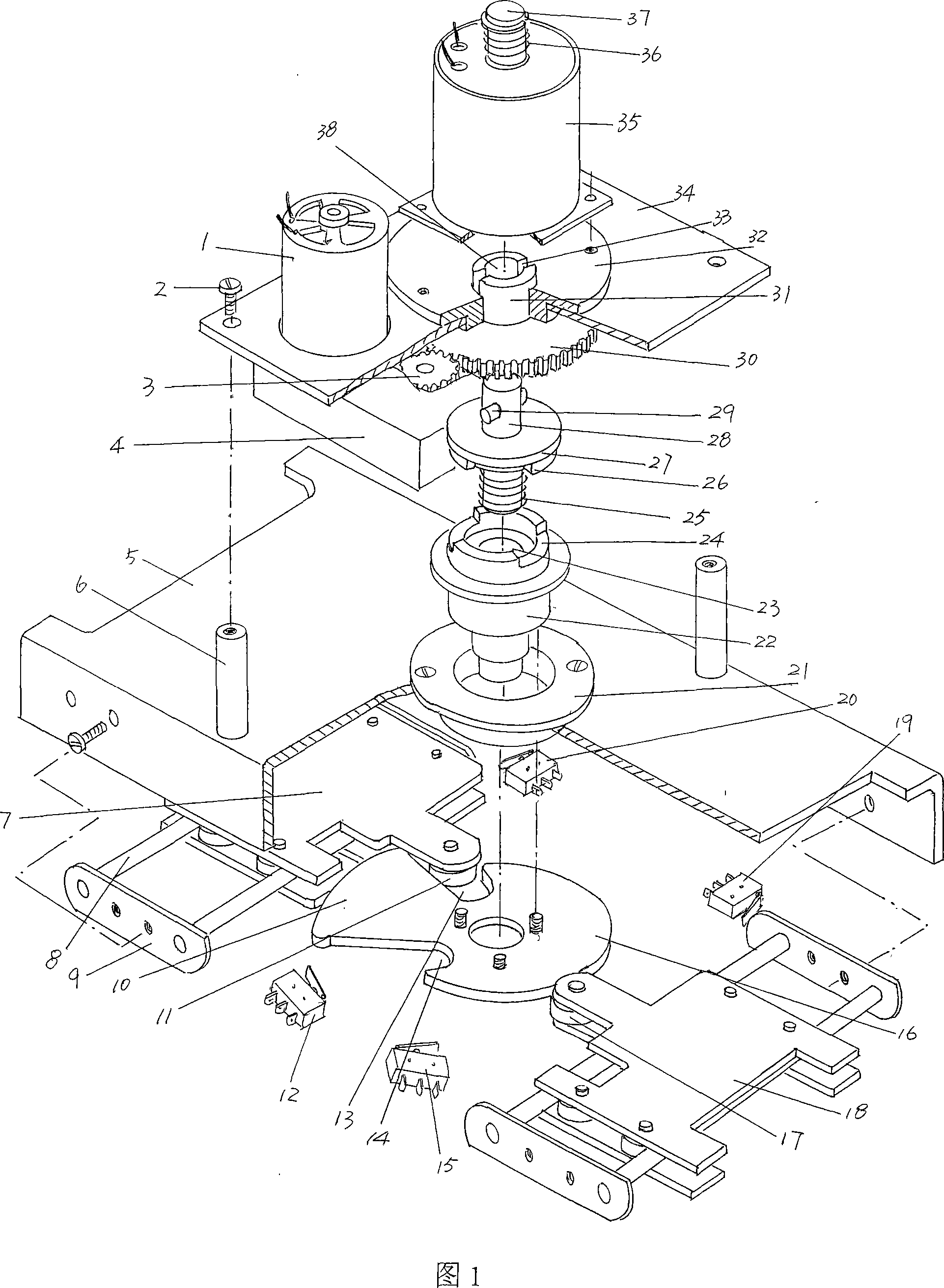

Mechanical interlocking transmission device of double power supply automatic switching switch

InactiveCN101145454ASmall rotation angleImprove operational reliabilitySwitch power arrangementsSolenoid valveTransfer switch

A mechanical interlock transmission device for dual-power automatic transfer switches is provided, which comprises a motor, a speed reducing mechanism, upper and lower fixed plates, a transmission main shaft, first and second slippers, first, second, third and fourth micro-switches, and a cam rotary disk. The invention is characterized in that the device further comprises a solenoid valve, a main gear, a main gear shaft, and an intermediate shaft, wherein the solenoid valve is fixed below the upper fixed plate and is provided inside with a solenoid valve plug and a second return spring; the main gear is fixed below the upper fixed plate by the main gear shaft and engaged with a pinion of the speed reducing mechanism; the top end of the intermediate shaft is inserted into a gear shaft hole of the main gear shaft and the bottom end thereof is covered with a first return spring and then inserted into a central shaft hole of the transmission main shaft; the middle part of the intermediate shaft is provided additionally with a clutching toothed block seat on which a clutching toothed block is formed and engaged with a clutching toothed socket of the top of the transmission main shaft. The invention has the advantages of small motor rotation angle, short switching time, improved operational reliability of the circuit breaker, long service life, and easy manual operation.

Owner:CHANGSHU YONGXIANG ELECTROMECHANICAL

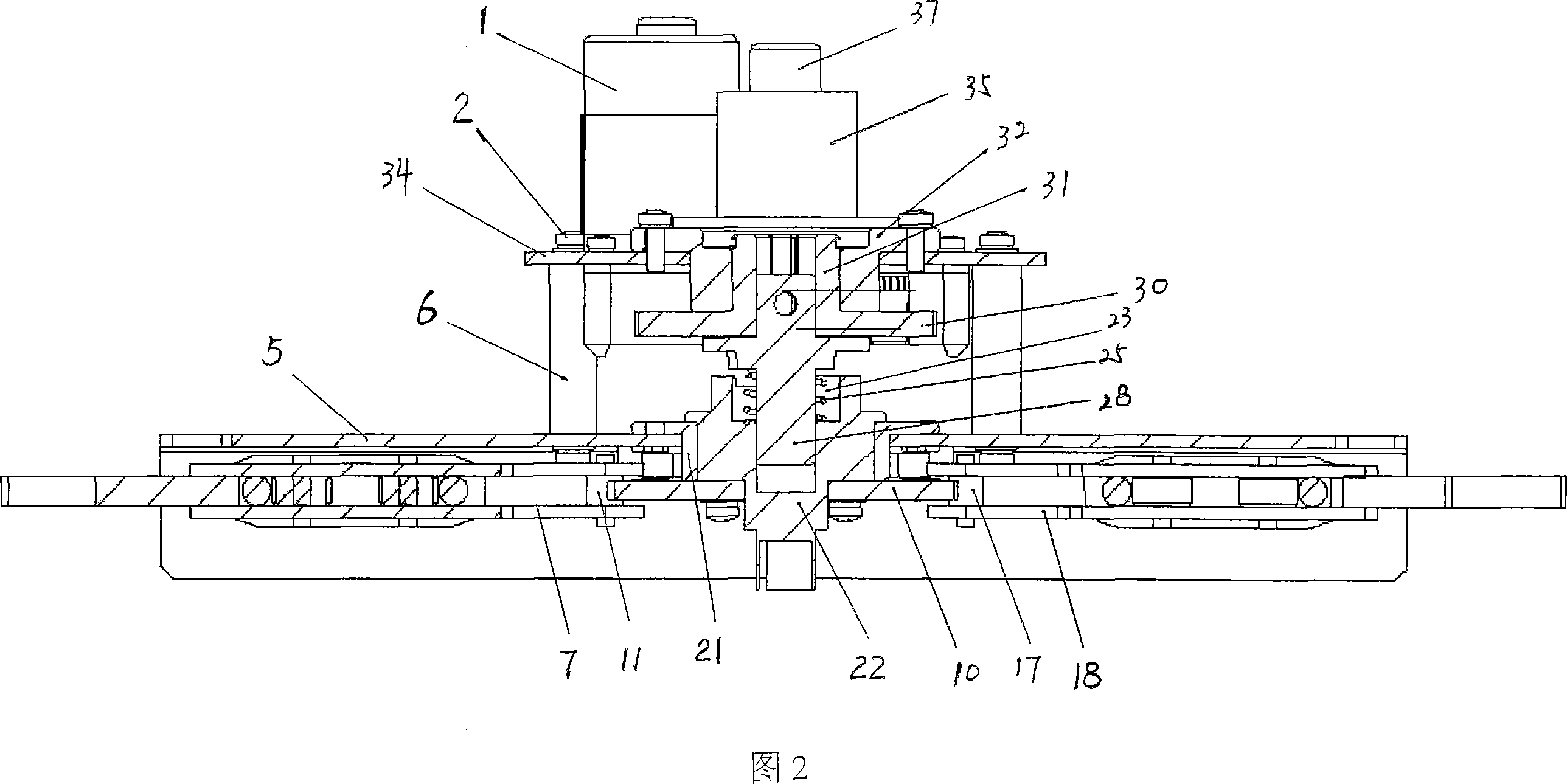

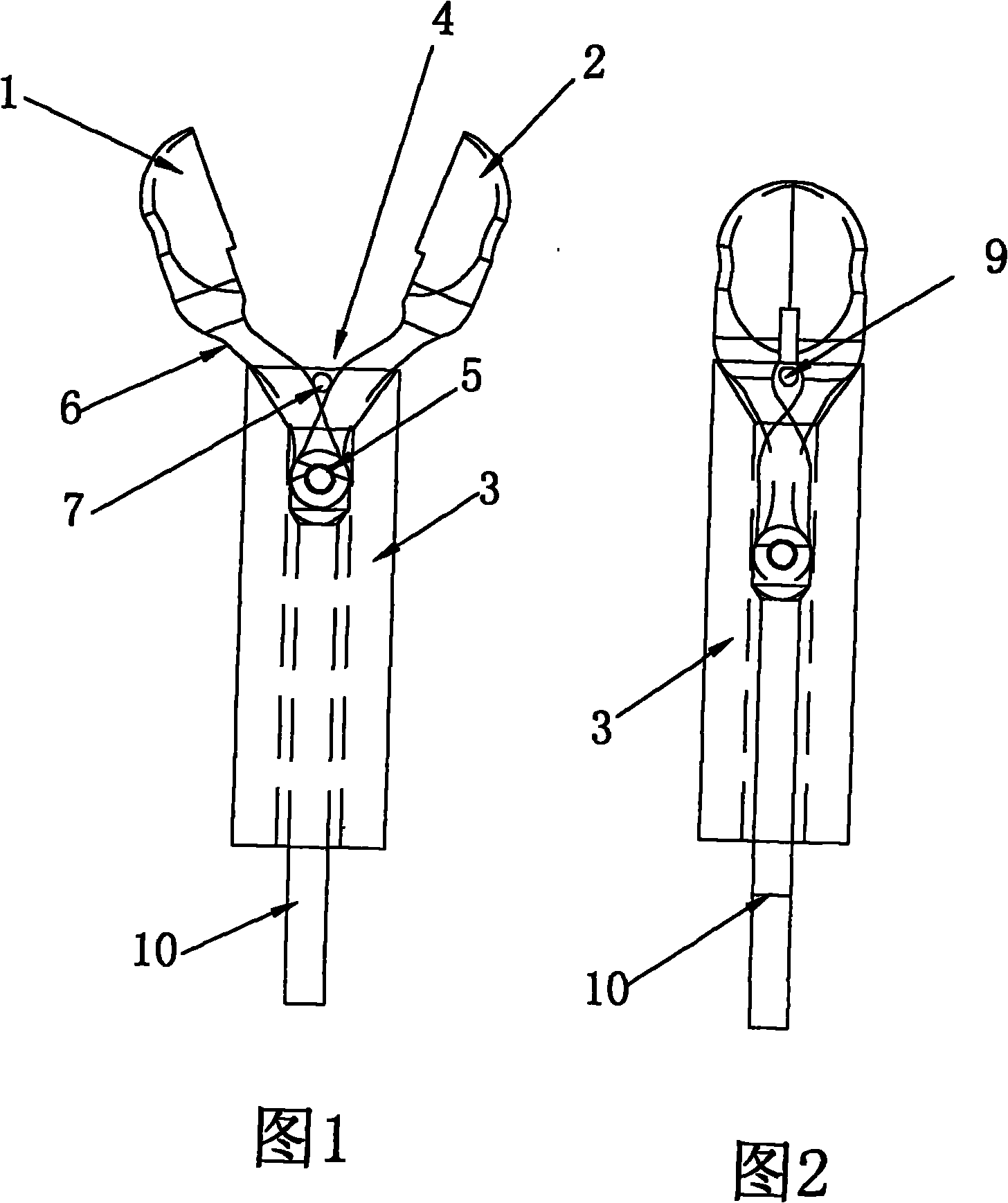

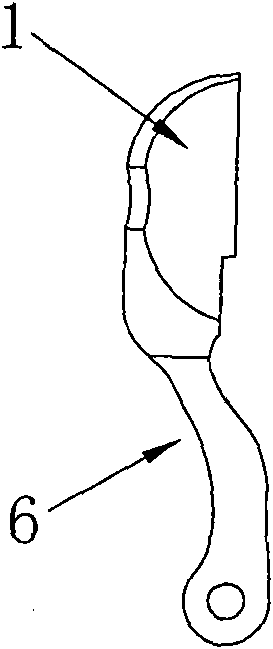

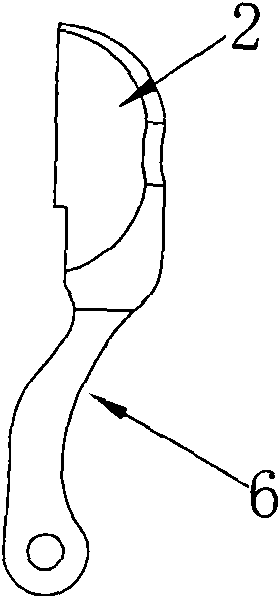

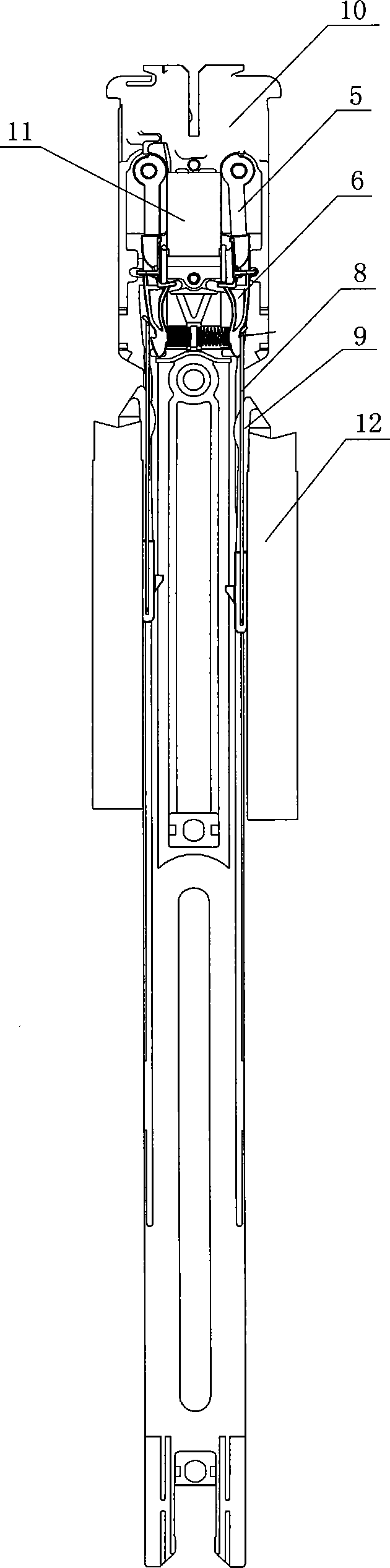

Sleeve structured medical in vivo minimally-invasive object-catching forceps

InactiveCN101836881AThere will be no deformation and jamming of the connecting rodThere will be no stuck phenomenonVaccination/ovulation diagnosticsSurgical forcepsForcepsIn vivo

The invention provides sleeve structured medical in vivo minimal-invasion object-catching forceps, comprising a binding clip component. The forceps are characterized in that the binding clip component mainly consists of a left binding clip (1), a right binding clip (2), a sleeve (3) and a control part (4) for controlling the open and close and the moving distance of the left binding clip (1) and the right binding clip (2), wherein the jaw parts of the left binding clip (1) and the right binding clip (2) extend out of the sleeve (3), while the tail parts of the left binding clip (1) and the right binding clip (2) are connected with each other through a connecting pin (5); the connecting pin (5) is connected with a drive inhaul cable one end of which is arranged in the sleeve (3) in a penetrating manner; outsides of the left binding clip (1) and the right binding clip (2) are provided with drive surfaces (3) which props against the port wall of the sleeve (3) and can automatically closed when driving the left binding clip (1) and the right binding clip (2) to contract inwards the sleeve (3); and the control part (4) is arranged on the sleeve (3). The forceps have the advantages of simple structure, convenient manufacture, low cost and high strength.

Owner:南京思维斯精密机械制造有限公司

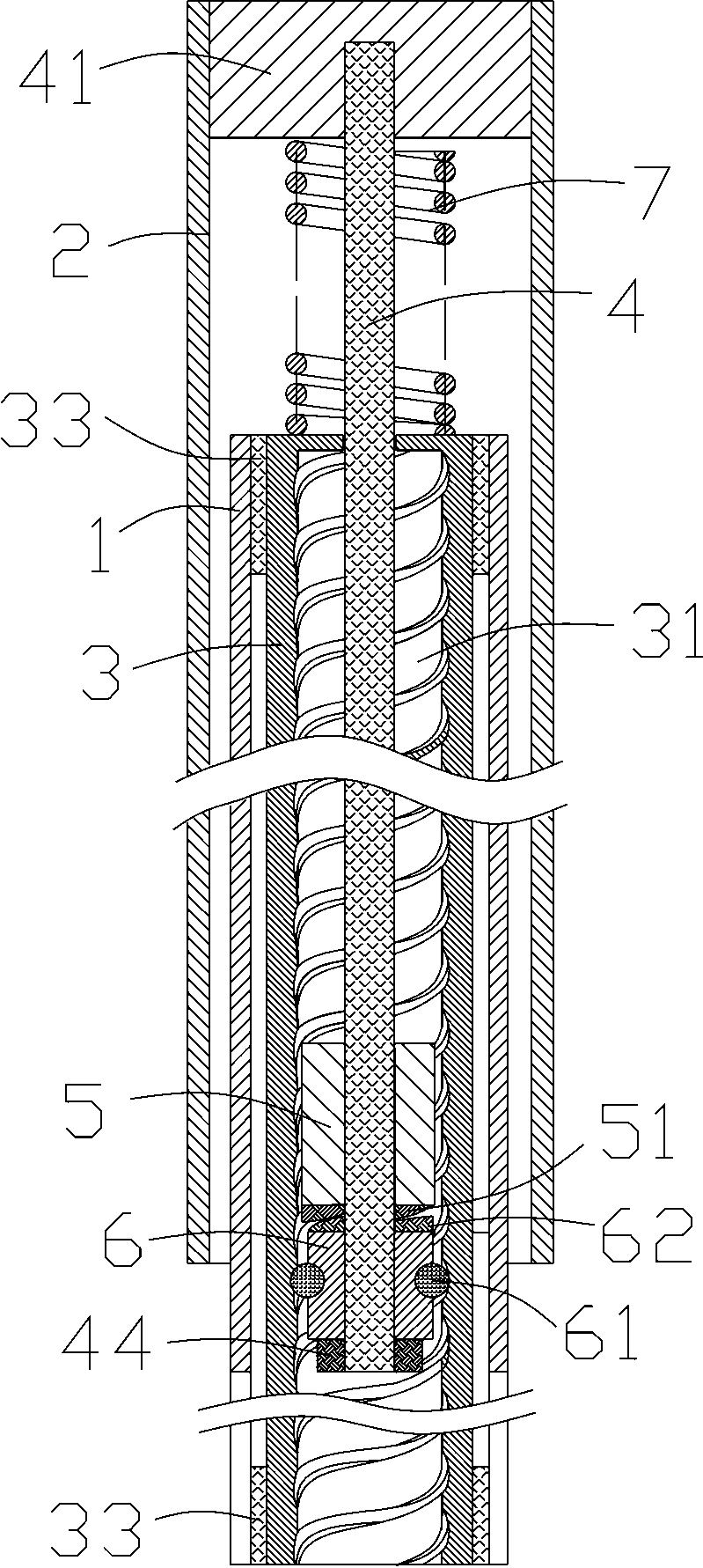

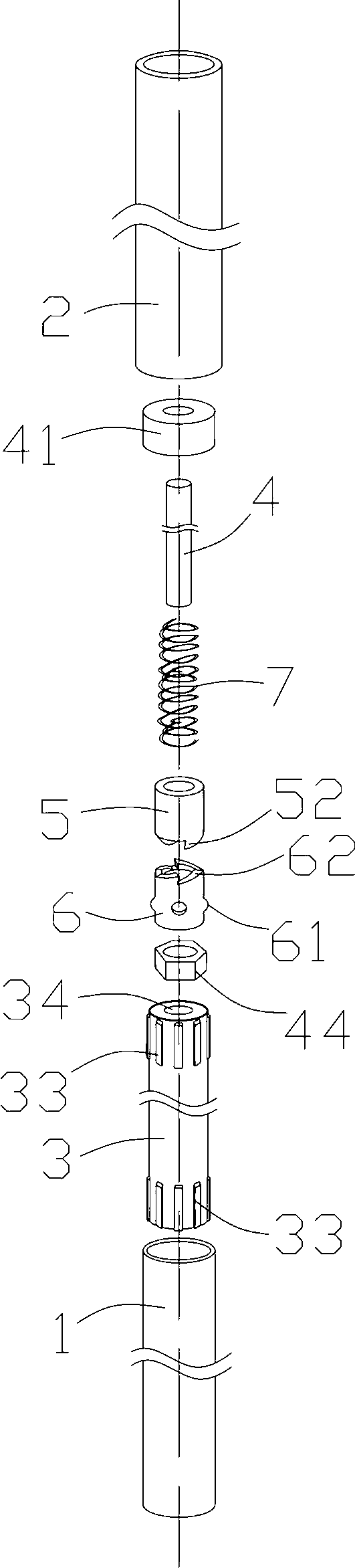

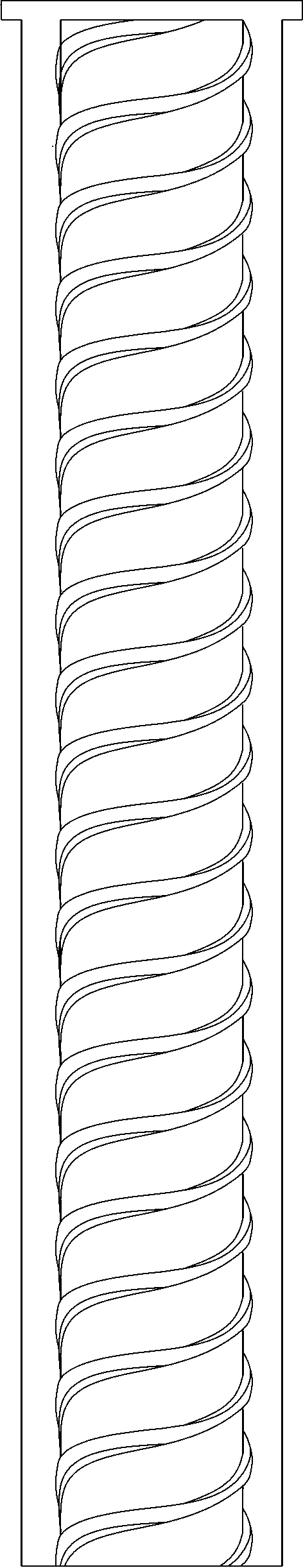

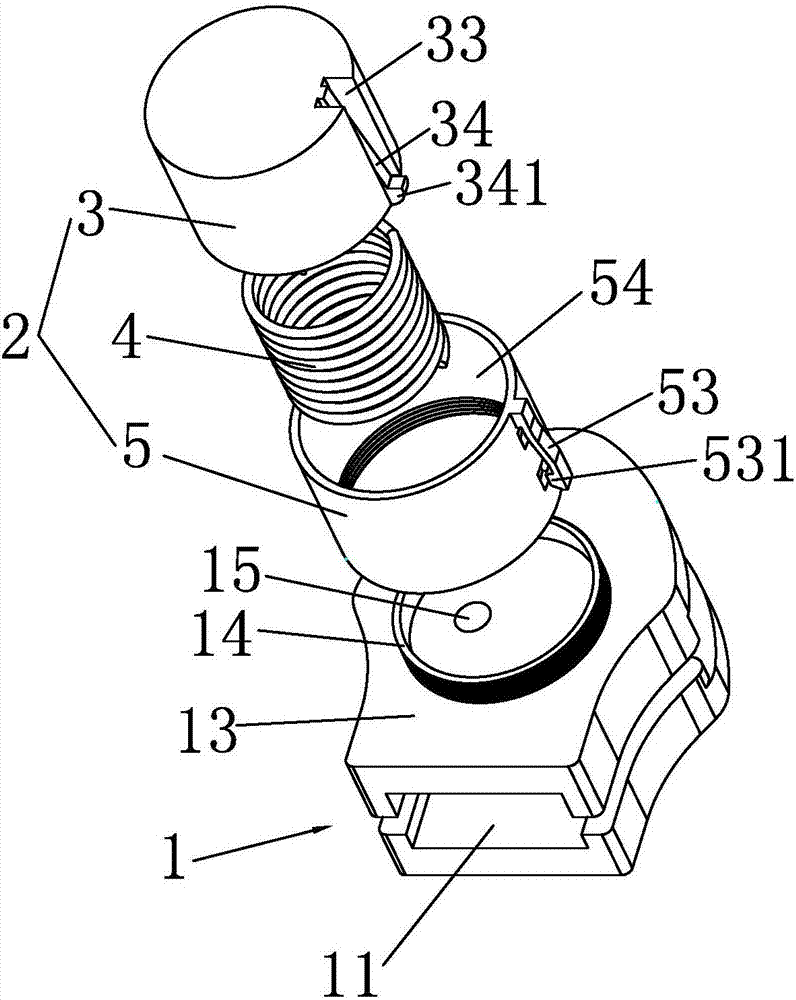

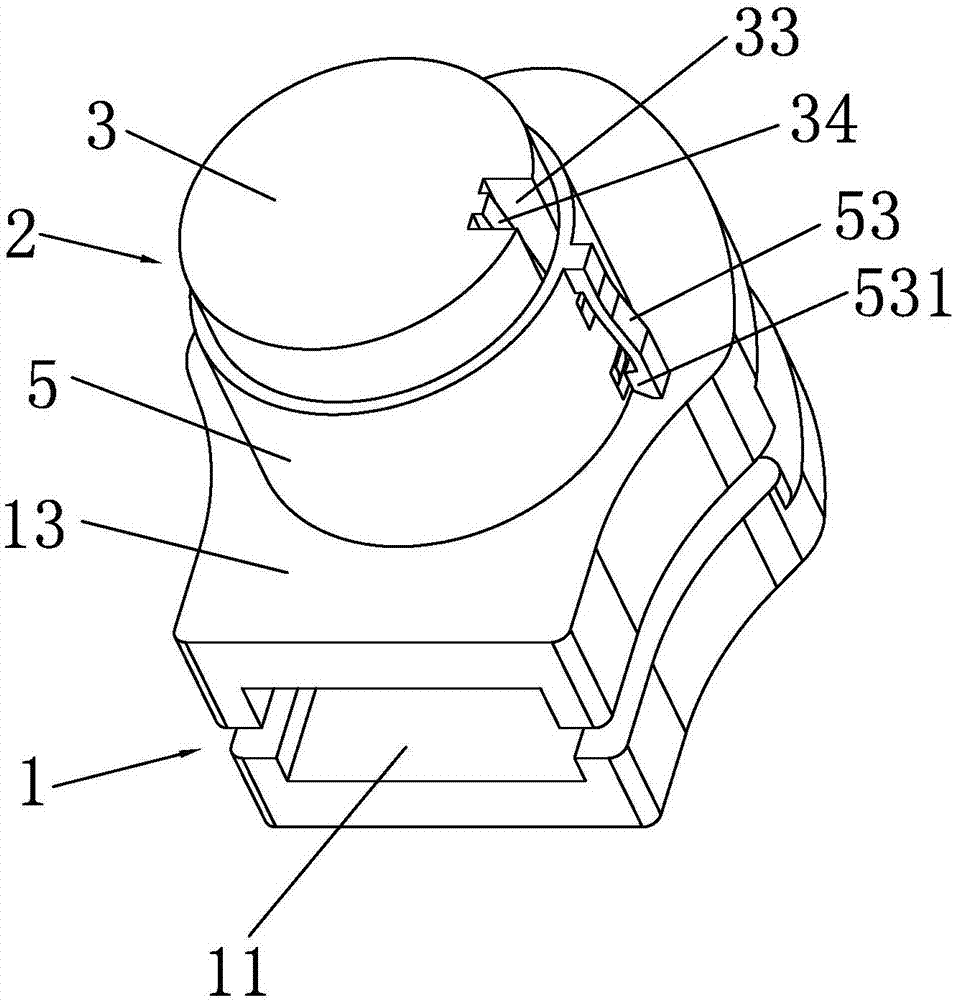

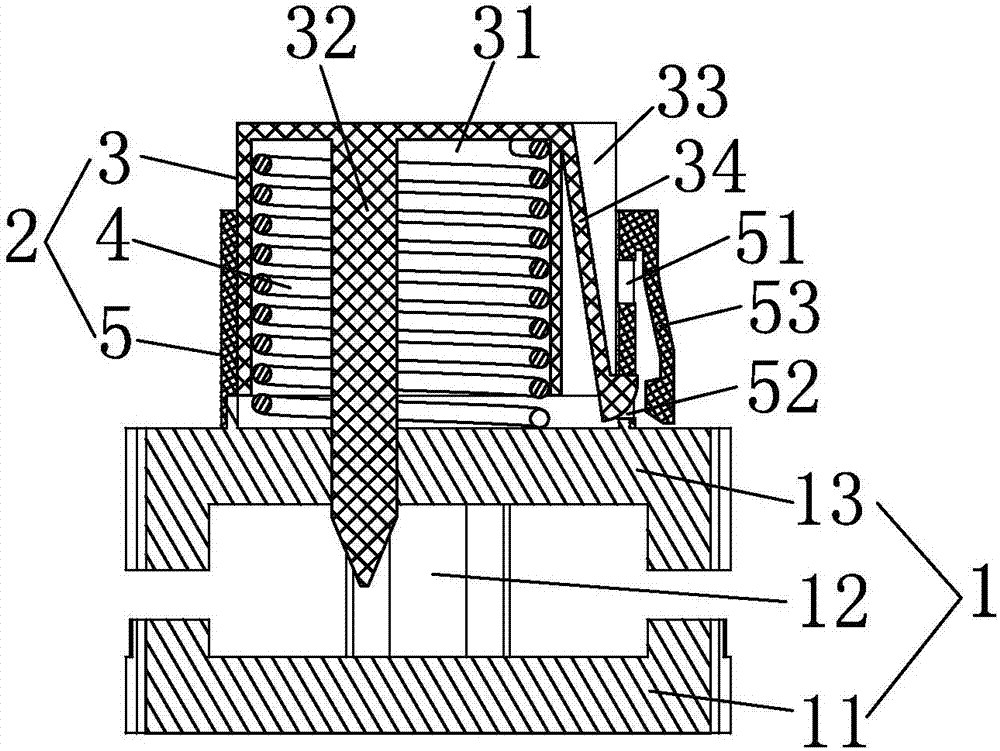

Manually-pressed type rotating mop rod

ActiveCN103120575ASimple structureFew partsCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a manually-pressed type rotating mop rod. The manually-pressed type rotating mop rod comprises an inner rod body, an outer rod body, a rotating sleeve, a guide shaft core, a rotating guide piece, a blocking portion and a braking portion. The inner rod body and the outer rod body are mutually connected in a sleeved mode. The rotating sleeve is arranged in the inner rod body and the inner wall of the rotating sleeve is provided with a spiral groove. The guide shaft core is arranged in the rotating sleeve, and the upper end of the guide shaft core is fixedly connected with the outer rod body. The rotating guide piece is sleeved at the lower end of the guide shaft core and capable of rotating along the guide shaft core. The blocking portion is arranged at the lower end of the guide shaft core and used for blocking the rotating guide piece from slipping off. The braking portion is capable of preventing the rotating guide piece from rotating. The rotating guide piece is capable of moving vertically in a small distance between the blocking portion and the braking portion. The manually-pressed type rotating mop rod is simple in structure, small in number of components, easy to assemble and high in production efficiency, and dewatering effect is improved greatly, and the phenomenon that a mop head idles can not happen in long-term use.

Owner:浙江美添乐家居用品股份有限公司

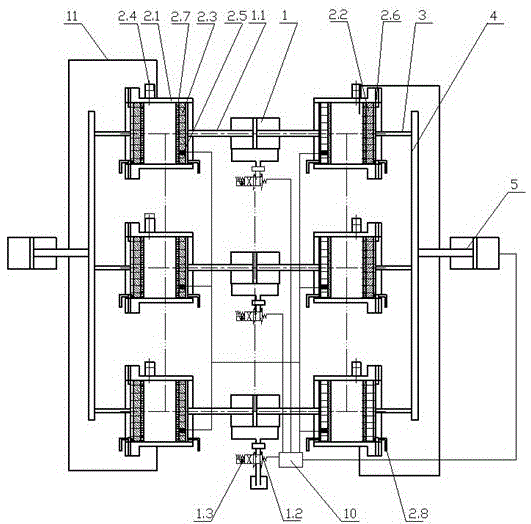

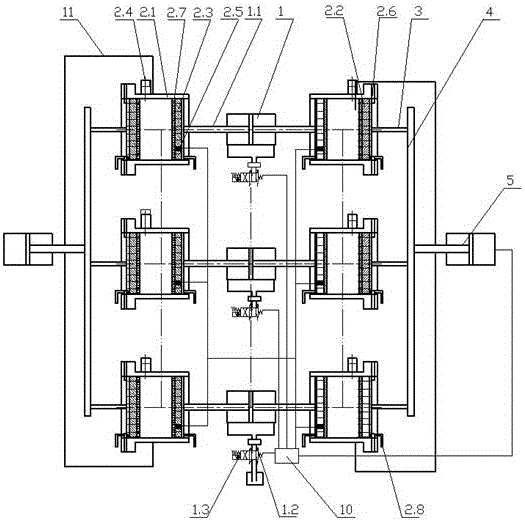

Sewage sludge reduction dewatering method

InactiveCN105601080ARealize unloadingAchieving deep reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSewage

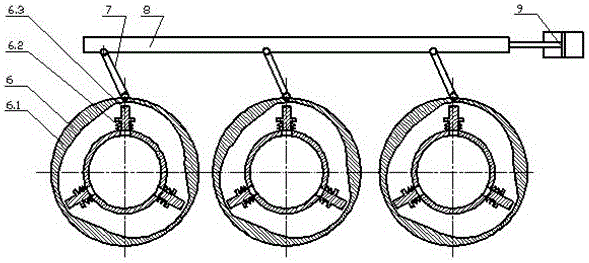

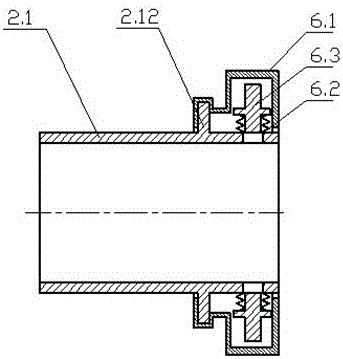

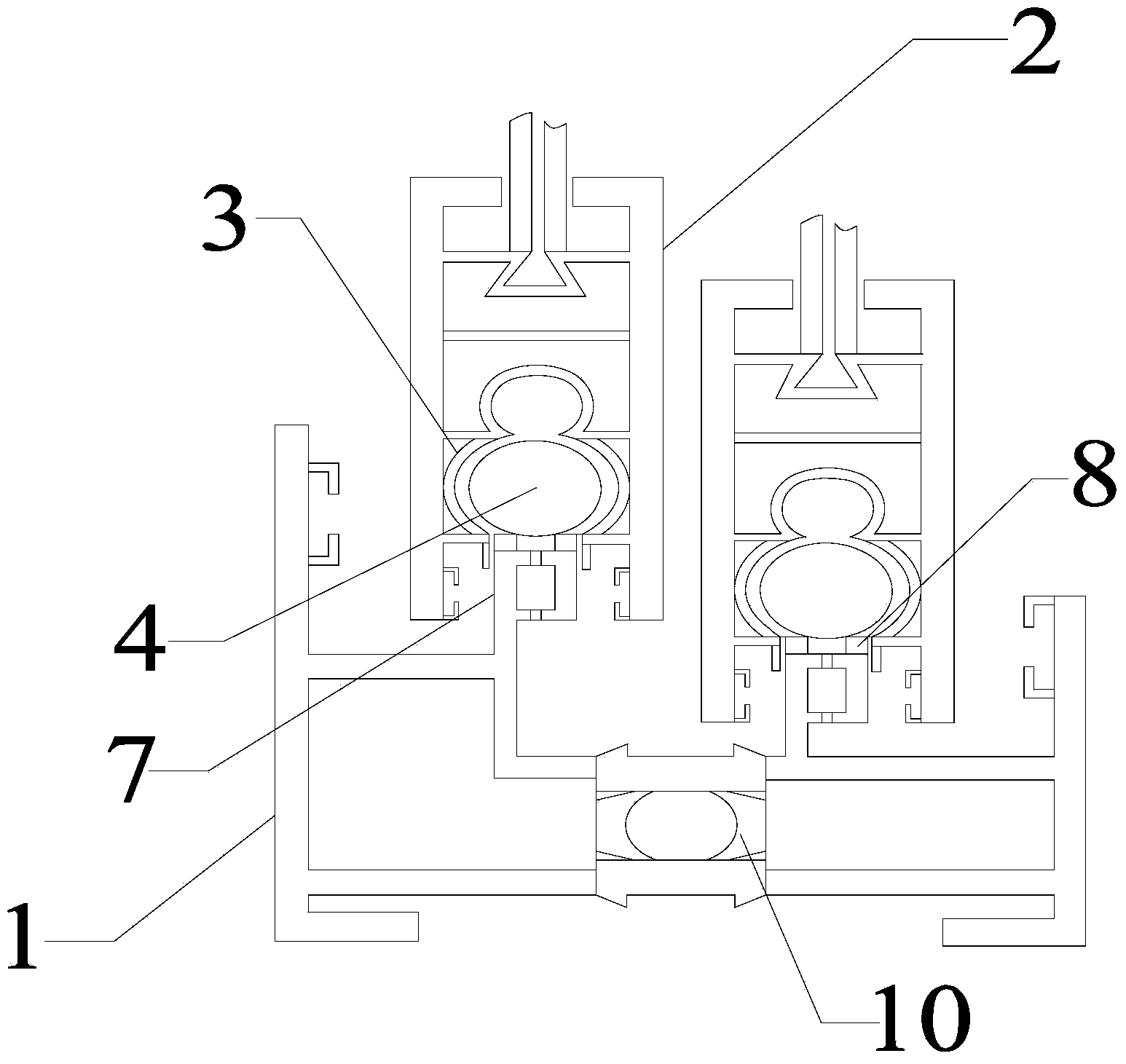

The invention discloses a sewage sludge reduction dewatering method which is based on a reduction dewaterer. The reduction dewaterer comprises at least one dewatering module, wherein each dewatering module comprises a two-way cylinder (1) and two symmetrically arranged dewatering units (2); each dewatering unit (2) comprises a dewatering shell (2.1), a supporting plate (2.2) and an extrusion plate (2.3); the supporting plate (2.2) is positioned on the outer side of the dewatering shell (2.1); the extrusion plate (2.3) is positioned on the inner side of the dewatering shell (2.1); the dewatering shell (2.1) is provided with a feed port (2.4); the two-way cylinder (1) is provided with two piston rods (1.1); and the two piston rods (1.1) are respectively connected with the extrusion plates (2.3) of the two dewatering units (2). The feed dewatering and extrusion dewatering are carried out at the same time, thereby enhancing the work efficiency. Meanwhile, the feed pressure is ingeniously used for dewatering in the extrusion dewatering process, thereby enhancing the power use effect.

Owner:CHINA JILIANG UNIV

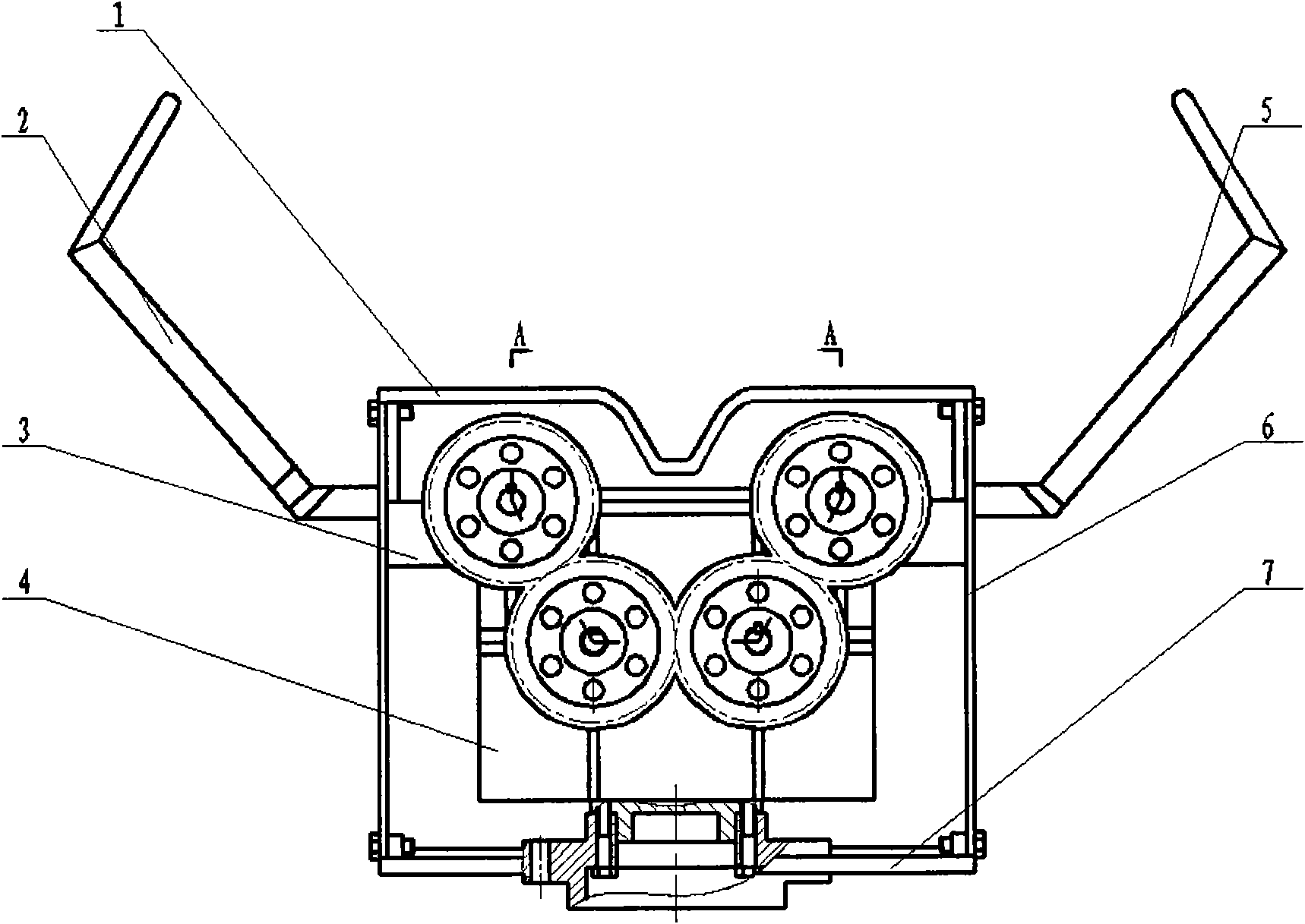

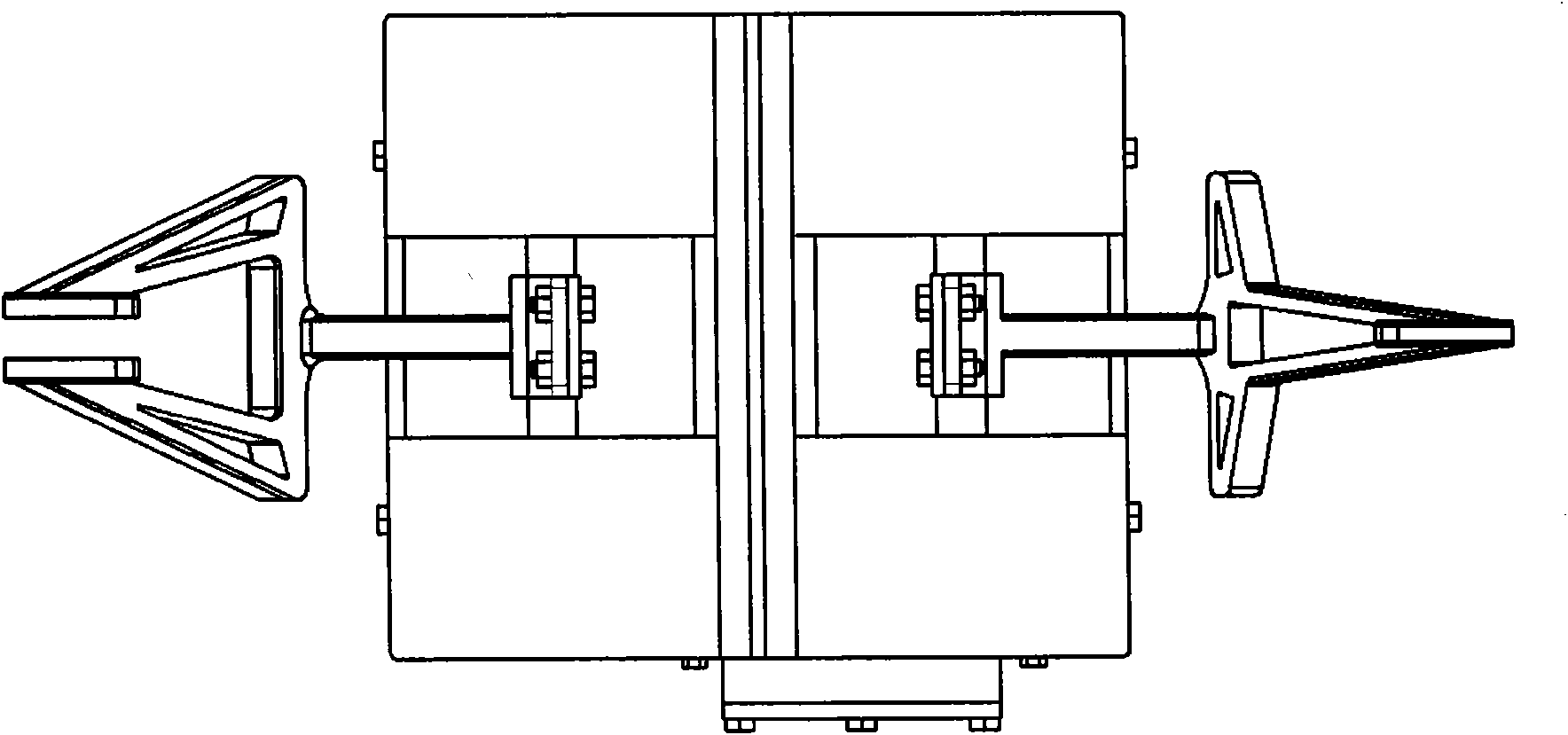

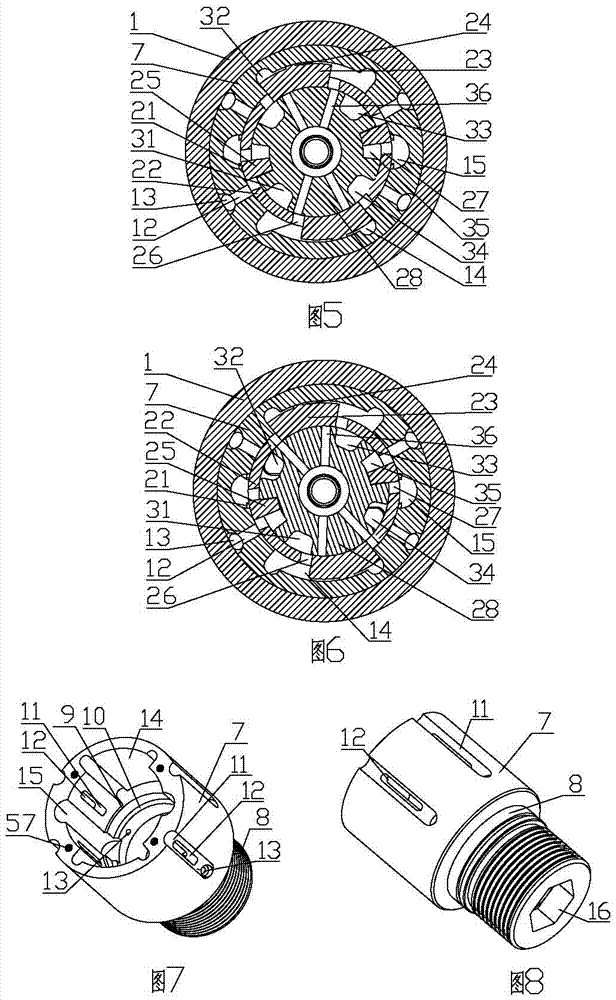

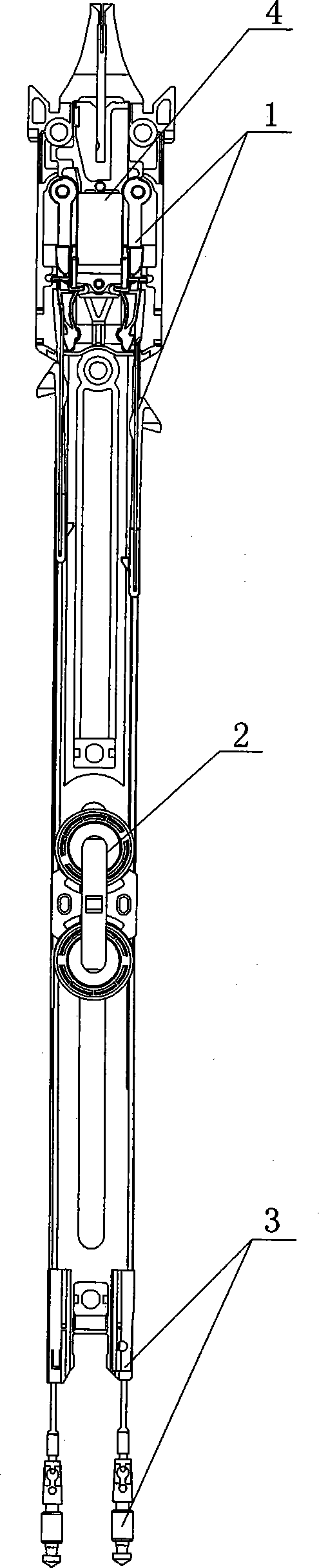

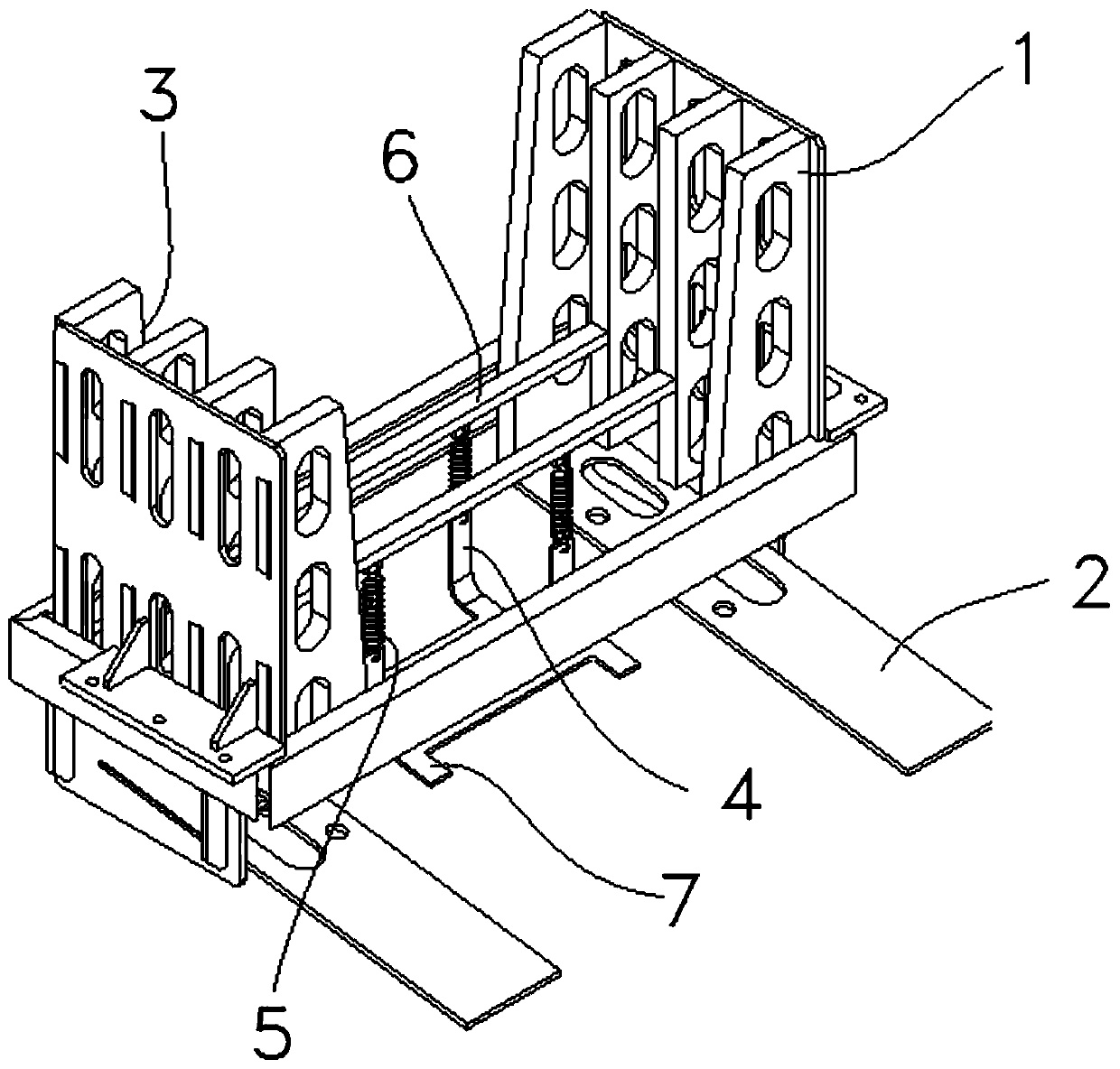

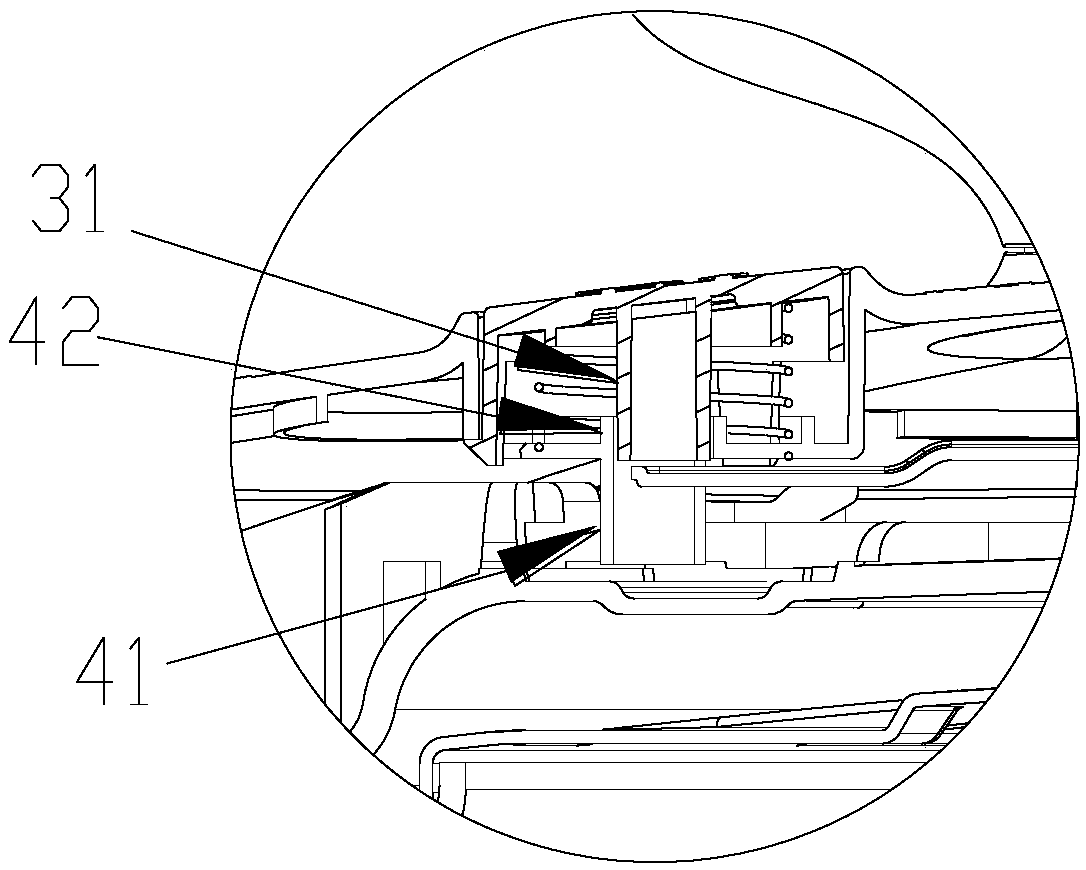

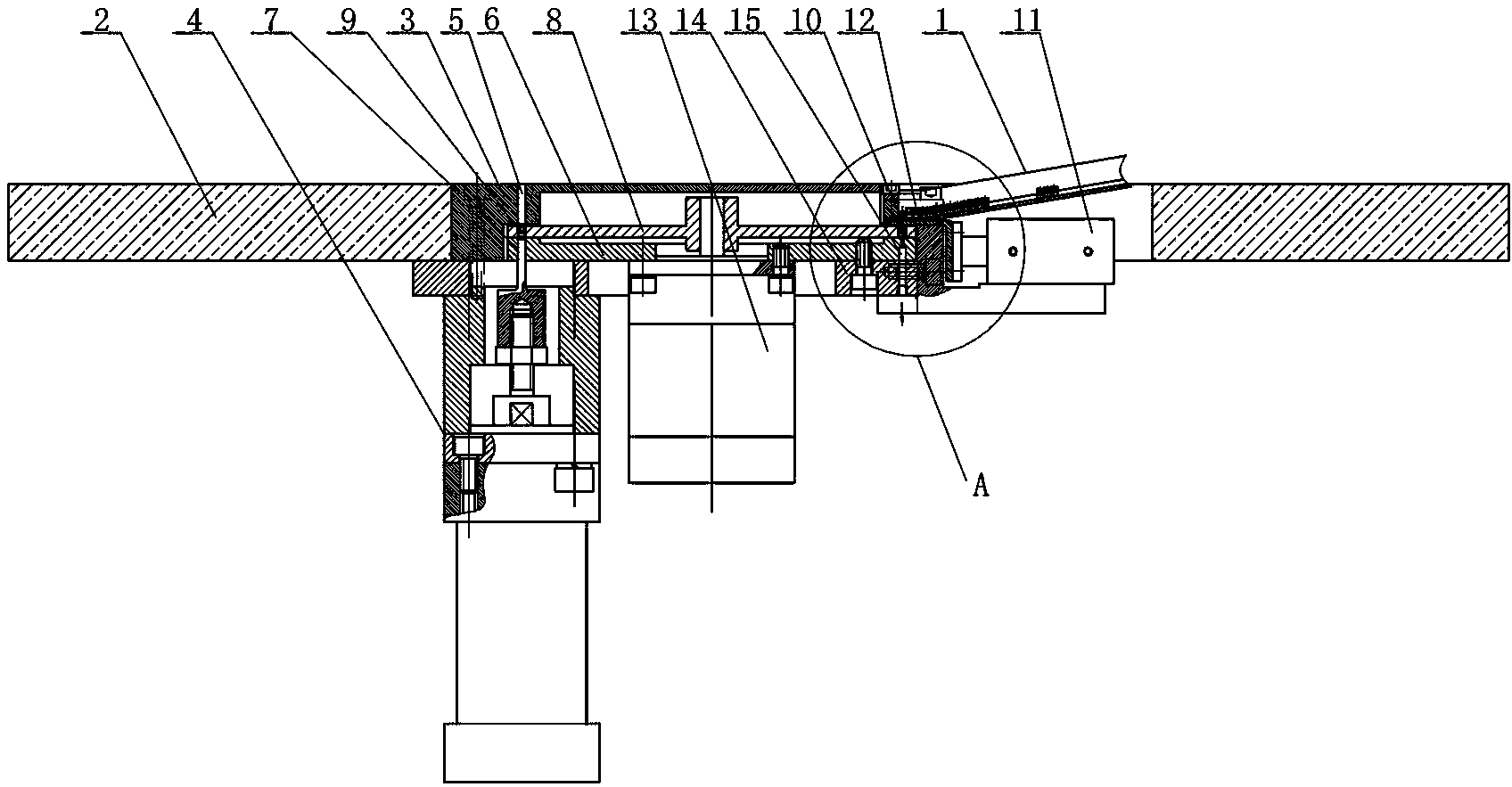

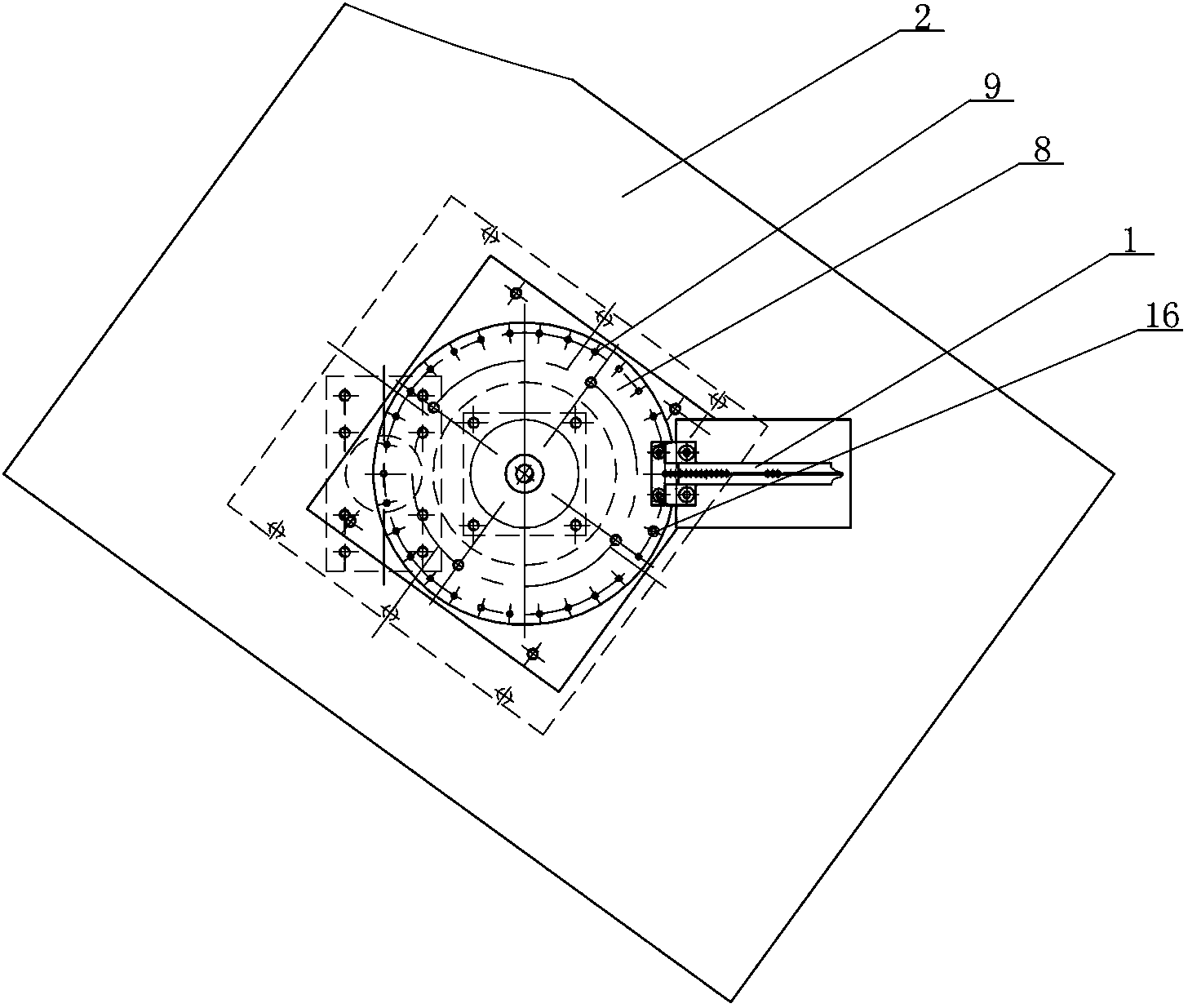

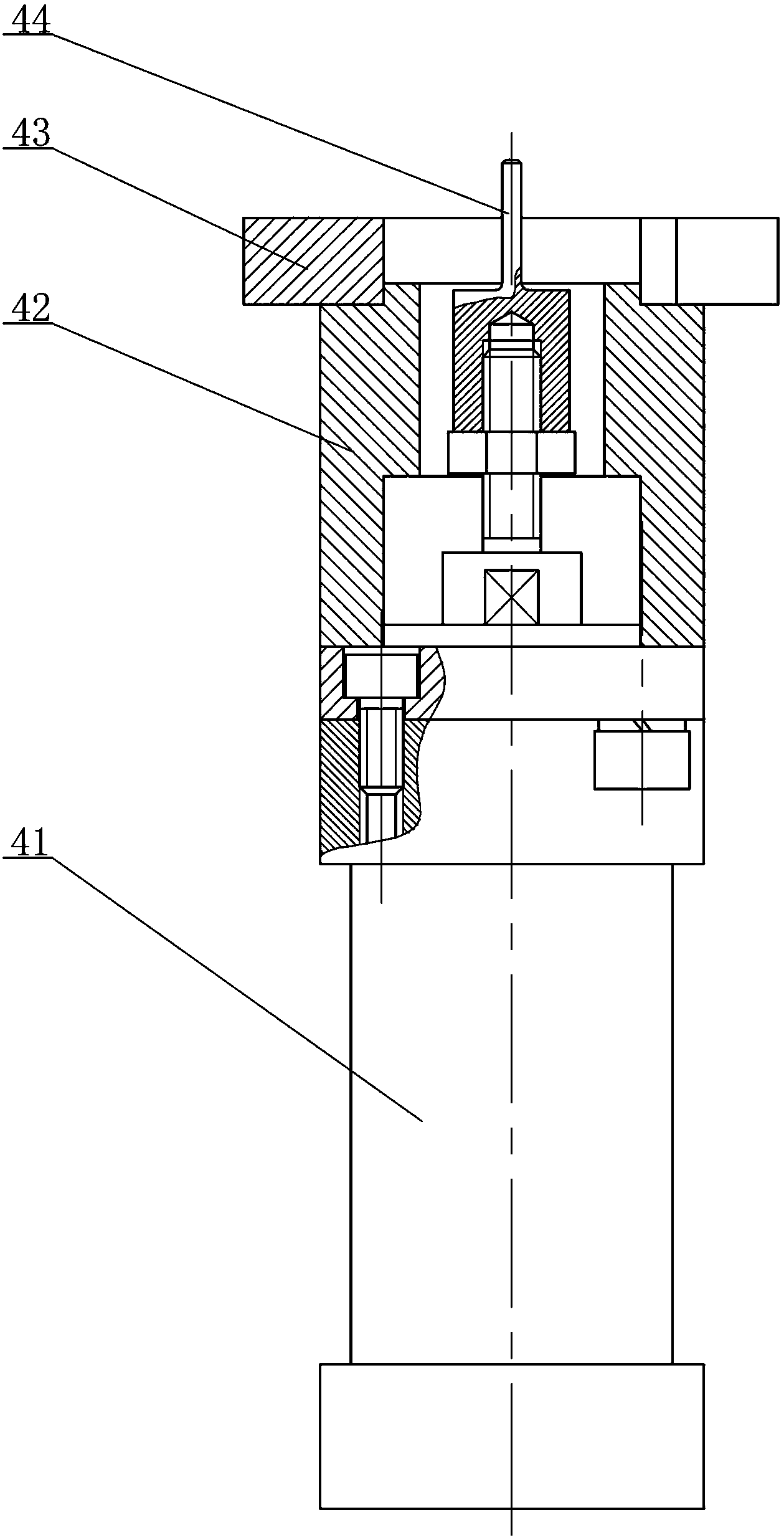

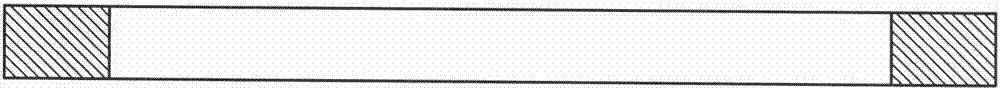

Space robot gripper mechanism

The invention discloses a space robot gripper mechanism, namely an end effector of a mechanical arm, which solves the problems of small gripping range, non-unique locking position, high probability of losing a target during griping and the like existing in the conventional gripper mechanism, greatly simplifies the entire mechanism and also improves the manufacturability. In the mechanism, a palm surface 1, an upper bearing seat 3, a lower bearing seat 4 and a box bottom 7 form a basic frame of the entire mechanism; two finger shafts 9 are arranged in bearing holes between the palm surface 1 and the upper bearing seat 3; two fingers 2 and 5 are fixedly connected with the finger shafts 9; the shaft ends of the two finger shafts are provided with gears 19; a motor 11 and a brake shaft 22 are arranged in through holes between the upper bearing seat 3 and the lower bearing seat 4; the shaft ends of the brake shaft 22 and the motor 11 are provided with gears 21; the gripper box bottom 7 is connected with the bearing seats and an external mechanism through flanges; and a box wall 6 is interconnected with the palm surface 1 and the box bottom 7 to package the entire gripper mechanism. The mechanism has the advantages of compact design, small volume, easiness of machining, convenience in assembly and disassembly and the like.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Intelligent lock and lock/unlock method thereof

ActiveCN1920230AAvoid failureAvoid deadlockNon-mechanical controlsElectric permutation locksEngineeringElectromagnet

The invention relates to an intelligent door lock used in outdoor box, and relative locking and unlocking method, wherein said door lock comprises a rotational handle, a read head, a lock pin element and a locking plate; said lock pin element comprises bottom plate, circuit board, driving device, locking pin, lever, button, and pin; said pin is matched to the pin hole of locking plate; the read head is connected to the key to power; the driving device drives the locking pin to lock and release the lever; the button will rotate the lever when the locking pin releases the lever, and the lever will drive the pin to leave the pin hole of locking plate; the motion of lock pin element is powered by key, to avoid failure of power resource or dead lock of circuit board; the driving device is electromagnetic magnet and the locking pin is the movable iron core of electromagnetic magnet, to avoid limiting the movable iron core, when moving; and the lever pin will not be clamped. The invention has simple structure and high reliability.

Owner:SUS TELECOMM +1

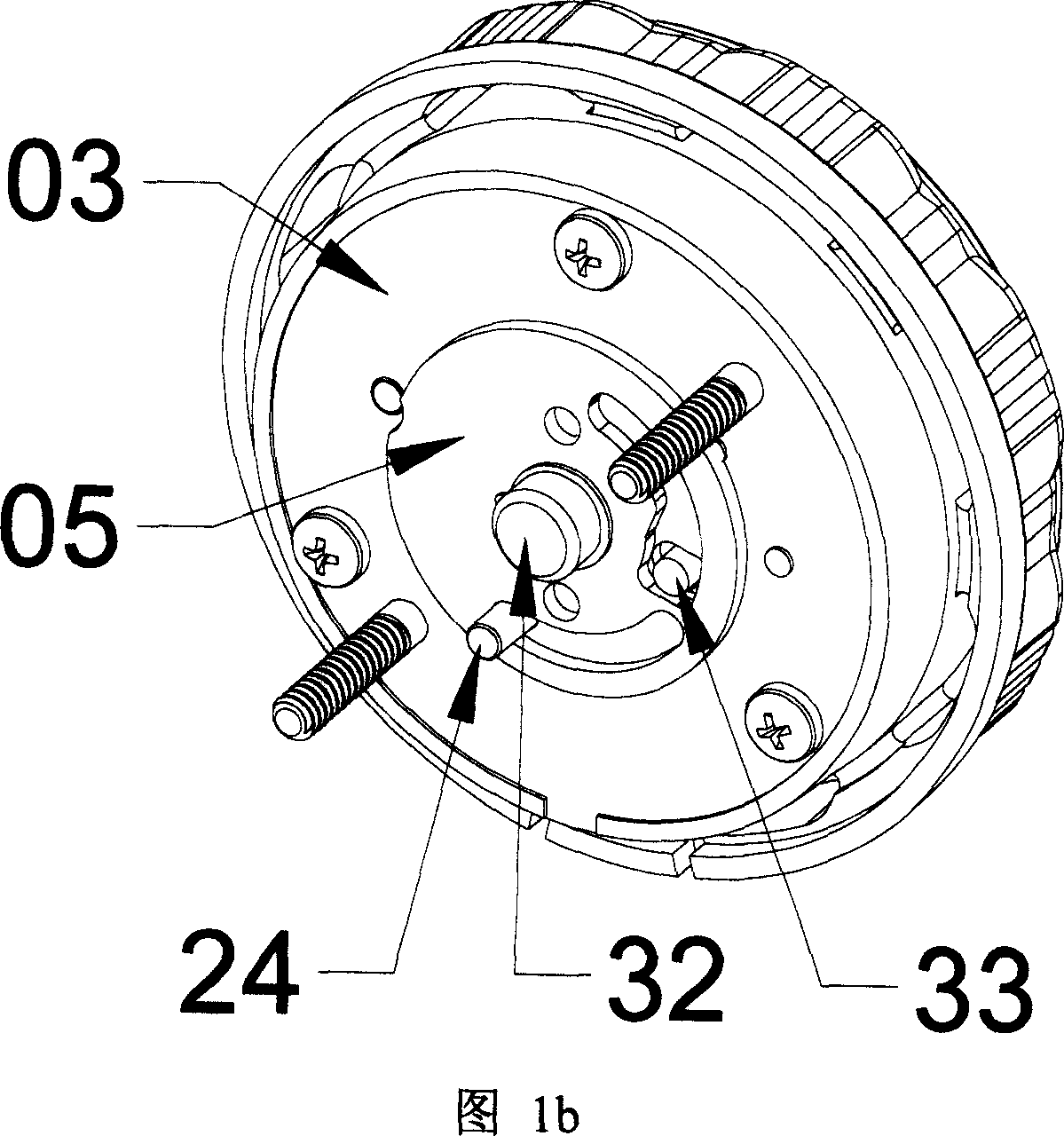

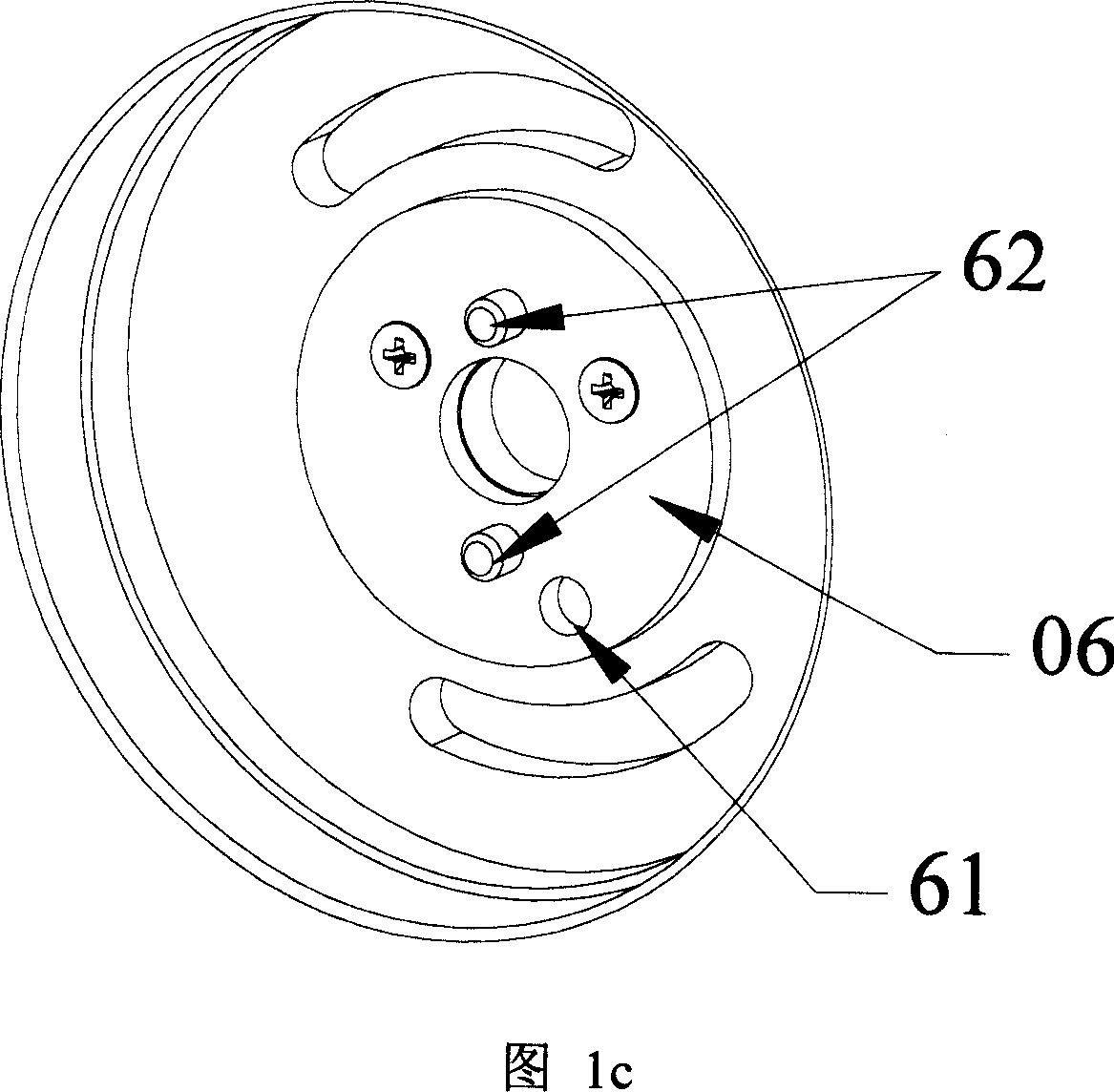

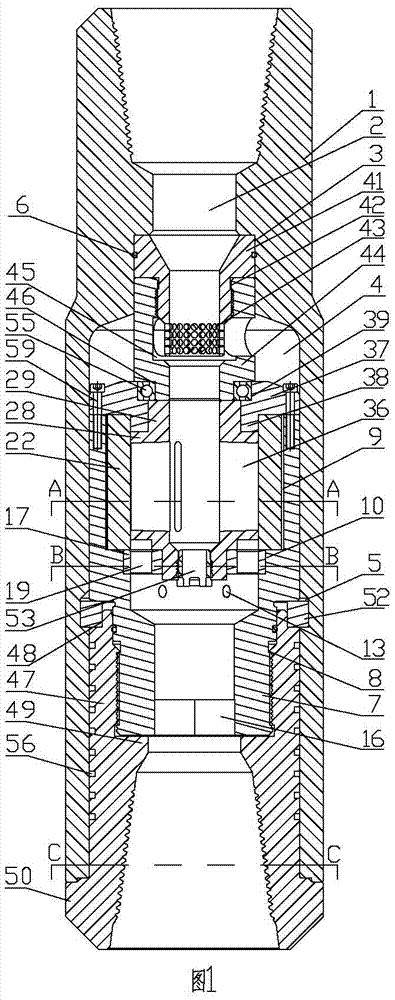

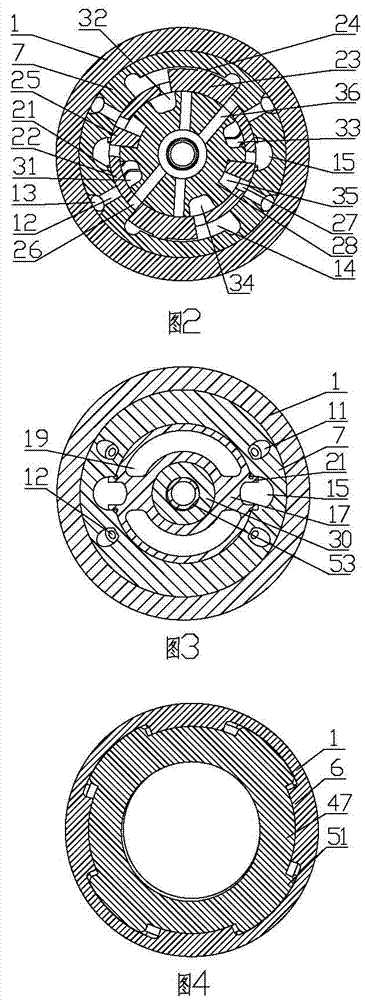

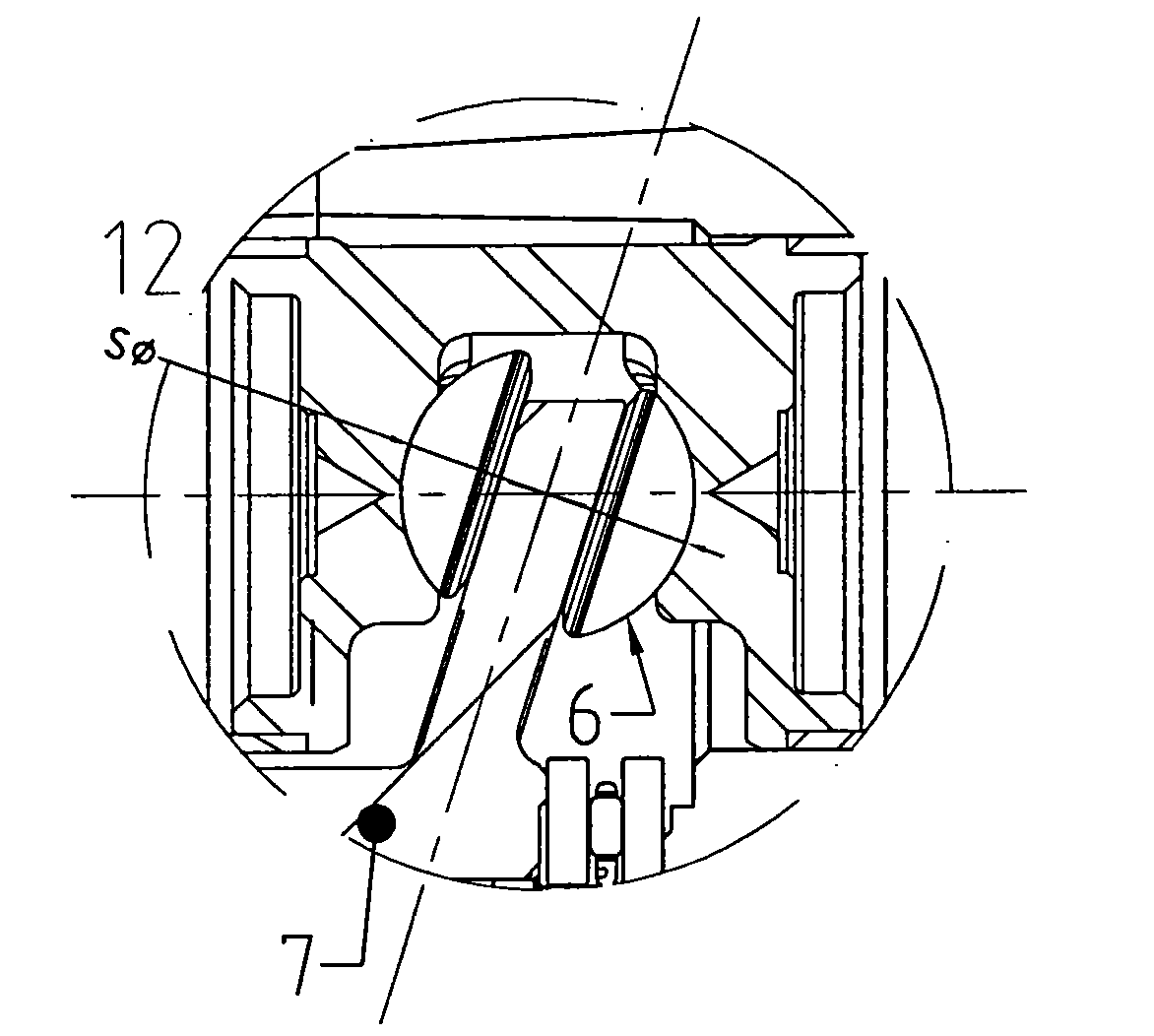

Frequency-adjustable torque force impact acceleration device

The invention relates to the technical field of well drilling hydraulic torque force impact tools, and provides a frequency-adjustable torque force impact acceleration device. The frequency-adjustable torque force impact acceleration device comprises an outer cylinder, an impact cylinder, a reversing sleeve base, an impact hammer, a reversing sleeve, a gland, a diversion filter screen, a bearing pedestal and a lower connector. An upper step hole, a middle step hole and a lower stop hole are formed in the outer cylinder, wherein the inner diameters of the upper step hole, the middle step hole and the lower step hole are sequentially decreased. The frequency-adjustable torque force impact acceleration device is reasonable and compact in structure, few in part and convenient to assemble, interval parts are not prone to damage and can not get stuck, an internal thread in the inner wall of the lower connector below the outer cylinder and an annular table does not need to be connected with a drill stem through a conversion connector any more, and the impact frequency can be regulated according to requirements by regulating a spray nozzle. Meanwhile, impact force can be directly transmitted to a drill bit and is converted into mechanical impact force through drilling hydraulic force, and therefore the drill bit can obtain stable torque and unceasingly cut a stratum to eliminate stick slip, the service life of the drill bit is prolonged, the drilling speed in hard rock layers is increased, great drilling cost and drilling time are saved, and the application range is wide.

Owner:CANGZHOU GREAT DRILL

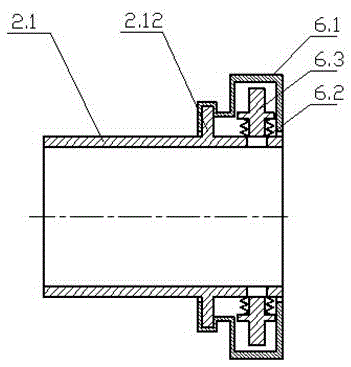

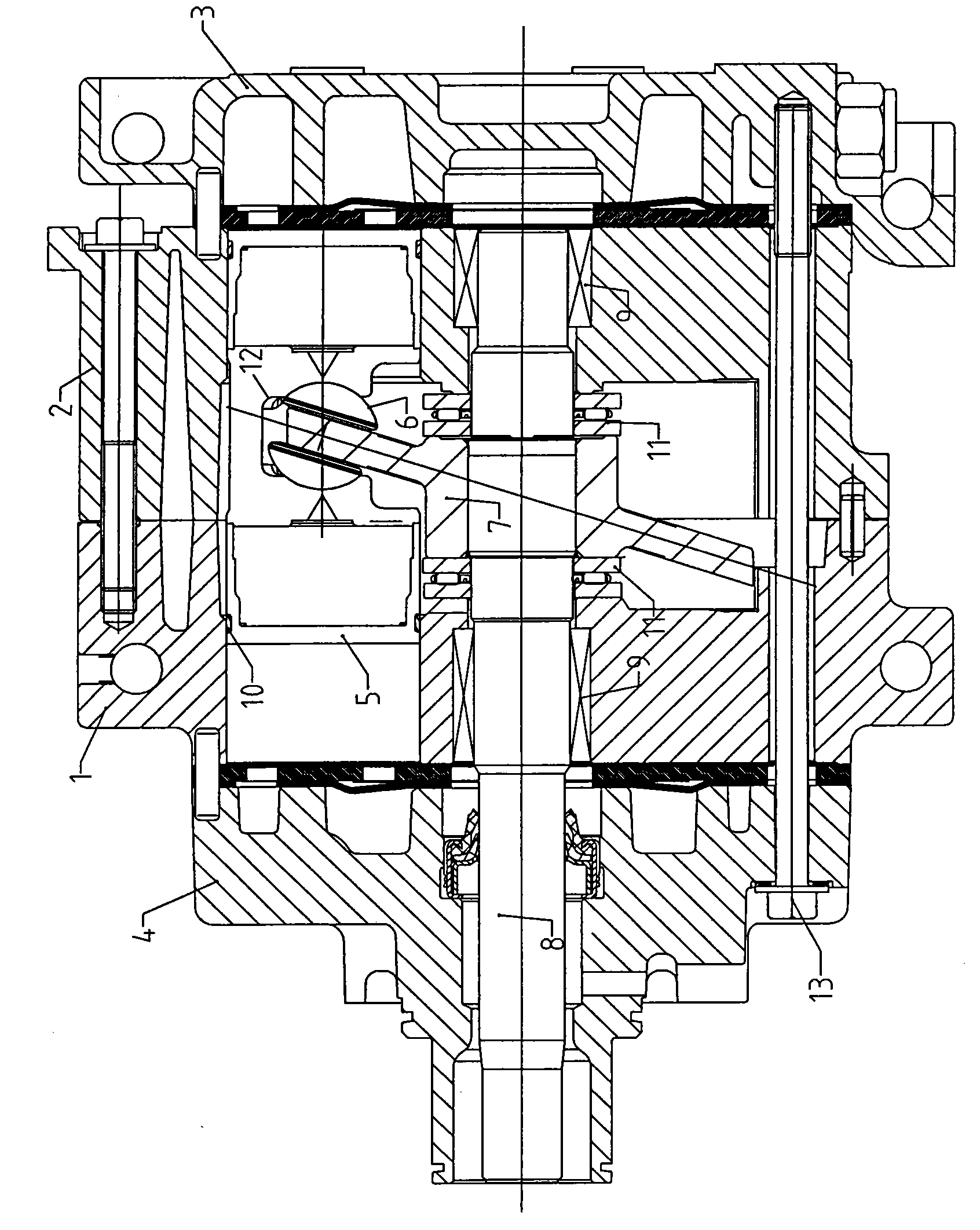

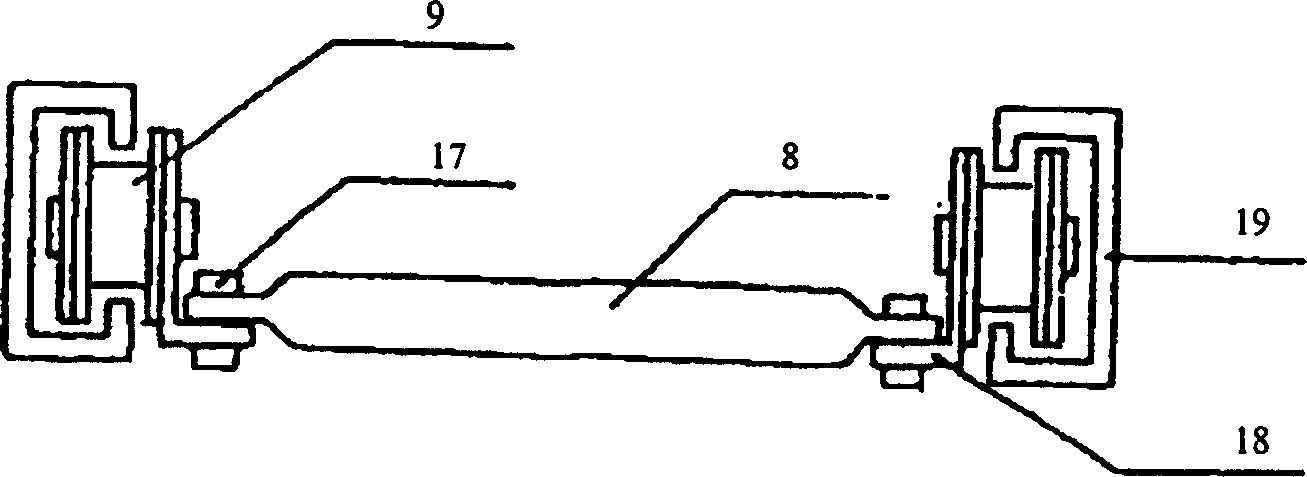

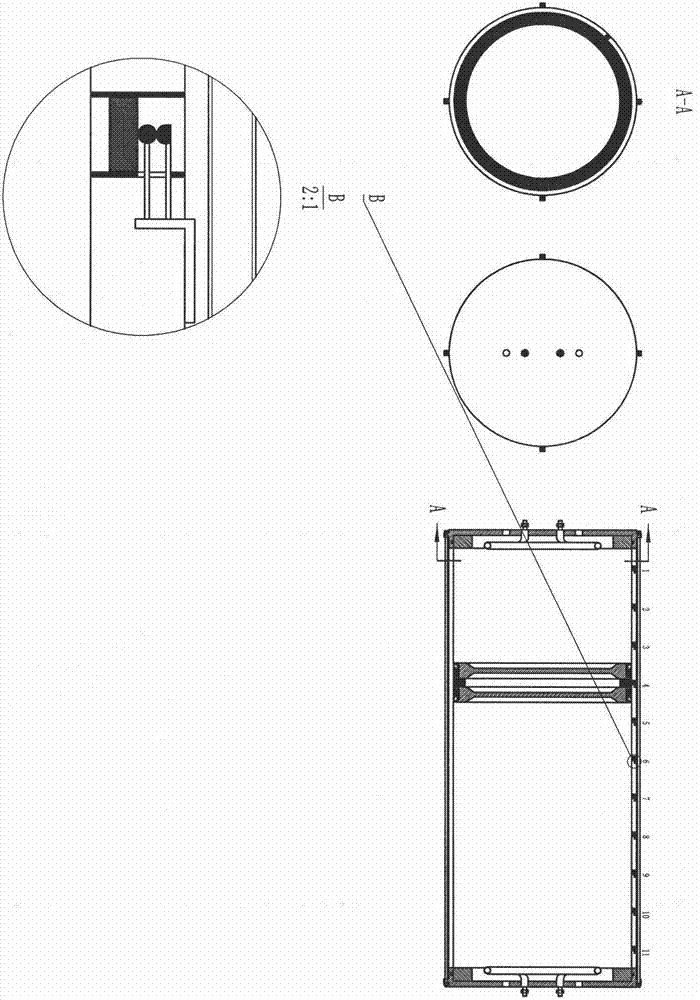

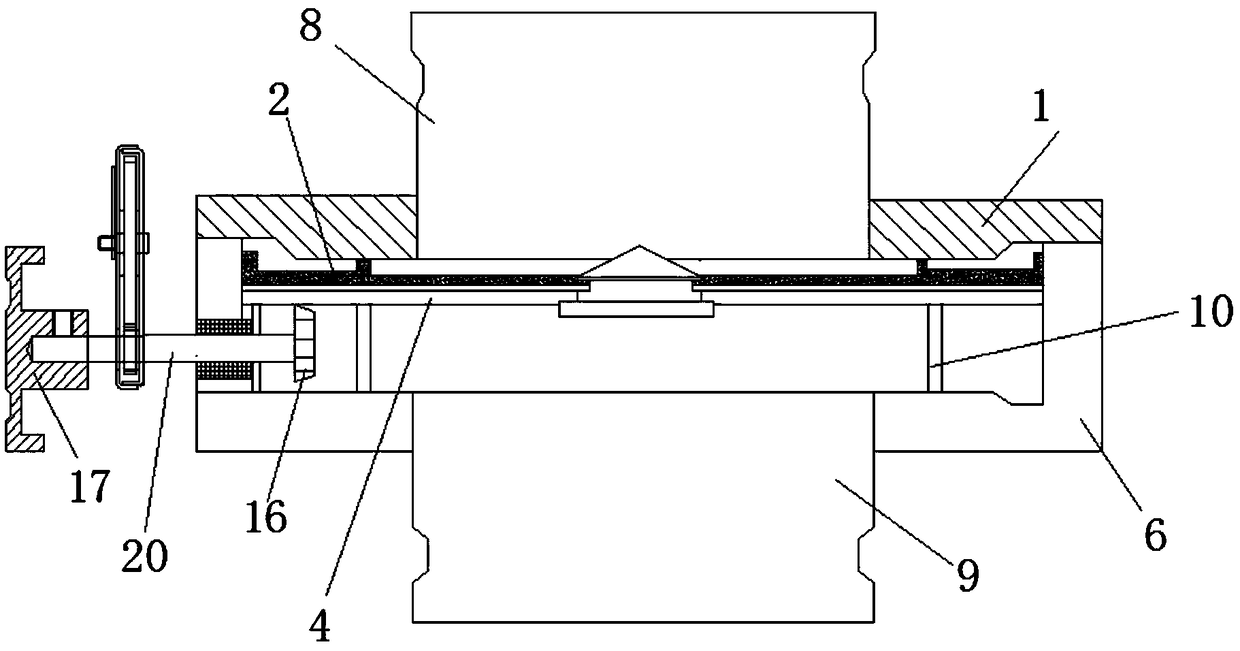

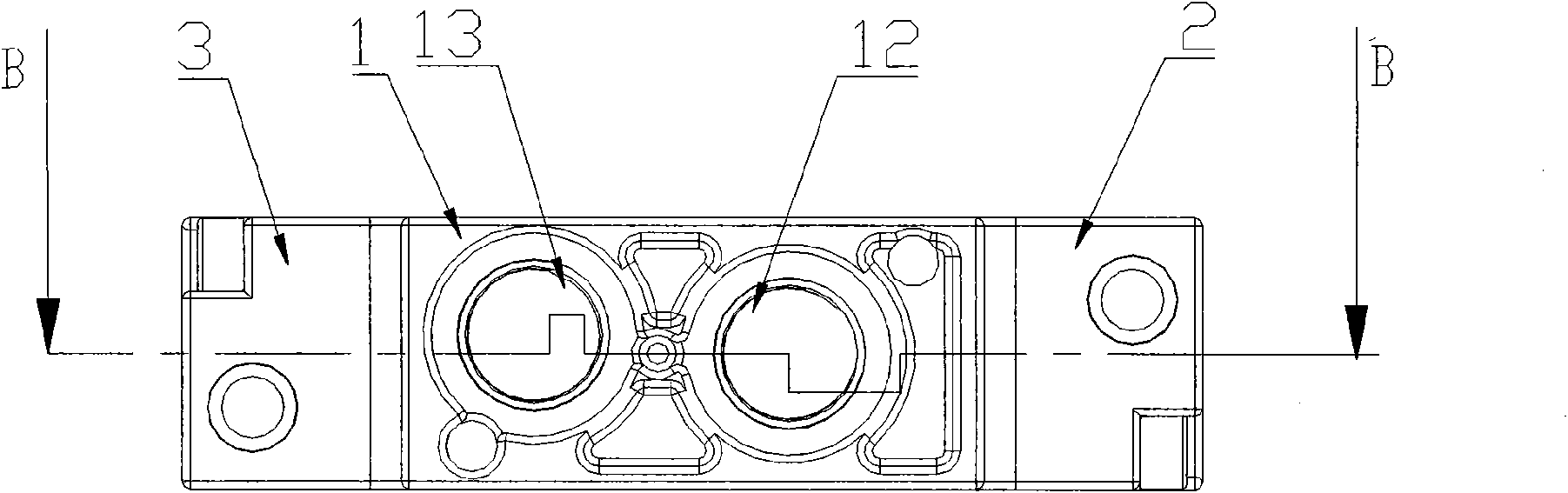

Swash plate double-headed piston compressor

ActiveCN101598121AEntity part size reductionReduce axial sizePositive displacement pump componentsMulti-stage pumpsWear resistantPiston ring

A swash plate double-headed piston compressor comprises a spindle (8), a swash plate (7), a front cylinder body (1) and a back cylinder body (2); a plurality of piston chambers are arranged between the front cylinder body (1) and the back cylinder body (2), each piston chamber is provided with a double-headed hollow piston (5), the swash plate (7) is arranged on the spindle (8); the compressor is characterized in that the double-headed hollow piston (5) is symmetrically provided with two small hemisphere pits, each small hemisphere pit is internally provided with a small hemisphere (6), the swash plate (7) is inserted into the place between the two small hemispheres (6), and the heights of the two small hemispheres (6) plus the thickness of the swash plate (7) are less than the spherical diameter of the small hemisphere (6); the swash plate (7) is provided with an air pressure support ring slot for compensating and bearing load; the double-headed hollow piston (5) is provided with a piston ring (10) for supporting with diameter being less than that of the inner diameter of the piston chamber; a wear-resistant layer is arranged on the panel where the swash plate (7) is contacted with the small hemisphere (6). The invention has the advantages of simple structure, convenient manufacture and installation, long service life and high efficiency.

Owner:NANJING AOTECAR NEW ENERGY TECH

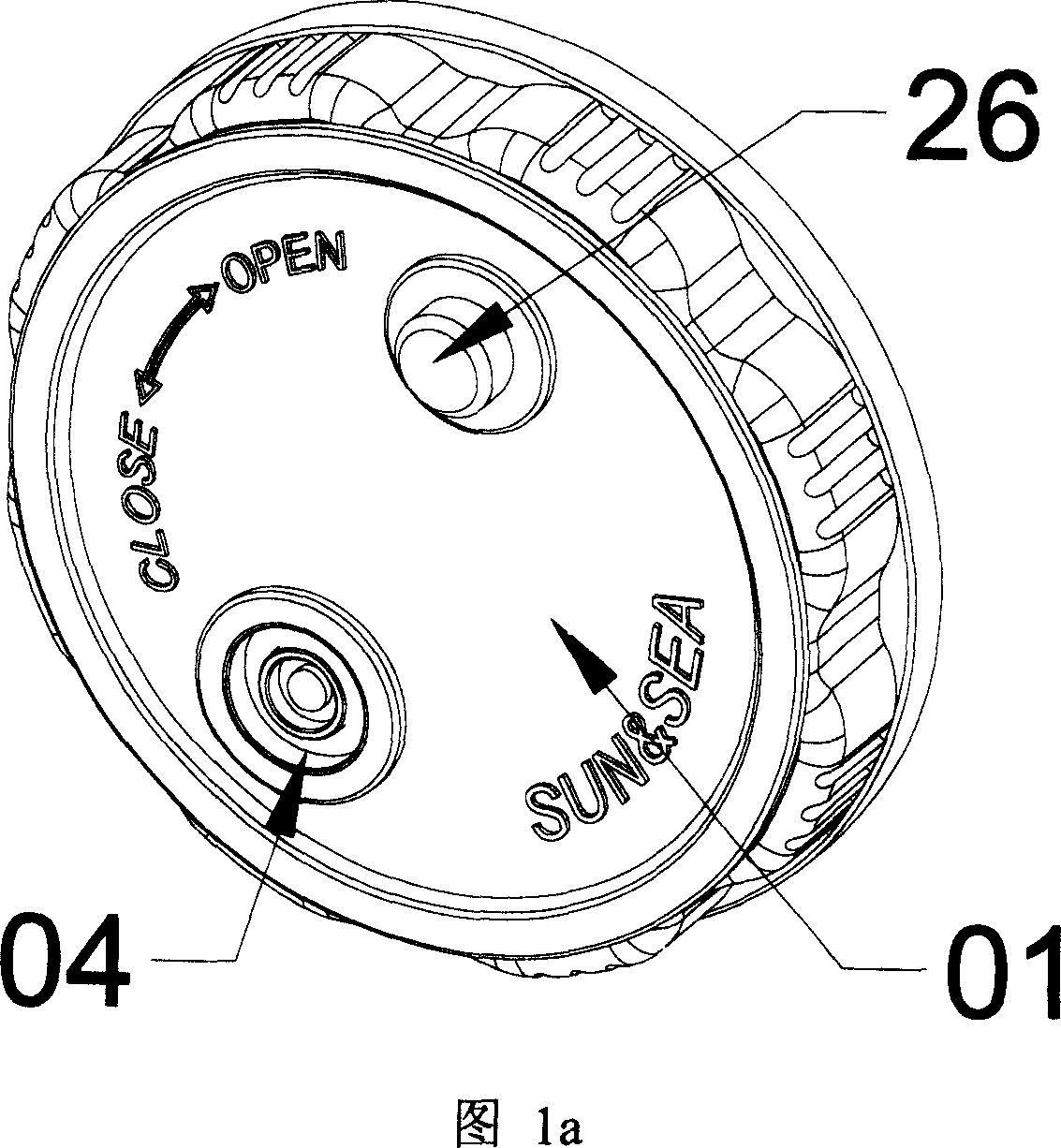

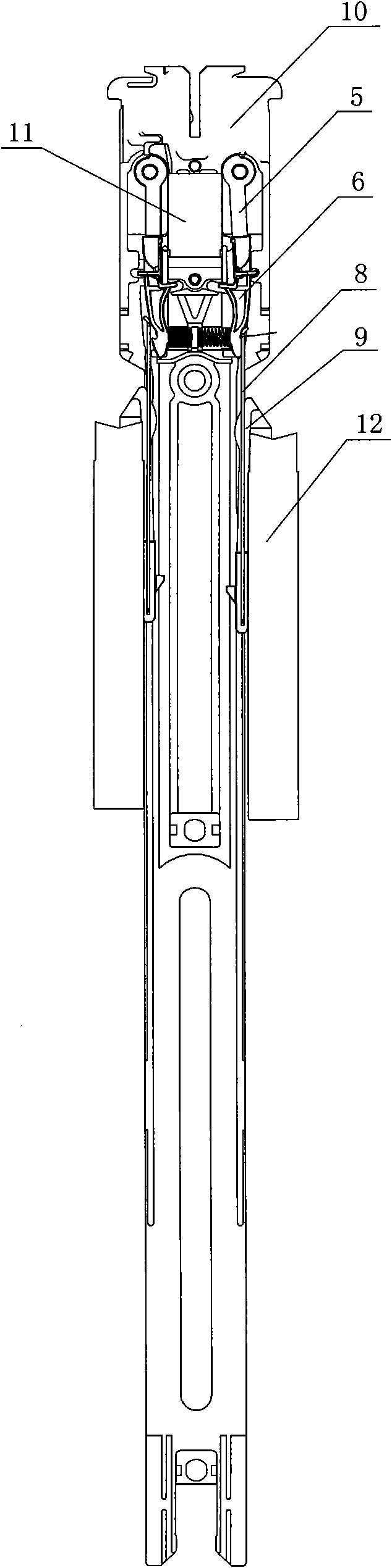

Pressing-type self-locking pull head

The invention discloses a pressing-type self-locking pull head, which comprises a pull head main body, wherein the pull head main body is formed by integrally connecting a lower wing plate, a guide pillar and an upper wing plate; a connecting ring is arranged at the top of the upper wing plate; a self-locking hole is formed in the connecting ring; a pressing-type self-locking mechanism is arranged at the top of the connecting ring; the pressing-type self-locking mechanism is composed of a movable button, a reset spring and a fixed seat; an accommodating cavity is formed in the movable button; a self-locking ejector is arranged in the accommodating cavity; an accommodating groove is formed in the outer sidewall of the movable button, and an elastic clamping block is arranged in the accommodating groove; a mounting through hole is formed in the fixed seat; a first clamping groove, a second clamping groove and an elastic oscillating bar are arranged on the sidewall of the fixed seat; the bottom of the fixed seat is fixedly connected to the connecting ring; the movable button is arranged in the fixed seat; the reset spring is arranged in the accommodating cavity; the bottom of the self-locking ejector freely runs through the self-locking hole; and the bottom of the elastic clamping block is clamped in the first clamping groove. The pressing-type self-locking pull head provided by the invention is simple in structure, convenient to assemble and use and good in self-locking effect.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

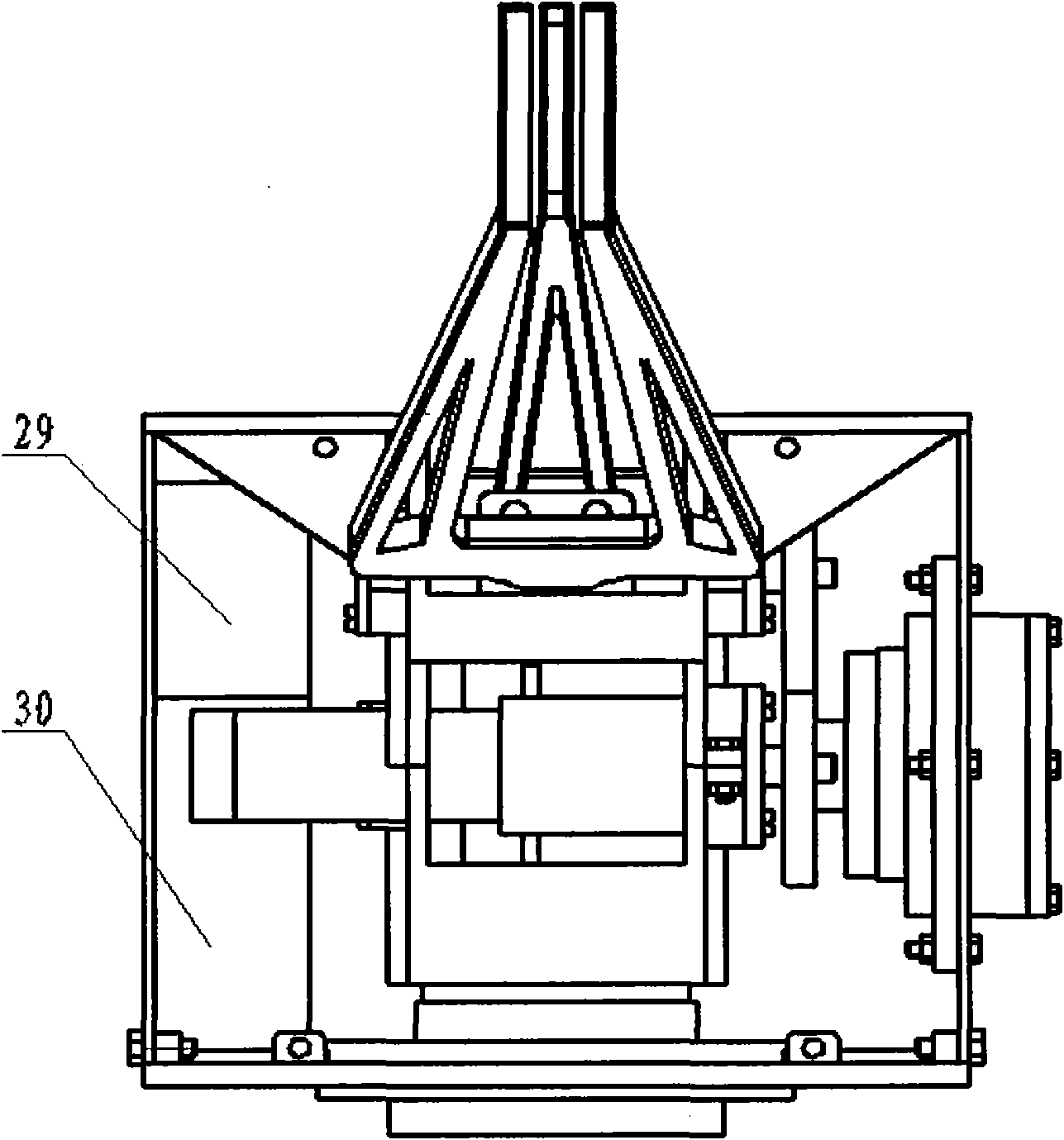

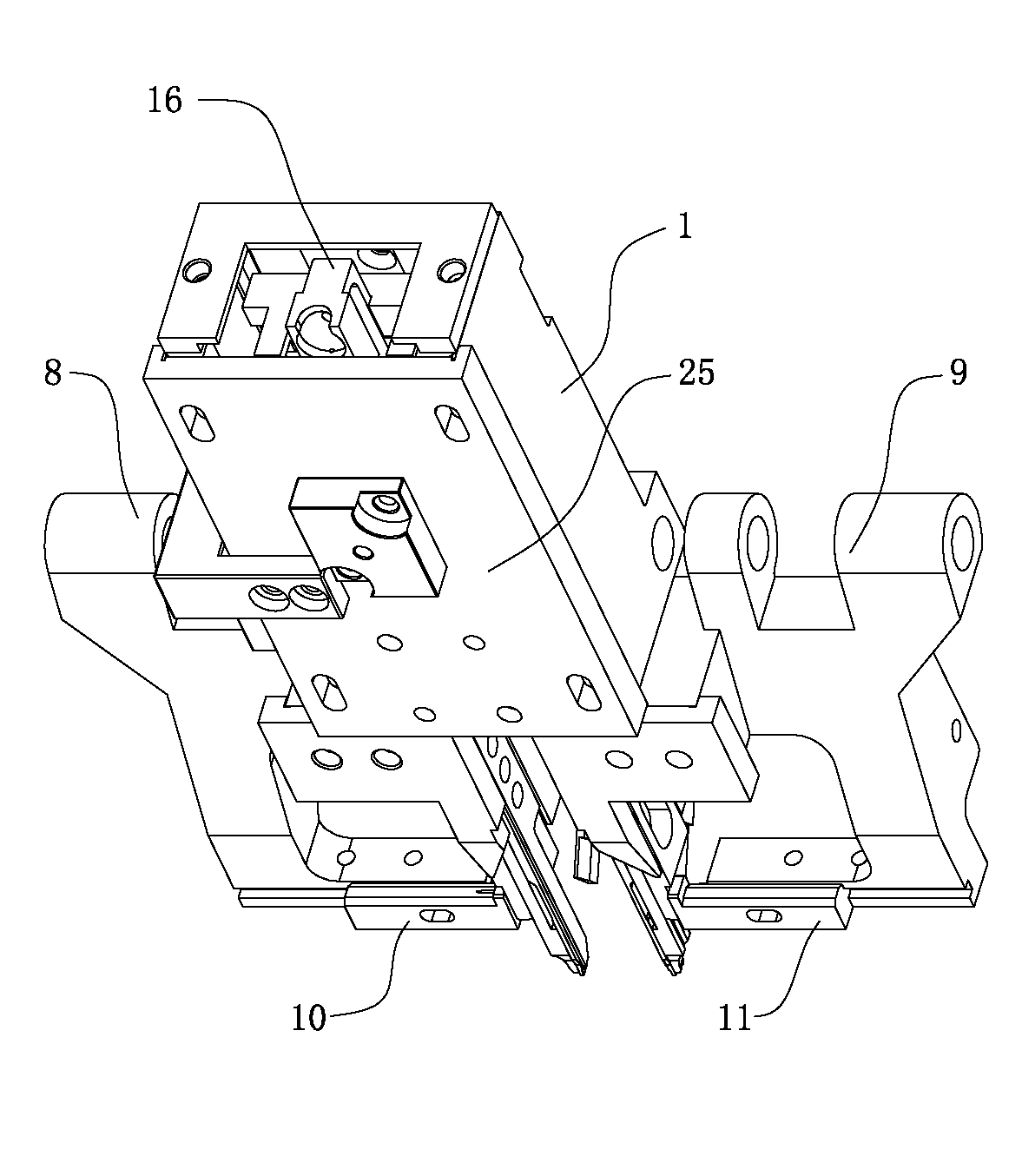

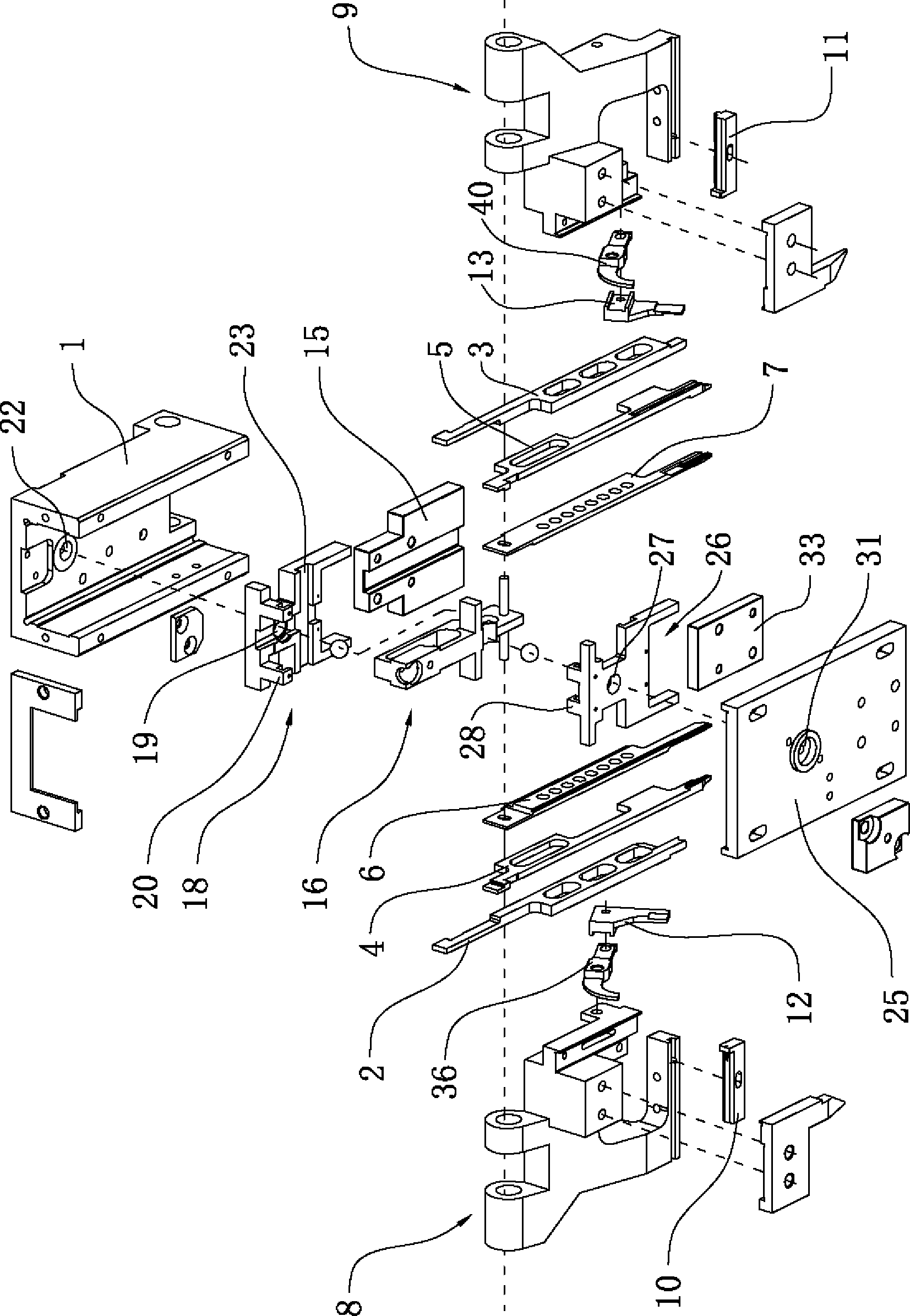

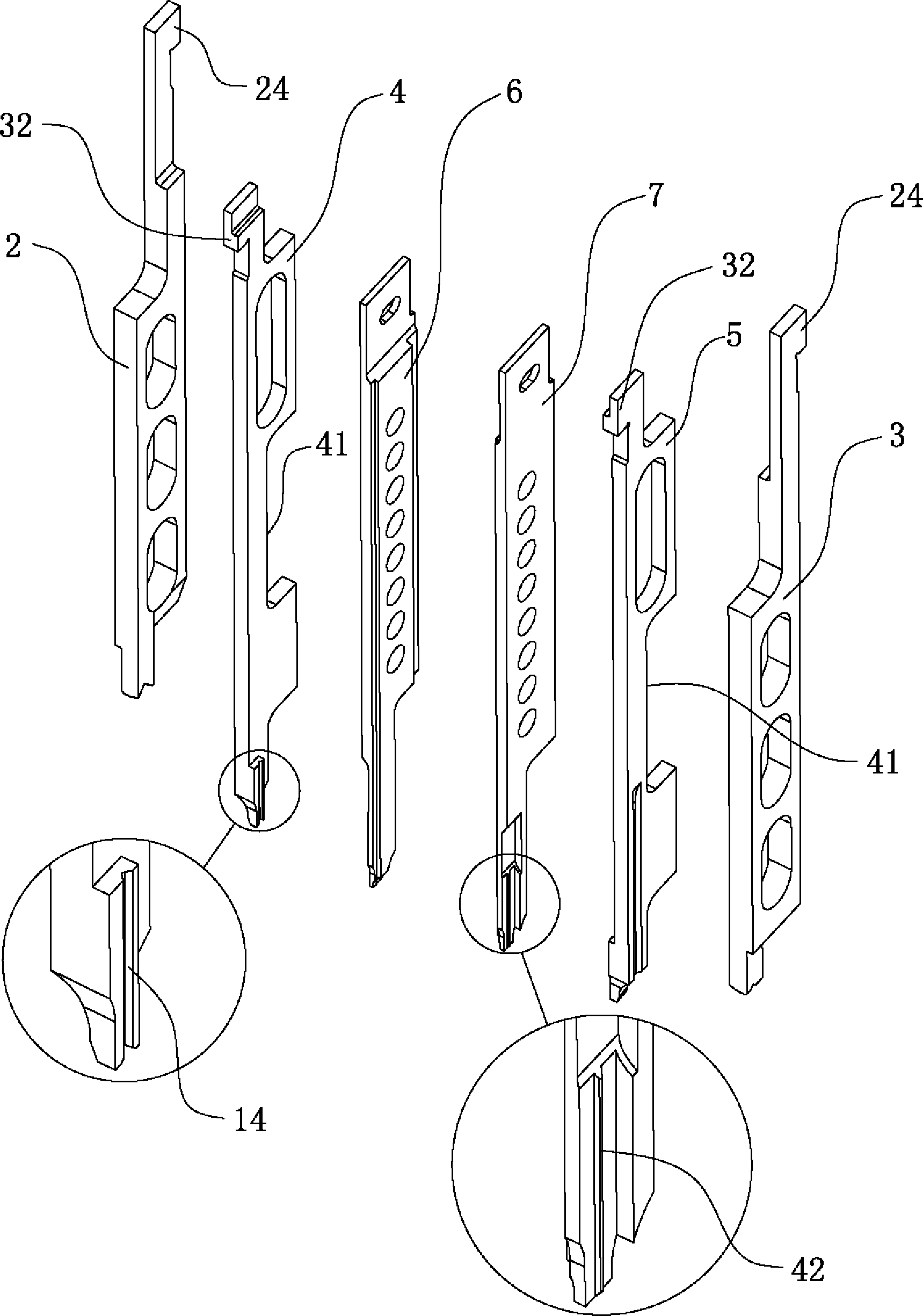

Component shaping and inserting mechanism for component inserting machine

InactiveCN102427717AIncrease insertion efficiencySimple structureElectrical componentsEngineeringElectronic component

The invention relates to the technical field of electronic component insertion, in particular to a component shaping and inserting mechanism for a component inserting machine. The component shaping and inserting mechanism comprises a tool box, a tool group and a link gear, wherein the tool group comprises a left-cut tool, a right-cut tool, a left molding tool, a right molding tool, a left push-type broach and a right push-type broach, wherein the left-cut tool, the left molding tool, the left push-type broach, the right push-type broach, the right molding tool and the right-cut tool are sequentially and movably arranged in the tool box from left to right; a left tool rest and a right tool rest are arranged at the lower part of the tool box, a left undercut tool and a right undercut tool are respectively assembled at the lower part of the left tool rest and the right tool rest, and the left tool rest and the right tool rest are respectively and movably provided with a left auxiliary molding tool and a right auxiliary molding tool; and pin guiding slots are respectively formed at the inner sides of the lower end parts of the lower end parts of the left molding tool and the right molding tool. The component shaping and inserting mechanism for the component inserting machine, disclosed by the invention, has the advantages of simple structure, low manufacturing cost, and no equipment locking phenomenon in a machining process, thus, the stability during component shaping and inserting machining is greatly increased, the inserting efficiency of the component inserting machine is increased, and the practicability is strong.

Owner:DONGGUAN SCIENCGO MACHINERY MFG

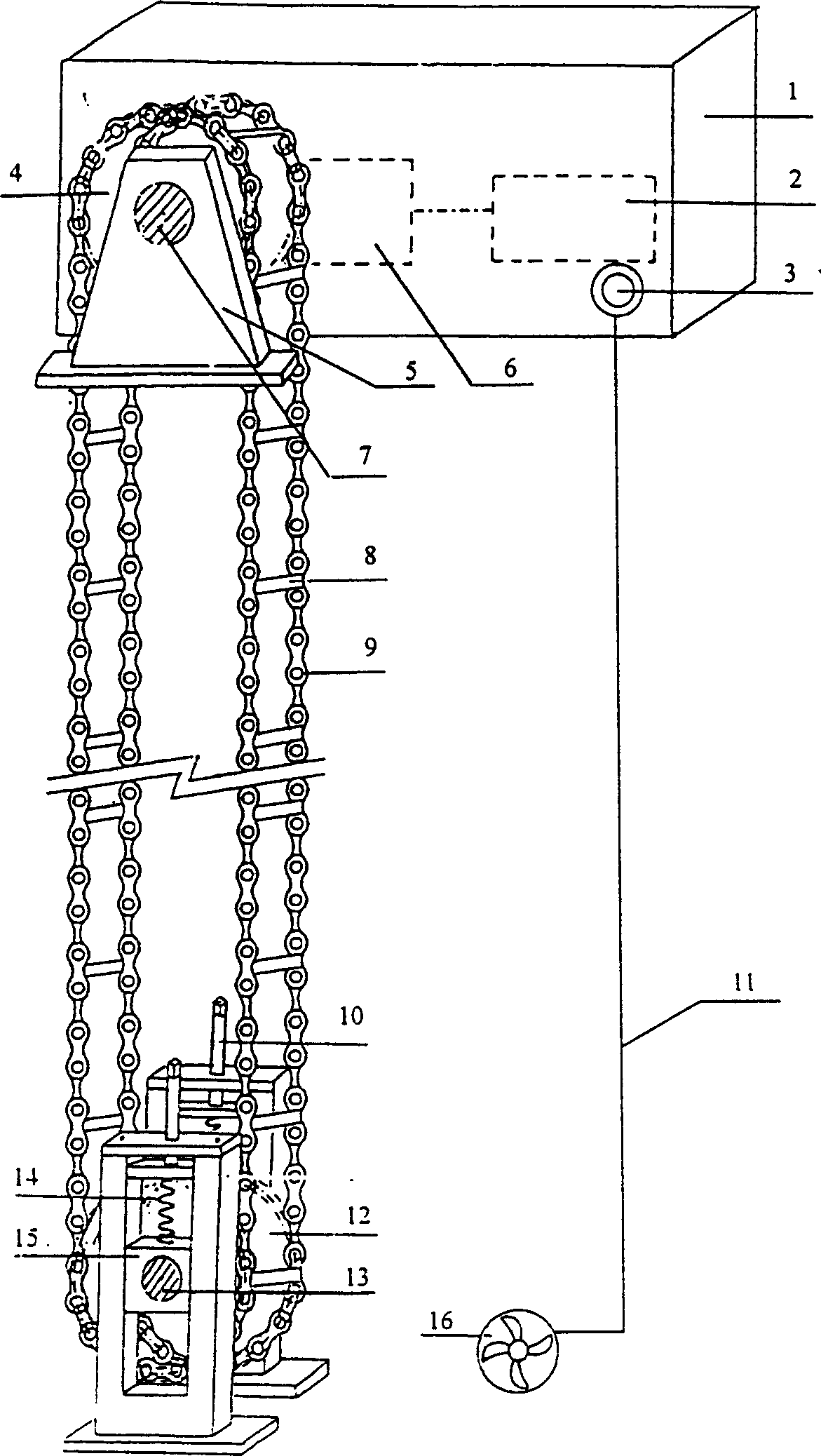

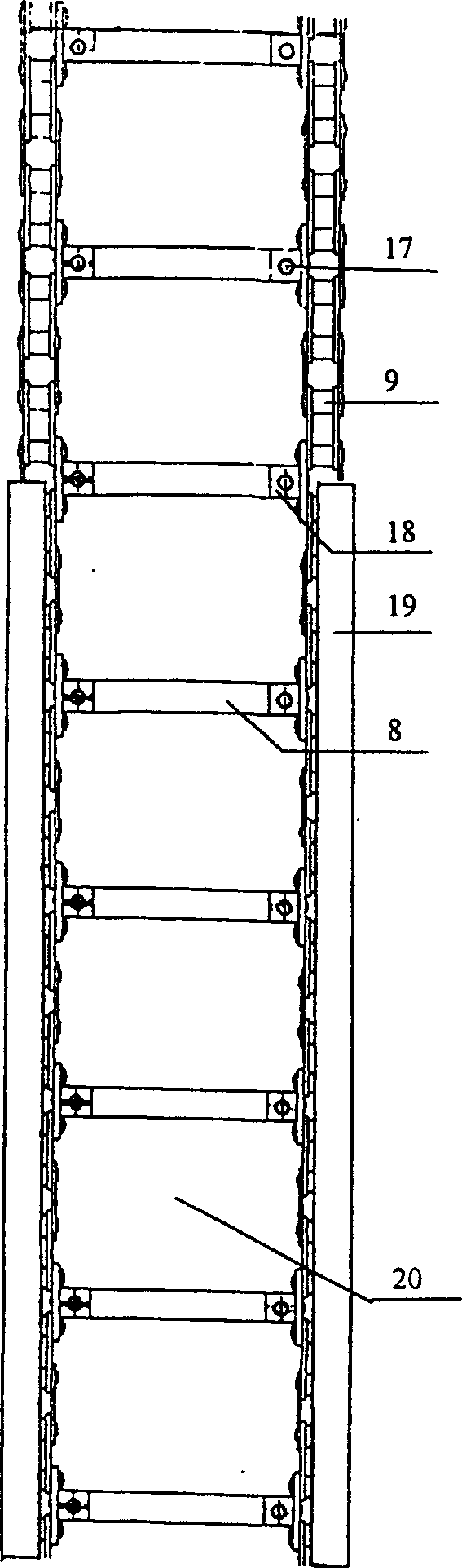

Hydaulic speed regulating type slow landing jack ladder escape device

InactiveCN1554458AKeep the speed of descent constantSolve the imbalanceBuilding rescueHigh riseControl theory

The emergency escape device for high rise building consists of jack ladder, guide track, chain wheel, speed varying mechanism, hydraulic speed regulating controller, etc. It is used for person in high rise building to escape in emergency. The present invention has the advantages of no need of outer driving force, relatively smooth lowering speed and no floating motion.

Owner:JIANGSU UNIV

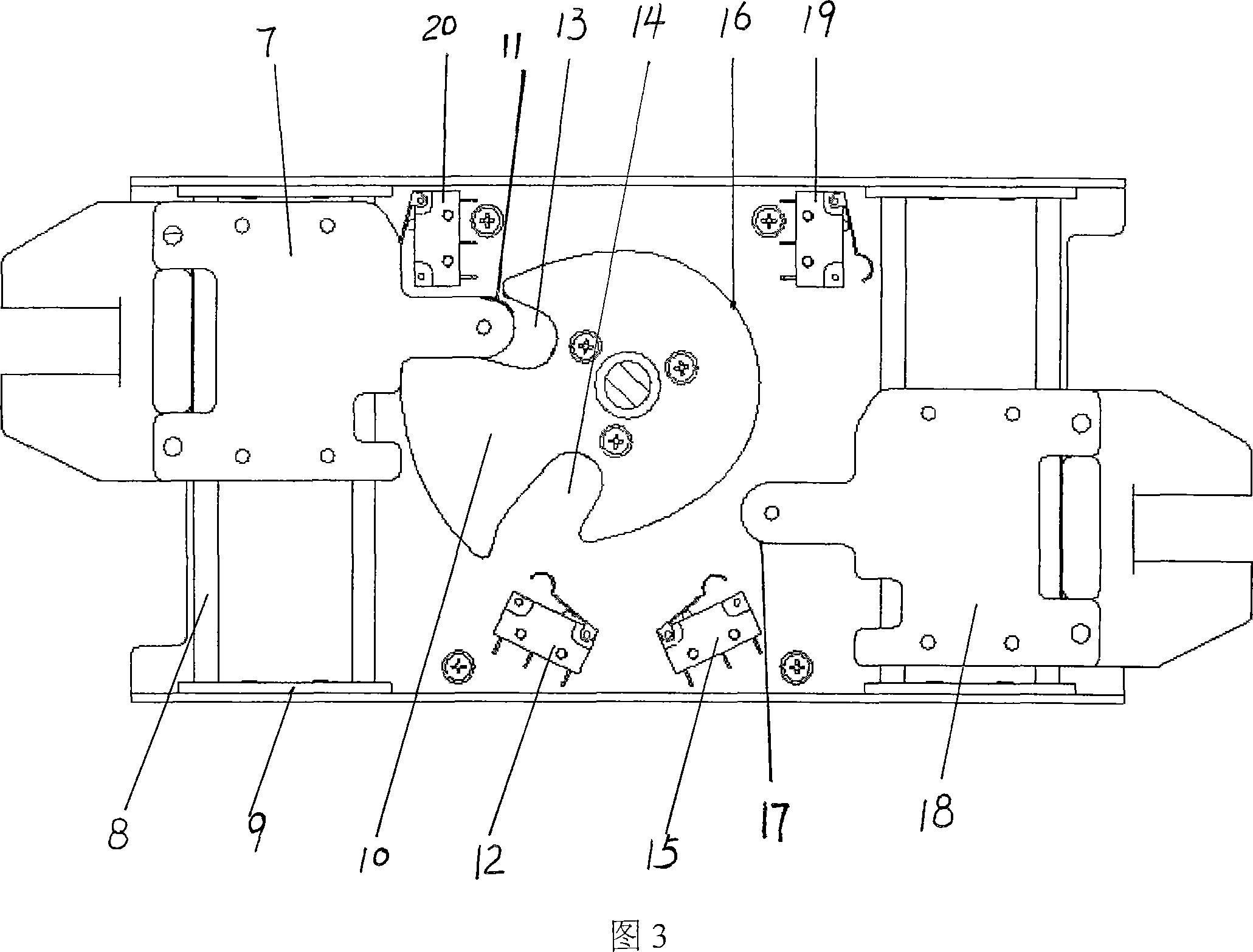

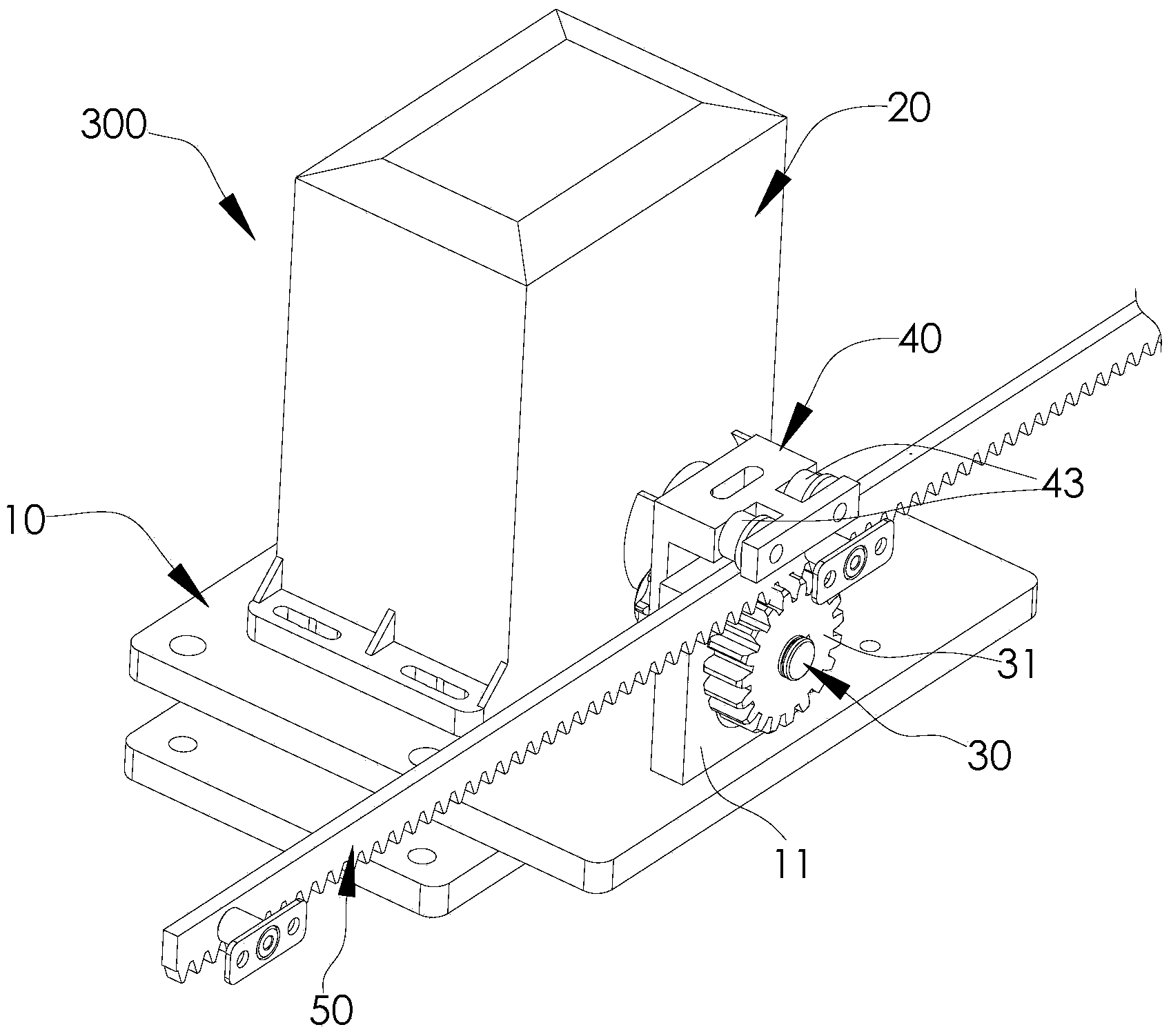

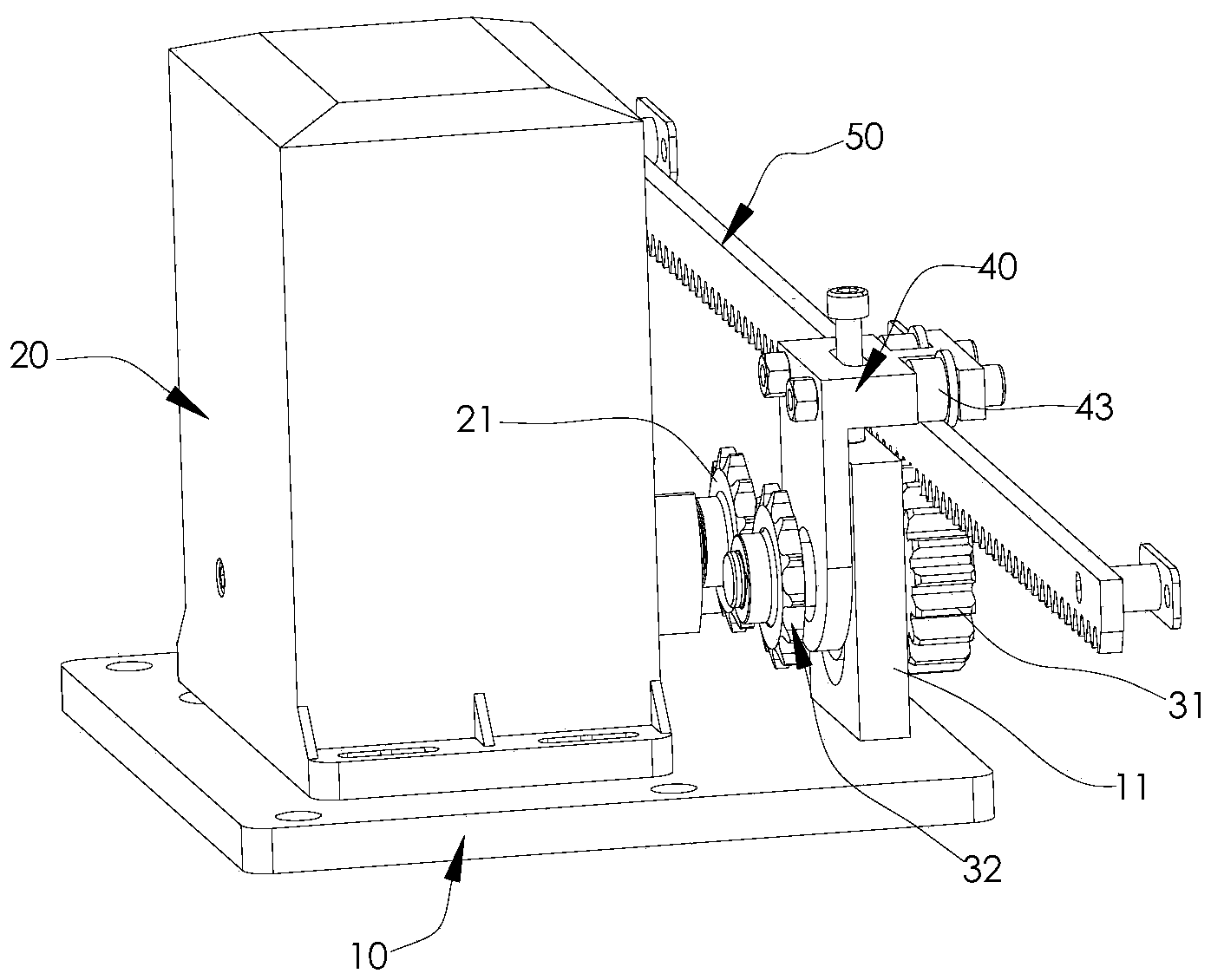

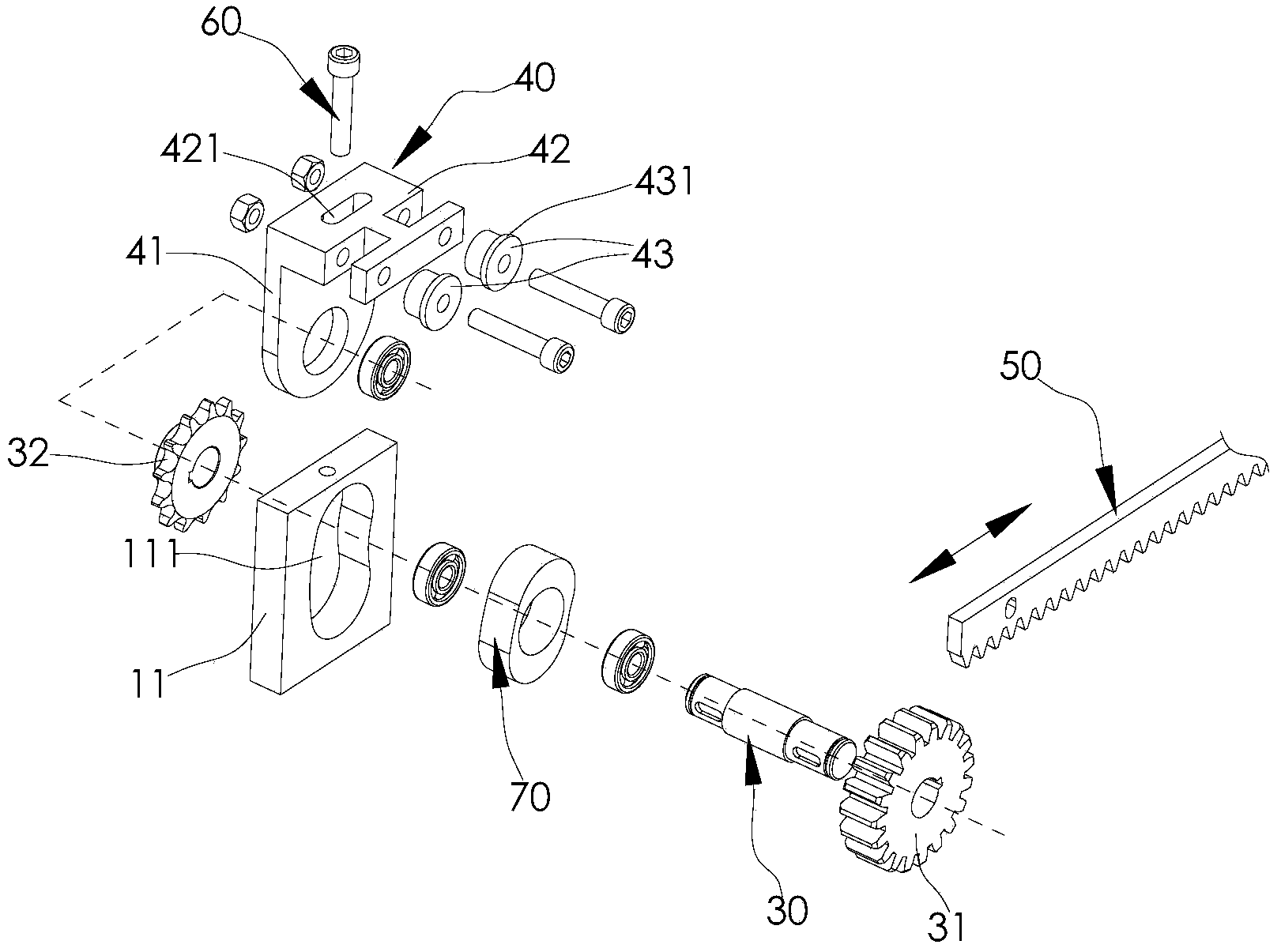

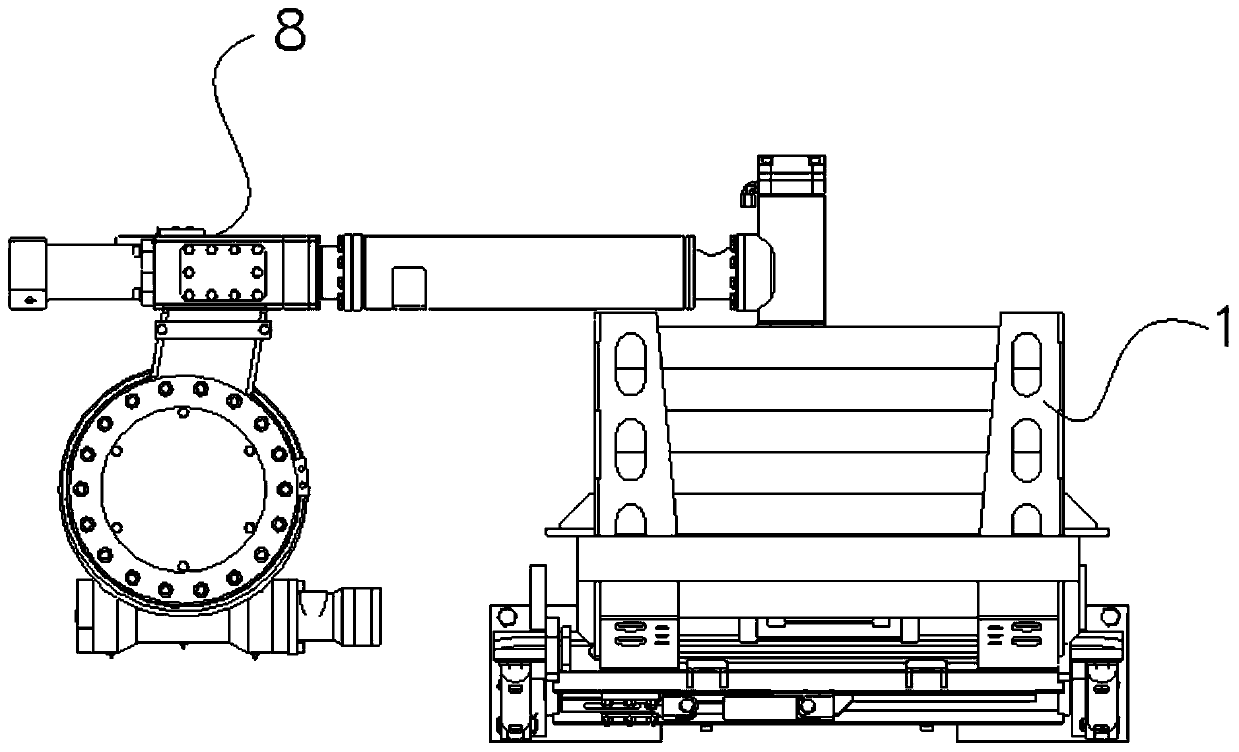

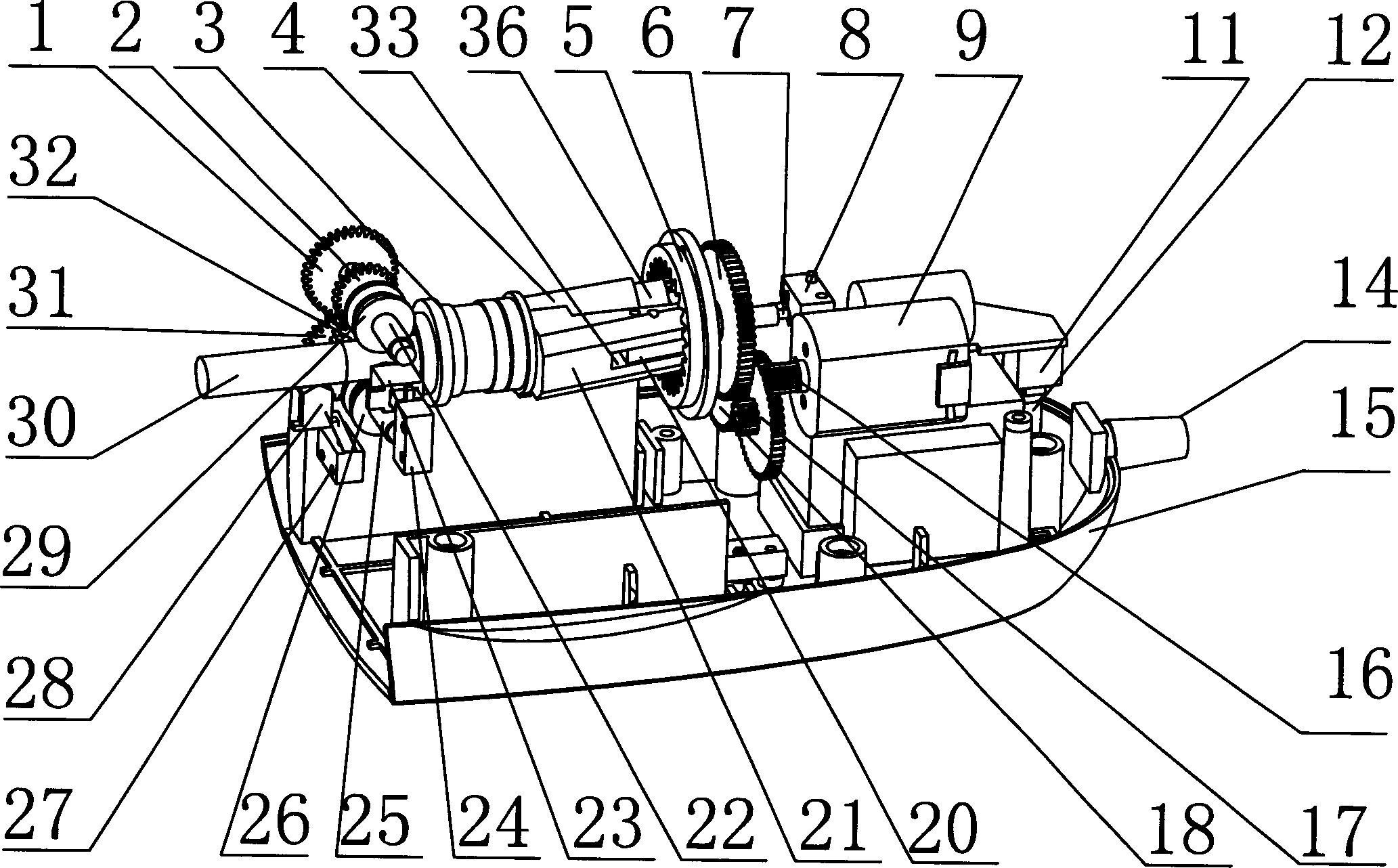

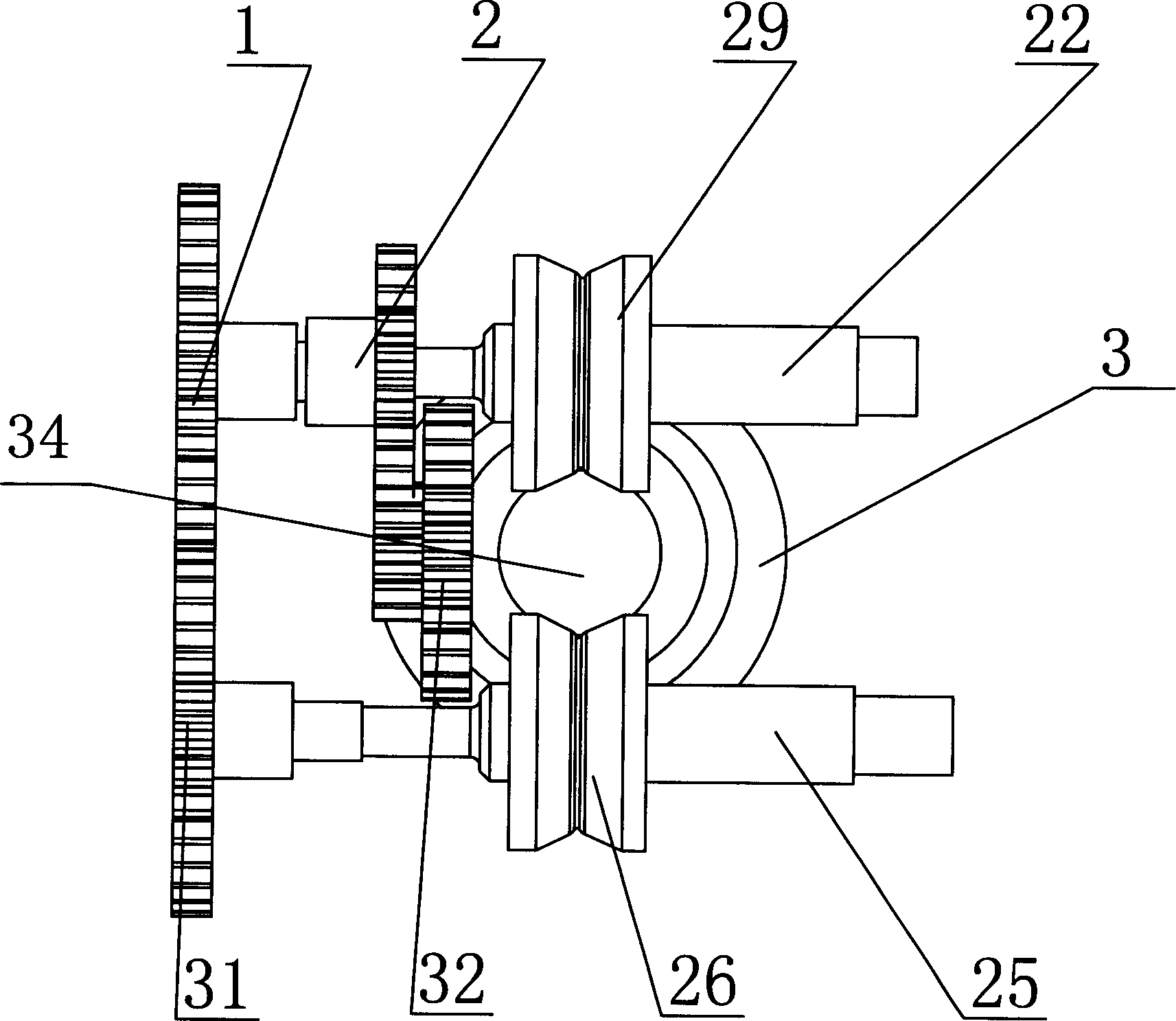

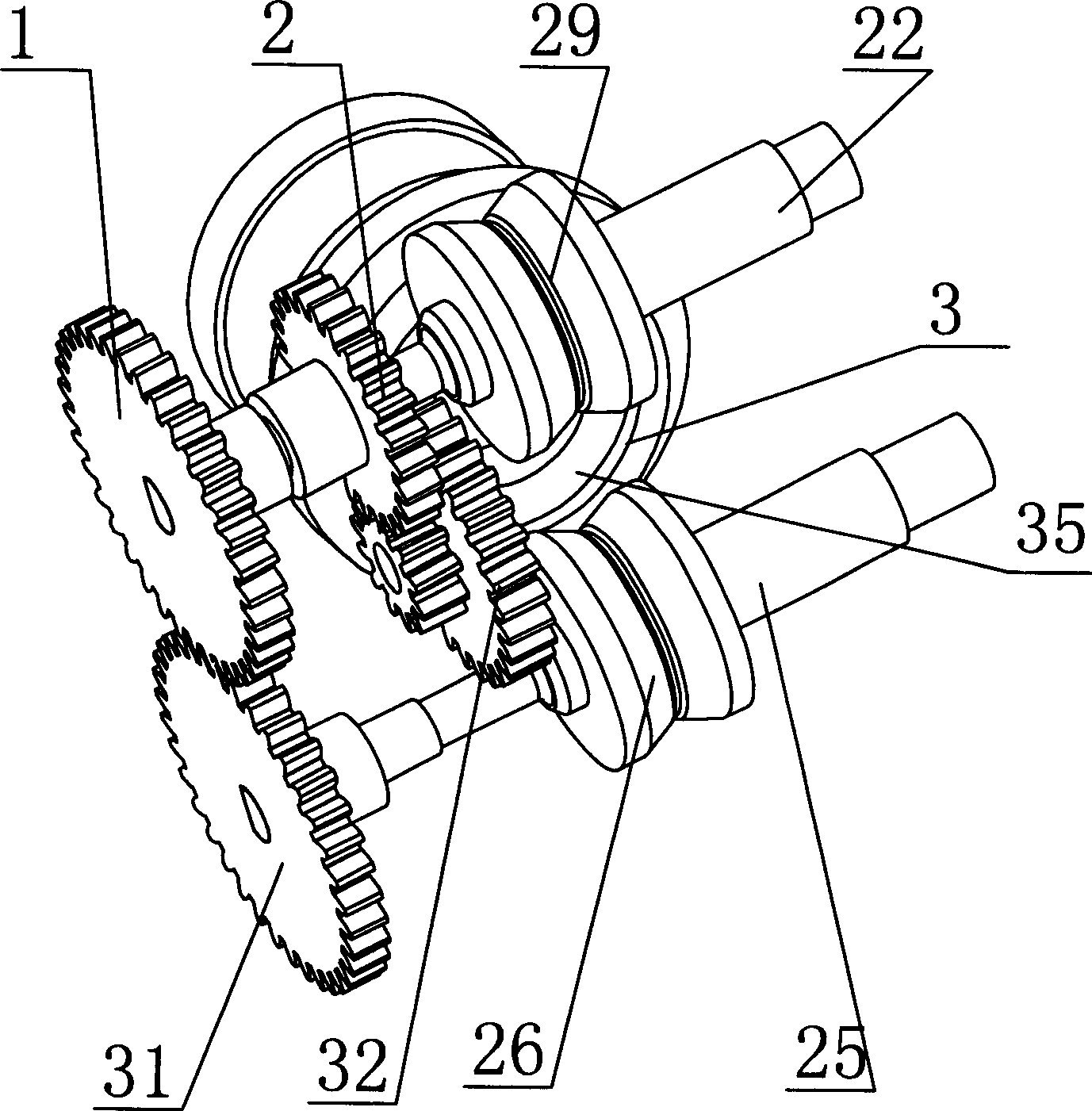

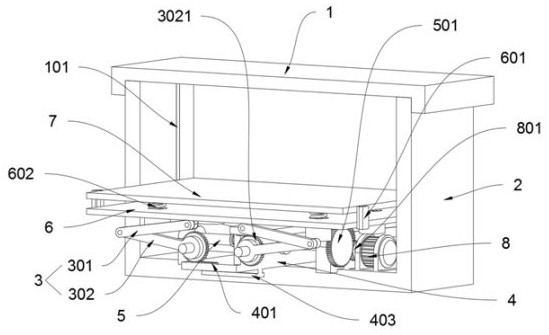

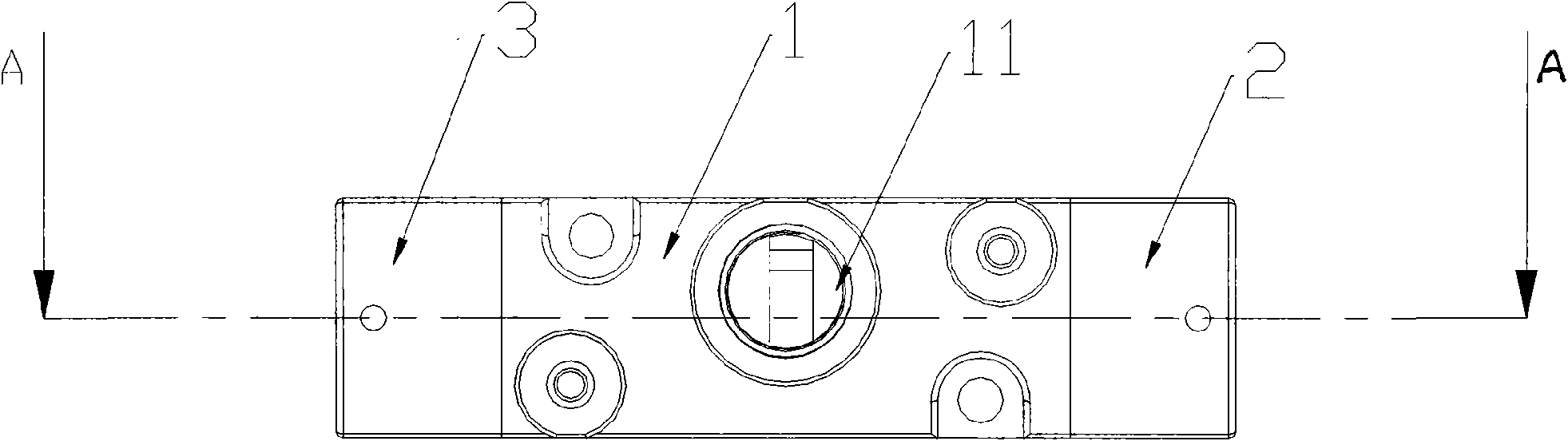

Self-adaptive drive device of trackless sliding door and door with device

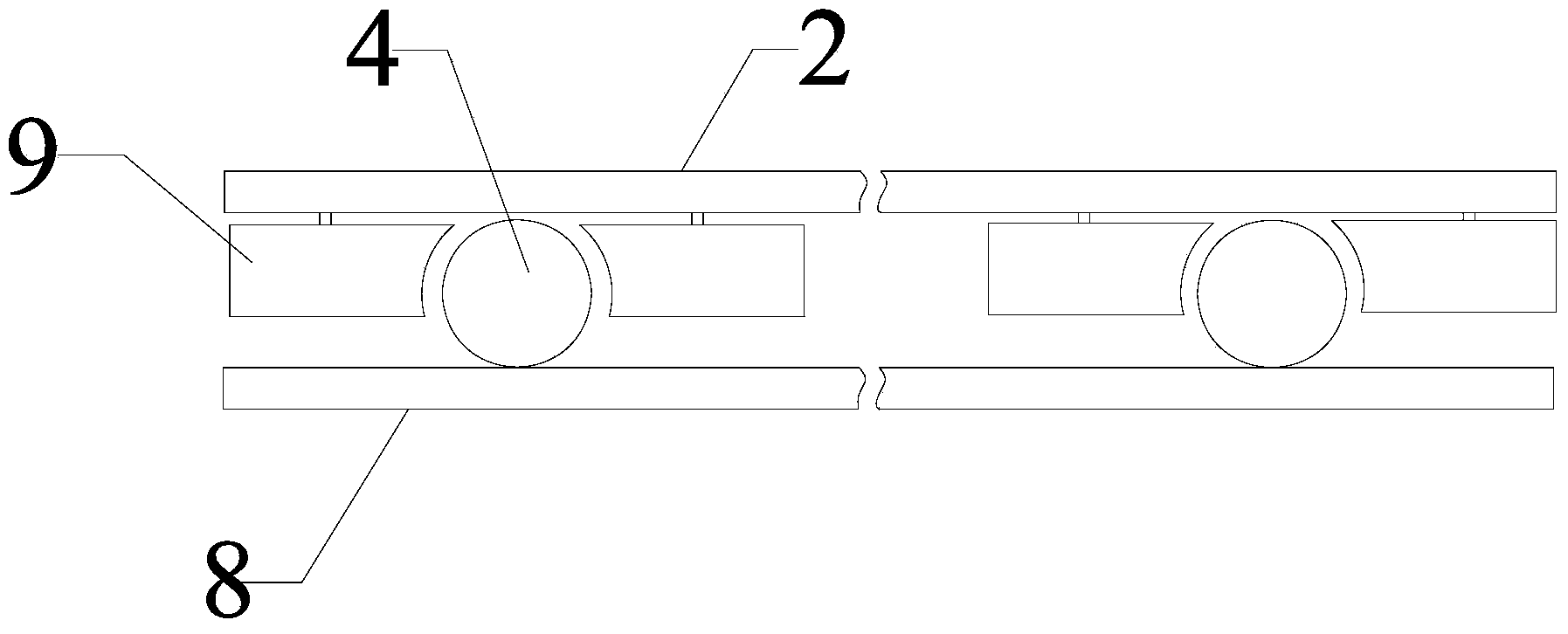

ActiveCN104234614ANo disengagementThere will be no stuck phenomenonGates/doorsPower-operated mechanismGear wheelDrive shaft

The invention relates to a self-adaptive drive device of a trackless sliding door and a door with the device. The self-adaptive drive device comprises a base; a motor; a drive shaft, wherein one end of the drive shaft is synchronously connected with a motor rotating shaft in a chain drive, belt drive or engagement manner, and the other end of the drive shaft is synchronously connected with a driven gear; a movable frame, wherein the movable frame has a degree of freedom of movement relative to the base in a plane perpendicular to the rotating axis of the drive shaft, and a guide part above the driven gear is arranged on the movable frame; a gear rack, wherein the gear rack is arranged between the driven gear and the guide part, teeth on the lower surface of the gear rack are engaged with the driven gear and the upper surface of the gear rack is in sliding, rolling or engagement fit with the guide part; a guide mechanism. The self-adaptive drive device of the trackless sliding door and the door with the device have the advantages that the door body can be enabled to automatically adapt to low or uneven parts of the ground and the phenomenon that the drive device is separated or gets stuck during transverse movement of the door body is avoided.

Owner:FOSHAN NANHAI DINGXIN ELECTRICAL & MECHANICAL EQUIP

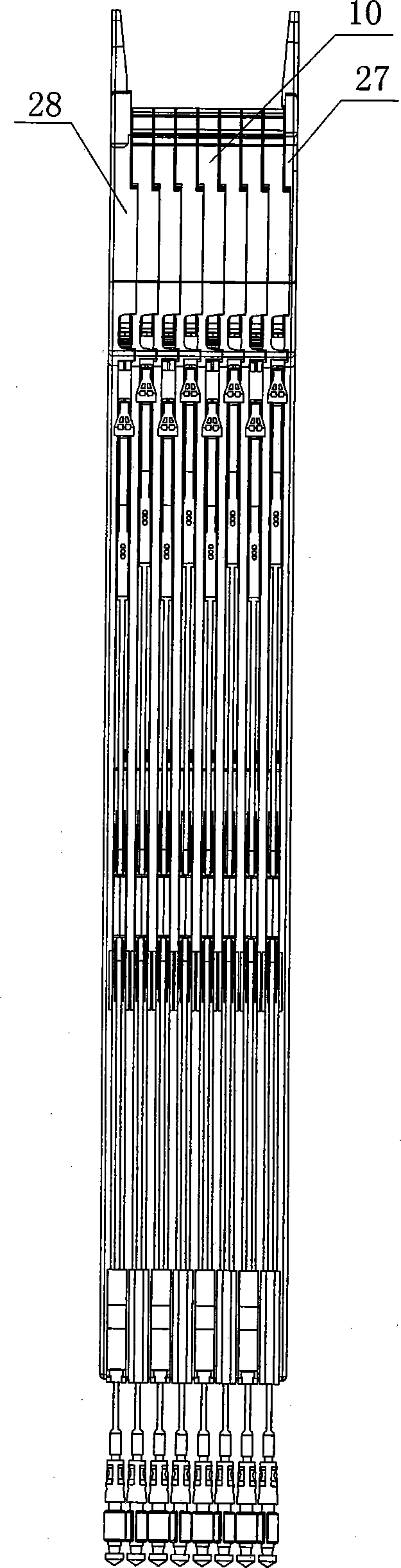

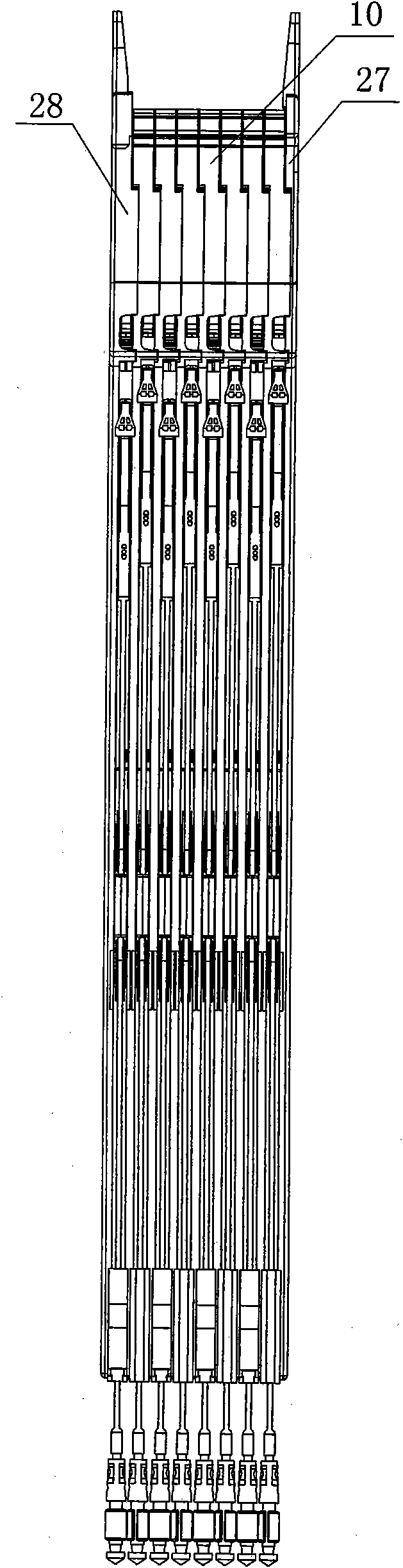

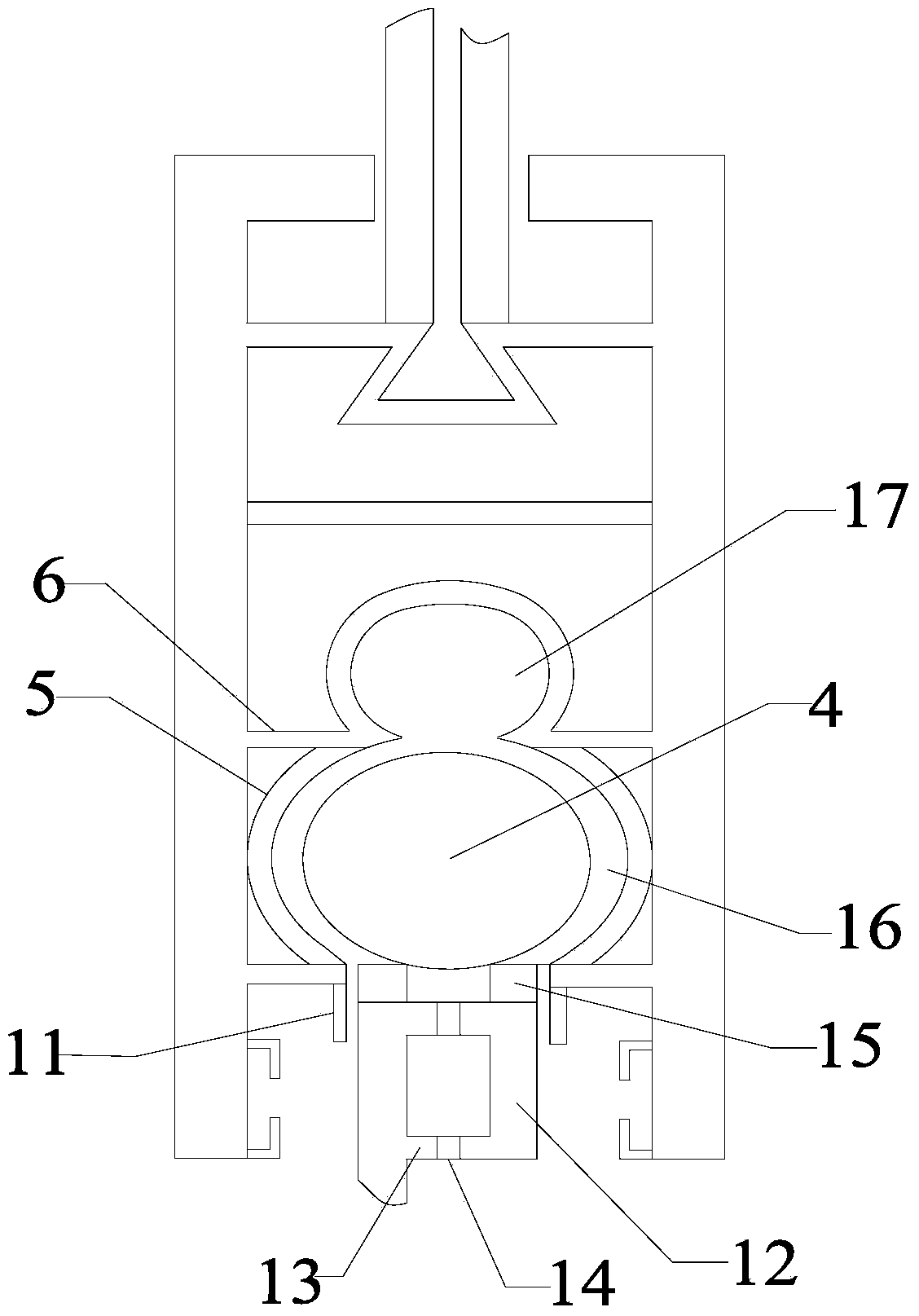

Novel electromagnetic valve component of electronic jacquard machine

The invention relates to a novel electromagnetic valve component of an electronic jacquard machine, which belongs to the technical field of textile manufacturing machines. The novel electromagnetic valve component comprises a base plate, a panel and clamping plates, wherein the clamping plates are positioned between the base plate and the panel; a driving mechanism, a pulley support structure, a joint quick insertion structure and an electromagnetic valve structure are arranged between the base plate and the clamping plate, between the clamping plate and the clamping plate and between the clamping plate and the panel; the driving mechanism comprises a moving iron and a vertical hook; the moving iron comprises a moving iron metallic body and a moving iron plastic body, and the vertical hook comprises a vertical hook metallic body and a vertical hook plastic body; the pulley support structure comprises a pulley, a pulley support, a pulley shaft and a copper sleeve; the copper sleeve is arranged on the pulley support, and the pulley shaft is inserted in the copper sleeve; the joint quick insertion structure comprises a quick joint, a through hole fixed block and a harness cord; and the electromagnetic valve structure comprises an electromagnet, and the electromagnet and the clamping plates are designed independently. The novel electromagnetic valve component has the advantages of reasonable structure design, convenient mounting and dismounting, wider application range, longer service life, higher stability and shorter production process to save the cost.

Owner:浙江奇汇电子提花机有限公司

Efficient and deep reduction treatment method for sewage sludge

InactiveCN105800900AImprove work efficiencyImprove power usageSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPistonEngineering

The invention discloses an efficient and deep reduction treatment method for sewage sludge. The method is based on a reduction treatment device, the reduction treatment device comprises at least one dehydration module, each dehydration module comprises a bidirectional oil cylinder (1) and two symmetric dehydration units (2), and each dehydration unit (2) comprises a dehydration barrel (2.1), a supporting plate (2.2) and an extruding plate (2.3). The supporting plates (2.2) are located on the outer sides of the dehydration barrels (2.1), the extruding plates (2.3) are located on the inner sides of the dehydration barrels (2.1), and feeding ports (2.4) are formed in the dehydration barrels (2.1). Each bidirectional oil cylinder (1) is provided with two piston rods (1.1) which are connected with the extruding plates of two corresponding dehydration units (2) respectively. According to the method, feeding dehydration and squeezing dehydration are carried out at the same time, so that work efficiency is improved; meanwhile, the pressure of fed materials is ingeniously utilized for dehydration in the squeezing dehydration process, and therefore the power use effect is improved.

Owner:CHINA JILIANG UNIV

Novel electromagnetic valve component of electronic jacquard machine

The invention relates to a novel electromagnetic valve component of an electronic jacquard machine, which belongs to the technical field of textile manufacturing machines. The novel electromagnetic valve component comprises a base plate, a panel and clamping plates, wherein the clamping plates are positioned between the base plate and the panel; a driving mechanism, a pulley support structure, a joint quick insertion structure and an electromagnetic valve structure are arranged between the base plate and the clamping plate, between the clamping plate and the clamping plate and between the clamping plate and the panel; the driving mechanism comprises a moving iron and a vertical hook; the moving iron comprises a moving iron metallic body and a moving iron plastic body, and the vertical hook comprises a vertical hook metallic body and a vertical hook plastic body; the pulley support structure comprises a pulley, a pulley support, a pulley shaft and a copper sleeve; the copper sleeve is arranged on the pulley support, and the pulley shaft is inserted in the copper sleeve; the joint quick insertion structure comprises a quick joint, a through hole fixed block and a harness cord; and the electromagnetic valve structure comprises an electromagnet, and the electromagnet and the clamping plates are designed independently. The novel electromagnetic valve component has the advantages of reasonable structure design, convenient mounting and dismounting, wider application range, longer service life, higher stability and shorter production process to save the cost.

Owner:浙江奇汇电子提花机有限公司

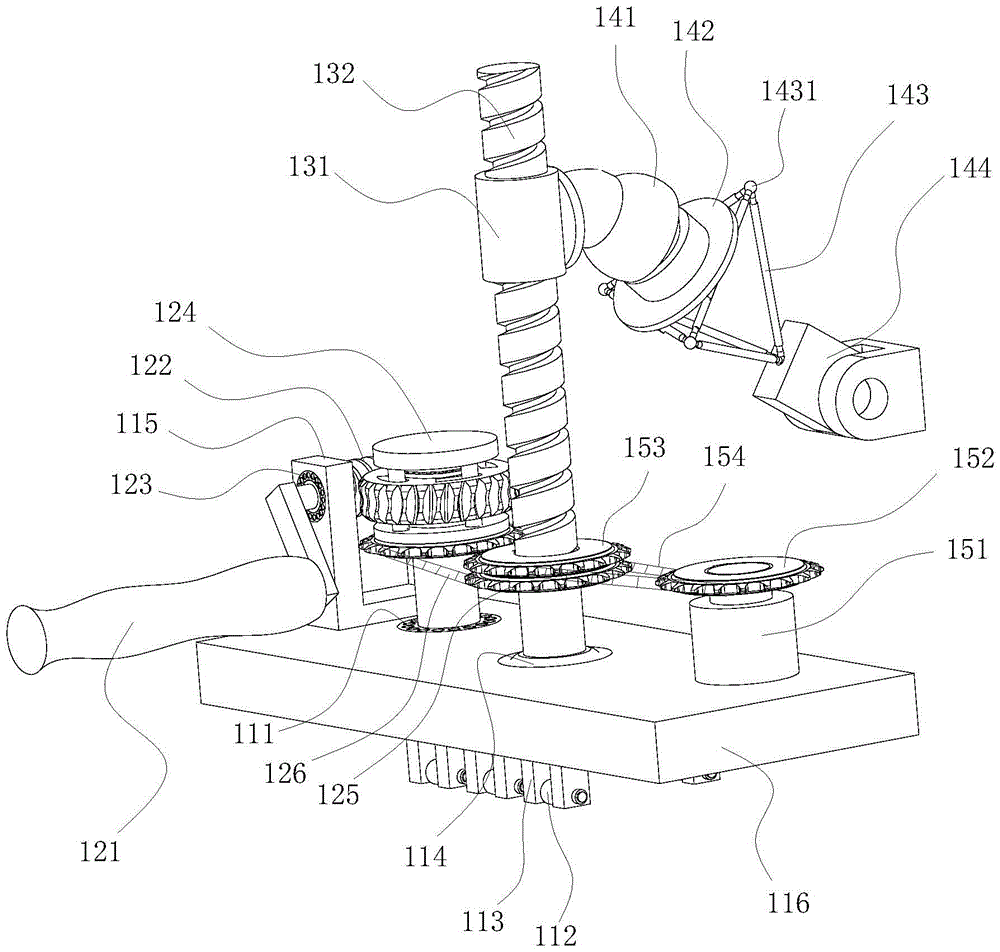

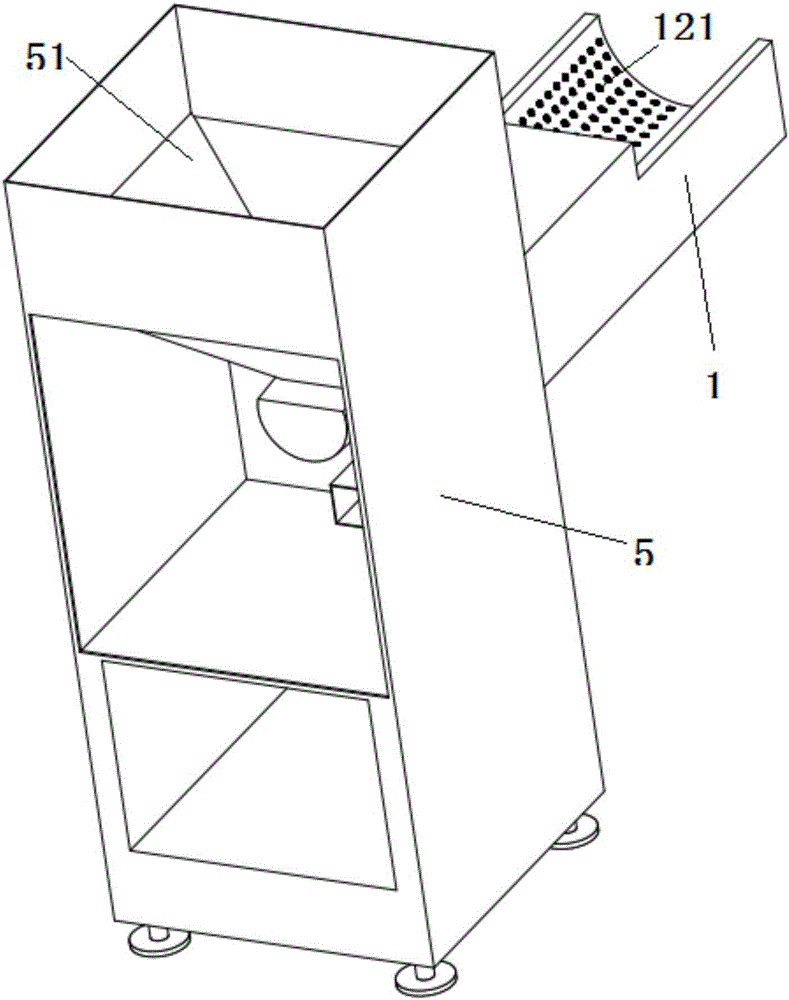

Ice cream machine

The invention relates to an ice cream machine. The ice cream machine is characterized by comprising a machine shell, a first transmission structure, a second transmission structure, a stirrer structure, a guide rail, a material cup fixture, a stirring and discharging structure, an upper limit inductor, a lower limit inductor and a controller; the first transmission structure and the second transmission structure are installed on the middle-lower portion and the middle-upper portion of the machine shell respectively; the stirrer structure comprises a power output shaft, a spiral stirring shaft, a baffle, a central stirring shaft, a spiral stirring blade, a stirring head, a first elastic structure and a second elastic structure; the guide rail is installed on the machine shell, the material cup fixture is slidingly installed on the guide rail and fixedly connected with the first transmission structure, and the stirring and discharging structure is installed in the material cup fixture; the upper limit inductor and the lower limit inductor are installed on the middle-upper portion and the bottom of the machine shell respectively; the controller is installed at the top of the machine shell, and the controller is electrically connected with the first transmission structure, the second transmission structure, the upper limit inductor and the lower limit inductor. The ice cream machine has the advantages that relative motion can be achieved between the spiral stirring shaft and the power output shaft, a blocking phenomenon cannot occur, the stirring and discharging structure is stable in installation, resonance cannot be generated during stirring, and the taste of ice cream is good.

Owner:SHUNDE POLYTECHNIC +1

Magnetic repulsion type ball holding rolling door/window

InactiveCN103967369ASimple structureReduce manufacturing costWing arrangementsWing suspension devicesMagnetic polesEngineering

The invention relates to the technical field of building doors and windows, in particular to a magnetic repulsion type ball holding rolling door / window. The magnetic repulsion type ball holding rolling door / window comprises a sliding seat arranged inside a door / window frame. Movable fan bodies are arranged on the sliding seat, and ball holding rolling devices are arranged between the sliding seat and the fan bodies. Each ball holding rolling device comprises two ball holding semicircular arms which are oppositely arranged, each ball holding semicircular arm comprises an arc plate with a semicircular cross section, a rolling channel is formed between every two corresponding arc plates, and a plurality of steel balls are arranged in each rolling channel. A plurality of evenly distributed magnet separation blocks are arranged inside each rolling channel. Magnetic poles of opposite sides of every two adjacent magnet separation blocks are the same, and each steel ball is arranged between every two adjacent magnet separation blocks. According to the magnetic repulsion type ball holding rolling door / window, the principle that the magnet separation blocks opposite in magnetism repel is utilized, the multiple magnet separation blocks are arranged in the rolling channels, the structure is simple, the manufacturing cost is low, and the steel balls will not be stuck; besides, each steel ball revolves on its axis instead of rolling, so that the steel balls are not prone to damage, the service life of the steel balls is long, and normal use of the magnetic repulsion type ball holding rolling door / window is guaranteed.

Owner:郭建东

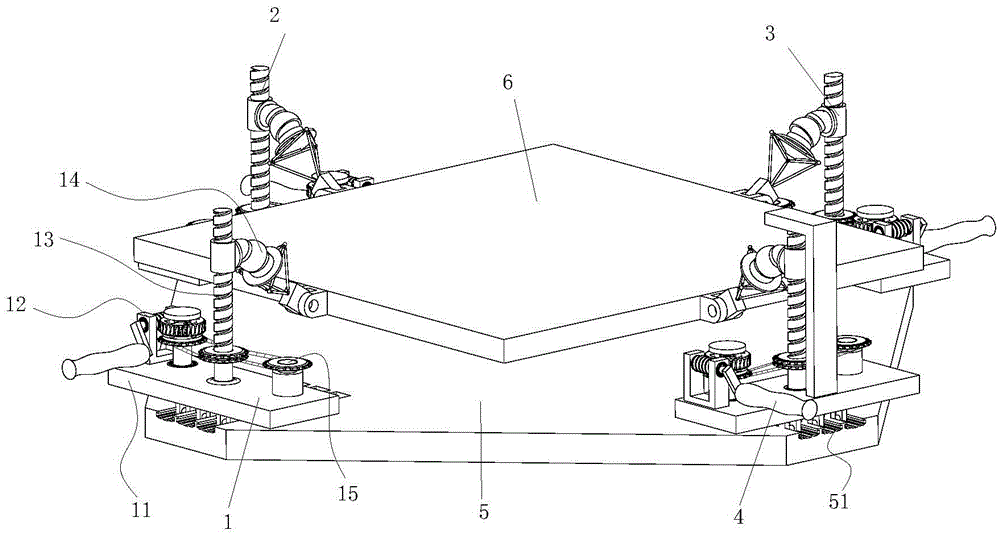

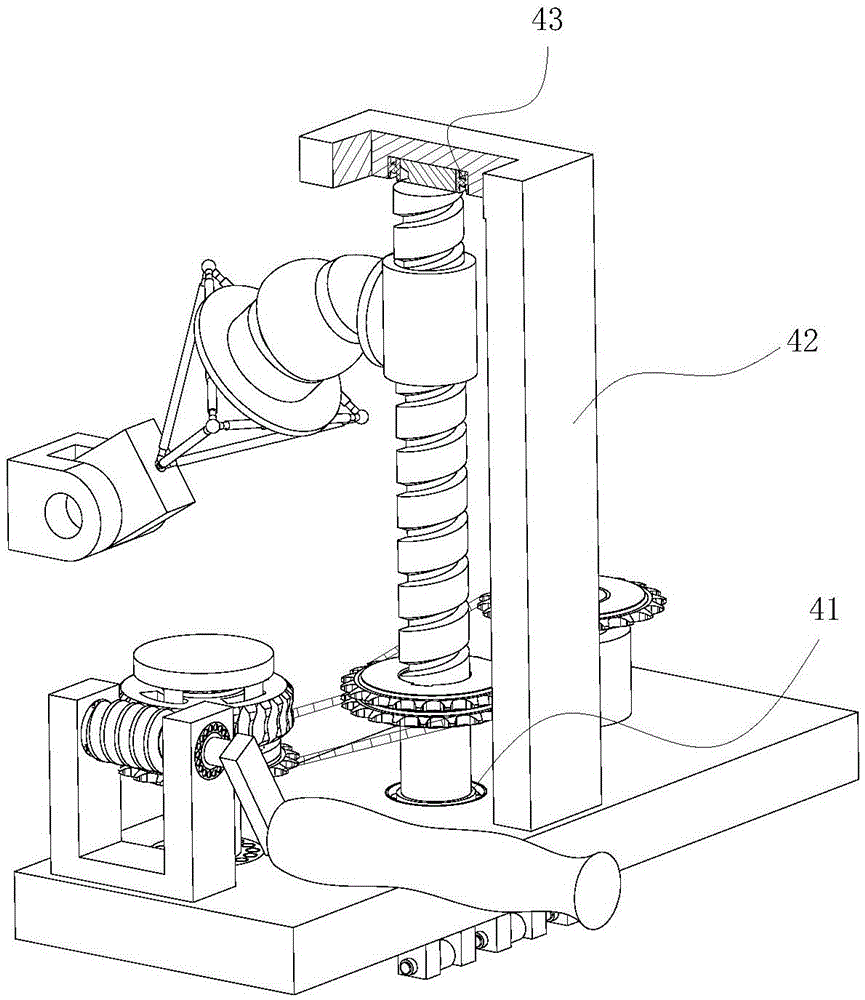

Precise horizontal adjustment device

ActiveCN105538263AImprove applicabilityEasy to useProgramme-controlled manipulatorWork benchesBall screwPetroleum engineering

The invention discloses a precise horizontal adjustment device. The precise horizontal adjustment device comprises a first chain, a second chain, a third chain, a fourth chain, a supporting base plate and an adjusting platform, wherein the four chains are uniformly distributed at the periphery of the supporting base plate, three of the four chains are the same, and the other chain is used for positioning a screw rod at a vertical position through a screw rod fixing frame, and the rest structure of the different chain is the same as that of the three chains; through a manual / electric switcher, the horizontal adjustment device can realize horizontal adjustment operation through a manual operation or an electric operation. The precise horizontal adjustment device adopts flexible joint assembly connection, so that a stuck phenomenon in a horizontal adjustment process of the adjusting platform is avoided, worm gears are matched with the ball screw rods to enable the horizontal adjustment process to be more stable and horizontal adjustment accuracy to be higher.

Owner:阜宁丰隆机电制造有限公司

Aqueous lubricating liquid for stamping, stretching and forming cell phone battery shell, preparation method and application method thereof

The invention discloses aqueous lubricating liquid for stamping, stretching and forming a cell phone battery shell, a preparation method and an application method thereof. The lubricating liquid comprises the following raw materials: 45# transformer oil, a non-ionic emulsifying agent, aqueous extreme-pressure lubricant, boric acid, an aluminum powder sinking agent, triethanolamine, isopropanolamine, synthetic petroleum sodium sulfonate, a branched chain phosphate aluminum protecting agent, a dicarboxylate based composite anti-rust agent, a butyl ether coupling agent, a hard water resistant agent, a defoaming agent and distilled water; the lubricating liquid is excellent in lubricating performance, anti-rust performance and settling performance, and the lubricating performance, the anti-corrosion performance and the cleaning performance are matched and stabilized for a long time, the antibacterial performance is good and the service life is long, the working liquid can be circularly added, the emission of the waste liquid is reduced, the environment cannot be polluted, and all indexes of 5% of diluent reach or exceed relative indexes of GB6144-2010.

Owner:AMER TECH CO LTD

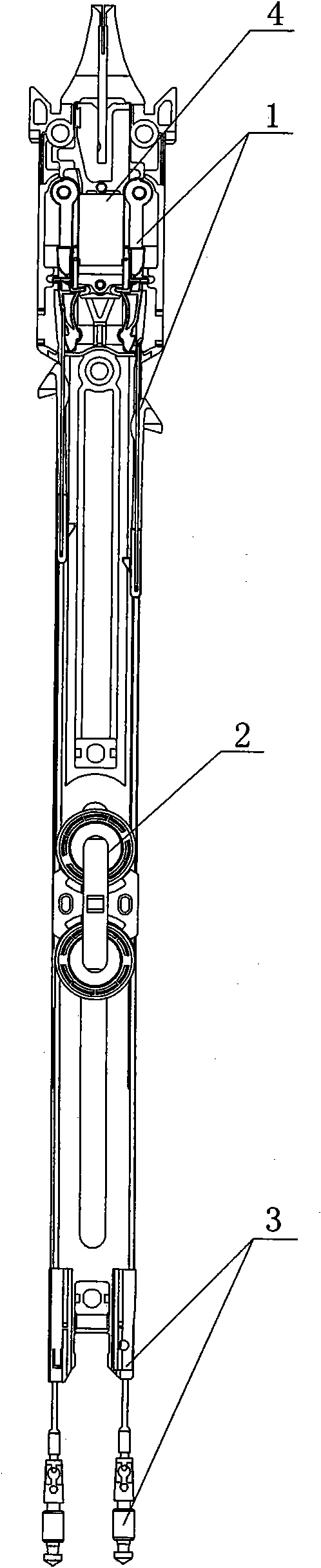

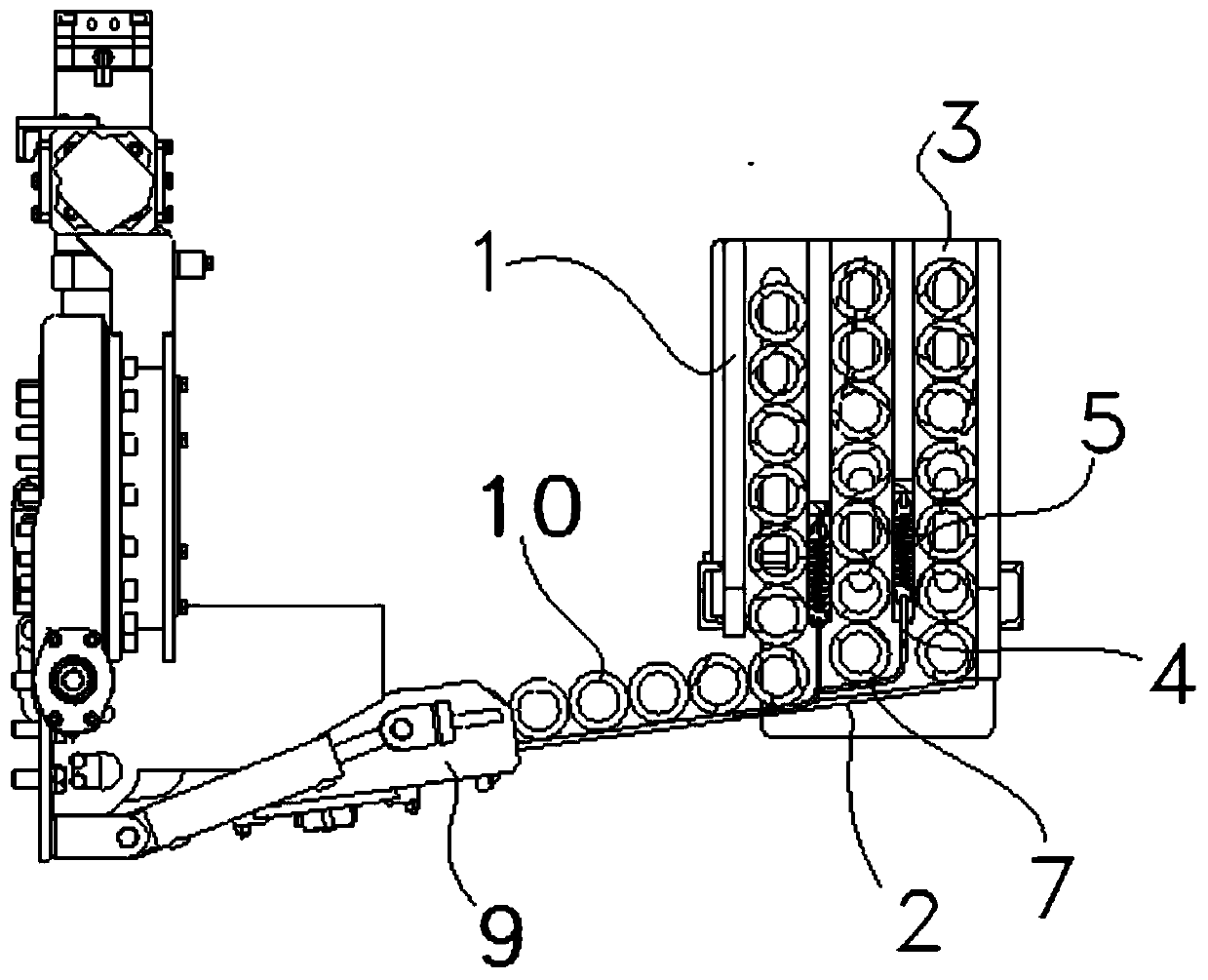

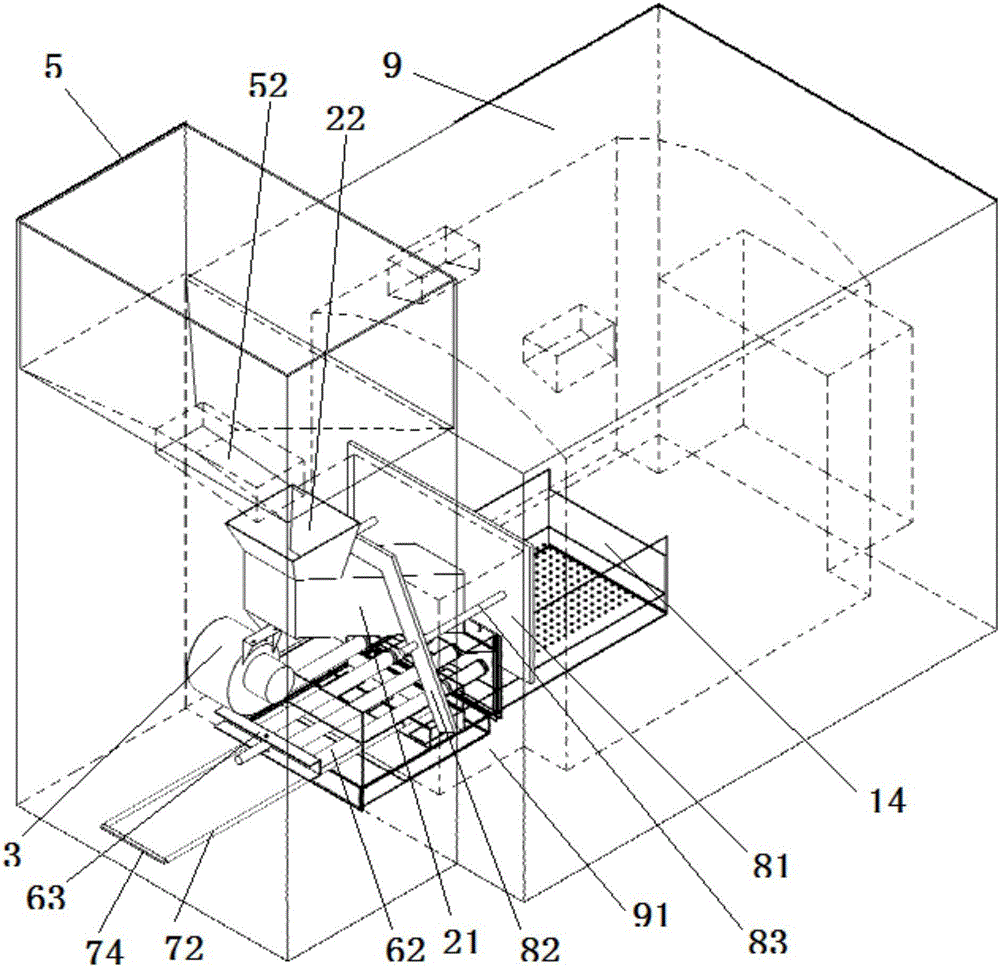

Drilling rod box with baffle and automatic drilling machine with the same

ActiveCN110397412AThere will be no stuck phenomenonIncrease the number ofDrilling rodsDrilling casingsMechanical equipmentManipulator

The invention belongs to the field of drilling mechanical equipment, and relates to a drill rod box with a baffle, and the drill rod box comprises a drill rod box body and a rolling plate, wherein theplane where the rolling plate is located is intersected with the ground, a drill rod rolls on the rolling plate, and a plurality of drill rod bins for storing the drill rod are sequentially arrangedin the drill rod box body in a separating manner; a baffle is arranged between adjacent drill rod bins, one end of the baffle is connected to the rolling plate, the other end of the baffle is connected to the drill rod box body, and the baffle reciprocates along the extension direction of the baffle; and the invention also relates to an automatic drilling machine with the drill rod box with the baffle, and the automatic drilling machine comprises a drilling machine, a manipulator and a drill rod placing flat plate, and also comprises the drill rod box provided with the baffle as described above, the rolling plate is fixedly connected with the drill rod placing flat plate, and the drill rod moves to the drill rod placing flat plate through the rolling plate. According to the invention, thebaffle is arranged between the adjacent drill rod bins, so that the drill rods in the plurality of drill rod bins are enabled to roll out in sequence, the drill rods are prevented from being blocked,the number of the drill rods in the drill rod box is increased, and the number of times of adding the drill rods in the drilling process is reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

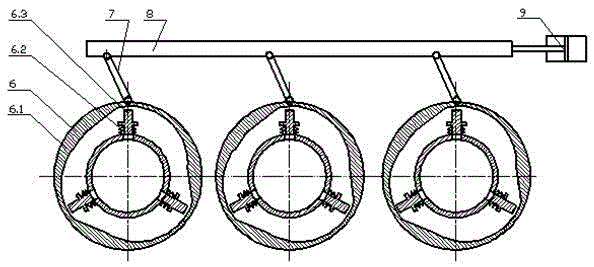

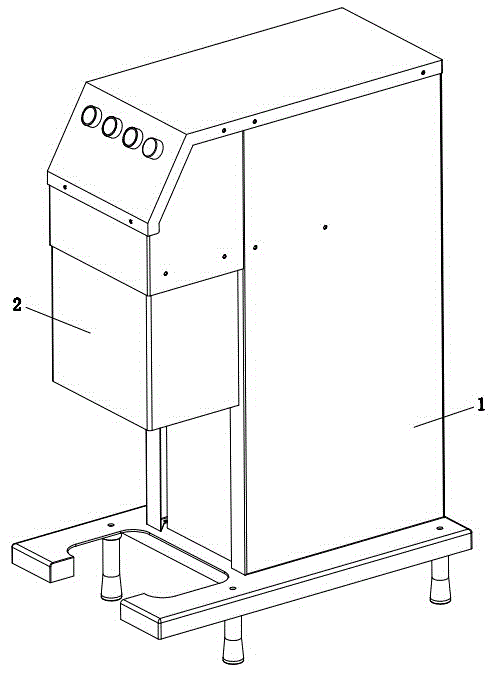

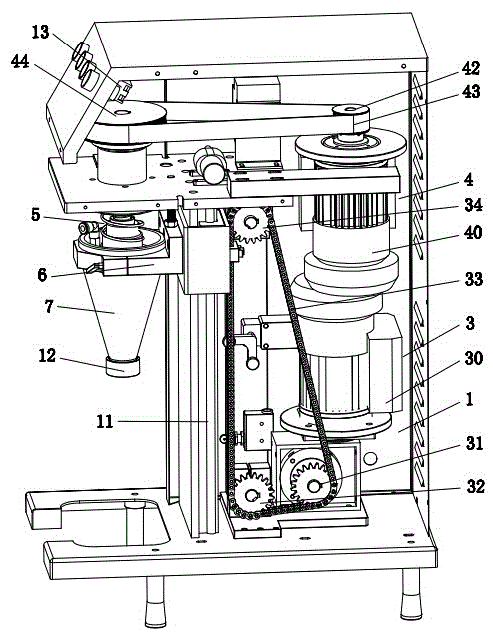

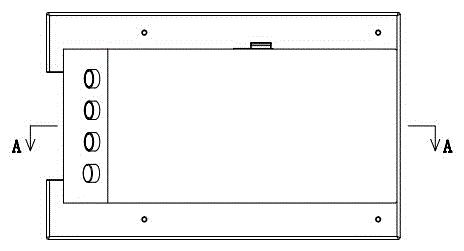

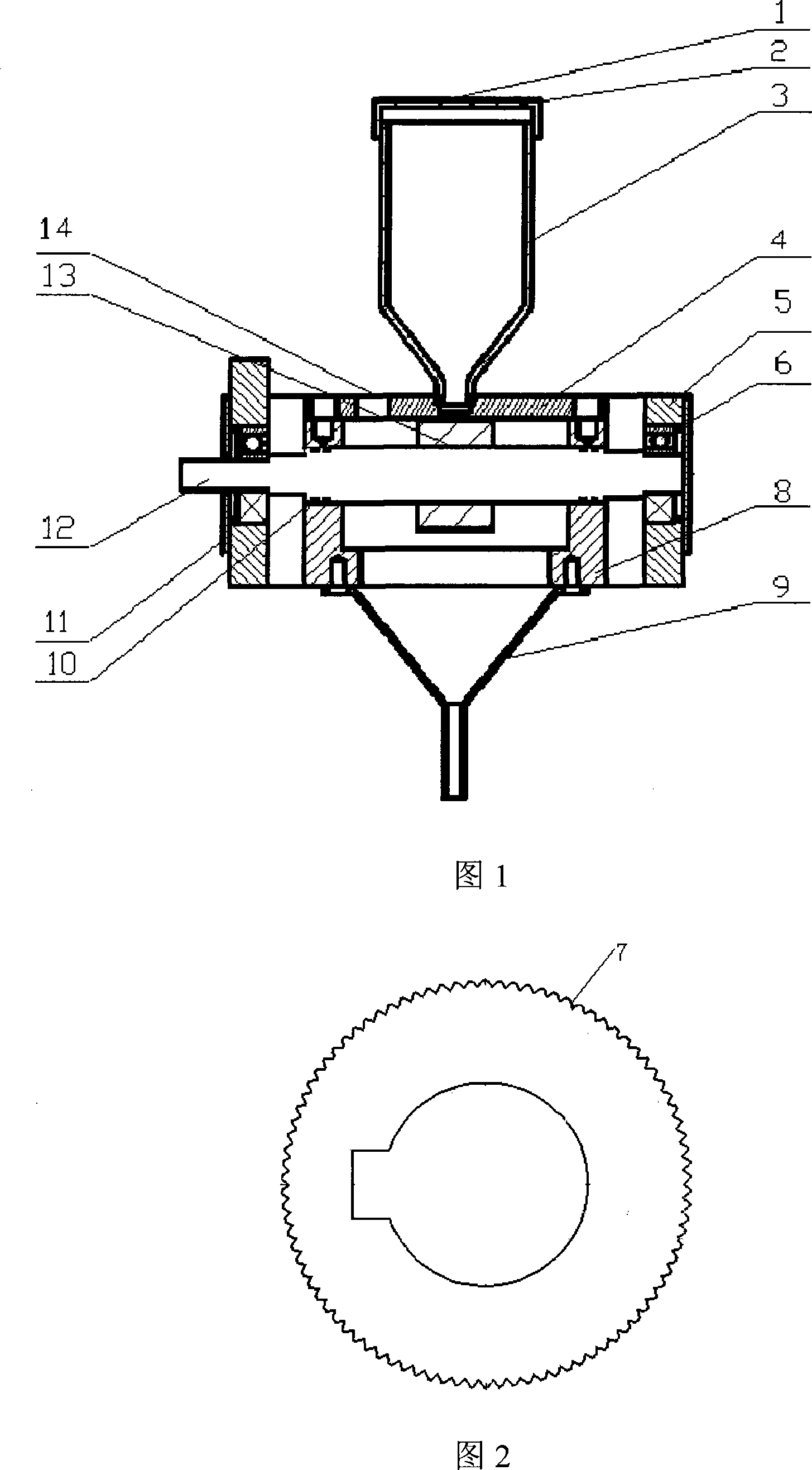

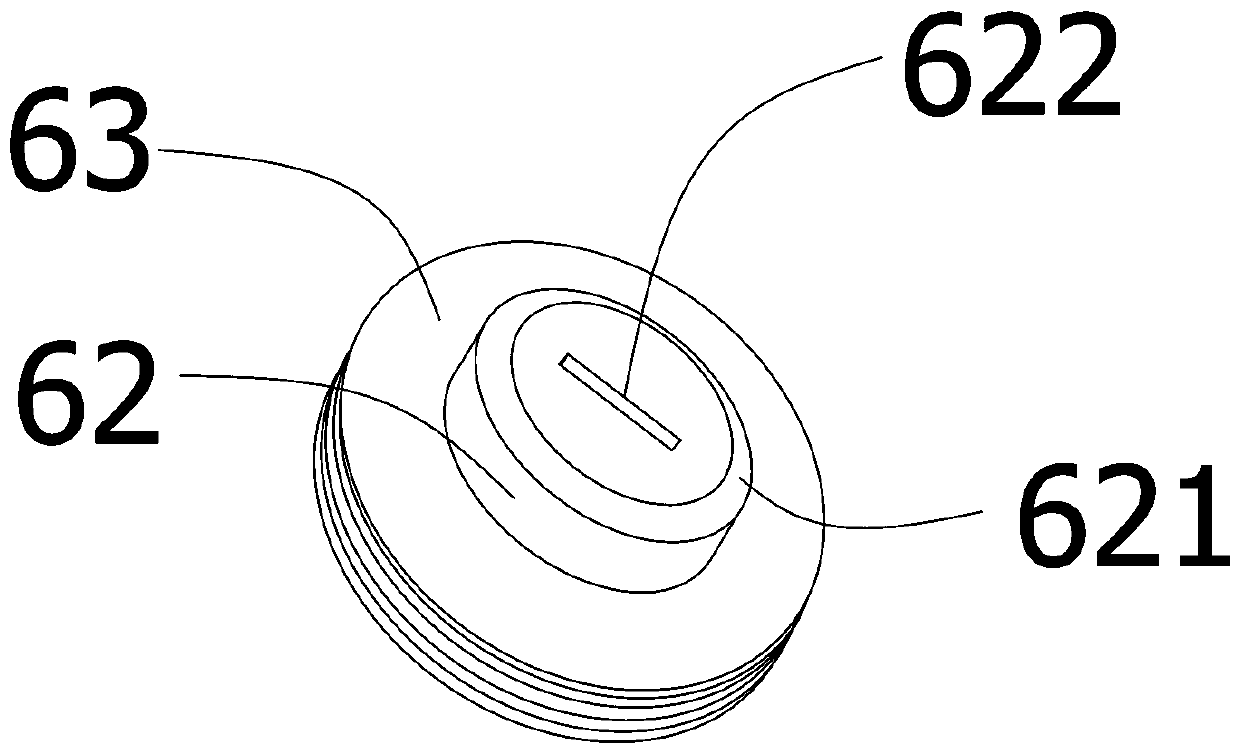

Synchronous powder feeder for laser reproduction

InactiveCN101230458AStrong granularity adaptabilityIntermittentMetallic material coating processesGranularityAtmospheric air

The invention relates to a synchronous powder feeder used for reproducing the laser and comprises an outer shell. An inner core is arranged inside the outer shell. A powder-storing chamber communicated with the inner core is arranged at the upper part of the outer shell and a powder-outlet device communicated with the inner core is arranged at the lower part of the outer shell. A rotating shaft passes through the inner core and is arranged on the outer shell through a bearing and the rotating shaft is connected with a drive electric motor. The upper key of the rotating shaft positioned in the inner core is connected with a powder-feeding roller, the upper end of the powder-feeding roller corresponds to the outlet of the powder-storing chamber, the lower end of the powder-storing chamber corresponds to the inlet of the powder-storing chamber and grooves for holding the powder are evenly distributed on the circumferential surface of the powder-feeding roller. An air vent, which communicates the inner core and the atmosphere, is arranged on the outer shell. The invention has the advantages that: firstly, the operation is stable and reliable and the phenomenon of the shaft gyration kinematic pair of the drive mechanism being interrupted and jammed fails to occur; and secondly, the powder feeding is continuous, even and controllable and a strong adaptability of the powder granularity is available.

Owner:ZHEJIANG UNIV OF TECH

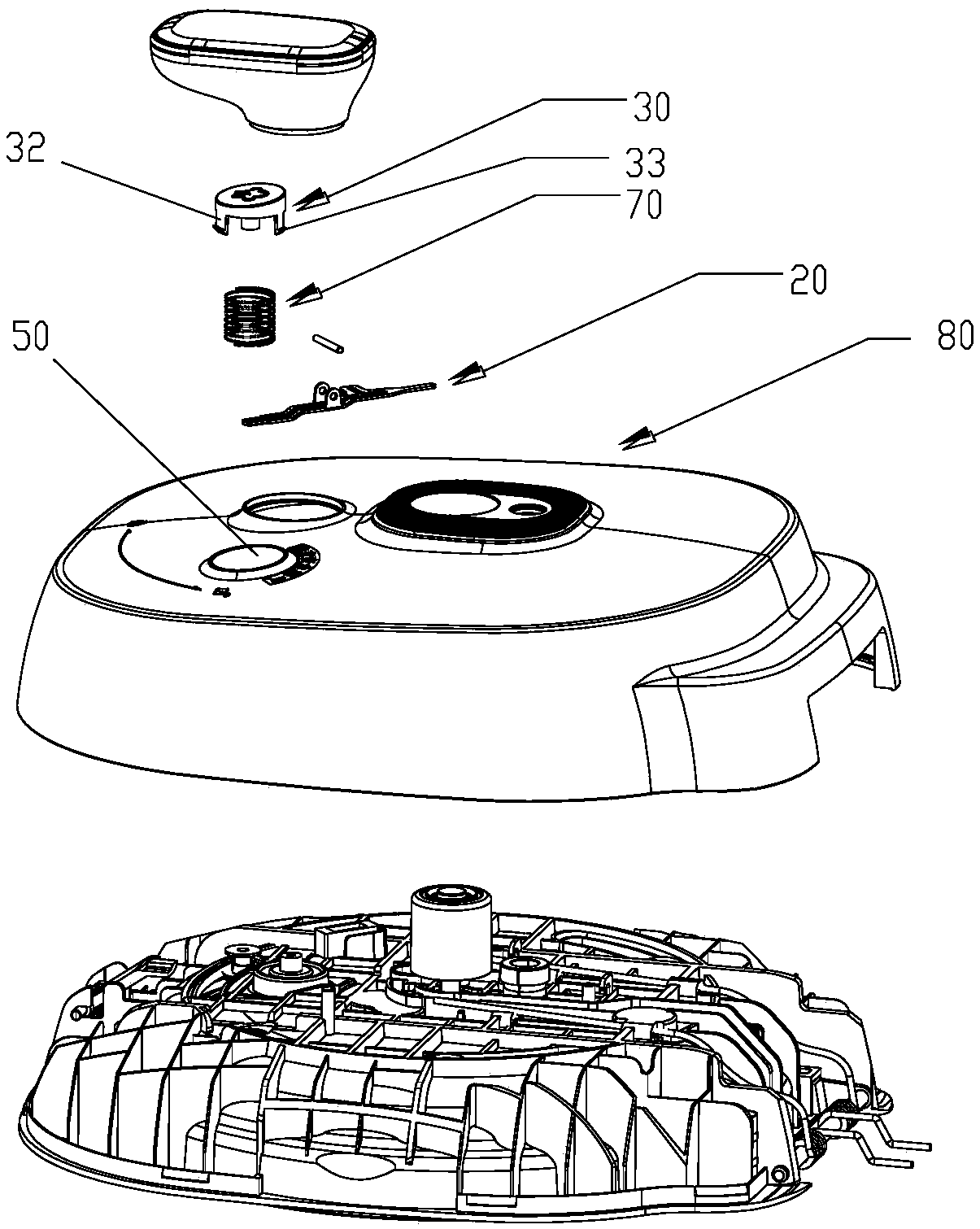

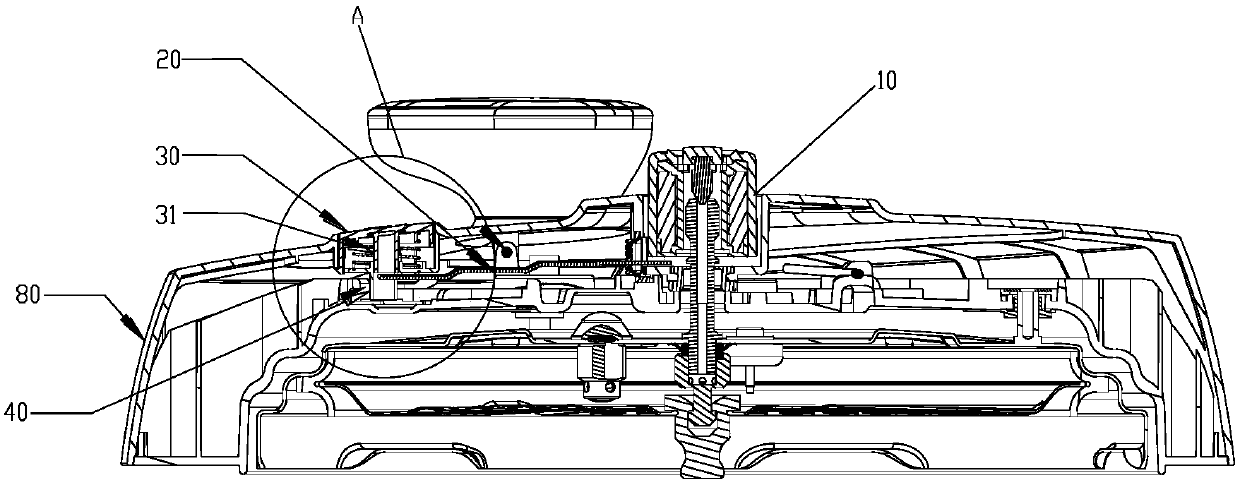

Pot cover and electric pressure cooker with same

The invention provides a pot cover and an electric pressure cooker with the same. The pot cover comprises a cover body and an exhaust device arranged on the cover body, wherein cover teeth are arranged on the cover body; the exhaust device comprises a pressure relief valve, a transmission lever, an exhaust button and a guide structure, wherein the pressure relief valve is arranged on the cover body, and the pressure relief valve has a pressure relief position for enabling the two sides of the cover body to be communicated, and a closed position for isolating the two sides of the cover body; the transmission lever is rotatably arranged on the cover body, and the first end of the transmission lever has a jacking position for jacking the pressure relief valve to relieve pressure and an avoidance position for avoiding the pressure relief valve; the exhaust button is movably arranged on the cover body; the bottom of the exhaust button is provided with a transmission column; the transmissioncolumn is arranged in an avoidance hole of the cover body in a penetrating mode, and the transmission column is used for pressing the second end of the transmission lever; and the guide structure isarranged on the cover body and is arranged around the avoidance hole, so that the movement of the transmission column is guided, and the exhaust button is prevented from being inclined, the side wallof the exhaust button and a surface cover groove cannot be stuck, and the exhaust is normal.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

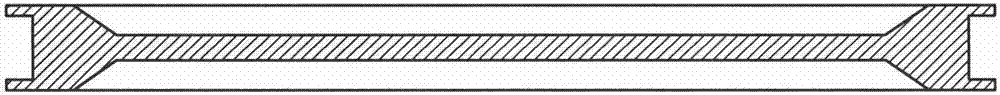

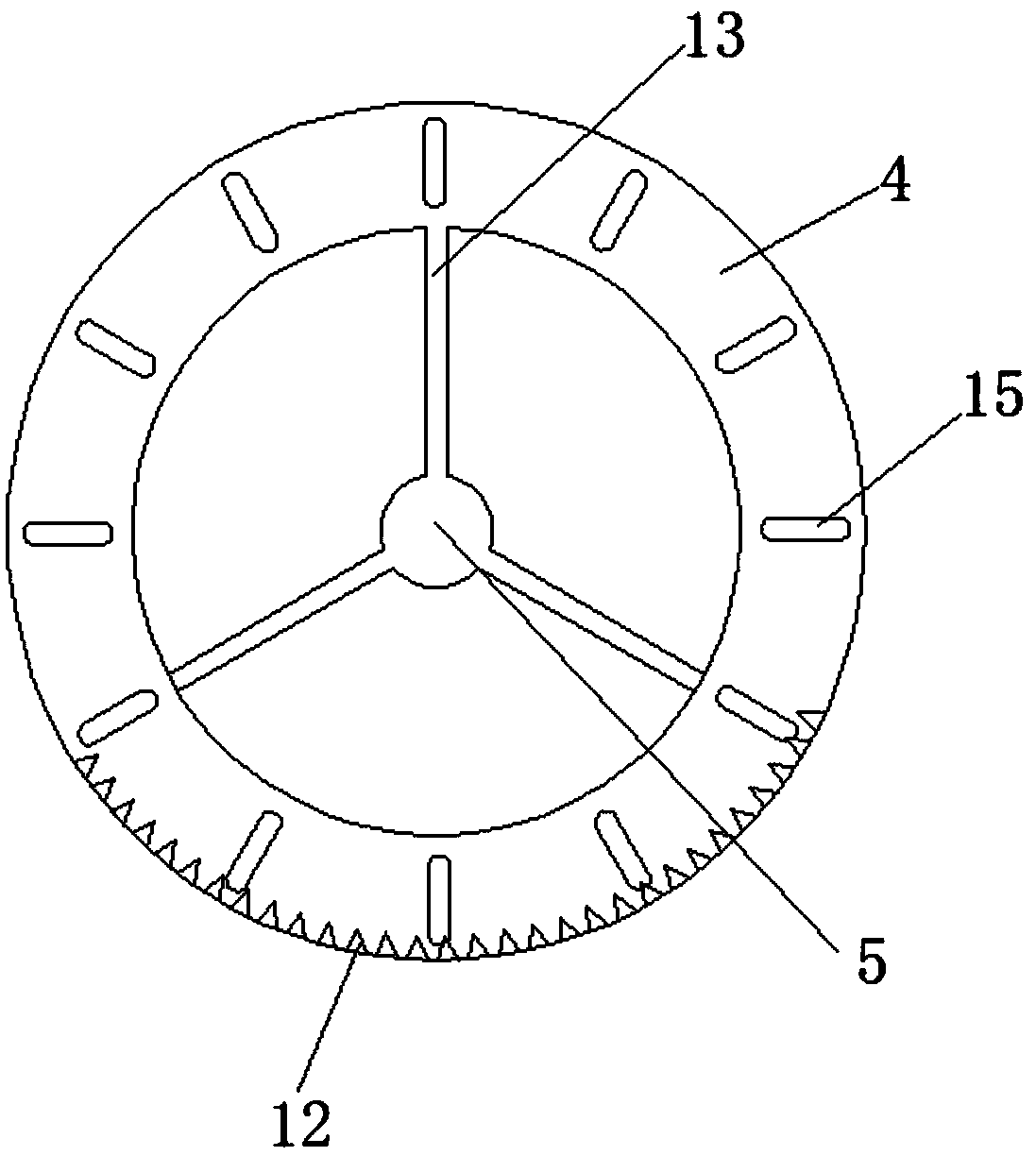

Rivet conveying mechanism of full-automatic rivet attaching machine

The invention relates to a rivet conveying mechanism of a full-automatic rivet attaching machine. The rivet conveying mechanism of the full-automatic rivet attaching machine mainly solves the problems that the existing rivet conveying mechanism of the full-automatic rivet attaching machine is apt to get stuck by U-shaped rivets and the fault rate is high. The rivet conveying mechanism of the full-automatic rivet attaching machine is characterized in that a wheel disc base (6) is arranged between an upper cover plate (3) and a lower punching head assembly (4), and a plurality of through holes (9) through which the U-shaped rivets can freely pass are equidistantly formed in the peripheral circumference of a conveying wheel disc (8); a rivet falling hole (10) which can only hold one U-shaped rivet is formed in the end of a vibrating bottom plate (102), and the rivet falling hole (10) corresponds to another one through hole (9) in the conveying wheel disc (8) at the same time when a lower rivet hole (7) corresponds to a through hole (9) in the conveying wheel disc (8). The rivet conveying mechanism of the full-automatic rivet attaching machine can better adapt to rivets with different specifications, can prevent or reduce the phenomenon that the rivet conveying mechanism gets stuck by the U-shaped rivets, has the characteristics of low fault rate and convenience in maintenance and operation, can meet the demands of customers and is worthy of being popularized and used.

Owner:东莞市恒兴隆实业有限公司

Electric pencil planer

InactiveCN1810522ARealize automatic feedingImplement automatic logoutSharpenersEngineeringDrive motor

The electric pencil planer includes motor, transmission mechanism, planing mechanism, feeding mechanism, withdrawal mechanism and reverse rotating mechanism. The motor is connected to the transmission mechanism diving the planing mechanism, and the feeding mechanism also driven with the motor is located in the path for planing the pencil to feed the pencil into the planing mechanism. After the pencil is planed to the preset location, the withdrawal mechanism is triggered to make the motor rotate in reverse direction and the feeding mechanism driven with the inversely motor withdraws the pencil from the planing mechanism. Owing to the feeding mechanism and the withdrawal mechanism, the electric pencil planer has automatic feeding and automatic withdrawal of pencil and high pencil sharpening efficiency.

Owner:JUXING ELECTRONICS HUIZHOU

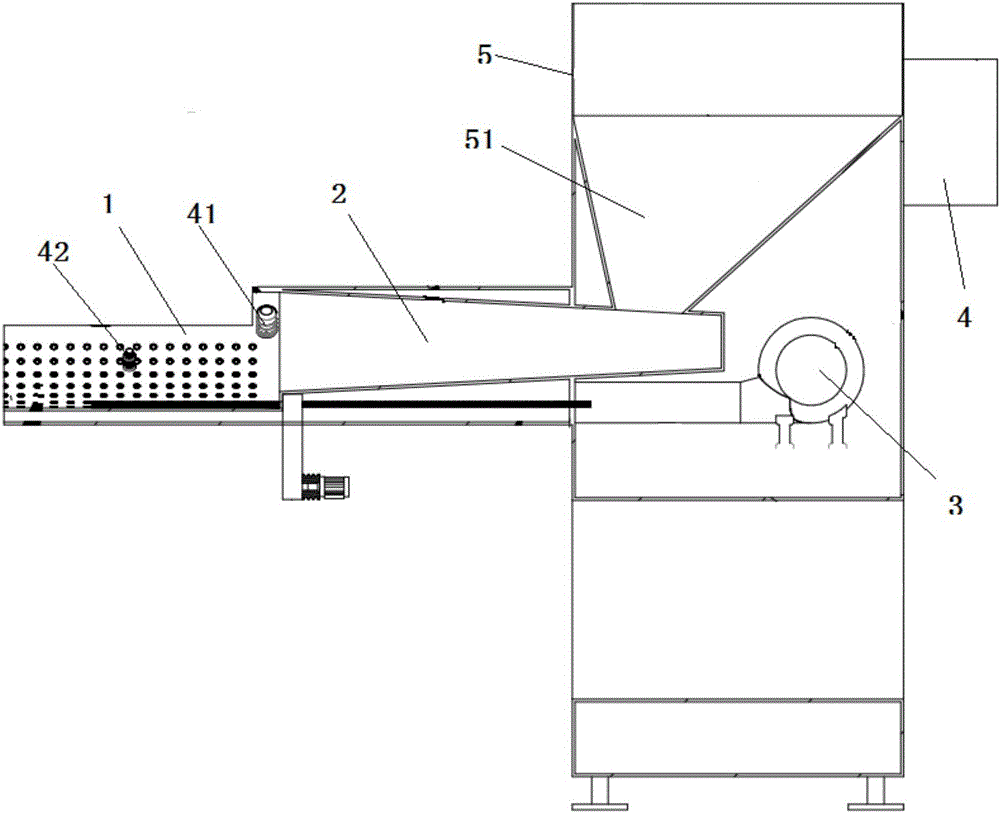

Vibrating feed combustor and control method thereof

ActiveCN106642192ASave man hoursReduce electric powerFuel supply regulationSolid fuel combustionSlagFlue

The invention discloses a vibrating feed combustor, comprising a combustion grate, a feeder, a blower and a controller, wherein the combustion grate comprises a grate enclosure, a first division plate and a second division plate arranged horizontally are arranged in the grate enclosure to divide the space encircled by the grate enclosure into a combustion trough, a combustion trough air flue and a slag receiving chamber, the first division plate is provided with vents, the combustion trough air flue is provided with an air inlet in one side in the horizontal direction, and the blower is communicated with the combustion trough air flue via the air inlet; the feeder is an electric vibrating feeder and comprises a feed pipe, the lower port of the feed pipe is arranged above the combustion trough, a first temperature sensor is arranged in the combustion grate, a second temperature sensor is arranged in a baking room, and the controller is connected with the blower, the electric vibrating feeder, the first temperature sensor and the second temperature sensor and used for controlling the frequency or magnitude of the electric vibrating feeder and the air quantity of the blower according to the temperature in the combustion trough and the difference between the current temperature in the baking room and a preset temperature.

Owner:湖南驱动源电气技术有限公司

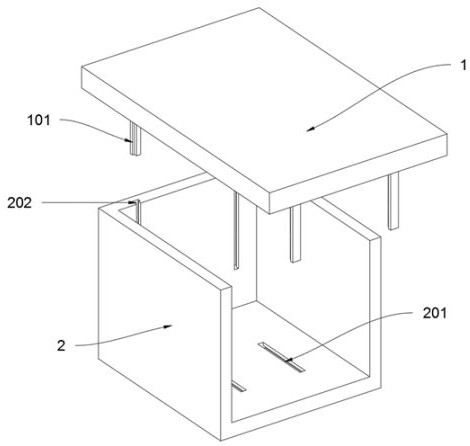

Anti-infection isolation device for clinical medicine of neonatology department

InactiveCN112494250AEasy to operateConvenient medical operationBaby-incubatorsFull Term NeonateIntensive care medicine

The invention discloses an anti-infection isolation device for clinical medicine of neonatology department, and relates to the technical field of isolation devices, and solves the problems that an existing isolation device for newborns is small in size, the newborns are very inconvenient to put into the isolation device, and small space is inconvenient for medical staff to perform medical operation on the newborns. An anti-infection isolation device for clinical medicine of neonatology department comprises a connecting rod ascending mechanism; The connecting rod ascending mechanism is composedof an upper connecting rod and a lower connecting rod. The newborn supporting bed of the device can ascend and descend autonomously, the newborn supporting bed can ascend to the top of the isolationbox from the interior of the isolation box so that medical staff can put newborns into the isolation box and perform medical operation conveniently, then the newborn supporting bed descends into the isolation box again and is covered with a top isolation cover. The isolation device is convenient and flexible, and is convenient for medical staff operation.

Owner:陈良锴

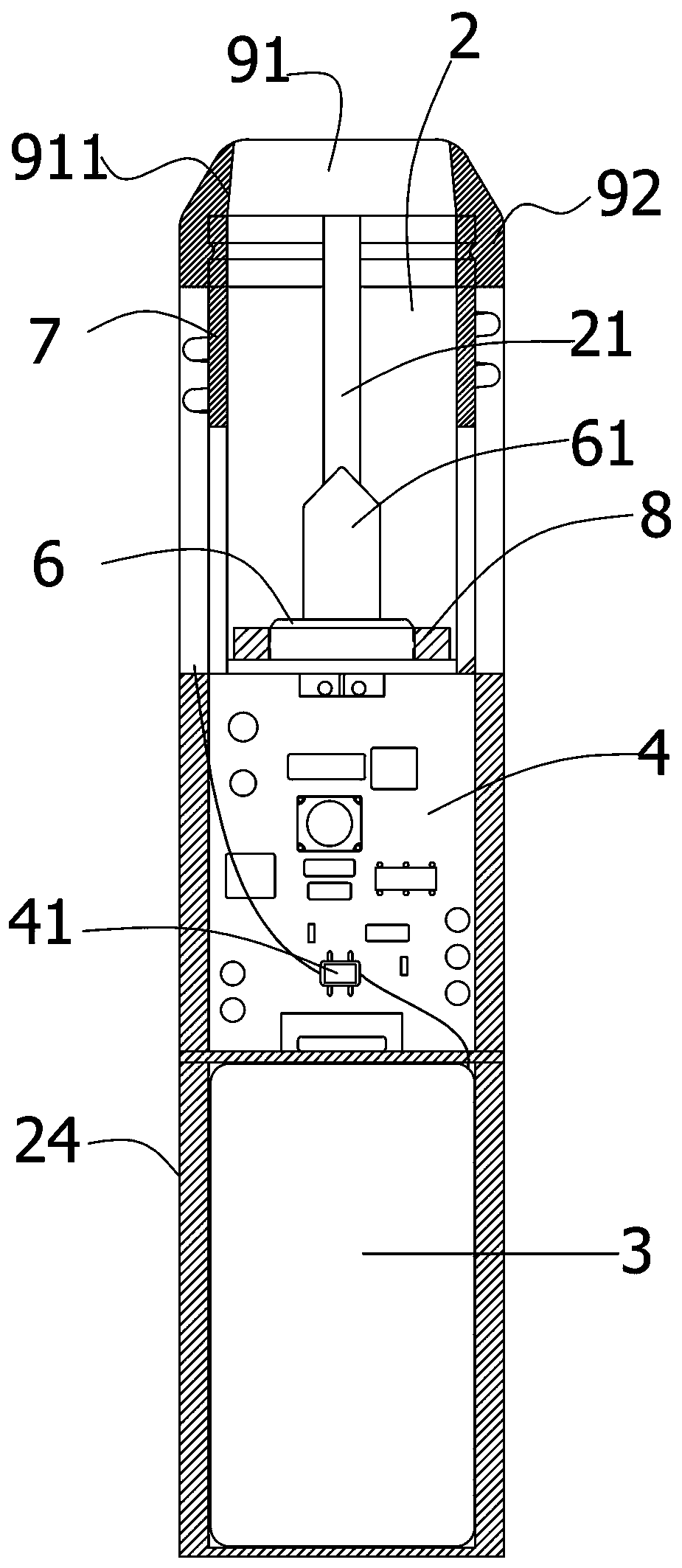

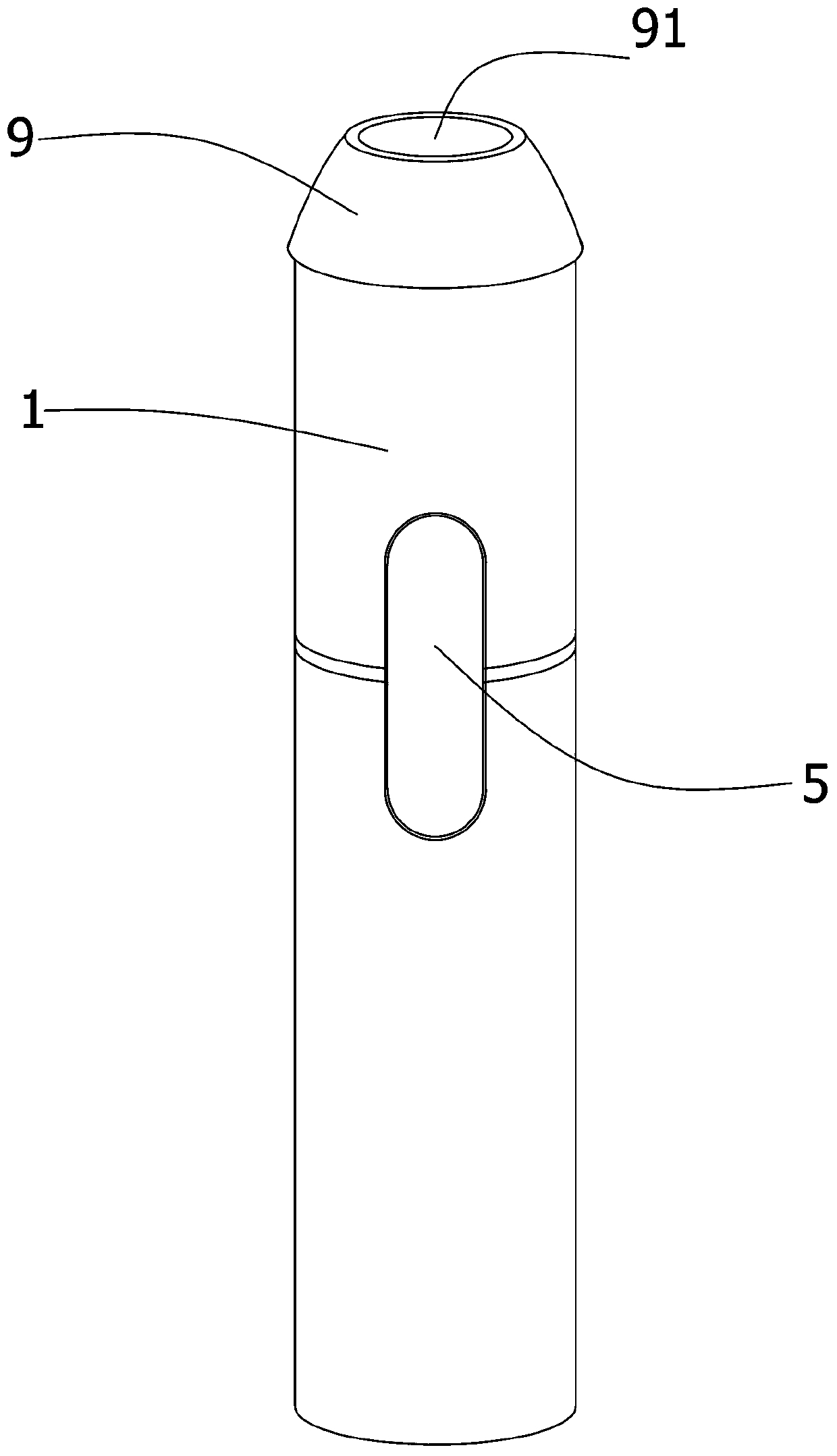

Heating non-combustion electronic cigarette appliance with smoke cartridge capable of automatically popping up

The invention discloses a heat-not-burn electronic cigarette appliance with smoke cartridges capable of automatically popping up. The heat-not-burn electronic cigarette appliance comprises a body, a heating chamber which is arranged in the body and is used for accommodating and heating the smoke cartridge, a battery used for providing heating electric energy for the heating chamber, and an integrated circuit board which is used for integrally controlling a heating circuit. A heating base is fixedly arranged on a bottom side in the heating chamber, a heating part is detachably arranged on the heating base and is used for allowing the smoke cartridge to be inserted and fixed and heating the smoke cartridge, and an attraction part which generates a magnetic field and generates magnetic forcewhen being powered on is arranged at the top of the heating chamber, the heat-not-burn electronic cigarette appliance also comprises a pop-up piece which is arranged on the heating base in a sliding and sleeving mode and used for rapidly moving upwards under the magnetic force of the attraction part and driving the smoke cartridge to pop up, a cover cap which is arranged at an outer end of the heating chamber in a sleeving mode and used for limiting the pop-up piece, and a boosting module which is used for increasing the voltage of the battery to enhance the magnetic force of the attraction piece to the pop-up piece. The smoke cartridge does not need to be manually pulled and inserted or moved out through the control of a supporting cap, and the problems of abrasion, abnormal sound and thelike of smoking set accessories are effectively avoided.

Owner:HUBEI CHINA TOBACCO IND +1

Piston-type electric water heater with variable-volume inner container

InactiveCN107401832AOverturn the way of water in and outStable temperatureWater heatersComing outEffect light

The invention discloses a piston-type electric water heater with a variable-volume inner container. A duplex piston is mounted in the inner container of a water tank of the electric water heater, and divides the inner container of the water tank into two cavities. One cavity is for holding cold water, and the other cavity is for holding hot water, so that the cold water and the hot water can be separated. When water enters the cold water cavity, the piston is pushed to discharge the hot water. Cold-water inlet or hot-water outlet are controlled by two two-position three-way electromagnetic valves positioned in the cavities respectively. The electromagnetic valves are interlocked, and when cold water enters one cavity, and hot water comes out from the other cavity. The length of the inner container of the water tank of the electric water heater is divided into ten equally, eleven reed pipe magnetism-sensitive special switches are mounted at the ten equant positions on the outer wall of the inner container of the water tank, and eleven volume indicators are mounted on a panel of the electric water heater and displayed as numbers of one to eleven. When the piston enters one equant position, the corresponding volume indicator is turned on by the corresponding reed pipe magnetism-sensitive special switch, vice versa, lighting of one volume indicator means that the piston is located at the position.

Owner:刘二九

Aperture type air regulation door

PendingCN108799531AGap wideningStacked tightlyOperating means/releasing devices for valvesSlide valveAir volumeActuator

The invention provides an aperture type air regulation door which comprises a left side plate, a blade positioning ring, arc-shaped blades, a gear regulation disc, an air guiding head, a body shell and an actuator, wherein the arc-shaped blades do not need axial rotation, do not have friction or jam with the inner wall of a pipeline, so that the clearance between each of the arc-shaped blades andthe inner wall of the pipeline is widened; the arc-shaped blades are folded at the air guiding head, one end of each of the arc-shaped blades is closely embedded into an annular groove of the air guiding head, and the arc-shaped blades are closely stacked, so that the air leakage is effectively reduced; a plurality of stems and the annular groove jointly support the blades on a leeside, so that the arc-shaped blades have higher capacity of resisting high wind pressure impact; a pointer and a dial are mounted on a gear box, the rotating radian of the pointer and that of each of the arc-shaped blades in the air regulation door are synchronous, the folding or unfolding degree of the blades of the air regulation door can be visually reflected, and the air volume in the pipeline can be precisely adjusted.

Owner:JIANGSU YONGSHENG OCEAN ENG CO LTD

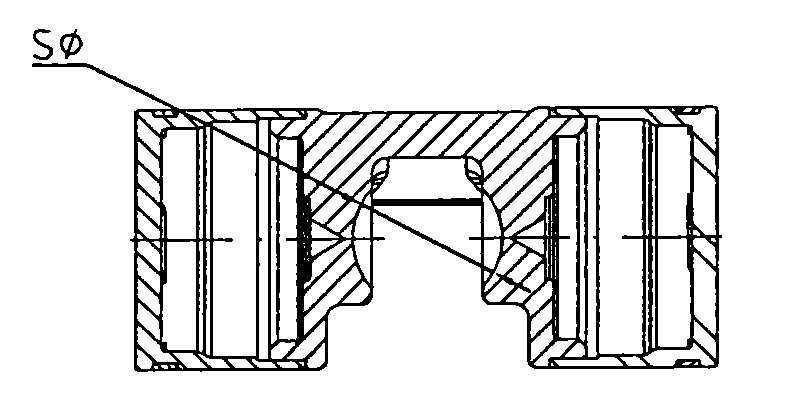

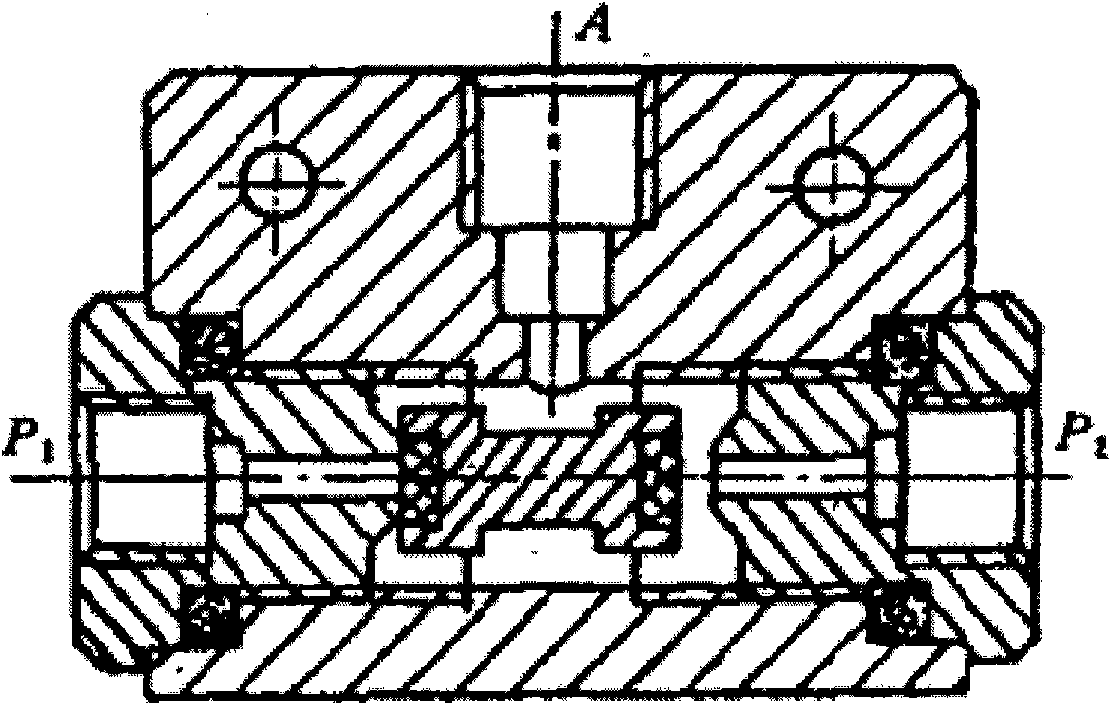

Strut type shuttle valve

ActiveCN101672382AAvoid direct impactThere will be no stuck phenomenonOperating means/releasing devices for valvesMultiple way valvesEngineeringShuttle valve

The invention discloses a strut type shuttle valve comprising a main valve body provided with a first air inlet, a second air inlet and an air outlet, and a main valve plug which can move between a first position and a second position is arranged in the valve cavity of the main valve body; when the main valve plug is arranged on the first position, the first air inlet is communicated with the airoutlet, and the second air inlet is not communicated with the air outlet; when the main valve plug is arranged on the second position, the second air inlet is communicated with the air outlet, and thefirst air inlet is not communicated with the air outlet. Two ends of the main valve body are respectively provided with a thrust device, two thrust devices are respectively connected with two ends ofthe main valve plug, and the thrust devices can push the main valve plug to move. The main valve plug of the shuttle valve with the structure is not directly driven by air inflow from the air inlet,thus avoiding direct shock to the main valve plug by the air inflow; therefore, the stuck phenomenon of the main valve plug can be avoided, and the problem of blow-by gas between air inlets can be effectively solved.

Owner:FESTO CHINA AUTOMATION MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com