Electric pencil planer

A pencil and electric technology, applied in the field of pencil sharpeners, can solve the problems of stuck, inconvenient to use, difficult to control cutting force, etc., and achieve the effect of improving efficiency and convenient sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

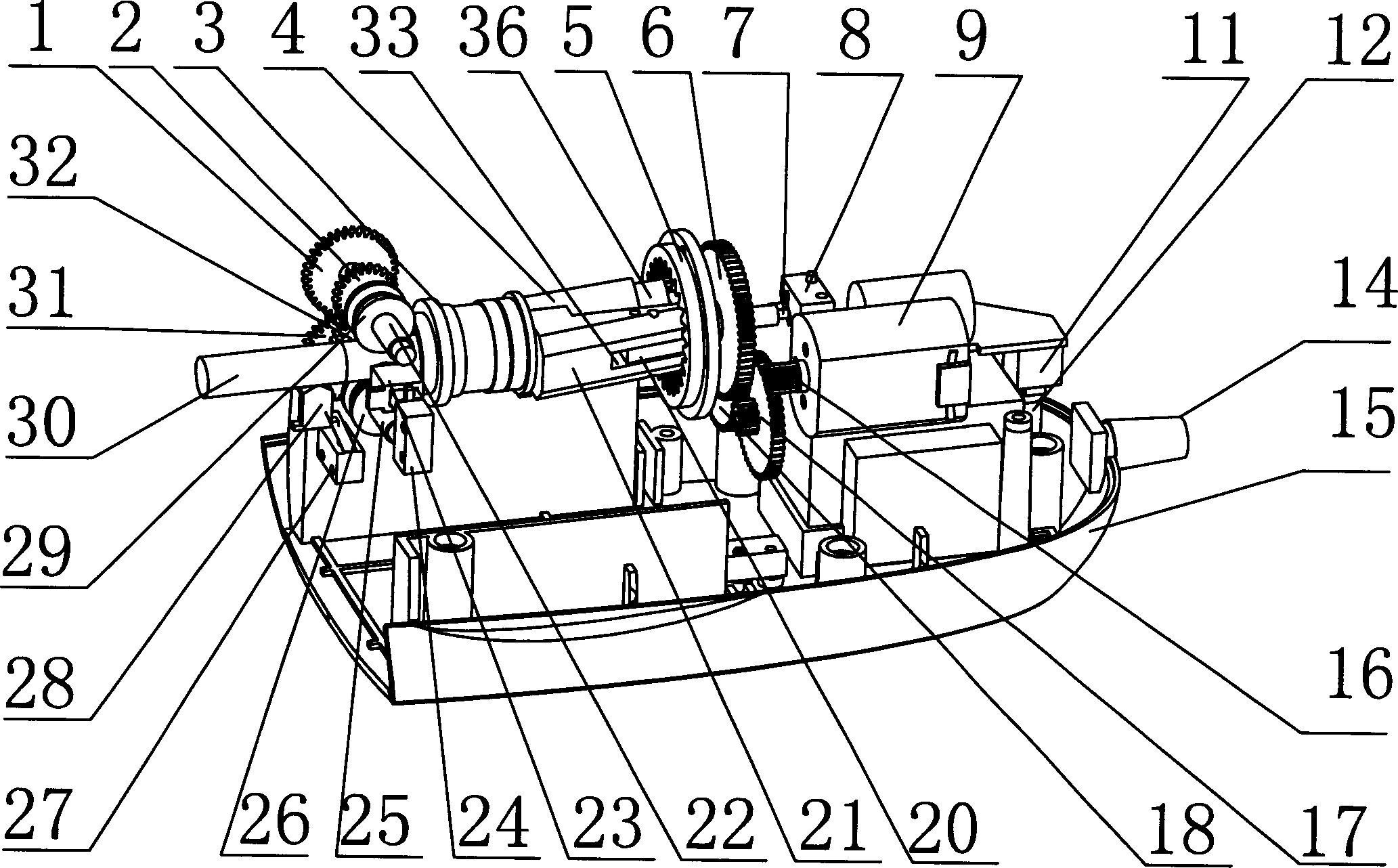

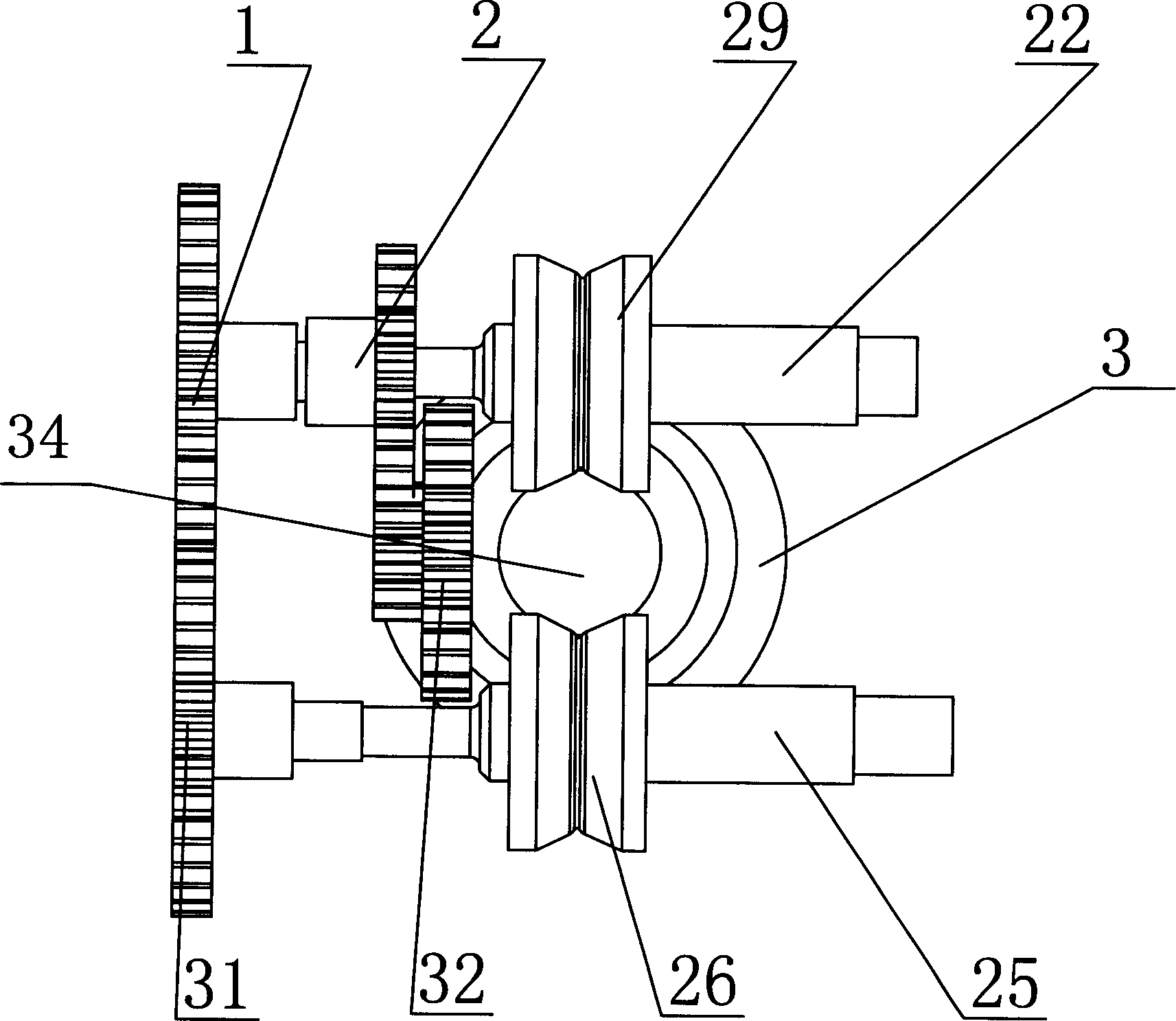

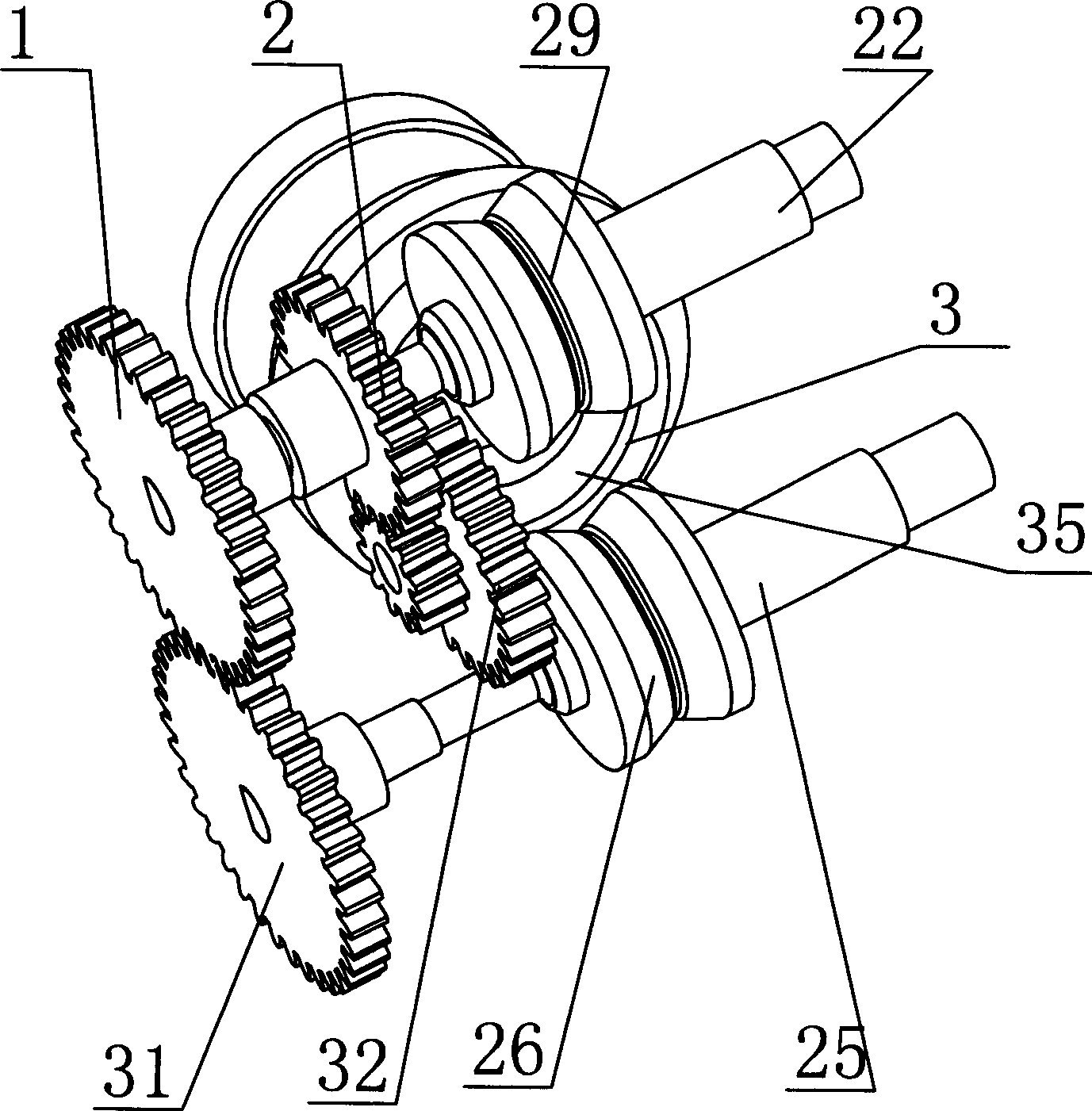

[0017] see Figure 1 to Figure 6 , The electric pencil sharpener includes a housing 15 and a motor, a transmission mechanism, a planing mechanism, a feeding mechanism and a manual reversing mechanism arranged in the housing 15 . The motor provides the power for sharpening and feeding the pencil. The transmission mechanism receives the power input by the motor and outputs the power to the planing mechanism and the feeding mechanism. The planing mechanism is used for planing pencils. The feeding mechanism is used to realize the automatic feeding and automatic withdrawal of the pencil. The manual reversing mechanism is used to reverse and exit the pencil that stays in the machine when the pencil is too short to finish planing and cannot automatically exit.

[0018] The output end of the motor is connected to the input end of the transmission mechanism, the output end of the transmission mechanism is connected to the input end of the planing mechanism, the manual reversing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com