Synchronous powder feeder for laser reproduction

A technology of laser remanufacturing and synchronous powder feeding, applied in the field of powder conveying device, can solve the problems of intermittent transmission mechanism, uneven powder feeding rate, powder blocking, etc. adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

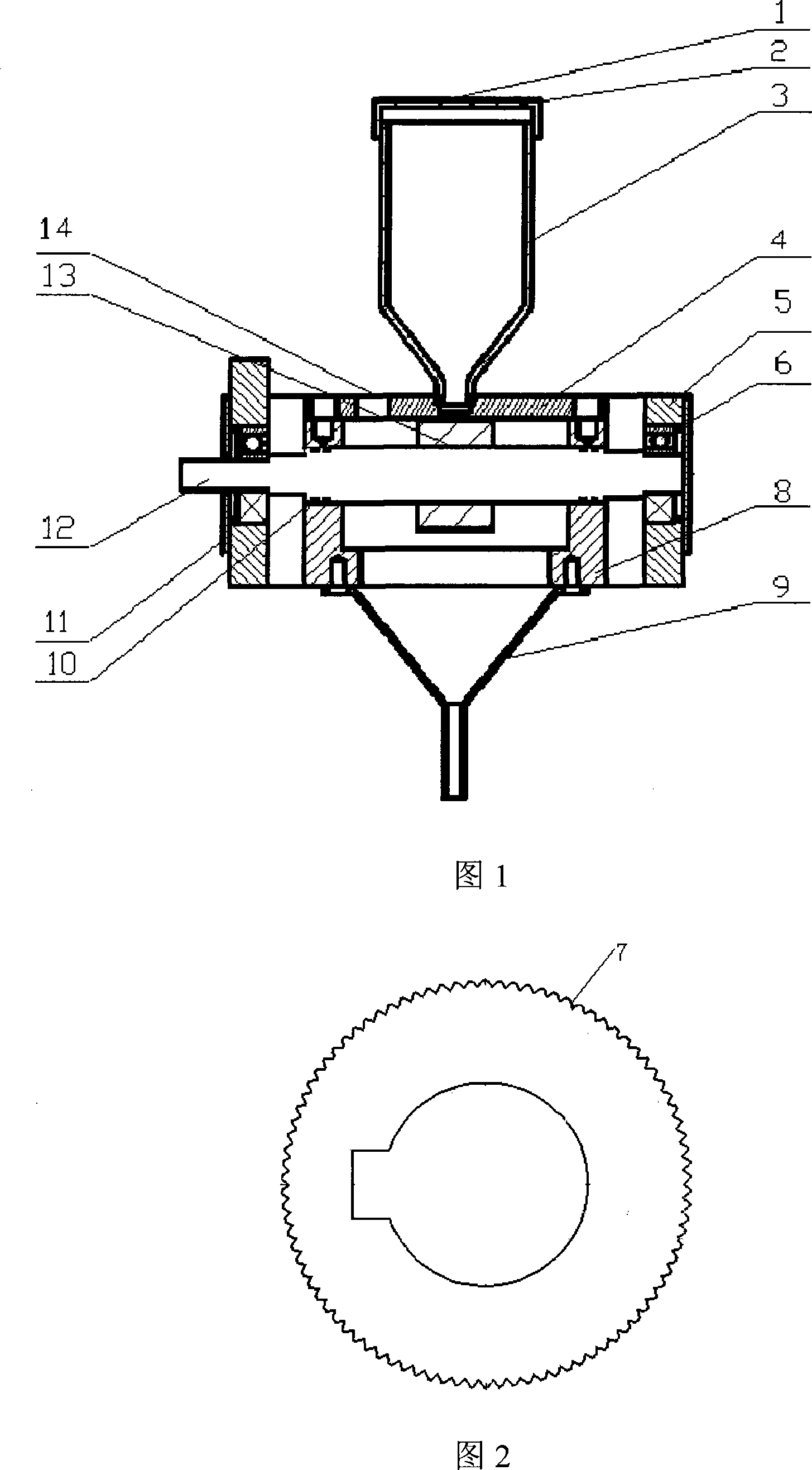

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] See Figure 1-2: a synchronous powder feeder for laser remanufacturing, including a casing 5, which is equipped with a core 8, a powder storage bin 3 connected to the core 8 is installed above the casing 5, and a powder storage bin 3 connected to the core 8 is installed below the casing 5. The powder outlet funnel 9, the rotating shaft 12 runs through the inner core 8 and is installed on the shell 5 through the rolling bearing 6, the rotating shaft 12 is connected with the stepper motor through a coupling, and the rotating shaft 12 located in the inner core 8 is keyed with a powder feeding roller Wheel 13, the upper end of the powder feeding roller 13 corresponds to the outlet of the powder storage bin 3, the lower end of the powder feeding roller 13 corresponds to the entrance of the powder outlet funnel 9, and the circumferential surface of the powder feeding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com