Space robot gripper mechanism

A robot hand and space technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of non-unique locking position, easy loss of targets, small capture range, etc., to achieve compact interior, save interior space, and improve transmission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

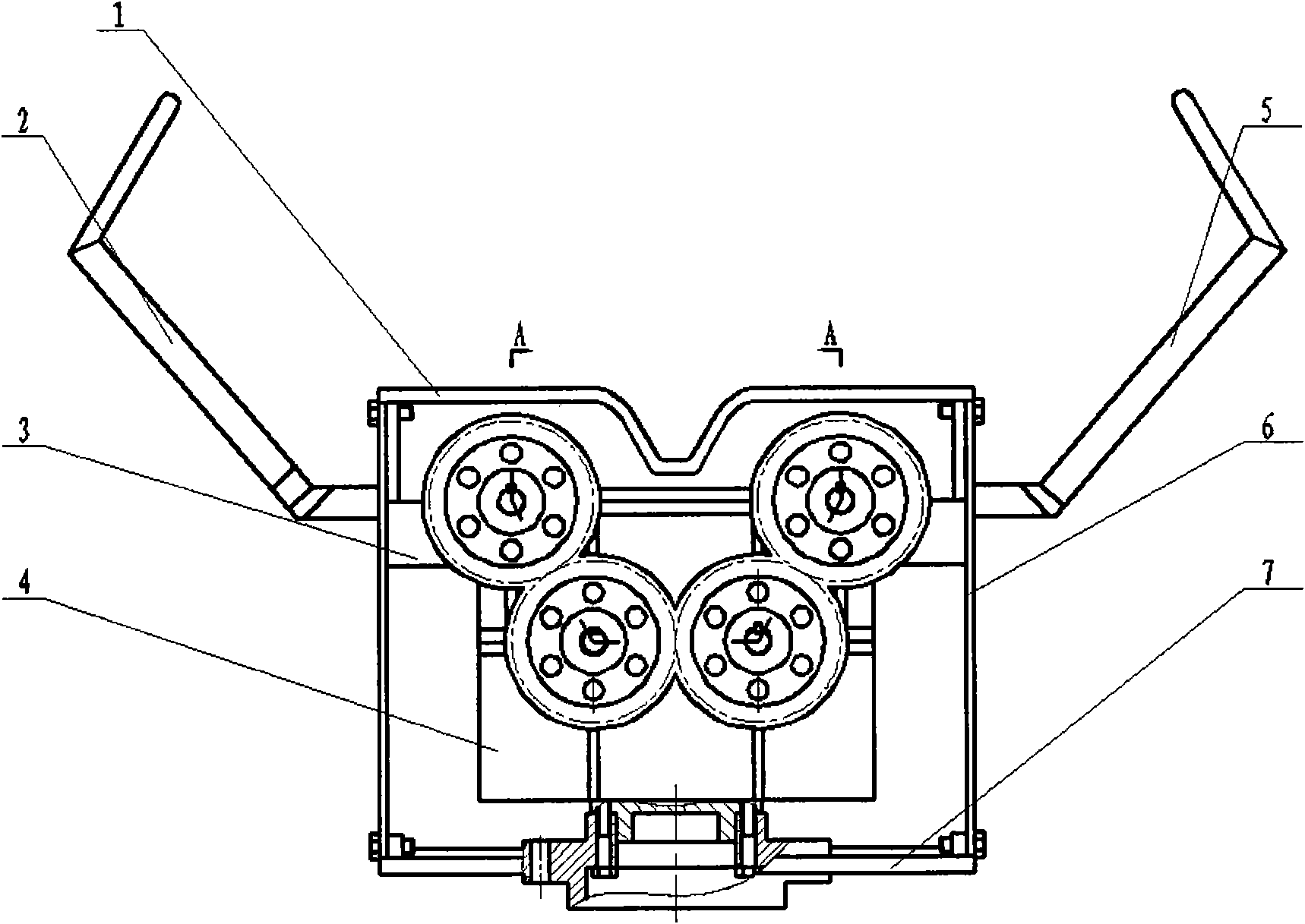

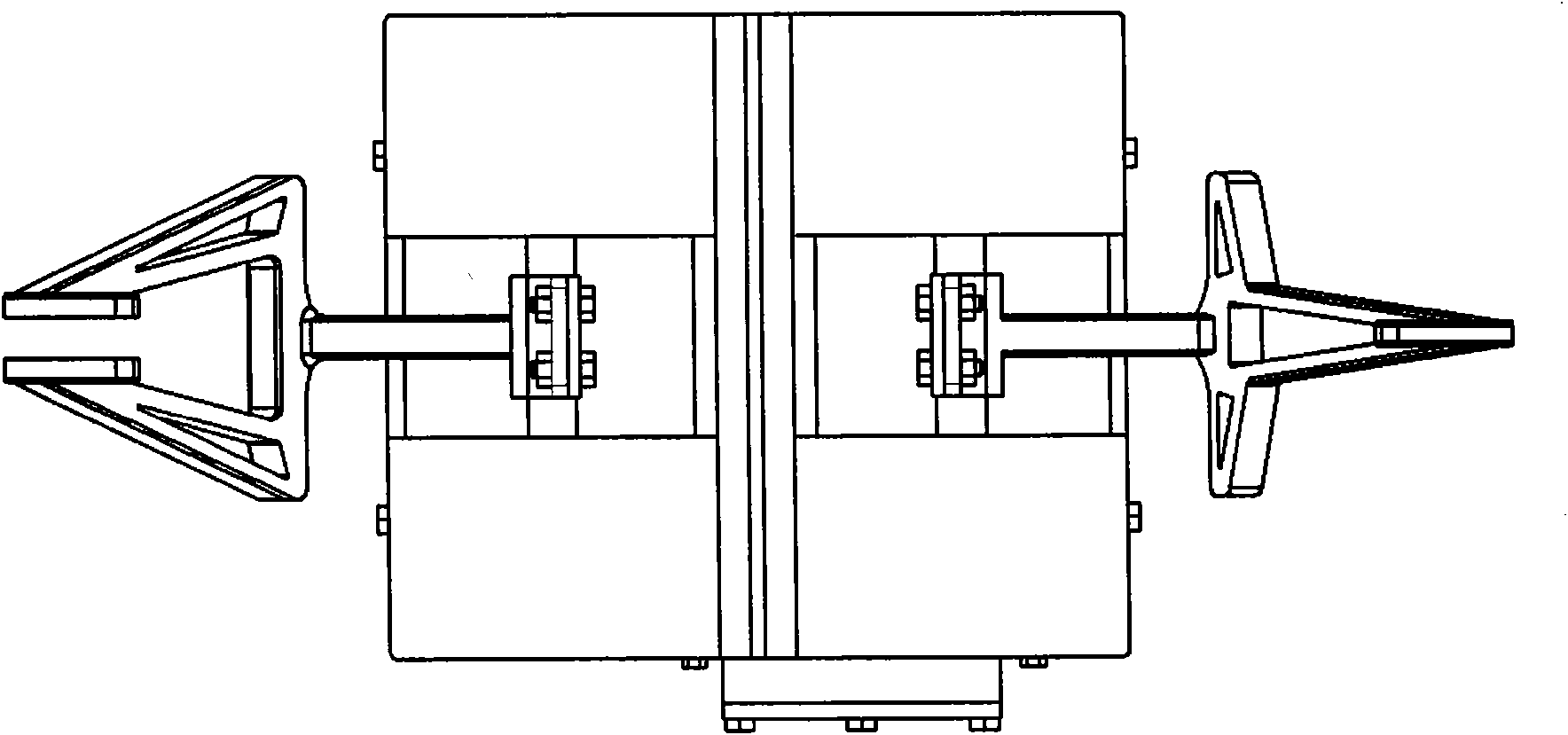

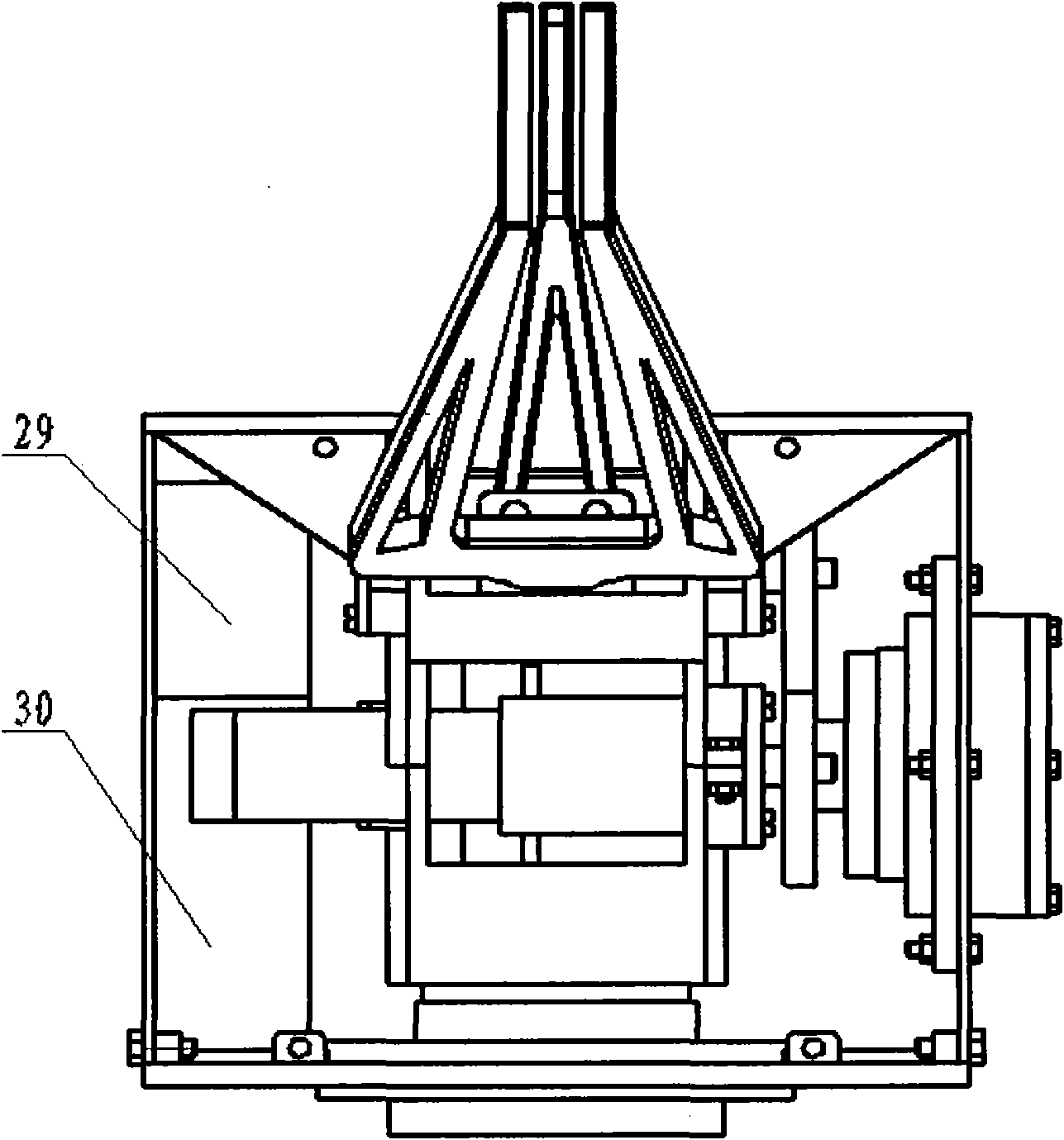

[0018] Specific implementation mode one: see figure 1 , image 3 As shown, the present invention is located at the operation end of a kind of mechanical arm, carries out the grasping operation, and its structure comprises palm surface 1, upper bearing seat 3, lower bearing seat 4 and box bottom 7 are positioned with conical pin, and bolt is fixedly connected to form this gripper The basic skeleton of the organization. Wherein the combination of the palm surface 1 and the upper bearing seat 3 constitutes the bearing seat of the second finger shaft 9 and the first finger shaft (same as the second finger shaft); the combination of the upper bearing seat 3 and the lower bearing seat 4 constitutes the motor 11 transmission Shaft and brake shaft 22 bearing housing. Its design adopts split type for easy assembly.

[0019] see Figure 4 As shown, two finger shafts 9 are installed in the bearing hole between the palm surface 1 and the upper bearing seat 3, and are positioned by end...

specific Embodiment approach 2

[0026] Specific implementation mode two: see figure 1 , image 3 , The claw mechanism transmission system is made up of motor 11, gear 19 (2), gear 21, gear 27, brake shaft 22, finger shaft 9 (2). Motor 11 is fixedly connected with bearing seat 3,4 up and down by screw, and at this moment, motor output shaft 11, finger shaft 9 (2), braking shaft 22 form four shafts parallel in pairs. The synchronous rotation of the first finger 5 and the second finger 2 is realized through the gear transmission group: that is, the gear 21 is driven by the motor 11, and through meshing with the gear 19 and the idler 27, the motion is transmitted to the finger shaft 9 and the second finger respectively One-finger finger axis (the same as the two-finger finger axis), so as to realize the synchronous opening and closing movement of two fingers.

[0027] Palm surface 1, upper bearing seat 3, lower bearing seat 4, box wall 6, box bottom 7, one finger 5, two fingers 2, finger cover plates 16 (2 pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com