Component shaping and inserting mechanism for component inserting machine

A plug-in machine and plug-in technology, applied in electrical components, electrical components and other directions, can solve the problems of affecting the normal production of plug-in machines, high manufacturing cost, popularization and application, and tedious equipment maintenance work, and achieve simple structure, low manufacturing cost and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

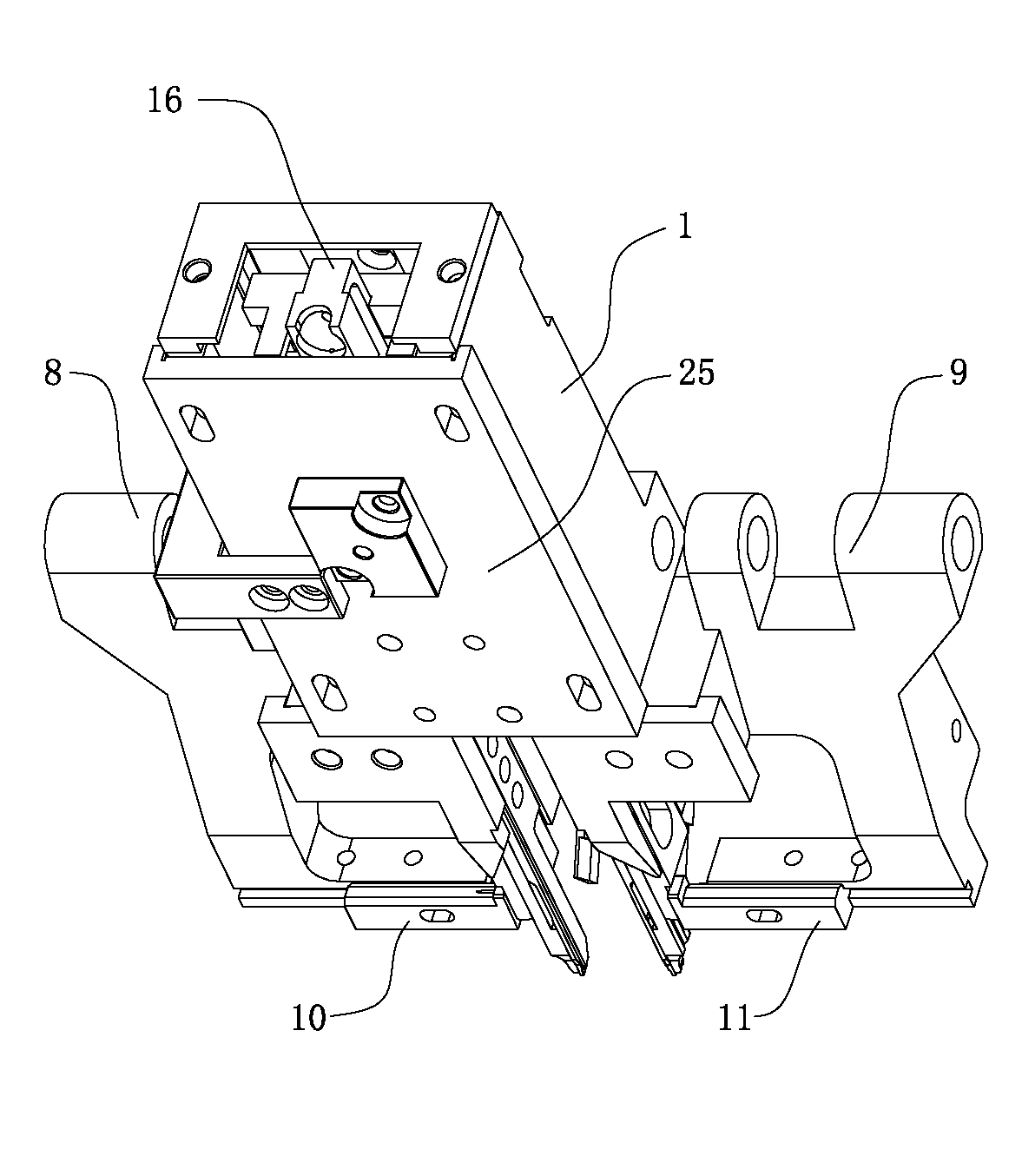

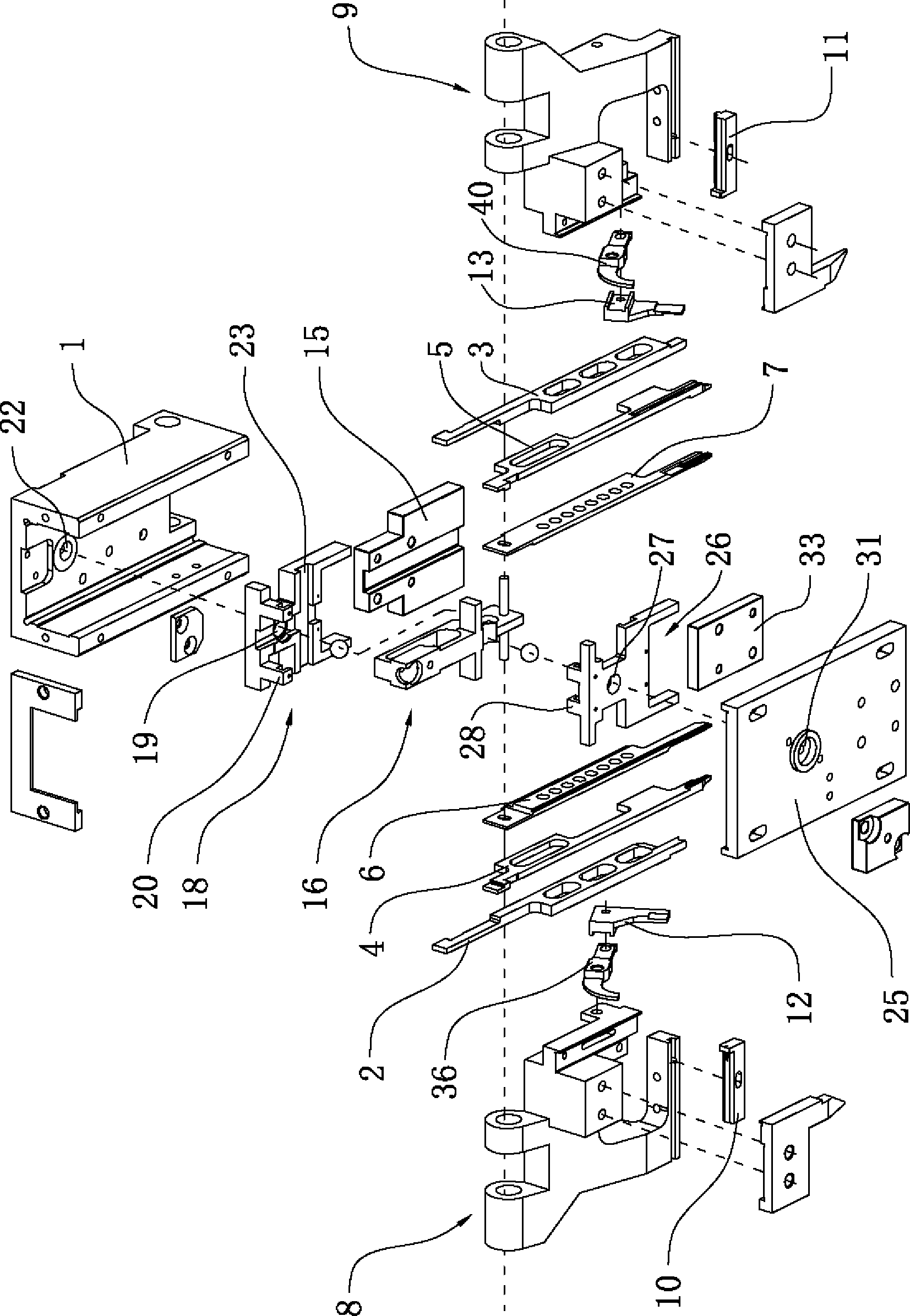

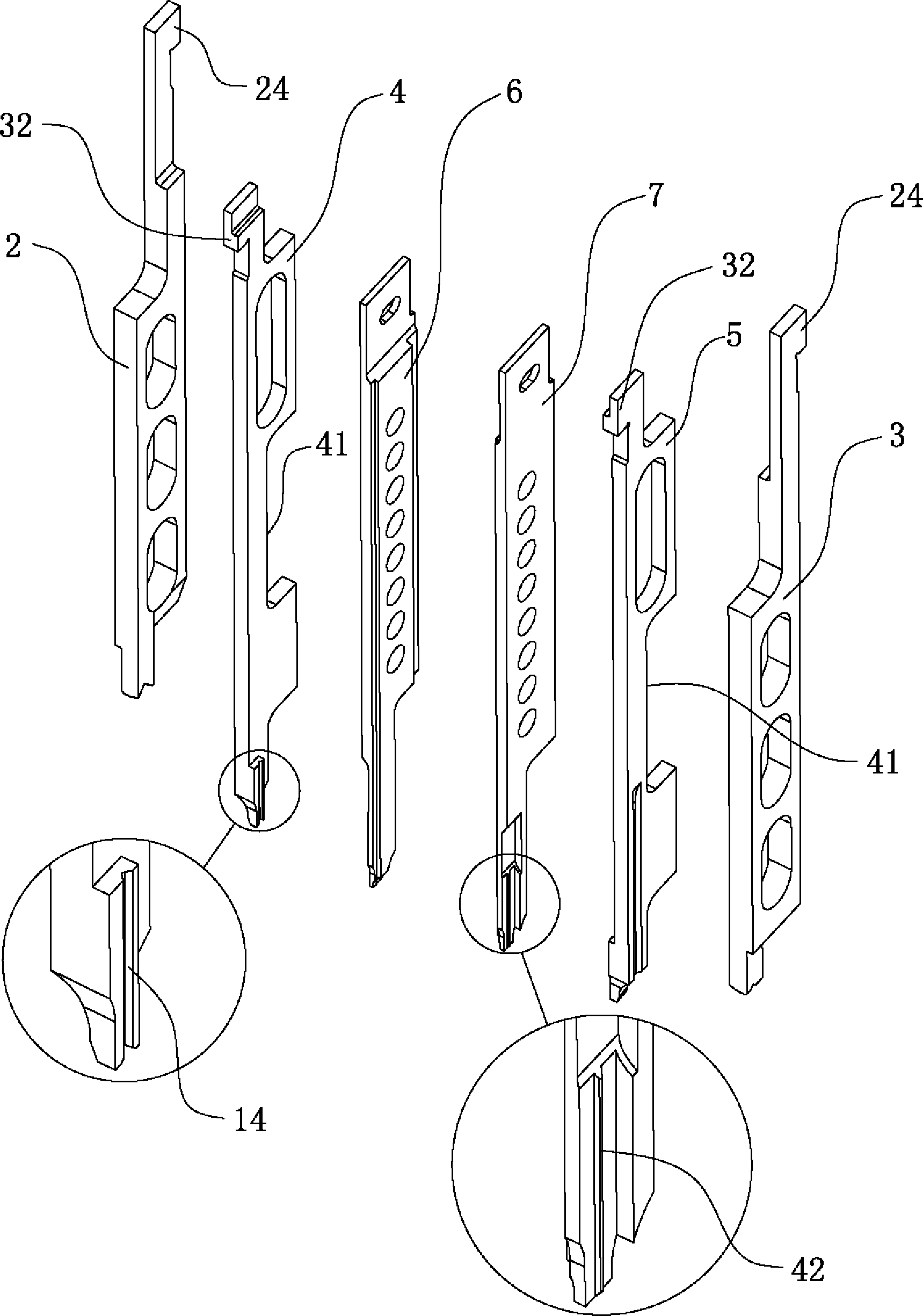

[0026] Such as Figure 1 to Figure 9 Shown, a plug-in machine plastic plug-in mechanism, including a knife box 1, a knife set set in the knife box 1 and a linkage mechanism that drives the knife set to move up and down, the knife set includes a left cutter 2, a right cutter 3, a left cutter Forming knife 4, right forming knife 5, left pushing knife 6, right pushing knife 7, the left cutting knife 2, left forming knife 4, left pushing knife 6, right pushing knife 7, right forming knife 5, right cutting knife 3 From left to right, it is installed in the knife box 1 sequentially; the bottom of the knife box 1 is provided with a left knife rest 8 and a right knife rest 9, and the bottom of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com