Strut type shuttle valve

A shuttle valve and spool technology, applied in the field of spool type shuttle valve, can solve the problems of the main spool that is easy to blow-by gas and easy to get stuck, and achieves the effect of solving the blow-by gas and avoiding direct impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

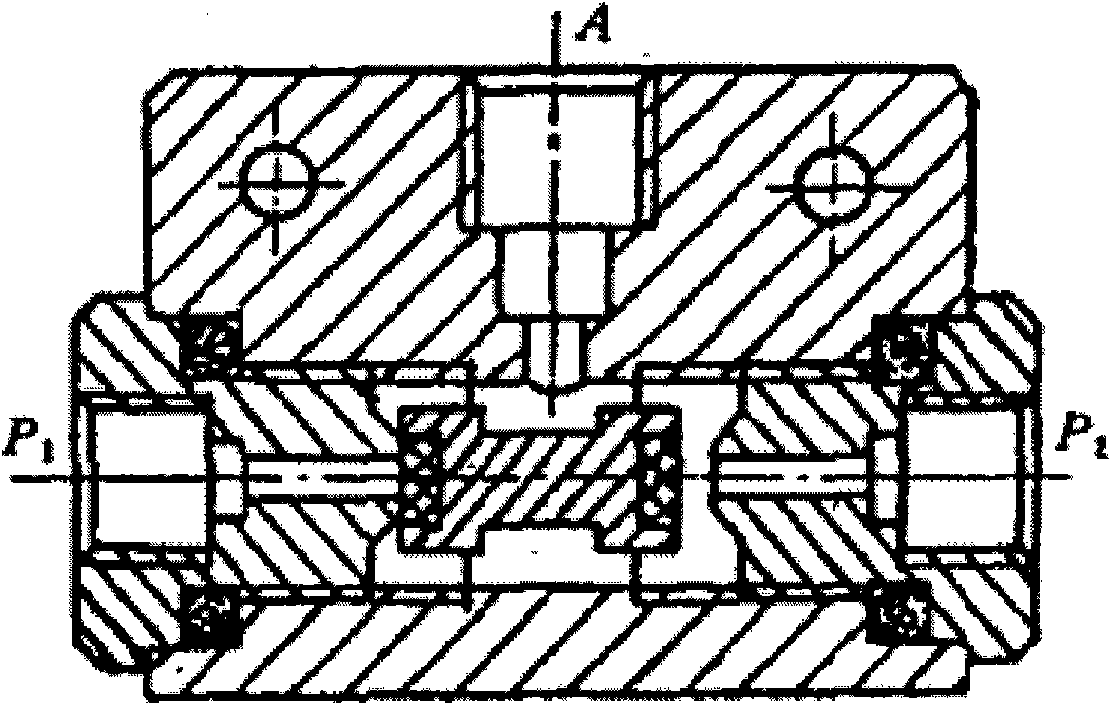

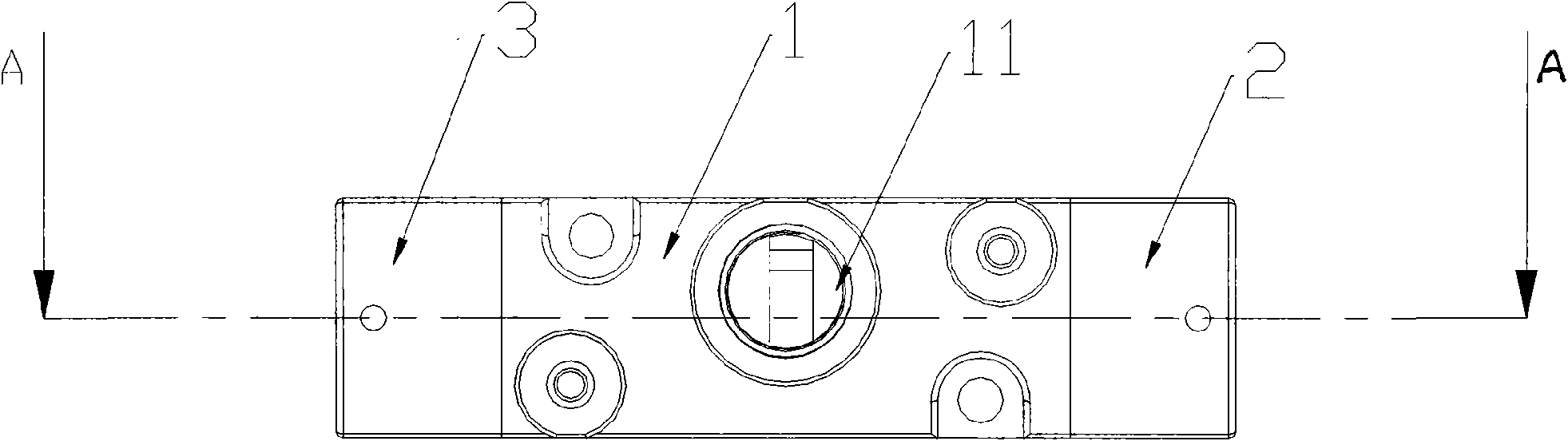

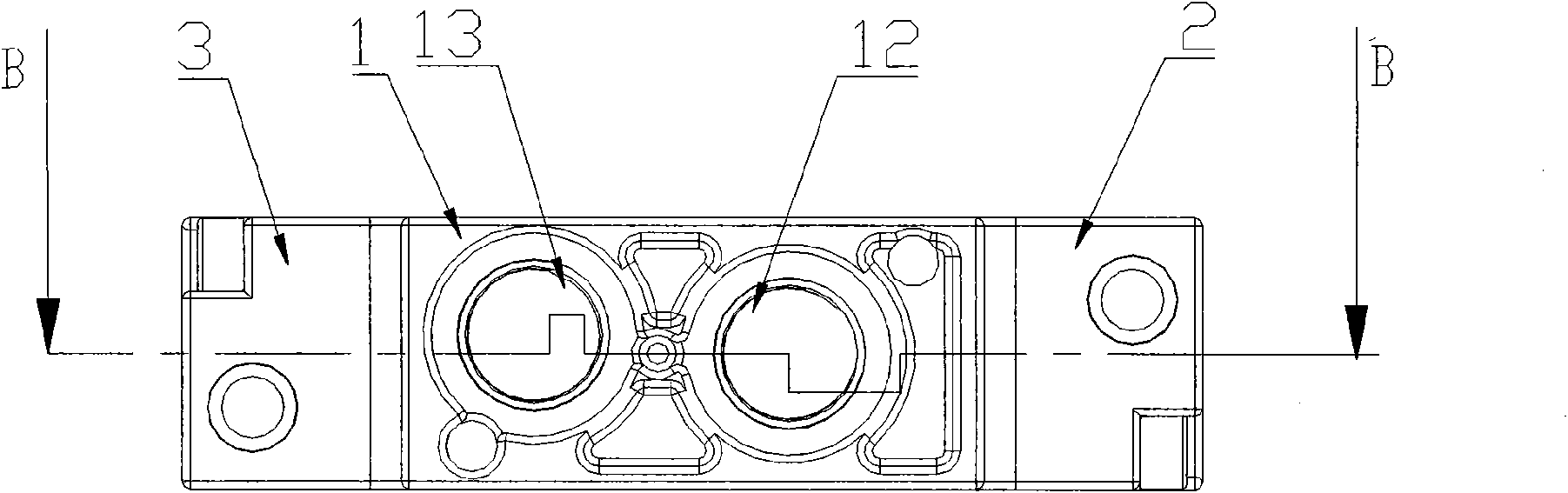

[0019] Such as figure 2 , 3 , 4, the spool type shuttle valve includes a main valve body 1, and the main valve body 1 is provided with an air outlet 11, a first air inlet 12 and a second air inlet 13. Both ends of the main valve body 1 are respectively provided with a pilot valve 2, 3 as a thrust device, and the pilot valves 2, 3 are connected with the main valve body 1. The thrust device can also be an electromagnet, an electromagnetic pilot valve or a manual device, as long as the device can make the main valve core in the main valve body move back and forth in the valve cavity.

[0020] Such as Figure 5 As shown, the first air inlet 12 and the second air inlet 13 are arranged in the axial direction of the valve cavity 15, and the valve cavity 15 of the main valve body 1 is fixedly provided with a first sealing ring 16, a second se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com