Drilling rod box with baffle and automatic drilling machine with the same

A drill pipe box and drill pipe technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of adding drill pipes, hidden dangers, narrow space, etc., and achieve the effect of increasing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

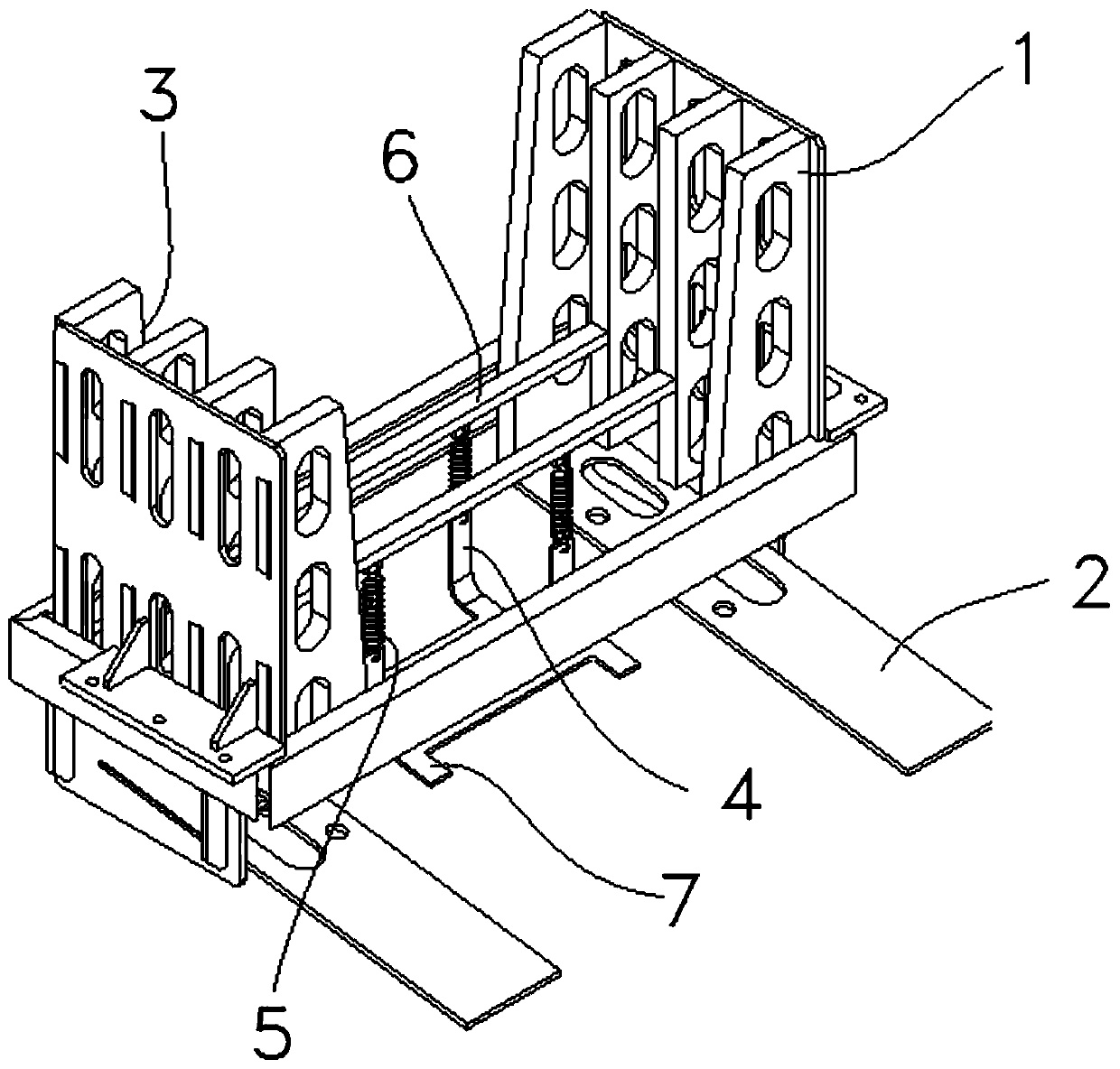

[0030] see figure 1 , which is a drill box provided with a baffle, including a drill box body 1 and a rolling plate 2, the rolling plate 2 is arranged between the drill box body 1 and the ground, the plane where the rolling plate 2 is located intersects the ground, and the drill The rod 10 rolls on the rolling plate 2, and the rolling direction of the drill rod on the rolling plate 2 is the first direction. The drill rod box body 1 is provided with several drill rod bins 3 for storing the drill rod 10, and several drill rod bins 3 The projections on the ground along the first direction are arranged sequentially; the side of the drill pipe warehouse 3 close to the rolling plate 2 is provided with a drill pipe outlet for the drill pipe 10 to pass through, and the drill pipe 10 moves toward the drill pipe outlet in the drill pipe warehouse 3; A baffle plate 4 is arranged between adjacent drill rod bins 3, one end of the baffle plate 4 is overlapped on the rolling plate 2, the oth...

Embodiment 2

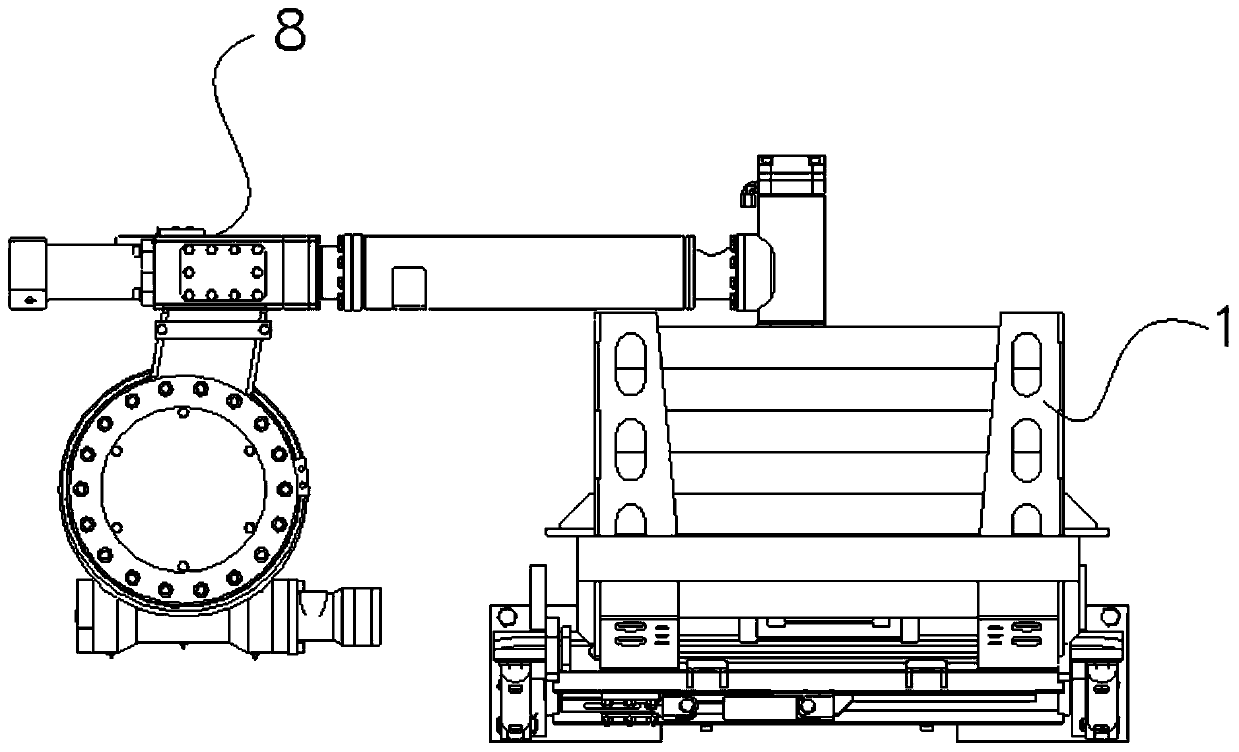

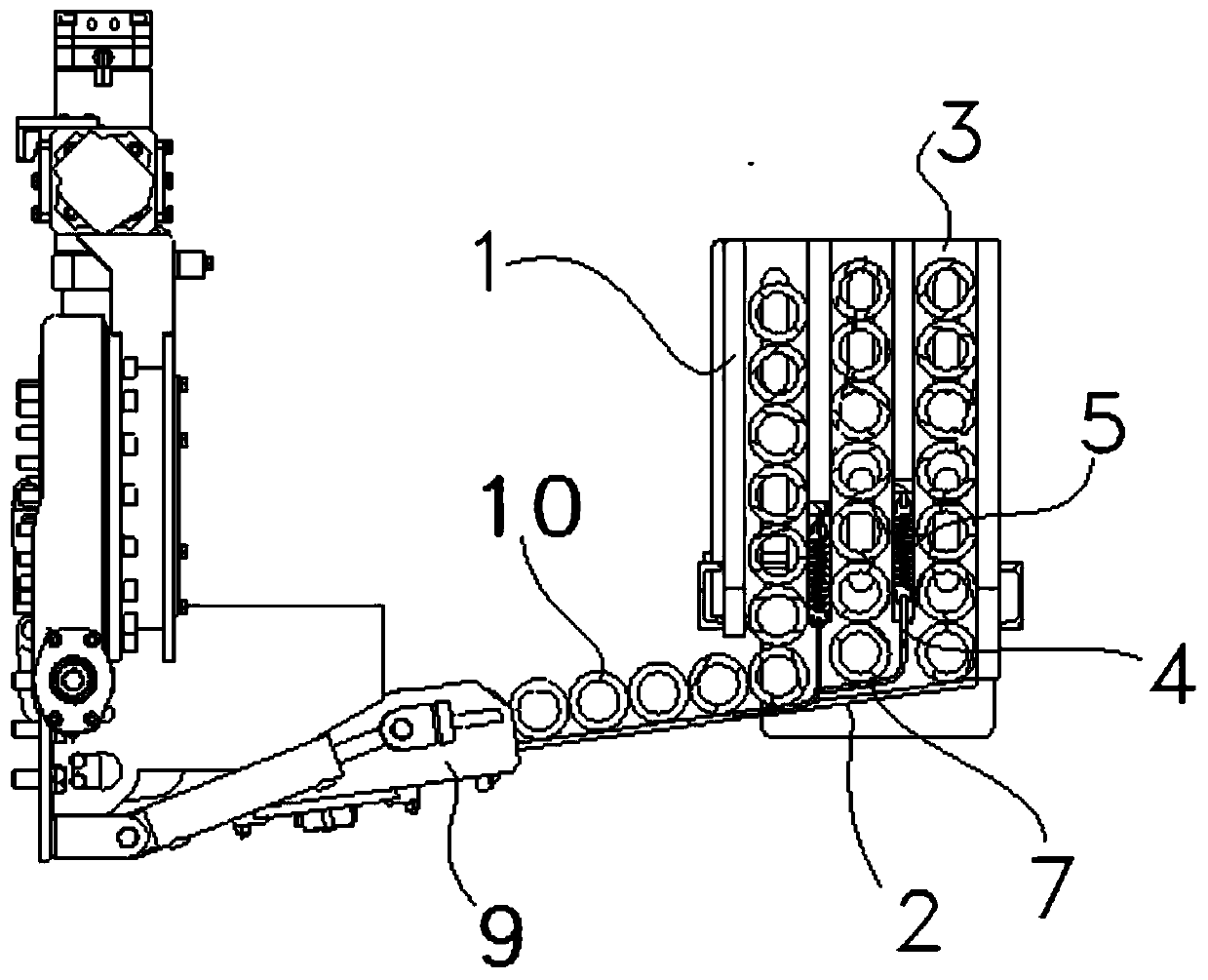

[0033] see Figure 2 ~ Figure 3 , an automatic drilling machine provided with a baffle drill rod box, comprising a drilling machine, a manipulator 8 and a drilling rod placement plate 9, the drilling machine and the drilling rod placement plate are arranged within the range of motion of the manipulator, and also include the above-mentioned A drill rod box provided with a baffle, the drill rod placement plate 9 is arranged in the first direction, the drill rod placement plate 9 is connected to the rolling plate 2, and the drill rod 10 rolls onto the drill rod placement plate 9 through the rolling plate 2 .

[0034] In actual use, the manipulator 8 grabs a drill pipe 10 from the drill pipe placement plate 9, and due to gravity, the drill pipe placement plate 9 and other drill pipes 10 in the rolling plate 2 will sequentially roll a drill pipe along the first direction The position of the diameter, the drill pipe 10 in the drill pipe chamber 3 on the side close to the first dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com