Rivet conveying mechanism of full-automatic rivet attaching machine

A technology of conveying mechanism and button sewing machine, which is applied in the field of automatic pneumatic button sewing machine, which can solve the problems of high failure rate and U-shaped rivet stuck, and achieve the effect of low failure rate and convenient maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

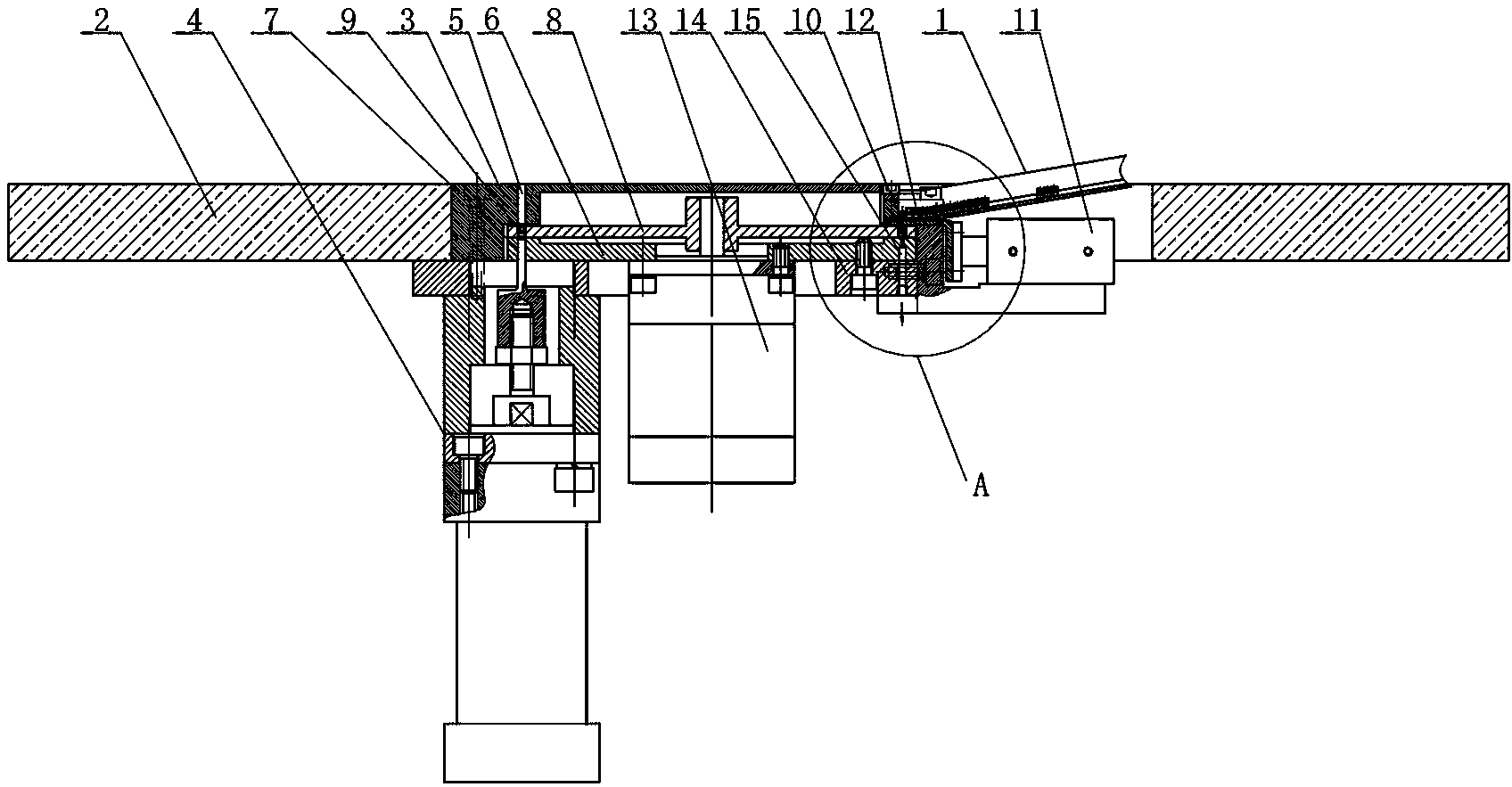

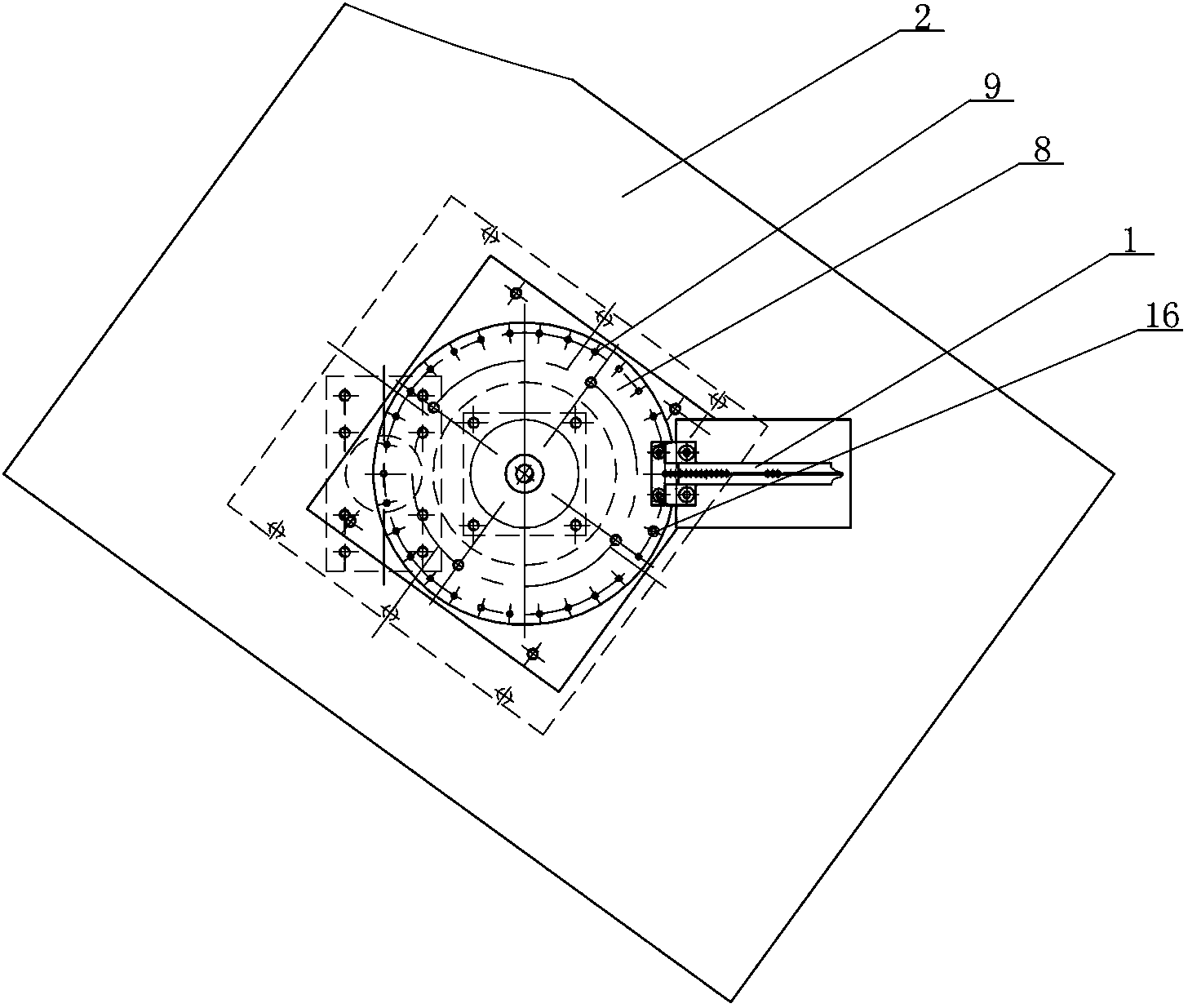

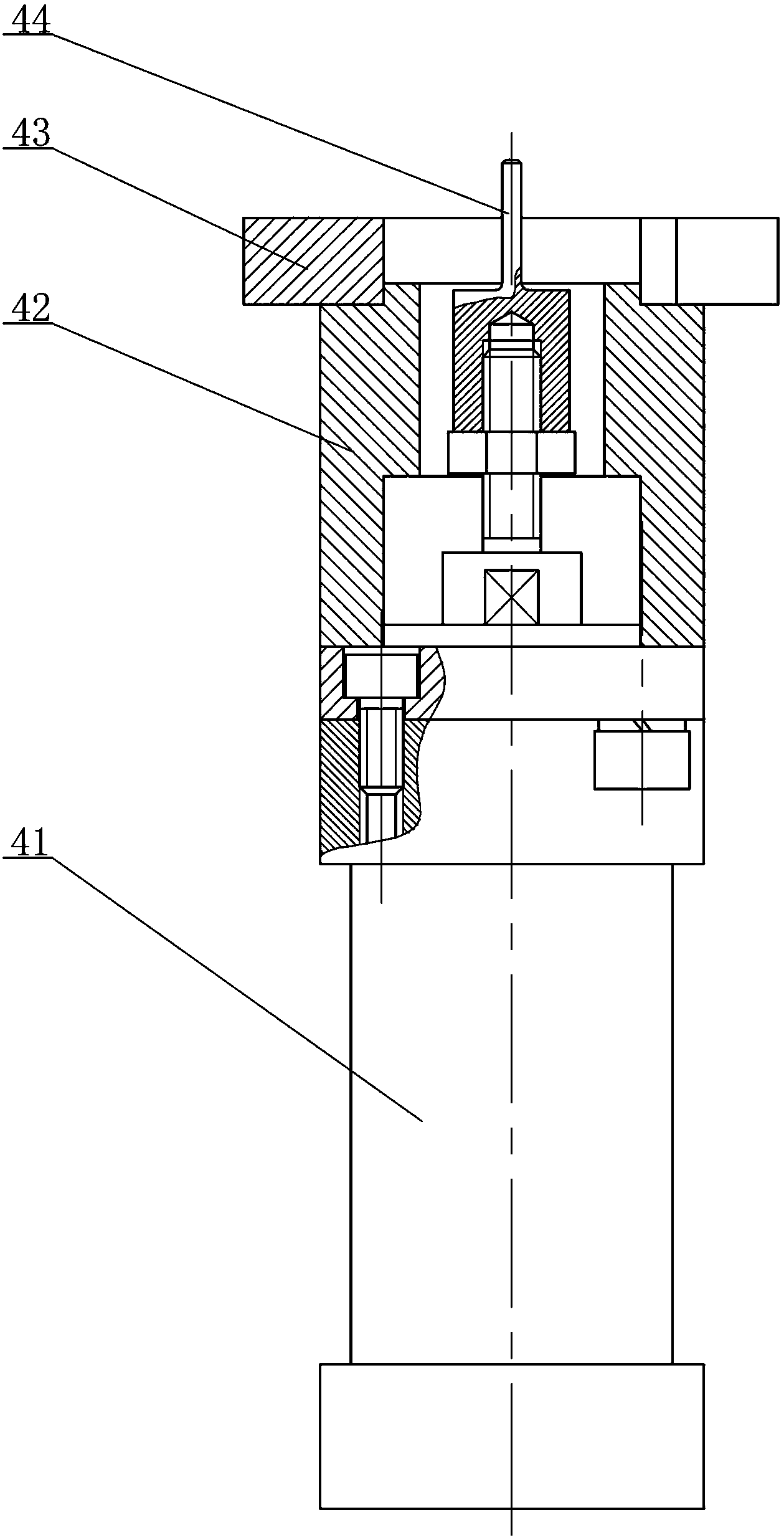

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Depend on Figure 1-Figure 7 As shown, the rivet conveying mechanism of the automatic button sewing machine includes a slideway 1 and a workbench 2. The slideway 1 includes an arrangement vertical plate 101 and a vibrating bottom plate 102, and the workbench 2 is fixed with an upper cover plate 3 and the lower punch assembly 4, the upper cover plate 3 is provided with an upper rivet hole 5, the upper cover plate 3 and the lower punch assembly 4 are provided with a wheel base 6, and the wheel base 6 is provided with an upper rivet The lower rivet hole 7 corresponding to the hole 5, the conveying wheel 8 that can rotate at an equal angle is installed on the wheel base 6, and the edge circumference of the transporting wheel 8 is equally provided with several through holes 9 through which U-shaped rivets can freely pass. The end of the vibrating bottom plate 102 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com