Novel electromagnetic valve component of electronic jacquard machine

A solenoid valve assembly and electronic jacquard technology, which is applied in the fields of jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of not considering the wear of pulley shafts and pulley brackets, shortening the service life of pulleys, and not considering efficiency, so as to shorten production Process, not easy to wear, wide range of use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

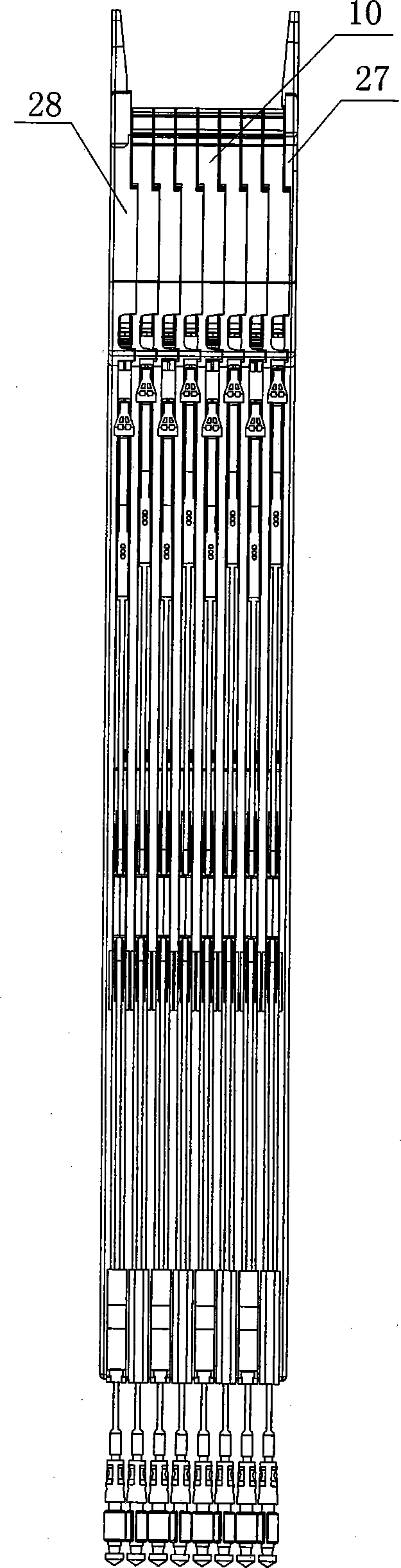

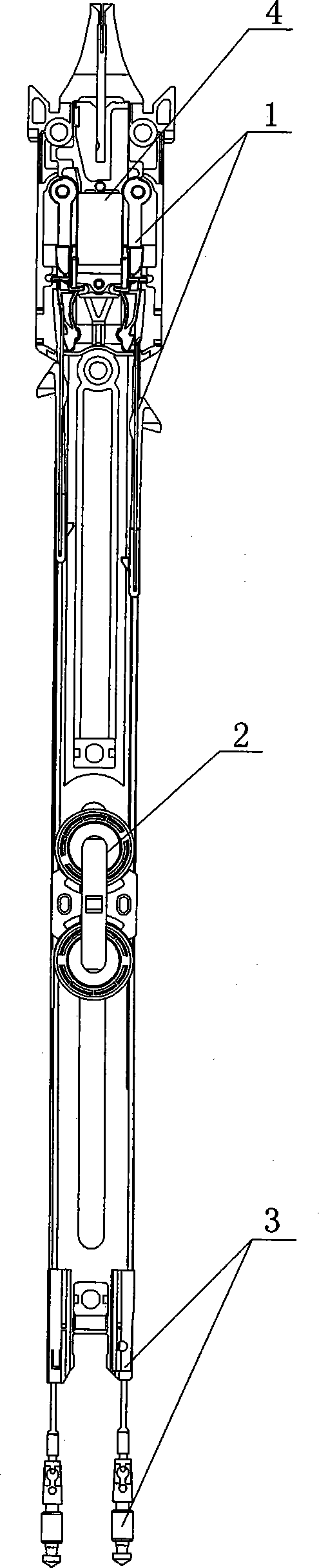

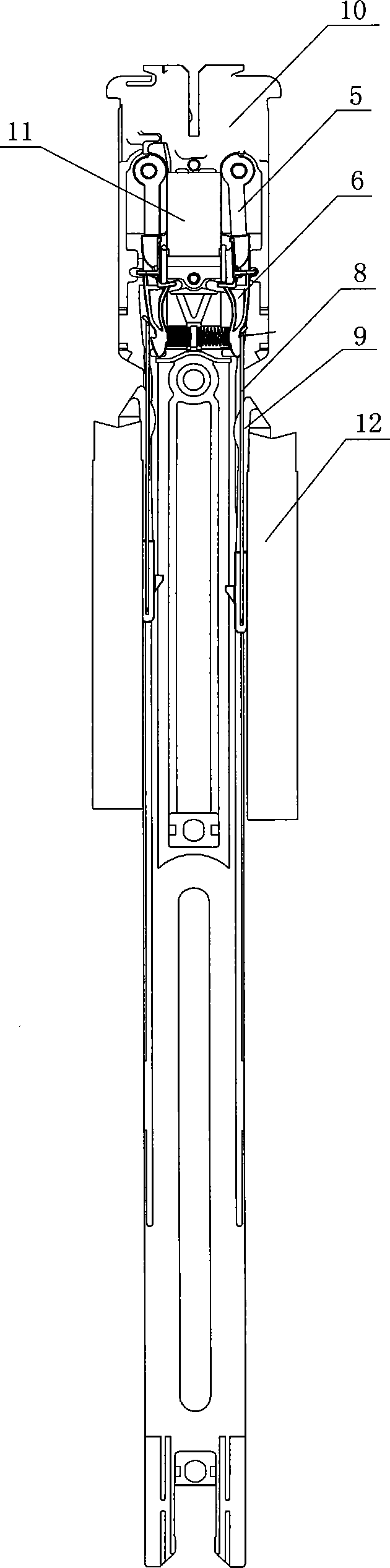

[0033] see Figure 1-2 , the present embodiment includes a bottom plate 28, a panel 27 and seven clamping plates 10, seven clamping plates 10 are located between the base plate 28 and the panel 27, between the base plate 28 and the clamping plate 10, between the clamping plate 10 and the clamping plate 10, between the clamping plate 10 A transmission mechanism 1 , a pulley bracket structure 2 , a joint quick insertion structure 3 and a solenoid valve structure 4 are arranged between the panel 27 .

[0034] see Figure 3-7 , The transmission mechanism 1 includes a moving iron 22 and a vertical hook 23, the moving iron 22 is connected to the vertical hook 23, and the moving iron 22 is located at the upper end of the vertical hook 23. The moving iron 22 includes a moving iron metal body 5 and a moving iron plastic body 6 , both of which are integrally formed by injection molding; the moving iron metal body 5 is on the upper end of the moving iron plastic body 6 . Vertical hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com