Drive belt for transmitting drive movement, and method for producing drive belt

A transmission belt and belt body technology, which is applied in the field of transmission belts for transmission of transmission motion and for the manufacture of transmission belts, can solve problems such as shortened service life, undesired hardening of transmission belts, and damage to carbon fibers, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

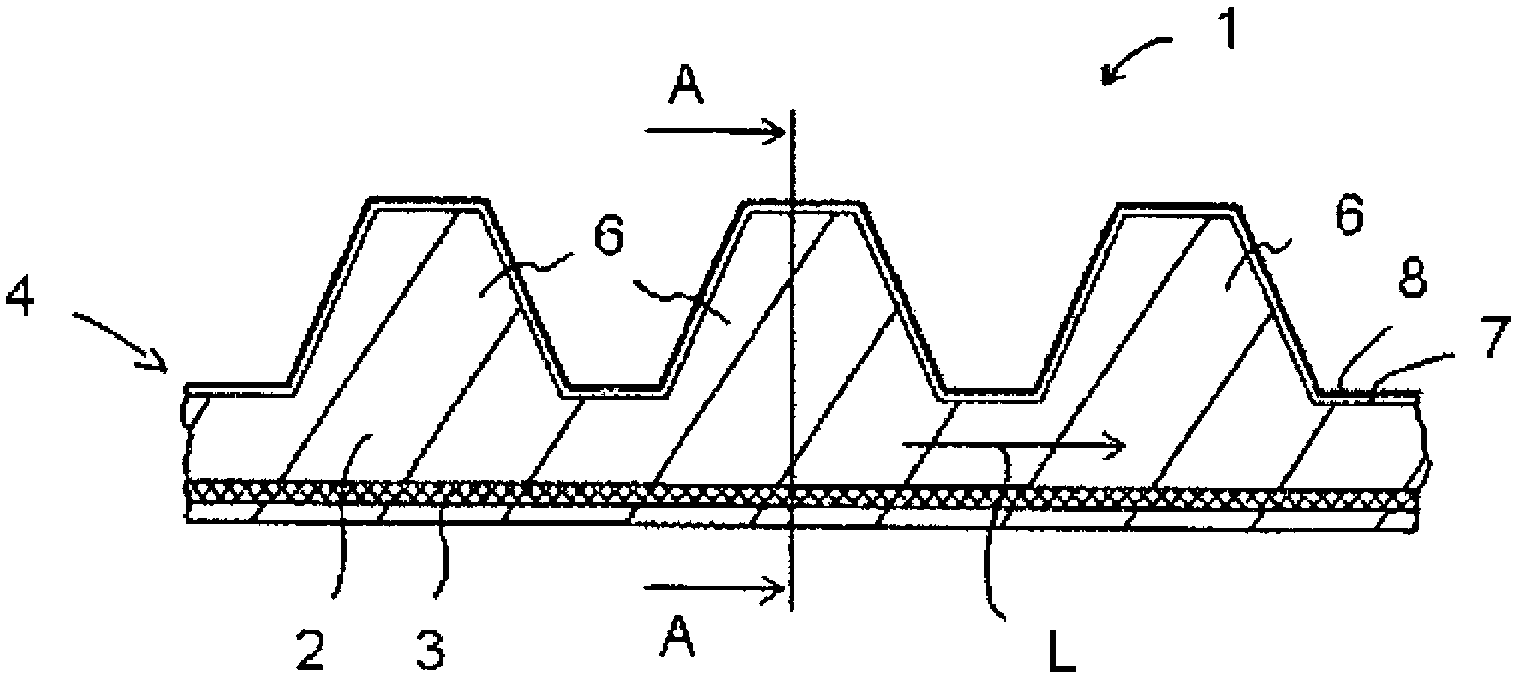

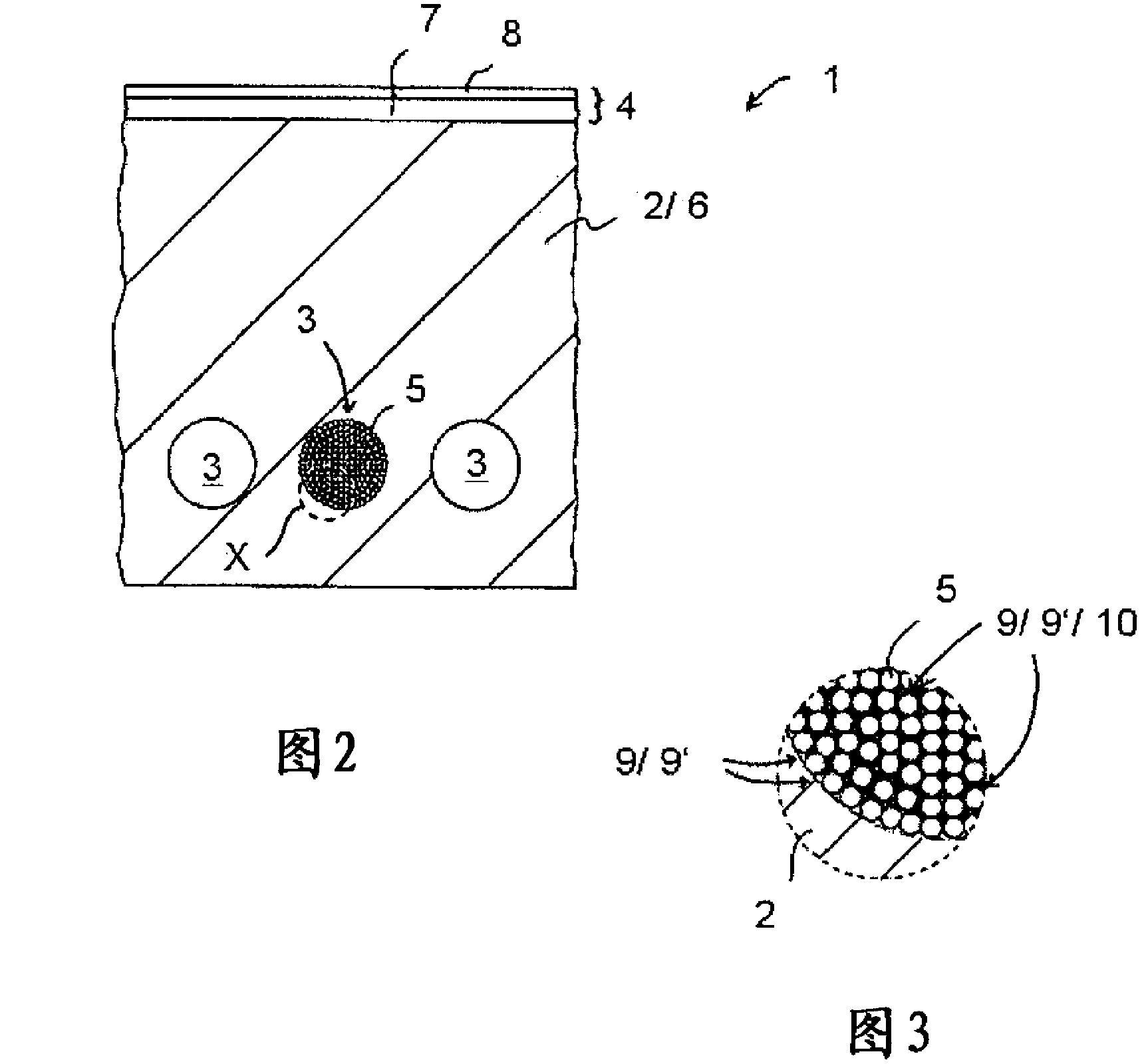

[0023] The transmission belt 1 for transmitting transmission motion has a belt body 2 defining the shape of the transmission belt 1 as a main component, a carbon rope 3 extending along the belt longitudinal L of the belt body 2 as a tensile reinforcement, and has a Coating 4 on the wear-prone working side. The carbon cords 3 functioning as tensile reinforcements are completely surrounded by the belt body 2 and have the effect of increasing the strength of the drive belt 1 in the belt longitudinal direction L. The carbon rope 3 is composed of a large number of individual carbon fibers 5 , which are helically twisted together.

[0024] According to the described embodiment of the invention, the drive belt 1 is designed as a toothed belt. For this purpose, the belt body 2 has belt teeth 6 arranged successively in the belt longitudinal direction L. As shown in FIG. Here, the configuration of the transmission belt 1 as a toothed belt is only an exemplary option. The drive belt 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com