Coffee carbon polyester fiber elastic carpet and preparation method thereof

A technology of polyester fiber and polyester fiber layer is applied in the field of coffee charcoal polyester fiber elastic carpet and its preparation, which can solve the problems of complicated production process, reduced elasticity, hard hand feeling, etc., so as to reduce the processing process and accelerate arteriosclerosis. , the effect of high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

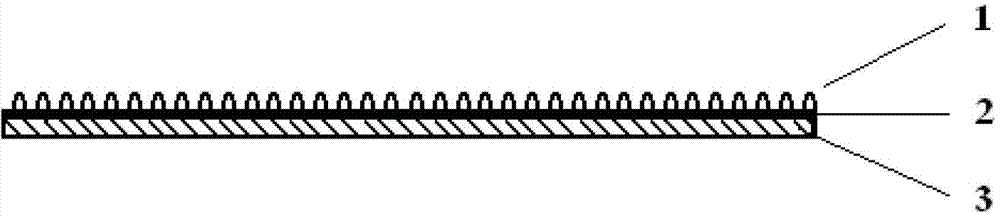

[0062] Please see attached figure 1 , a kind of coffee charcoal polyester fiber elastic carpet, it is characterized in that, comprises the coffee charcoal polyester fiber layer 1, polyester non-woven fabric layer 2 and the micro-airbag elasticity that are used to fix the coffee charcoal polyester fiber that are laminated successively from top to bottom Adhesive layer 3, the coffee charcoal polyester fiber layer is inserted into the polyester non-woven fabric layer through a large tufting loom, and the micro-airbag elastic adhesive layer is coated on the back of the polyester non-woven fabric layer.

[0063] The thickness of the coffee charcoal polyester fiber layer is 3mm.

[0064] The thickness of the polyester non-woven fabric layer is 0.1 mm.

[0065] The thickness of the micro-airbag elastic glue layer is 3mm.

[0066] The coffee charcoal polyester fiber layer is prepared from the coffee charcoal polyester fiber, comprising a polyester fiber body and nano-scale coffee ch...

Embodiment 2

[0088] Please see attached figure 1 , a kind of coffee charcoal polyester fiber elastic carpet, it is characterized in that, comprises the coffee charcoal polyester fiber layer 1, polyester non-woven fabric layer 2 and the micro-airbag elasticity that are used to fix the coffee charcoal polyester fiber that are laminated successively from top to bottom Adhesive layer 3, the coffee charcoal polyester fiber layer is inserted into the polyester non-woven fabric layer through a large tufting loom, and the micro-airbag elastic adhesive layer is coated on the back of the polyester non-woven fabric layer.

[0089] The thickness of the coffee charcoal polyester fiber layer is 20mm.

[0090] The thickness of the polyester non-woven fabric layer is 0.2mm.

[0091] The thickness of the micro-airbag elastic glue layer is 10mm.

[0092] The coffee charcoal polyester fiber layer is prepared from the coffee charcoal polyester fiber, comprising a polyester fiber body and nano-scale coffee cha...

Embodiment 3

[0113] Please see attached figure 1 , a kind of coffee charcoal polyester fiber elastic carpet, it is characterized in that, comprises the coffee charcoal polyester fiber layer 1, polyester non-woven fabric layer 2 and the micro-airbag elasticity that are used to fix the coffee charcoal polyester fiber that are laminated successively from top to bottom Adhesive layer 3, the coffee charcoal polyester fiber layer is inserted into the polyester non-woven fabric layer through a large tufting loom, and the micro-airbag elastic adhesive layer is coated on the back of the polyester non-woven fabric layer.

[0114] The thickness of the coffee charcoal polyester fiber layer is 50mm.

[0115] The thickness of the polyester nonwoven layer is 0.5mm.

[0116] The thickness of the micro-airbag elastic glue layer is 20mm.

[0117] The coffee charcoal polyester fiber layer is prepared from the coffee charcoal polyester fiber, comprising a polyester fiber body and nano-scale coffee charcoal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com