hdi printed circuit board high uniformity through-hole plating device

A printed circuit board, through-hole electroplating technology, applied in the direction of printed circuit, printed circuit manufacturing, printed component electrical connection formation, etc., can solve the problems that the concentration of the plating solution cannot be reasonably controlled, the plating layer is uneven, etc., and achieve the suppression of hydrogen evolution Side reactions, high cathode current efficiency, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the high-uniformity through-hole plating device for HDI printed circuit boards of the present invention will be further described below in conjunction with the accompanying drawings.

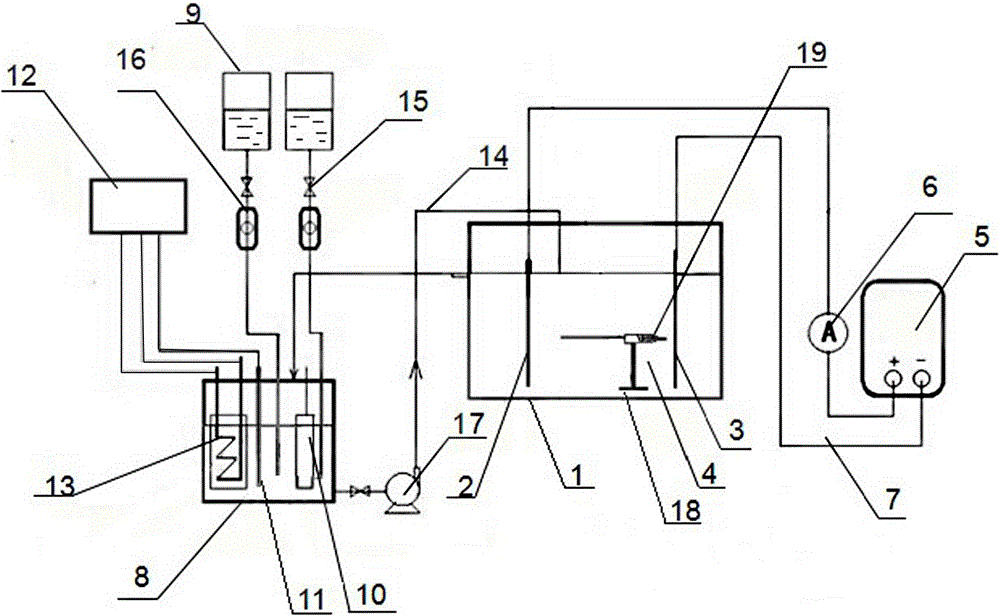

[0029] Such as figure 1 Shown is a schematic structural view of a preferred embodiment of the HDI printed circuit board high-uniformity through-hole plating device according to the present invention. The HDI printed circuit board high uniformity through-hole electroplating device according to the present invention comprises an electroplating tank 1, an anode 2, a cathode 3, a rectification power supply 5 and an ammeter 6, and the anode 2 and the cathode 3 are connected to the rectification power supply through a copper cable 7 5 is connected to the ammeter 6, and the electroplating tank 1 is provided with a spray mechanism 4. As the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com