A kind of preparation method of graphene/polyphenylene ether alloy heat conduction composite material

A heat-conducting composite material and composite material technology, which is applied in the field of preparation of graphene/polyphenylene ether alloy heat-conducting composite materials, can solve the problem of unfavorable dispersion of heat-conducting fillers in polymer heat-conducting composite materials, difficulty in preparing polyphenylene ether heat-conducting composite materials, and high impact Problems such as the fluidity of molecular composite materials, to achieve good mechanical properties, excellent performance, and favorable effects for processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

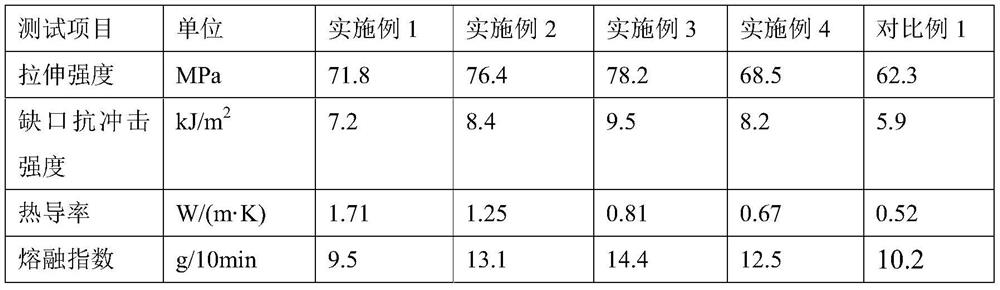

Examples

Embodiment 1

[0027] 本实施例的一种石墨烯 / 聚苯醚合金导热复合材料的制备方法,制备方法包括如下步骤:

[0028] (1)将一定量的聚苯醚合金加入适量的甲苯 / NMP的混合溶液中,待其溶解后加入适量石墨烯并进行超声分散3h形成混合均匀的溶液;上述甲苯 / NMP混合溶液与聚苯醚合金的质量比为10:1,NMP与甲苯的体积比为1:1,石墨烯与聚苯醚合金的质量比为8:92,聚苯醚合金中聚苯醚与高抗冲聚苯乙烯的质量比为2:1;

[0029] (2)将甲醇加入上述混合溶液中,快速搅拌溶液,使聚苯醚合金从甲苯 / NMP混合溶液中析出。加入的甲醇的量与混合溶液的体积比范围为1:1;

[0030] (3)将步骤(2)所得的固液混合物进行抽滤,用甲醇洗涤滤饼数次并置于真空干燥箱中90℃下干燥16h,最后经注塑机注塑成型即可得到石墨烯 / 聚苯醚合金导热复合材料;

Embodiment 2

[0032] 本实施例的一种石墨烯 / 聚苯醚合金导热复合材料的制备方法,制备方法包括如下步骤:

[0033] (1)将一定量的聚苯醚合金加入适量的甲苯 / NMP的混合溶液中,待其溶解后加入适量石墨烯并进行超声分散1h形成混合均匀的溶液;上述甲苯 / NMP混合溶液与聚苯醚合金的质量比8:1,NMP与甲苯的体积比为2:1,石墨烯与聚苯醚合金的质量比为5:95,聚苯醚合金中聚苯醚与高抗冲聚苯乙烯的质量比为3:1;

[0034] (2)将甲醇加入上述混合溶液中,快速搅拌溶液,使聚苯醚合金从甲苯 / NMP混合溶液中析出。加入的甲醇的量与混合溶液的体积比范围为1:1;

[0035] (3)将步骤(2)所得的固液混合物进行抽滤,用甲醇洗涤滤饼数次并置于真空干燥箱中100℃下干燥20h,最后经注塑机注塑成型即可得到石墨烯 / 聚苯醚合金导热复合材料。

Embodiment 3

[0037] 本实施例的一种石墨烯 / 聚苯醚合金导热复合材料的制备方法,制备方法包括如下步骤:

[0038] (1)将一定量的聚苯醚合金加入适量的甲苯溶剂中,待其溶解后加入适量石墨烯,并进行超声分散2h形成混合均匀的溶液。 上述甲苯溶剂与聚苯醚合金的质量比7:1,石墨烯与聚苯醚合金的质量比为4:96,聚苯醚合金中聚苯醚与高抗冲聚苯乙烯的质量比为4 :1;

[0039] (2)将甲醇加入上述混合溶液中,快速搅拌溶液,使聚苯醚合金从甲苯溶液中析出。加入的甲醇的量与混合溶液的体积比范围为1:1;

[0040](3)将步骤(2)所得的固液混合物进行抽滤,用甲醇洗涤滤饼数次并置于真空干燥箱中110℃下干燥24h,最后经注塑机注塑成型即可得到石墨烯 / 聚苯醚合金导热复合材料。

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com