A fast-curing lightweight board suitable for prefabricated buildings and its preparation method

A fast curing and assembled technology, applied in the field of building materials, can solve the problems of low early strength, slow setting time, slow strength development, etc., and achieve the effect of good stability and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

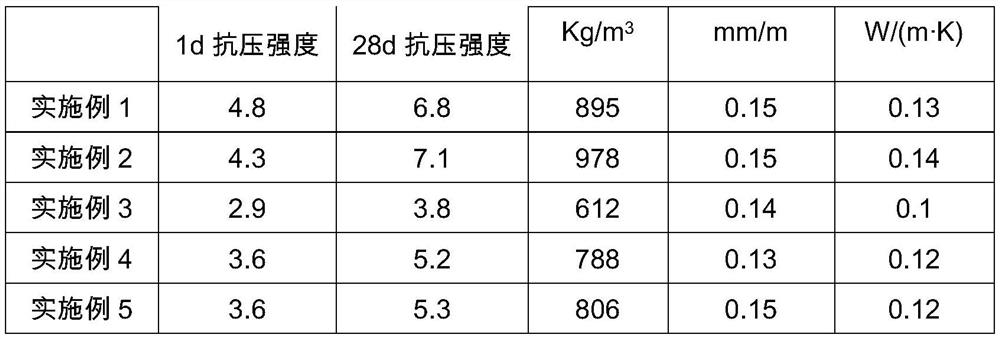

Embodiment 1

[0026] Prepare a fast-curing lightweight board suitable for prefabricated buildings. The raw materials and weight parts are: 70 parts of cement, 20 parts of grade II fly ash, composite early strength agent (sulfoaluminate cement and sodium sulfate according to the quality Ratio 10:1 Compounding) 4 parts, phosphogypsum dihydrate 6 parts, phosphogypsum dihydrate whiskers 3 parts, EPS 1.1 parts, nano-silica sol 0.3 parts, water reducing agent 0.2 parts, air-entraining agent 0.05 parts, water retention dose 0.1 part.

[0027] According to the above formula, weigh cement, secondary fly ash, composite early strength agent, phosphogypsum dihydrate, and phosphogypsum dihydrate whiskers and dry mix for 60 seconds, add nano-silica sol, water reducing agent, air-entraining agent, and water-retaining agent. At the same time, add water according to the water-to-material ratio of 0.34 and stir in the mixer for 2 minutes, then add EPS particles into the mixer and stir for 3 minutes, inject t...

Embodiment 2

[0030] To prepare a fast-curing lightweight board suitable for prefabricated buildings, the raw materials and weight parts are as follows:

[0031] 80 parts of cement, 10 parts of grade II fly ash, 2 parts of composite early strength agent (obtained by compounding sulphoaluminate cement and sodium sulfate at a mass ratio of 10:1), 10 parts of dihydrate phosphogypsum, dihydrate phosphogypsum crystal 5 parts of whiskers, 1.3 parts of EPS, 0.1 parts of nano-silica sol, 0.1 parts of water reducing agent, 0.1 parts of air-entraining agent, and 0.15 parts of water-retaining agent.

[0032] According to the above formula, weigh cement, secondary fly ash, composite early strength agent, phosphogypsum dihydrate, and phosphogypsum dihydrate whiskers and dry mix for 60 seconds, add nano-silica sol, water reducing agent, air-entraining agent, and water-retaining agent. At the same time, add water according to the water-to-material ratio of 0.34 and stir in the mixer for 2 minutes, then ad...

Embodiment 3

[0035] To prepare a fast-curing lightweight board suitable for prefabricated buildings, the raw materials and weight parts are as follows:

[0036] 60 parts of cement, 30 parts of grade I fly ash, 6 parts of composite early strength agent (obtained by compounding sulphoaluminate cement and sodium sulfate at a mass ratio of 10:1), 5 parts of dihydrate phosphogypsum, dihydrate phosphogypsum crystal 1 part of whisker, 0.6 part of EPS, 0.5 part of nano silica sol, 0.3 part of superplasticizer

[0037] According to the above formula, weigh cement, secondary fly ash, composite early strength agent, phosphogypsum dihydrate, and phosphogypsum dihydrate whiskers and dry mix for 60 seconds, add nano-silica sol, water reducing agent, air-entraining agent, and water-retaining agent. At the same time, add water according to the water-to-material ratio of 0.31 and stir in the mixer for 2 minutes, then add EPS particles into the mixer and stir for 3 minutes, inject the prepared slurry into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com