Horizontal slurry mixing device

A stirring device and slurry technology, applied in mixers, dissolving, mixers and other directions with rotating stirring devices, can solve problems such as large impact force, uneven slurry, and unfavorable service life of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

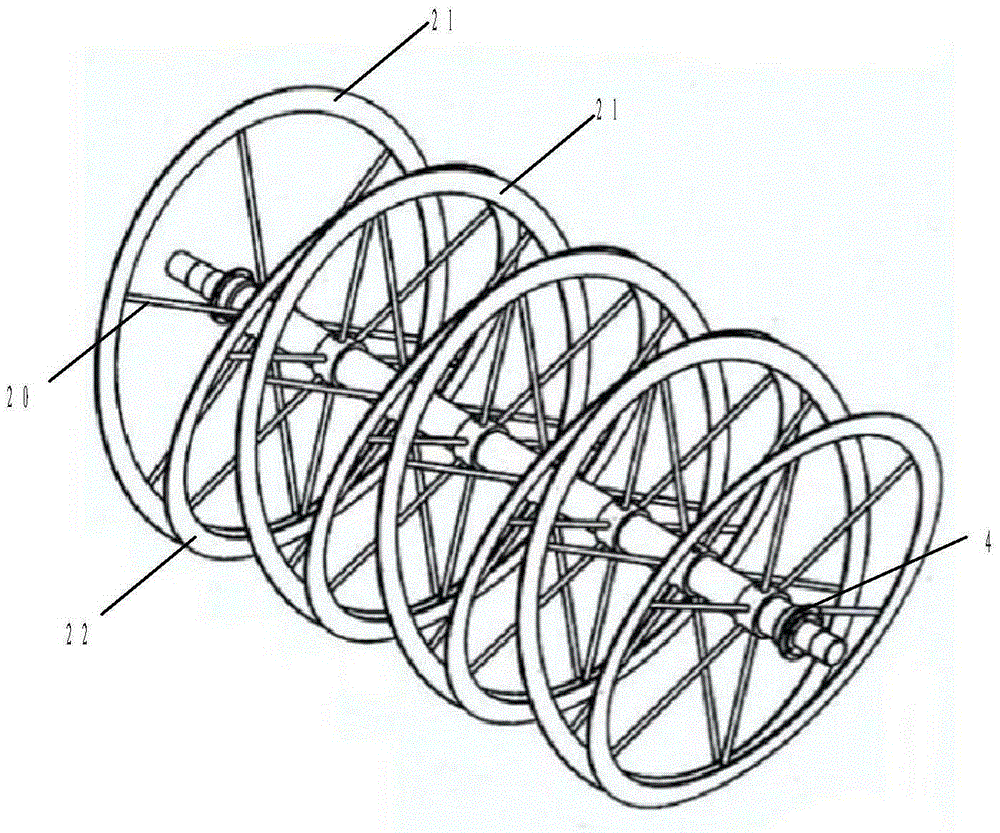

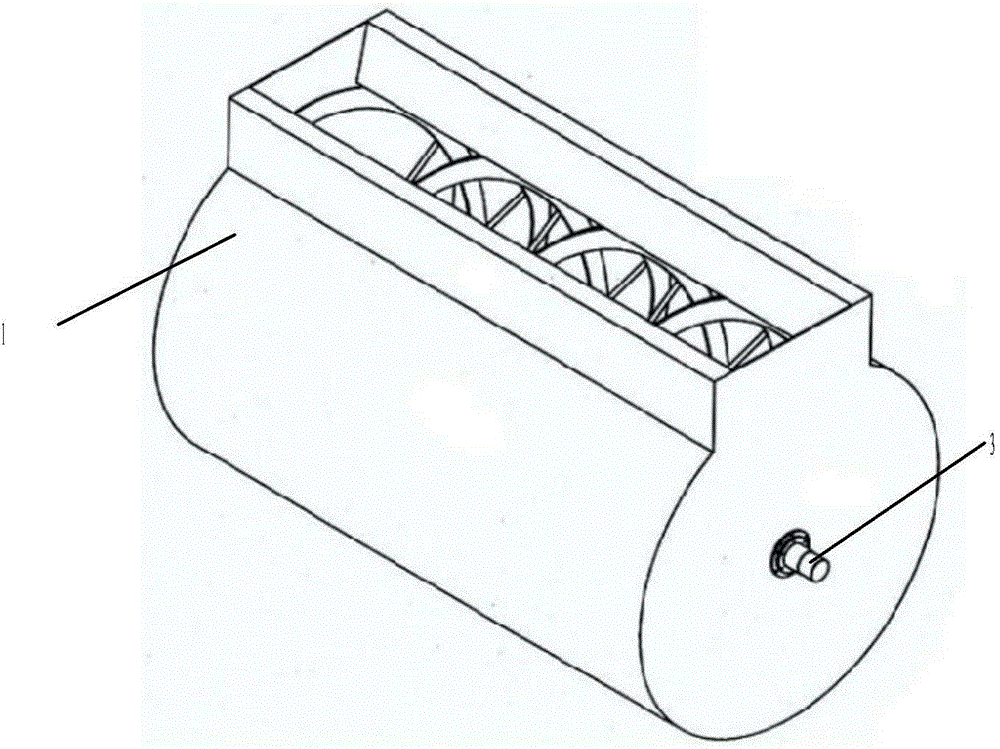

[0010] Such as figure 1 and figure 2 As shown, the horizontal slurry stirring device includes a cylindrical slurry box 1 and a stirring mechanism accommodated in the slurry box 1 .

[0011] The stirring mechanism has paddles 2 and a power shaft 3 mounted on the slurry tank 1 , the paddles 2 are equidistantly mounted on the power shaft 3 and rotate together with the rotation of the power shaft 3 . The blade 2 is an oval frame with six spokes 20 in the frame. The blades 2 include first blades 21 and second blades 22 arranged at intervals, and the first blades 21 and the second blades 22 are identical. A second paddle 22 is connected between two adjacent first paddles 21 , and the plane of the first paddle 21 is inclined to the plane of the adjacent second paddle 22 and connected in a V shape.

[0012] The spokes 20 are rod-shaped, and the included angles between two adjacent spokes 20 are equal. The spokes 20 are set in a rod shape, which can reduce the resistance of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com