A needle tracking inspection device, a detecting device and a needle tracking inspection method

An inspection device and inspection method technology, applied in the direction of measuring device, using optical device, optical testing defect/defect, etc., can solve the problem of inability to distinguish chip shadow 112 and exposed area 111, chip unqualified, etc., and achieve rapid abnormality , The effect of good precision and reliable precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

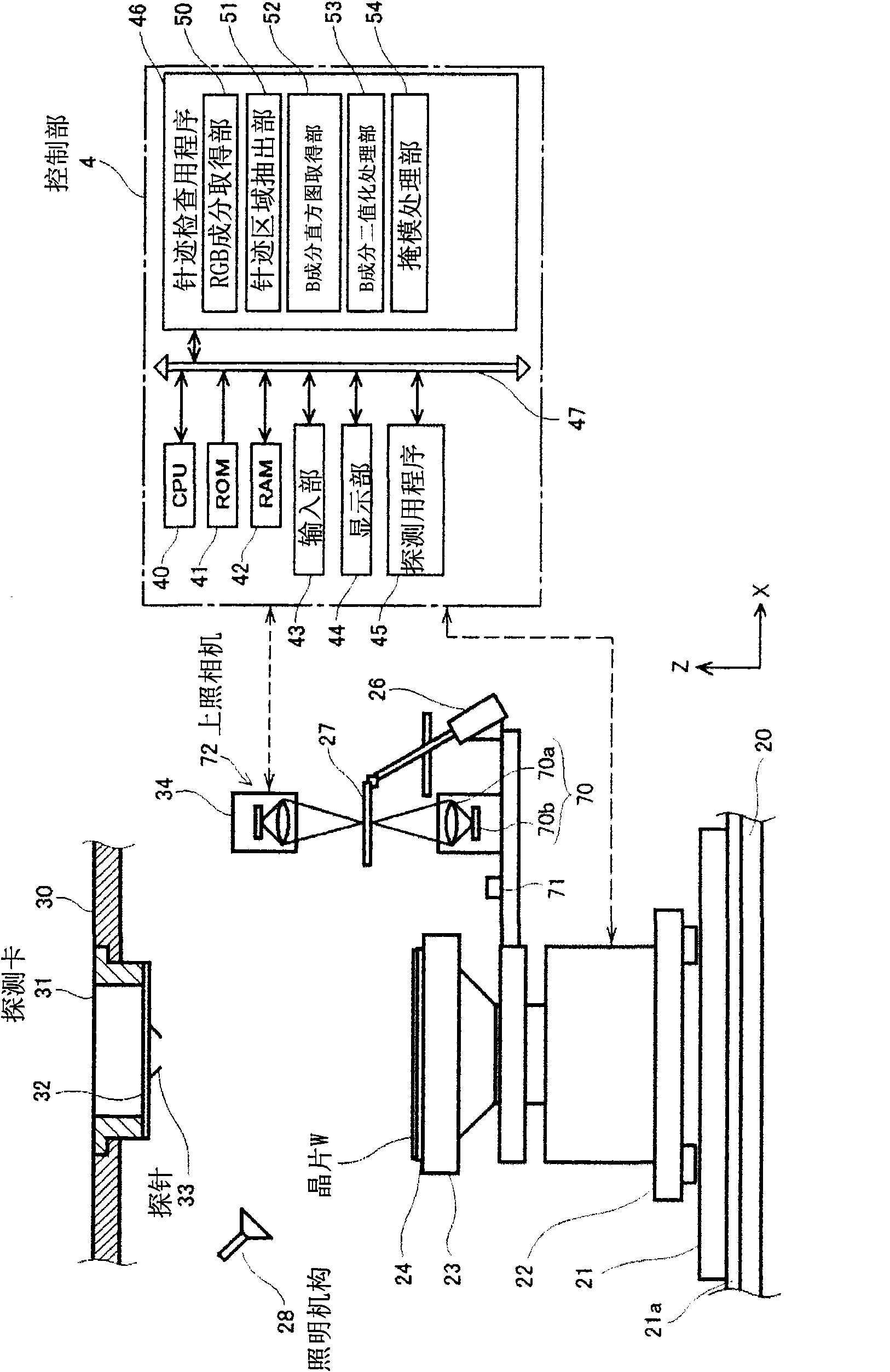

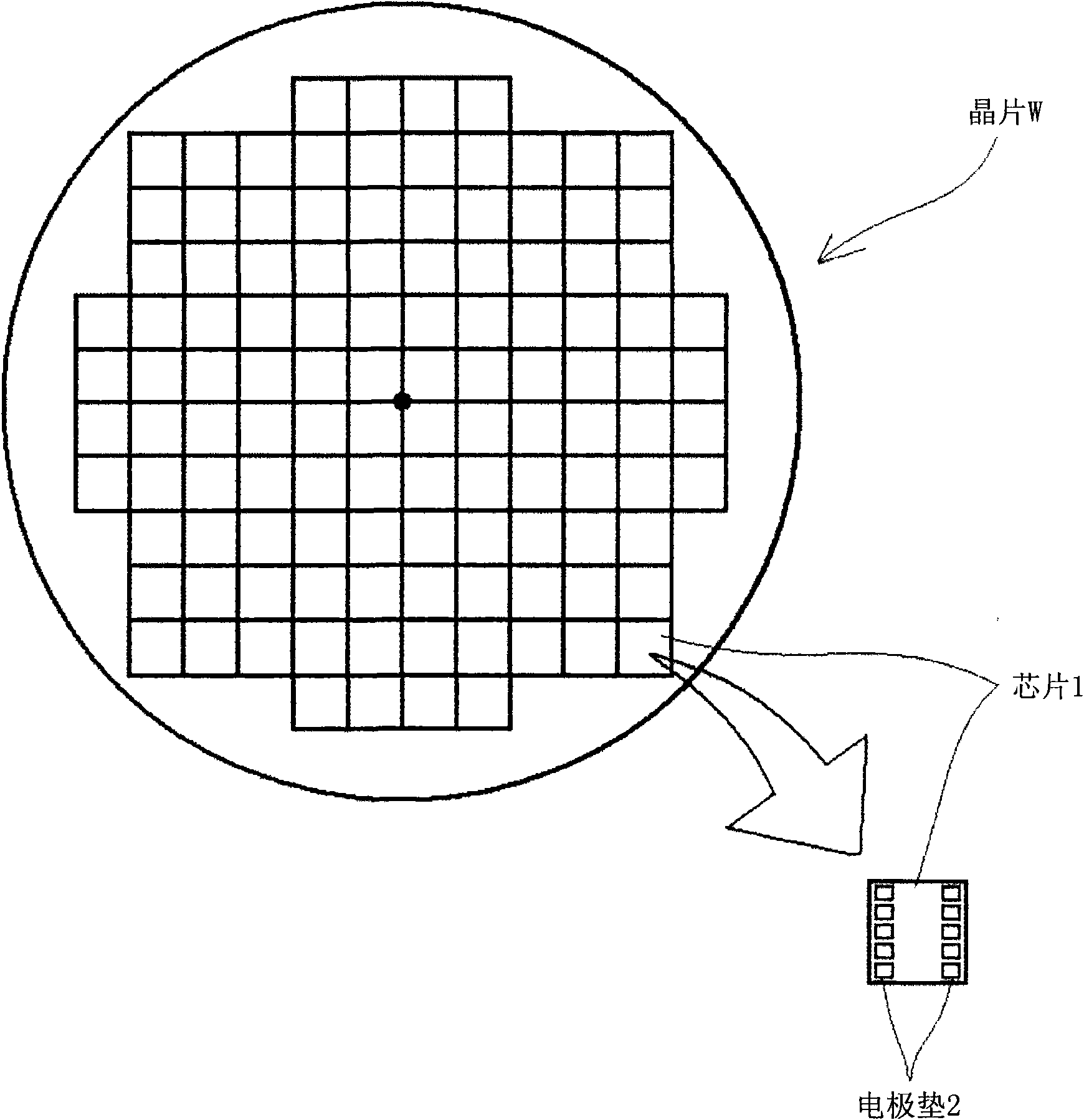

[0104] figure 1 It is a figure which shows the detection apparatus which incorporates the stitch inspection apparatus which concerns on embodiment of this invention. This detection device has a base 20 on which a first table 21 is mounted in a state of being movably supported on a first guide rail 21 a extending in parallel in the X direction, and passes through the first table through an axis. A ball screw and a motor (not shown) of the stage 21 can move in the X direction shown in the figure. In addition, on the first table 21, like the first table 21, the second table 22 is placed so as to be movable in the Y direction (not shown) perpendicular to the X and Z directions. On the second table 22 is placed a third table 23 that can move in the illustrated Z direction by a motor not shown.

[0105] On the moving body of the third workbench 23, a top suction cup (Chuck top) 24 as a mounting table is provided, which takes the Z-axis as the rotation center and has only a slight...

no. 2 approach

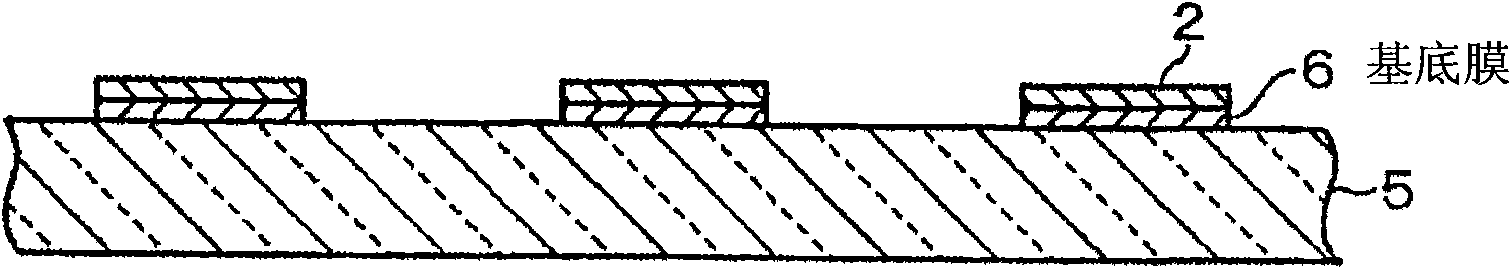

[0137]The present invention is a stitch inspection device which obtains a color image of an electrode pad, obtains an image corresponding to the R, G, and B components of the image, and utilizes the reflectance of the electrode pad and the reflection of the base film in the component data. Among these components, the difference in rate is the largest in the component data, and the exposed area is detected. Therefore, the imaging mechanism of the wafer W is not limited to the upper camera 72 of the first embodiment, and for example, another dedicated camera may be installed at a different position from the upper camera 72, for example, on the top plate or the like. In addition, as an imaging mechanism, it is not limited to a color camera capable of acquiring color images including R, G, and B components like the upper camera 72, and for example, three cameras that exclusively acquire R, G, and B components may be combined to form an imaging mechanism. mechanism.

[0138] Based...

no. 3 approach

[0141] In addition, as an embodiment of the present invention, the form shown in the following third embodiment is also possible. In the detecting device of the third embodiment, instead of the upper camera 72 and the lighting mechanism 28 provided in the first embodiment, a Figure 15 The shown upper camera 72m capable of acquiring imaging data D1 as a black-and-white image is further provided with R illuminating means 28r, G illuminating means 28g, and B illuminating means 28b for illuminating wafer W, which are composed of, for example, light emitting diodes. The R illumination mechanism 28r illuminates the wafer W with red light, the G illumination mechanism 28g illuminates the wafer W with green light, and the B illumination mechanism 28b illuminates the wafer W with blue light. As a result, in the upper camera 72m, only the image data of the components corresponding to the light sequentially irradiated from the respective illumination mechanisms 28r, 28g, and 28b can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com