Triangular weaving mechanism

A technology of triangle and circle transfer triangle, which is applied in the direction of weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of lengthening the running stroke of the machine head, increasing manufacturing costs, and reducing weaving efficiency, so as to reduce consumables and improve weaving efficiency , the effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

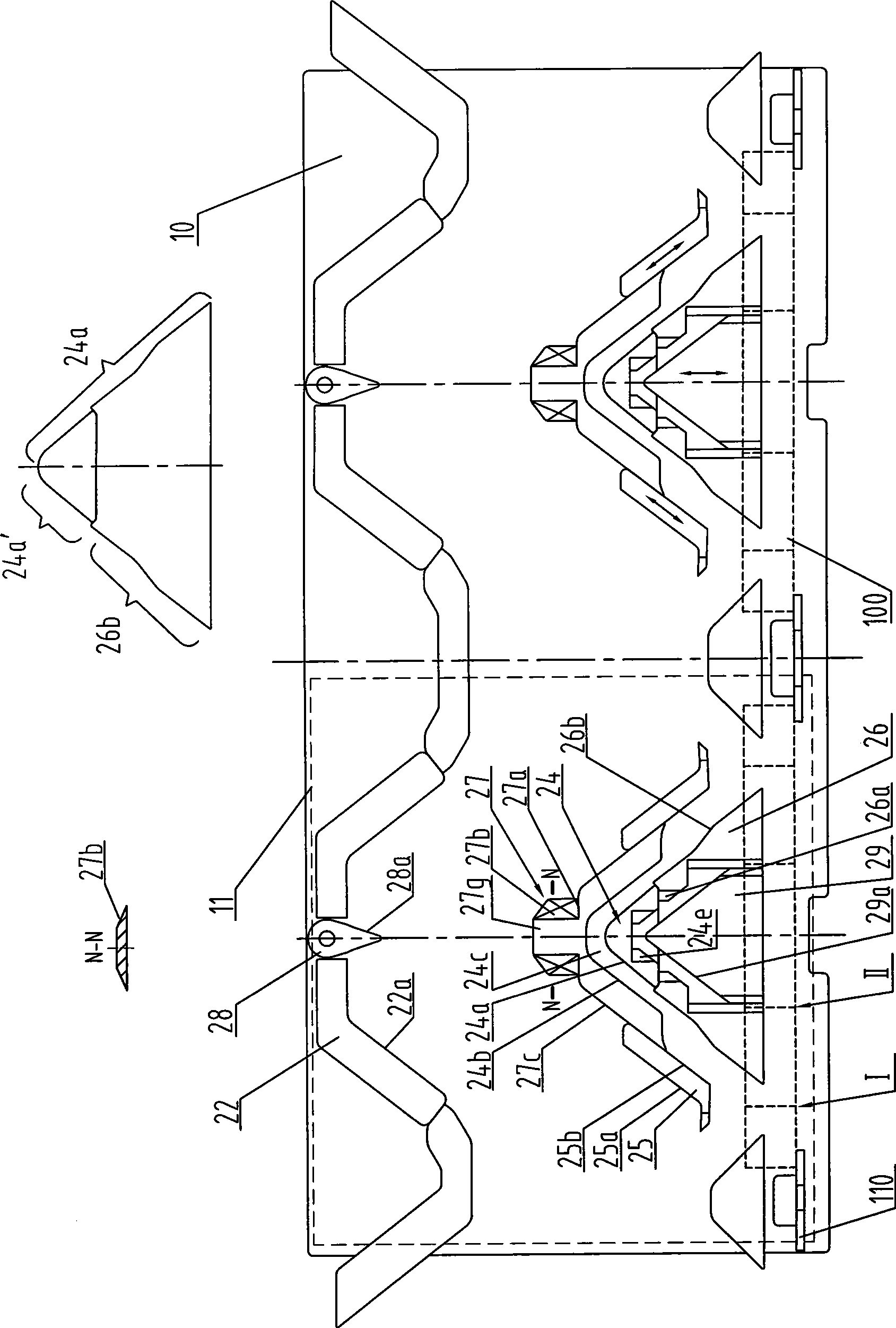

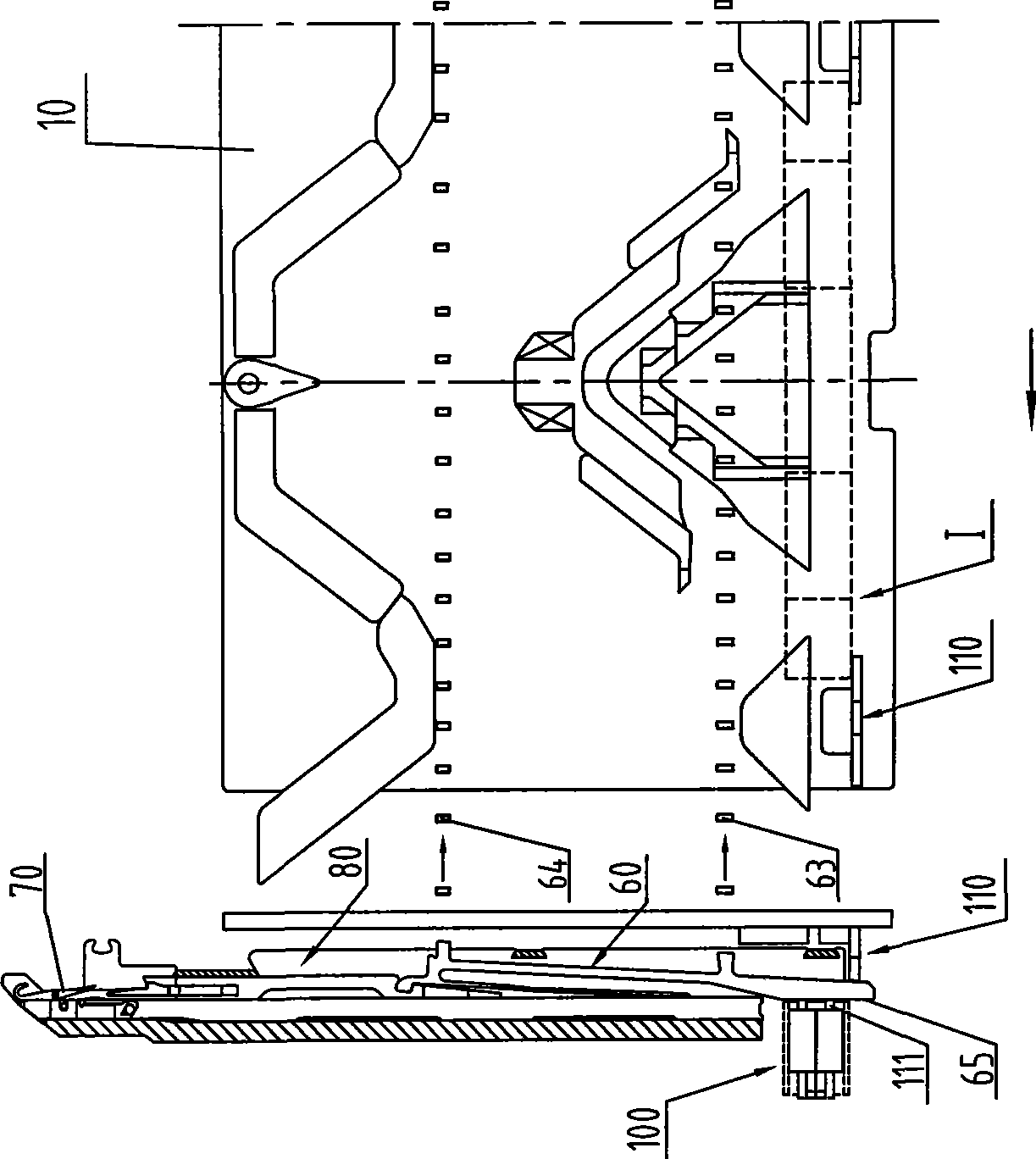

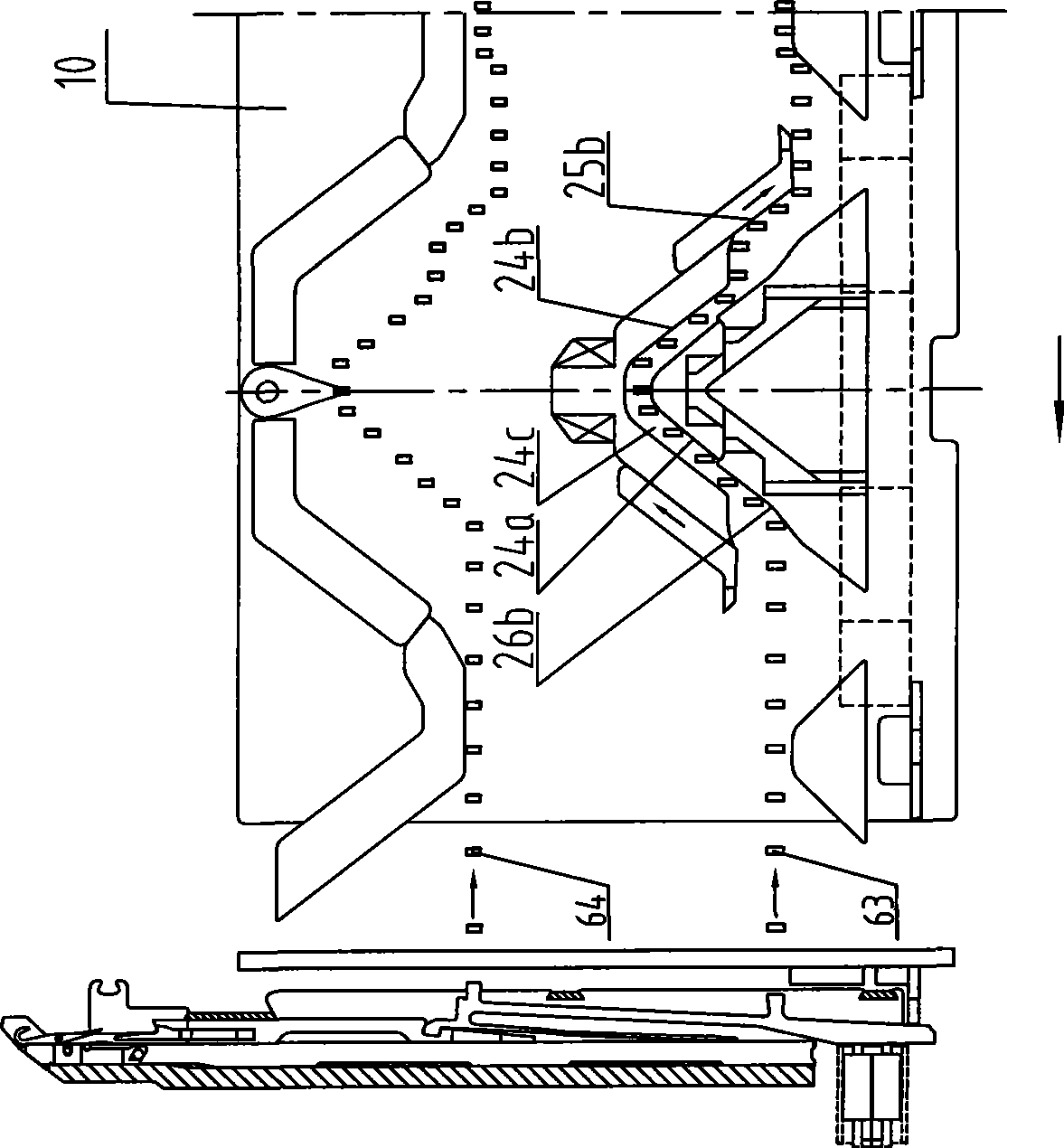

[0027] The present invention and its advantages will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] In the following embodiments, the random head of the knitting unit moves to the left, and the butts 63 and 64 of the needle jacks in each needle slot on the needle bed move to the right with respect to the cam mechanism for example.

[0029] control figure 1 , The cam knitting mechanism of the present invention mainly consists of a cam bottom plate 10 and a braiding cam. Two knitting units 11 are arranged on the triangular bottom plate, and each knitting unit 11 is provided with a needle movement surface for pushing the needle clock to make the knitting needle move up and down, such as: transfer circle stop surface 22a, swing transfer circle back needle surface 28a, forming Knuckle surface 24a, needle starting surface 26b, first stitch transfer starting surface 25a, second stitch transfer starting surface 27c, stitch transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com