Patents

Literature

41results about How to "Good moisture wicking function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

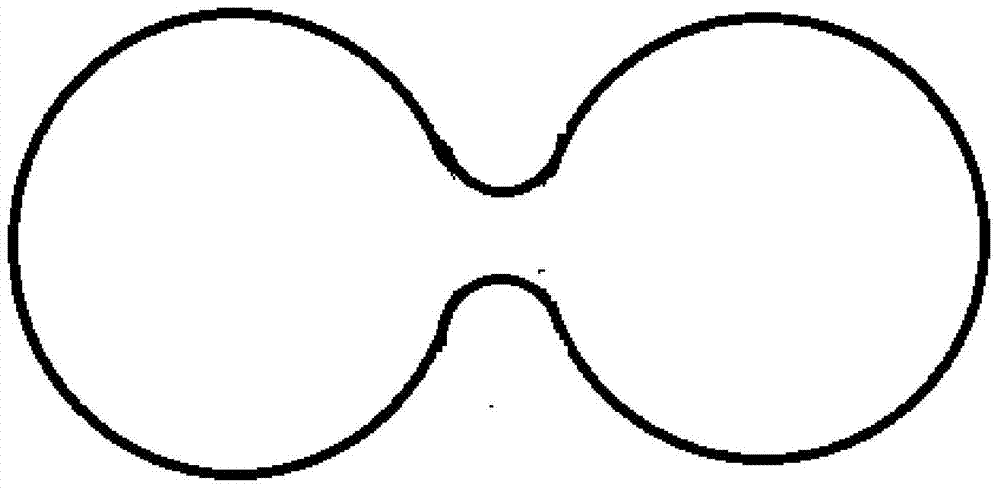

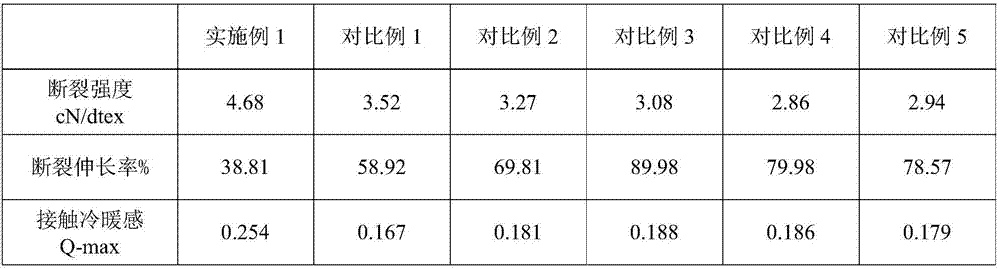

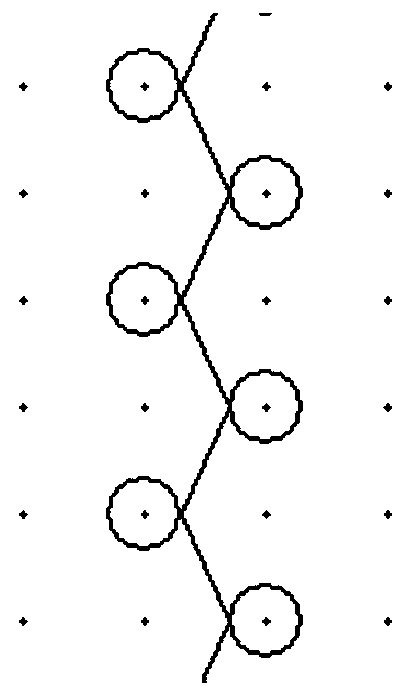

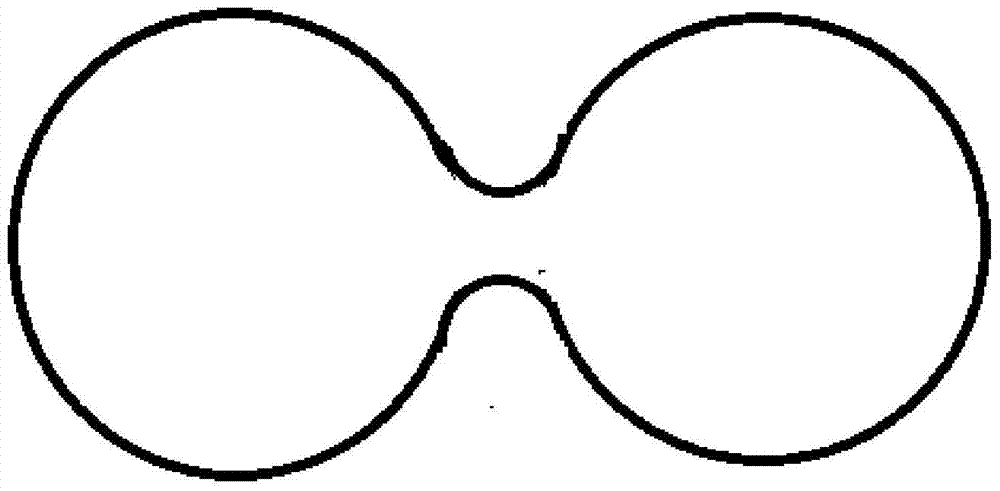

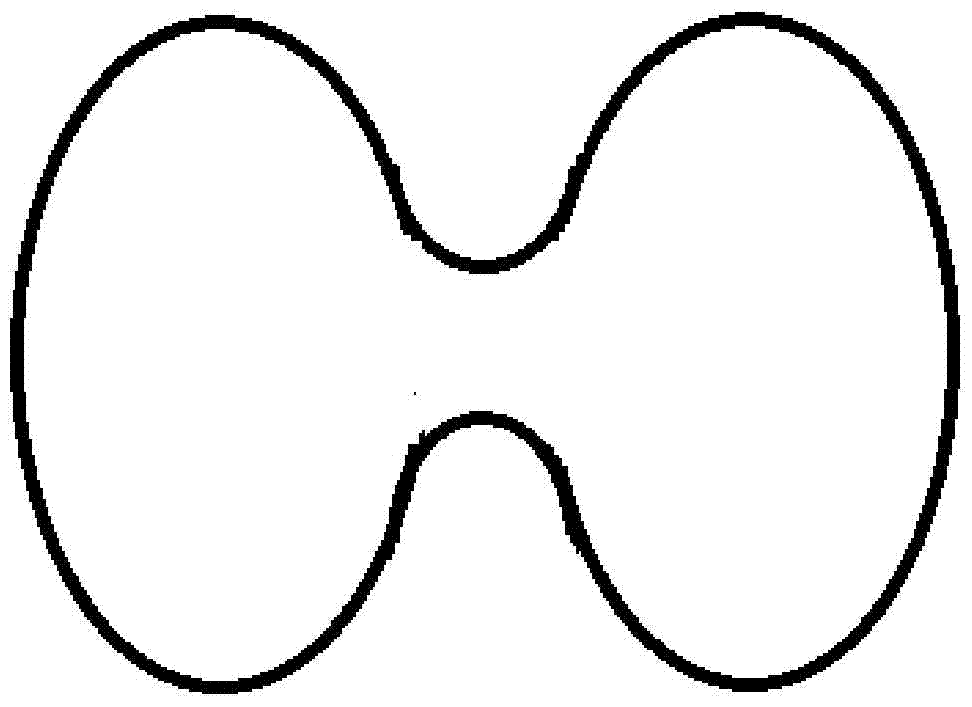

Novel elastic fiber and preparation method thereof

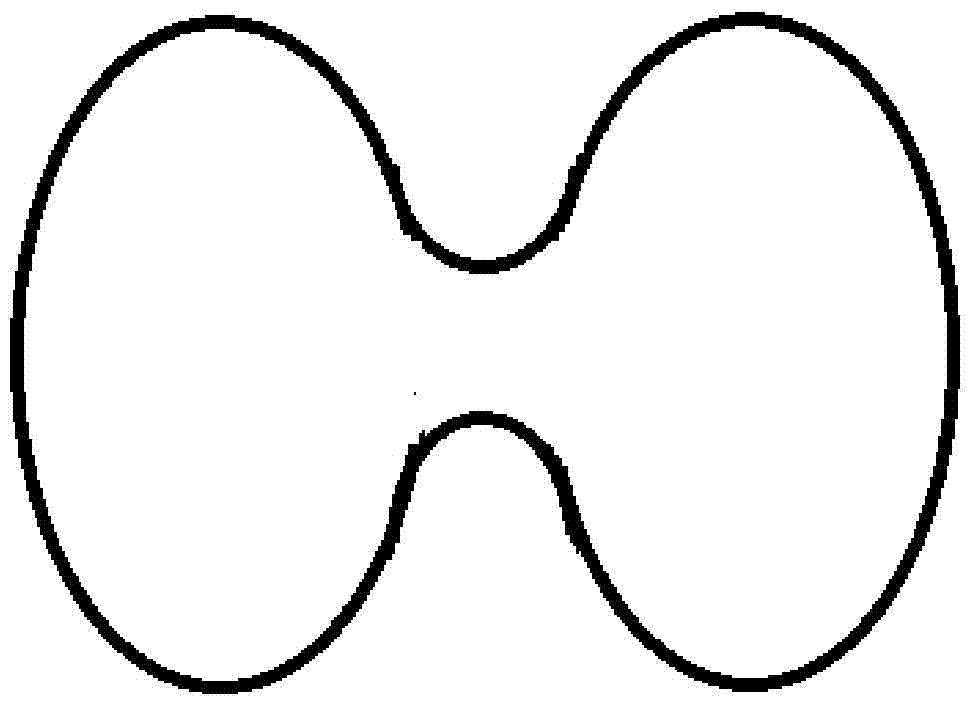

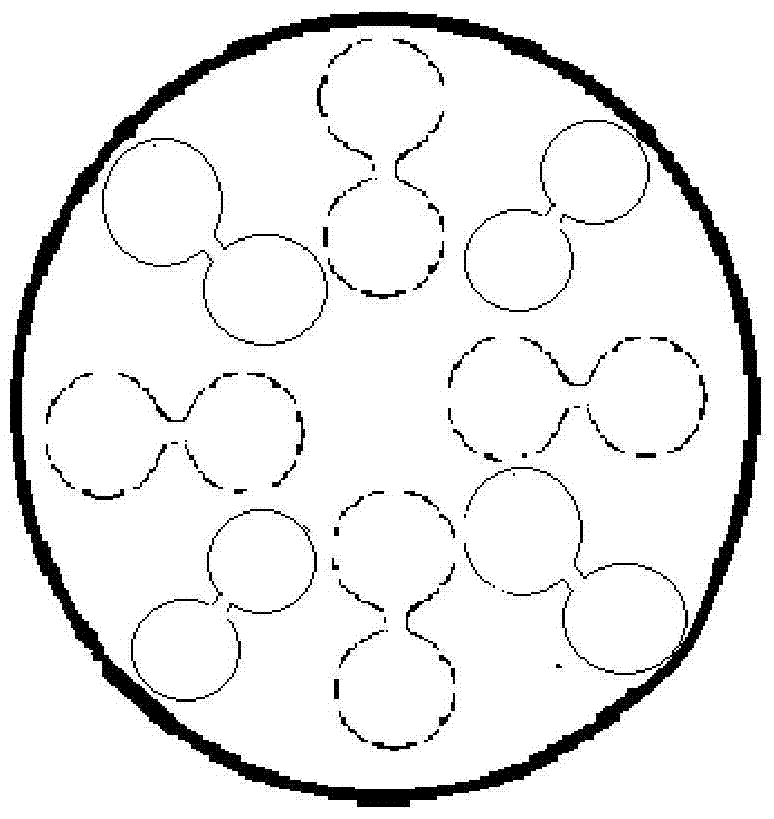

ActiveCN103882538AGood moisture wicking functionThe production process is simpleMelt spinning methodsPolyesterExternal connection

The invention provides a novel elastic fiber and a preparation method thereof. The novel elastic fiber is a two-component parallel composite fiber. In the cross section of the fiber, two parallel components are both in the shape of a round or an oval, and the two rounds or the two ovals are in tangent connection or in external connection. The novel elastic fiber is obtained by spinning two types of polyester chips, due to the fact that the shrinkage stress of the two fibers is different, different shrinkage effects are generated, the novel elastic fiber is made to have crimp elasticity very similar to that of natural wool, and therefore the novel elastic fiber has good elasticity. Large-scale production of the novel elastic fiber can be achieved, and meanwhile the production cost is lowered.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

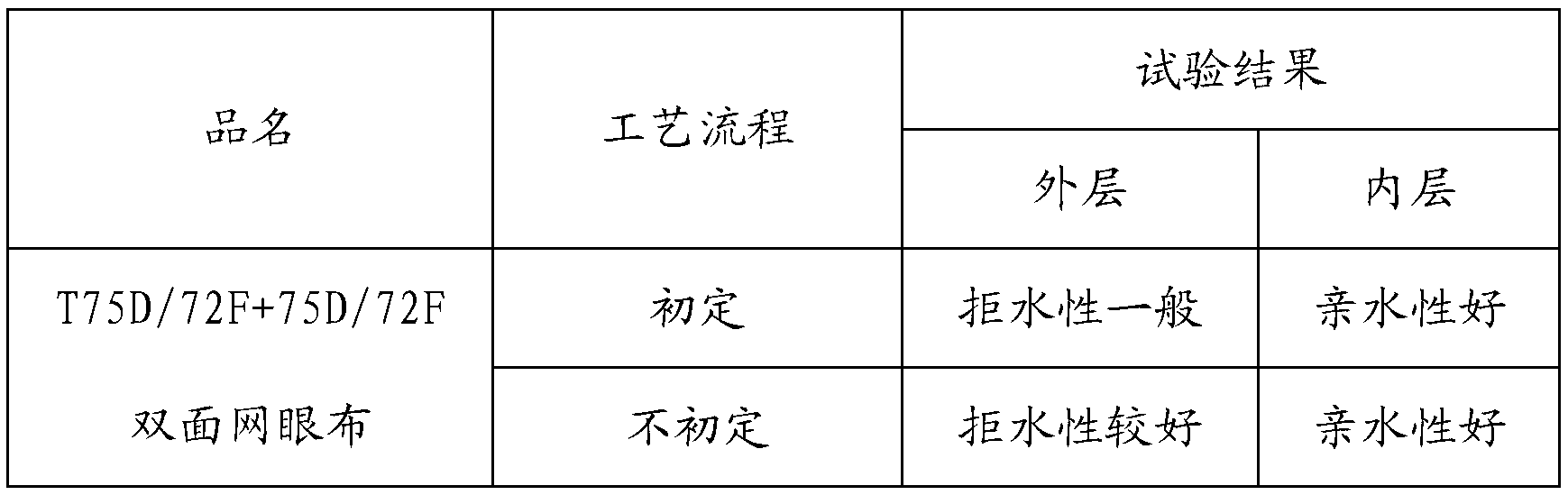

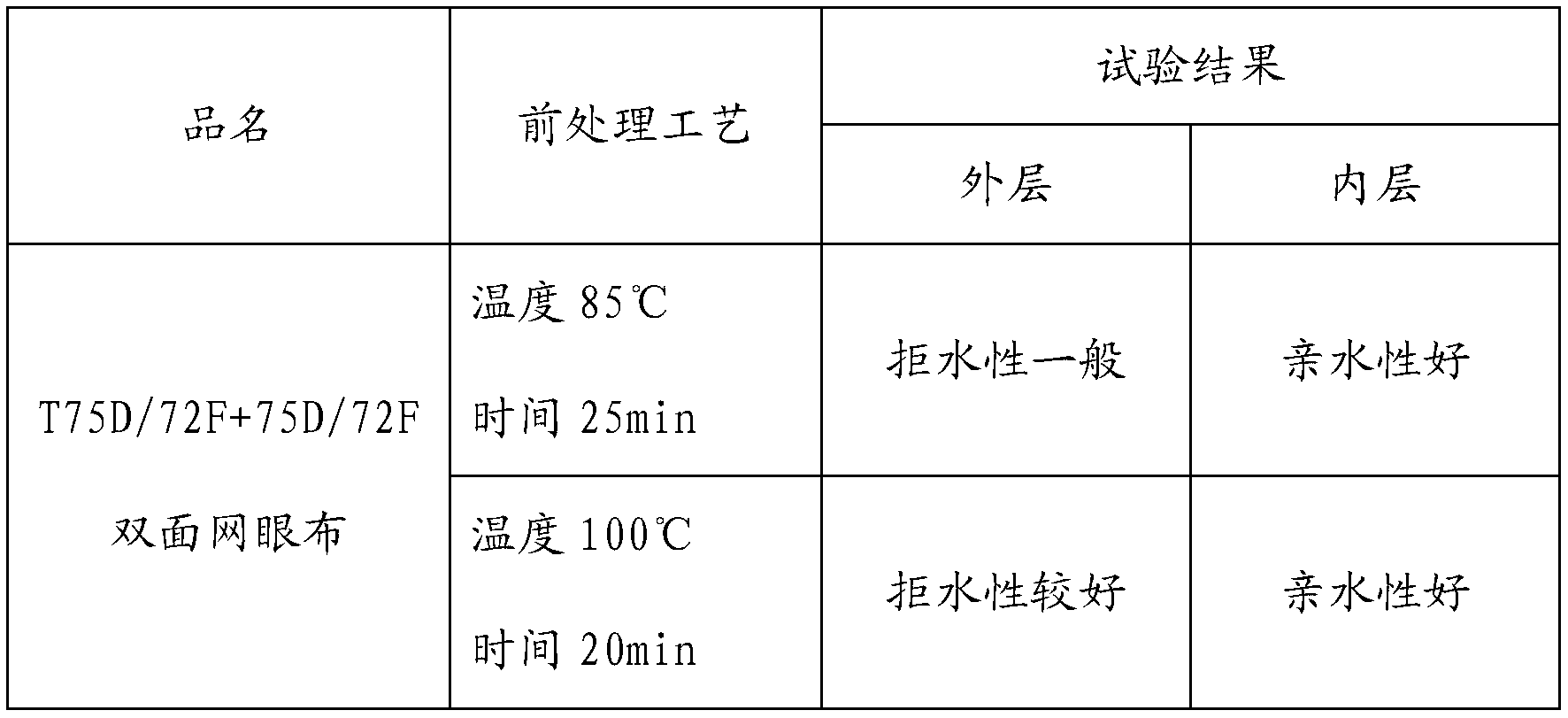

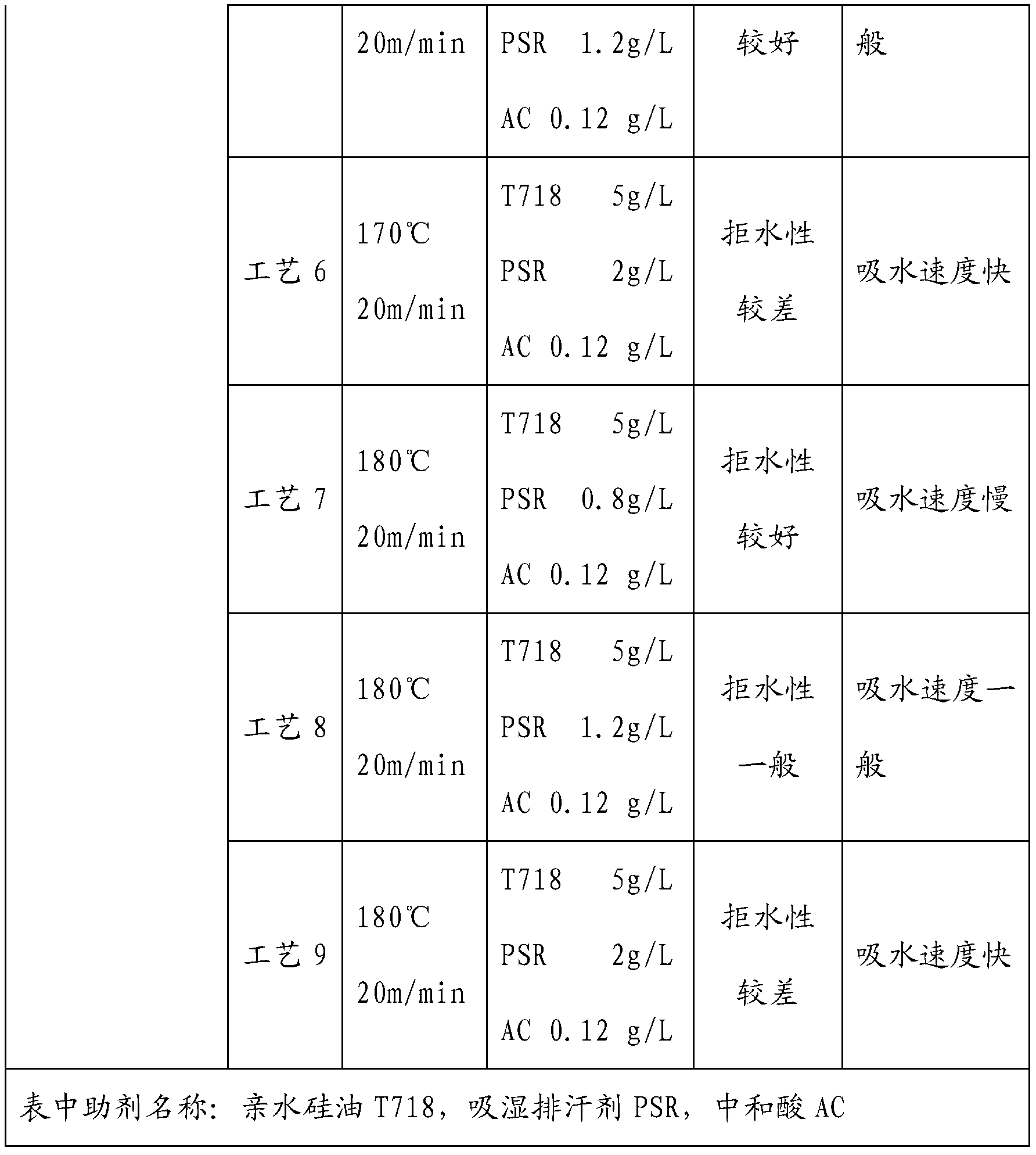

Anti-permeability and moisture absorption different-function knitted fabric and production process thereof

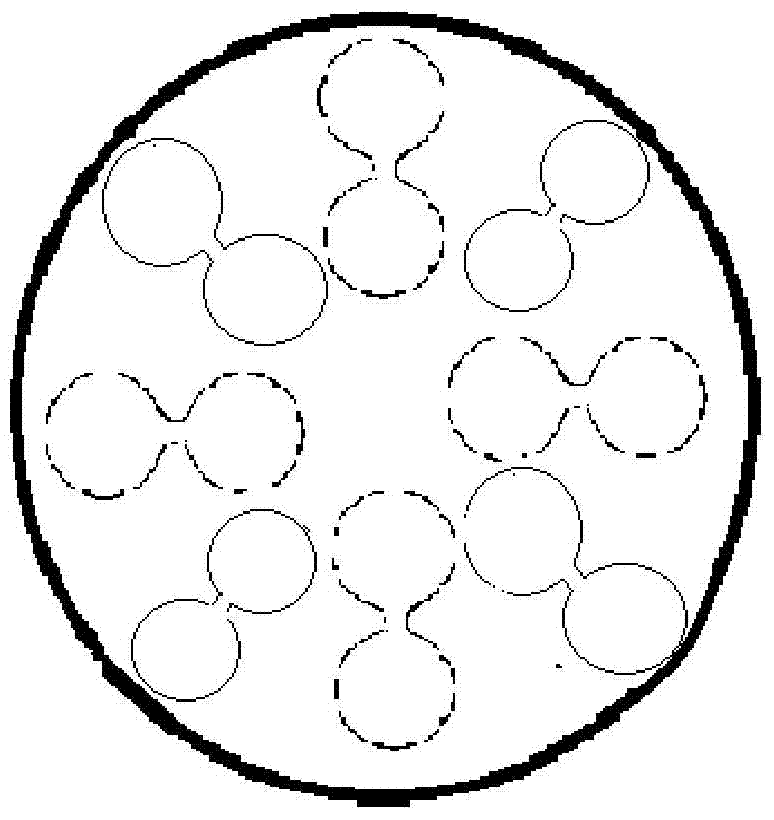

InactiveCN103233317AGood water repellencyWater repellency is not affectedSucessive textile treatmentsWeft knittingTextile designMoisture absorption

The invention discloses an anti-permeability and moisture absorption different-function knitted fabric and a production process thereof. The anti-permeability and moisture absorption different-function knitted fabric is of a double-layer structure, a middle connection tuck is connected between the outer layer and the inner layer, the outer layer and the middle connection tuck are made of water-repellency terylene subjected to surface modification processing, and the inner layer is made of terylene with irregular sections and having moisture absorption and sweat releasing functions. The production process of the anti-permeability and moisture absorption different-function knitted fabric includes steps of performing weaving to obtain grey fabric according to the double-layer textile design; performing preprocessing, dyeing, softening, dewatering and wet cutting for the grey fabric; and performing after finishing through a setting machine. According to the anti-permeability and moisture absorption different-function knitted fabric and the production process thereof, two different functions are combined in the inner layer and the outer layer of the fabric, and requirements of sports knitwear for combining inner layer moisture absorption and sweat releasing functions with outer layer sweat stain prevention function are met.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

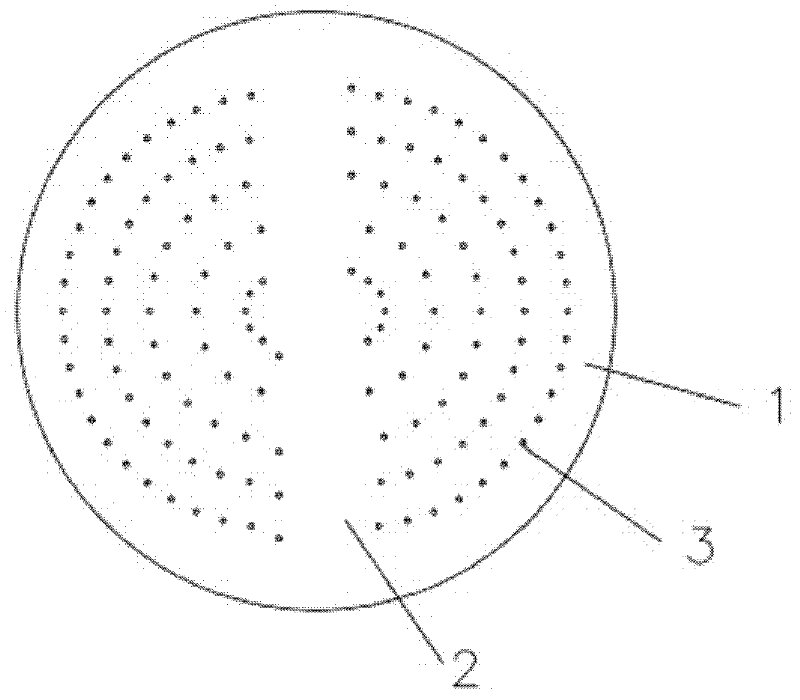

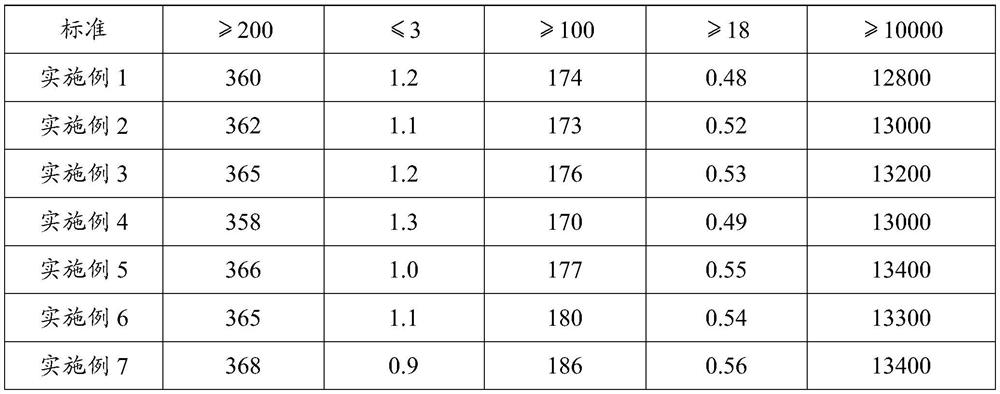

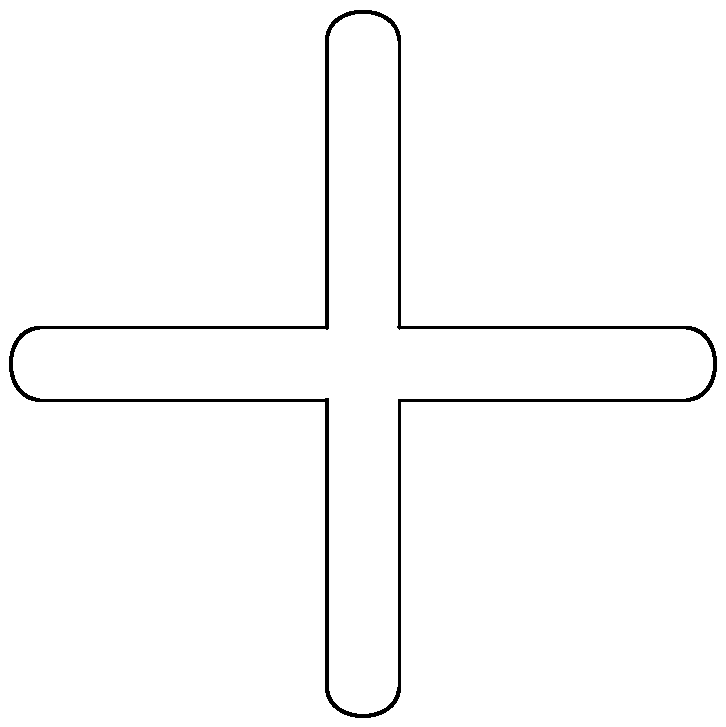

Textile with ultraviolet resistant , hygroscopic and perspiratory function, and its preparation method

InactiveCN1800465AGood UV resistanceGood moisture wicking functionWeft knittingFilament/thread formingChemistryPolyester

The invention discloses a textile with the functions of ultraviolet resistance and moisture absorption and relative producing method. It is formed by the polyester fiber with cross-type section, while the polyester fiber comprises nanometer titanium oxide grains in the weight of 1.0-3.0%, the UPF valve >40, the core absorption height and the dry speed are vertical 80-100mm / min, and horizontal 85-110mm / 10min, and the left water amount after 45 minutes is less than 10%. The invention has the advantages of ultraviolet resistance and moisture absorption.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

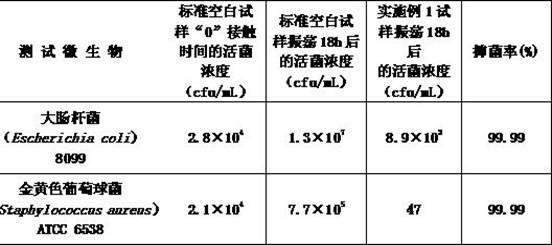

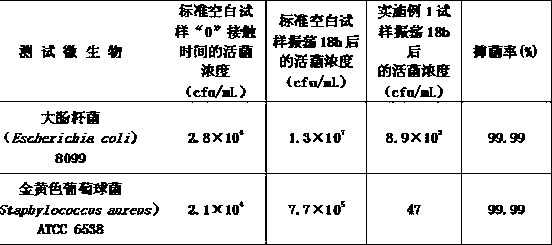

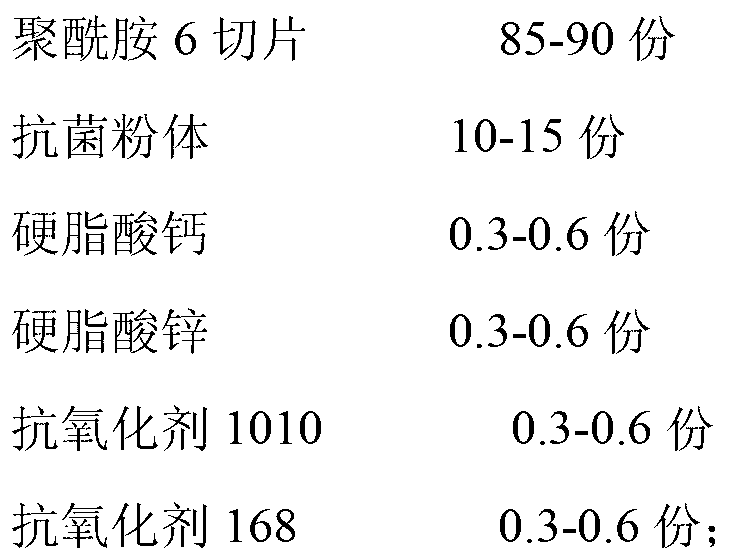

Antibacterial moisture-transfer chinlon 6 and preparation method thereof

ActiveCN102677215AReduce contentStrong ability to load copper ionsBiocideFilament forming substance formingPolyamideMoisture absorption

The invention discloses antibacterial moisture-transfer chinlon 6 comprising antibacterial master batches, polyamide 6 chips and calcium stearate, wherein the weight ratio of the antibacterial master batches to the polyamide 6 chips to the calcium stearate is (7-10) to (95-100) to (0.1-0.3). The antibacterial moisture-transfer chinlon 6 provided by the invention adopts nano porous bergmeal to carry cuprous oxide and has the characteristic of high copper ion carrying capacity, thereby not only saving the production cost and reducing the content of inorganic particles in melt, but also improving the stability of the spinning process; the antibacterial moisture-transfer chinlon 6 is scientific and reasonable in component proportion and can resist various bacteria, thereby having the advantages that the antibacterial range is high and the antibacterial ratio is above 99 the antibacterial moisture-transfer chinlon 6 has excellent moisture absorption and sweat discharging functions and a wide application range; and the operability of a preparation method is strong, the process is reasonable, the production efficiency is high, and industrialized production can be realized.

Owner:TAICANG HONGYI CHEM FIBER

Anti-bacterial fabric for shoes and production process thereof

Provided is anti-bacterial fabric for shoes and a production process thereof. Warp-knitted spacer fabric is adopted and comprises a surface layer for decoration, an inner layer in contact with the skin, and a spacing layer arranged between the surface layer and the inner layer. The inner layer is formed in such a manner that far infrared polyester fibers and chinlon-based cupric ion anti-bacterial fibers are interwoven. The far infrared polyester fibers serve as the spacing layer. In a bacteriostatic test of fabric, the bacteriostasis rate of Candida albicans reaches at 95.76%, the bacteriostasis rate of trichophyton rubrum reaches at 96.96%, the bacteriostasis rate of staphylococcus aureus reaches at 99.23%, and the bacteriostasis rate of colibacillus reaches at 99.99%. The anti-bacterial fabric has composite functions of heat preservation, bacteria prevention, health care, moisture conductivity and perspiration.

Owner:HAIXI NEW TEXTILE MATERIAL OF JINJIANG IND TECH ACAD +1

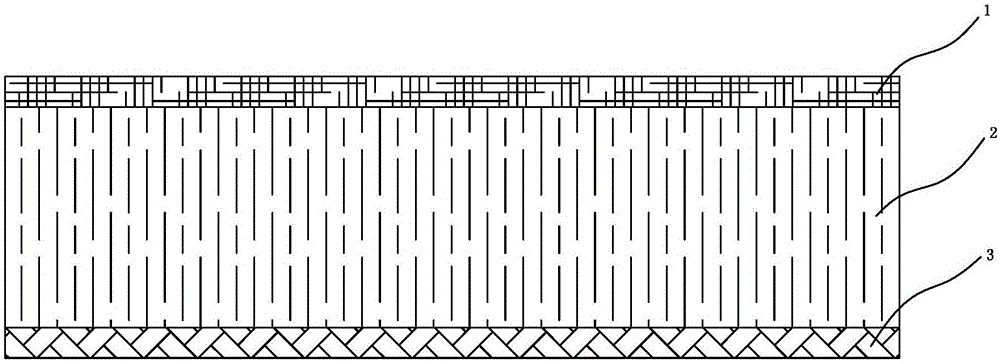

One-step pattern different dyeing cool composite fiber and preparation method thereof

ActiveCN107190353AImprove comfortSimple processFilament/thread formingConjugated synthetic polymer artificial filamentsSesamum orientaleTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a one-step pattern different dyeing cool composite fiber and a preparation method thereof. The one-step pattern different dyeing cool composite fiber is of an incomplete covered skin core structure; the incomplete covered skin core structure comprises an inner first polymer core layer with moisture absorption and sweat releasing functions and a second polymer skin layer with heat conduction and dissipation functions. The one-step pattern different dyeing cool composite fiber achieves a cool and dry composite excellent effect, and the wearing comfortableness is greatly improved. Furthermore, the one-step pattern different dyeing cool composite fiber is prepared through a one-step method, and can achieve a special effect with irregular patterns or sesame points after being dyed without post-processing. Therefore, the technological process is simplified, and the personality demand of people is also met.

Owner:CTA HIGH TECH FIBER +1

Preparation technology and method of polyester and cotton-fiber blended fabric

The invention discloses a preparation technology and method of a polyester and cotton-fiber blended fabric. The polyester and cotton-fiber blended fabric is formed through interweaving of 60% polyester fibers, 35% of cotton fibers and 5% of T-400 elastic fibers. The preparation technology includes the following five steps of 1, spinning, 2, sizing, 3, desizing, 4, weaving and 5, dyeing and finishing. The three fibers, namely 60% polyester fibers, 35% of cotton fibers and 5% of T-400 elastic fibers, are interwoven to form the fabric through a specific blending mode, the fabric thus is good in moisture absorption and sweat releasing function, very elastic, soft in hand feeling and good in strength, the production method is easy to operate, and the environmental protection requirements can beachieved.

Owner:WUJIANG XINWU TEXTILE

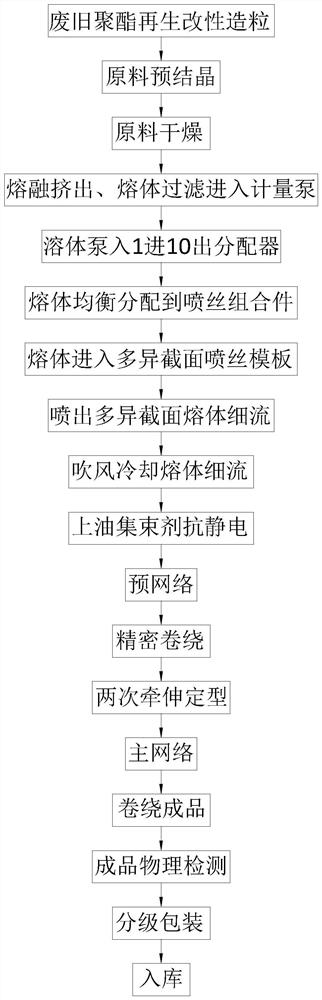

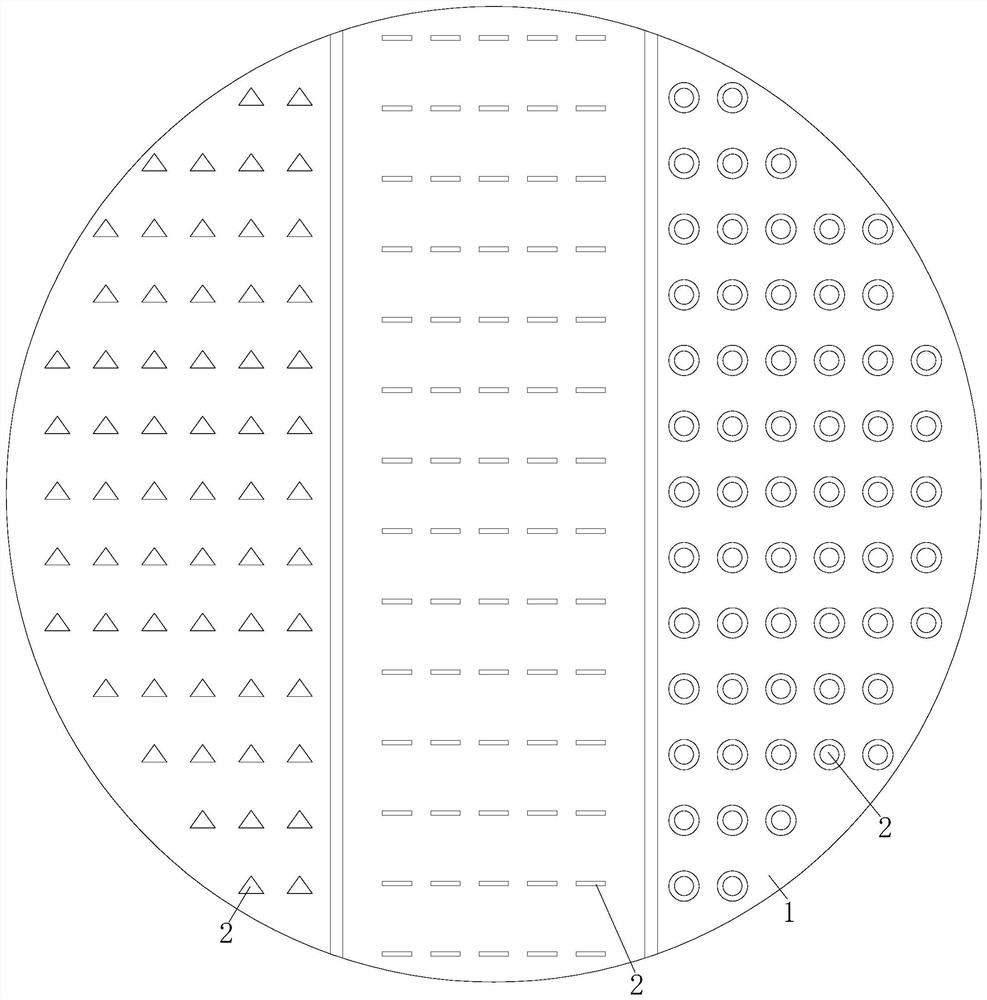

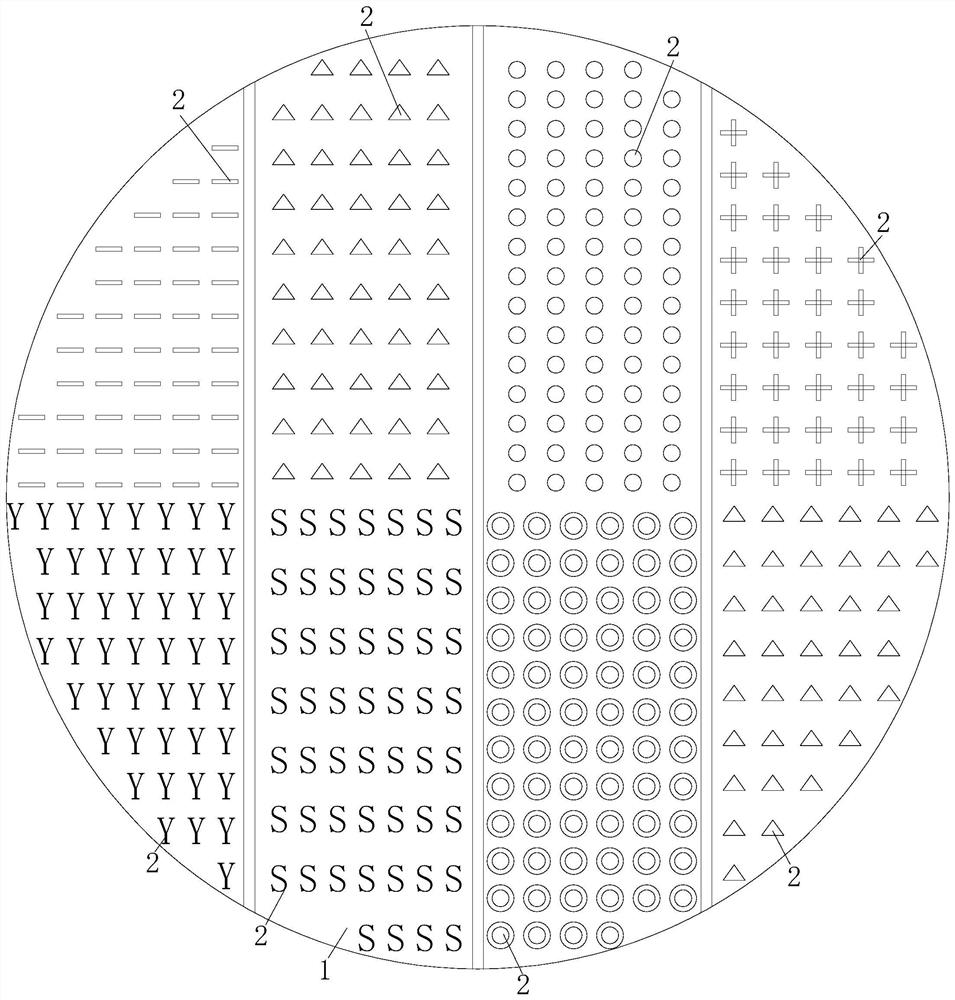

Method for spinning imitated cotton and linen fibers by waste polyester

PendingCN111793831ASoft lusterImprove fluffinessSpinning solution de-aeratingArtifical filament manufacturePelletizingPolyester

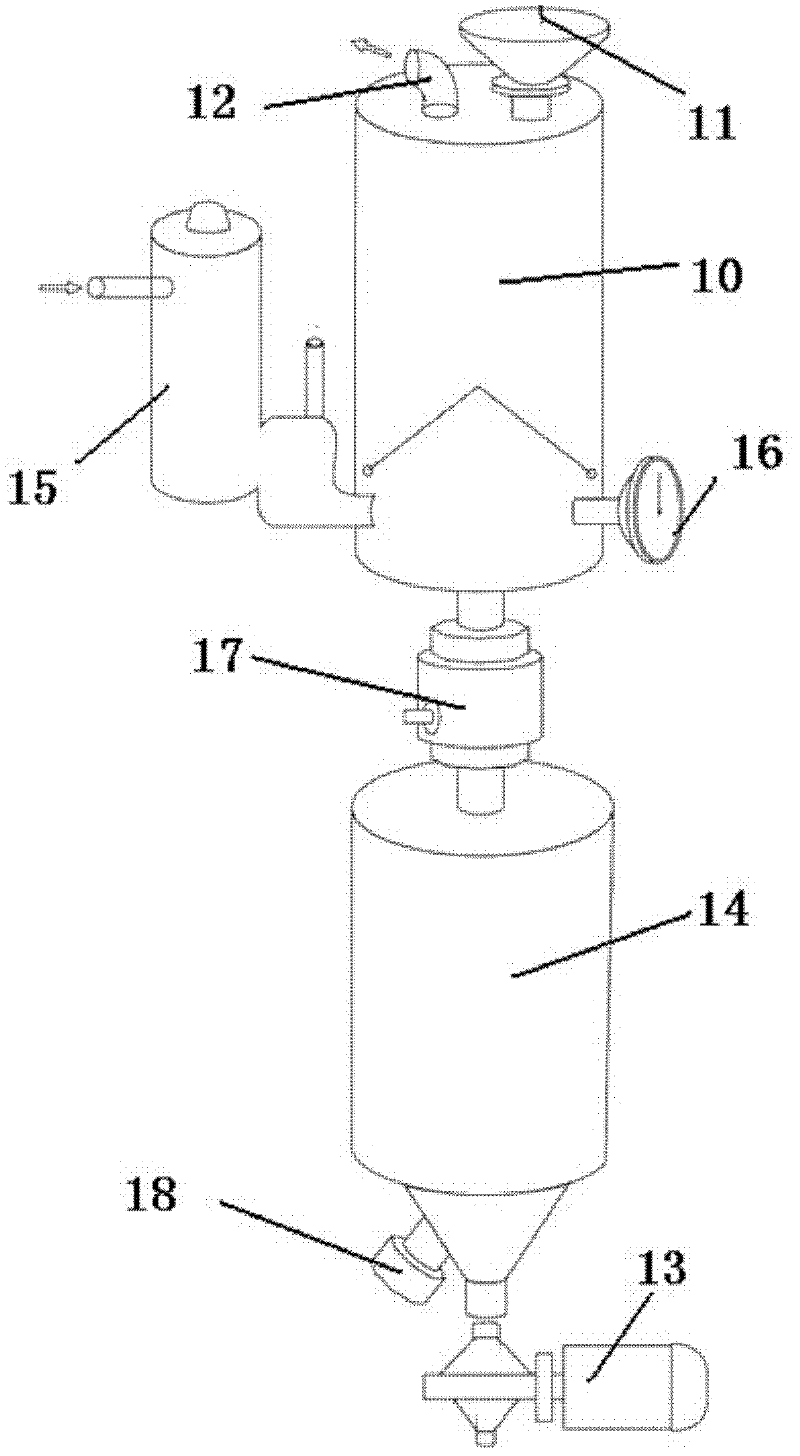

The invention relates to a method for spinning imitated cotton and linen fibers by waste polyester, which belongs to the field of spinning. The method comprises the following steps: a first step of regenerating, modifying and pelletizing the waste polyester; a second step of pre-crystallizing raw materials; a third step of drying the raw materials; a fourth step of melting and extruding, filteringmelt, and introducing the melt into a metering pump; a fifth step of pumping the melt into a distributor; a sixth step of distributing the melt to a spinneret combined part in a balanced mode; a seventh step of introducing the melt into a different-section spinneret template; an eighth step of spraying out fine flow with multiple different-section melts; a ninth step of blowing air to cool the melt fine flow; a tenth step of enabling an oil-coating bunching agent to be anti-static; an eleventh step of pre-networking; a twelfth step of precisely winding; a thirteenth step of stretching and reshaping twice; a fourteenth step of defining a primary network; and a fifteenth step of winding a finished product.

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

Method for manufacturing bottle piece spinning return material recycled polyester moisture-absorbing sweat-releasing POY filament

InactiveCN103668511AGood moisture absorption characteristicsGood moisture wicking functionFilament forming substance formingArtificial thread manufacturing machinesEngineeringContinuous production

The invention discloses a method for manufacturing a bottle piece spinning return material recycled polyester moisture-absorbing sweat-releasing POY filament. The method includes the following steps that (1) pre-crystallization is carried out on materials, wherein the materials are PET bottle piece return materials, and dried hot air is adopted for pre-crystallization; (2) the materials are fed in a screw mode, the PET bottle piece return materials are dried through hot air, and then the dried PET bottle piece return materials are fed into a screw extruding machine; (3) filtering, homopolymerization and pressurizing are carried out, wherein filtering, homopolymerization and pressurizing are carried out on melts generated through extruding of the extruding machine so as to guarantee continuous production of spun yarn and stability of melt pressure; (4) spinning is carried out, wherein the melts output from a pressurizing pump enter a spinning assembly, and are ejected from a spinneret plate through the spinning assembly and coiled and formed. The bottle piece spinning return material recycled polyester moisture-absorbing sweat-releasing POY filament manufactured in the method is good in moisture-absorbing and sweat-releasing characteristic, size stability and air permeability, and stability of fabrics is not influenced by any environment.

Owner:仪征市仲兴环保科技有限公司

Warp knitting moisture absorption and sweat releasing shirt fabric and preparation method thereof

InactiveCN110067076ALight and comfortable to wearIncrease elasticityWarp knittingHeating/cooling textile fabricsPolyesterEngineering

The invention relates to a warp knitting moisture absorption and sweat releasing shirt fabric and a preparation method thereof and belongs to the technical field of warp knitting shirt fabrics and production thereof. The fabric is made of 17-19% of polyester yarns, 13-75% of cotton yarns, 10-20% of extinction irregular cut polyester yarns and 0-35% of extinction cationic dyeable irregular cut polyester yarns through weaving by using a four-comb warp knitting machine. The warp knitting shirt fabric provided by the invention has the advantage of warp knitting textures made of cotton yarns and irregular cut polyester yarns in reasonable proportioning, the fabric has moisture absorption and sweat releasing functions, meanwhile, the amount of special yarns is reduced, the production cost can bereduced, and the fabric has the advantages of being light and thin, comfortable to wear, rich in color, smooth in hand feeling, moderate in elasticity, and the like.

Owner:JIANGNAN UNIV

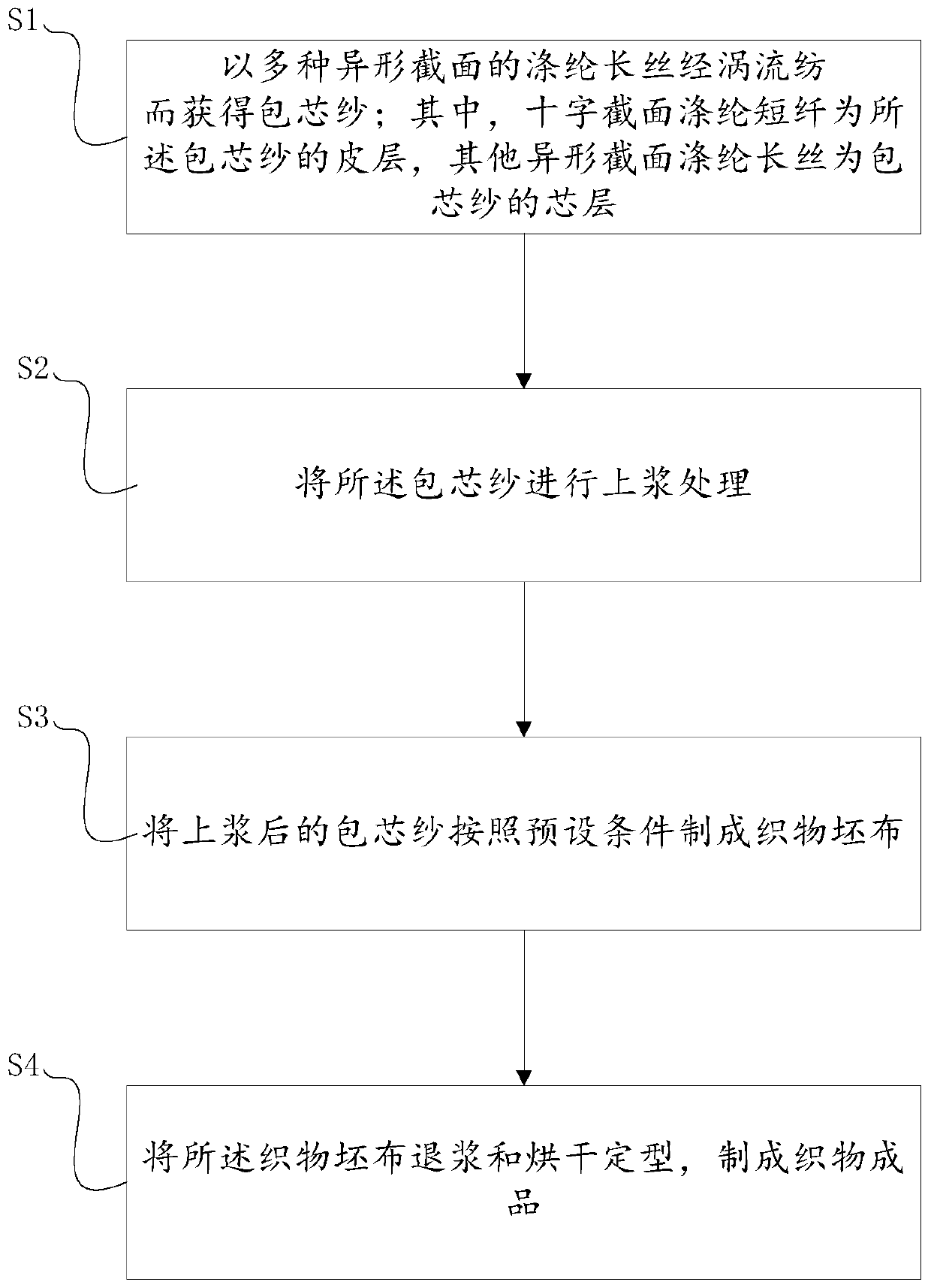

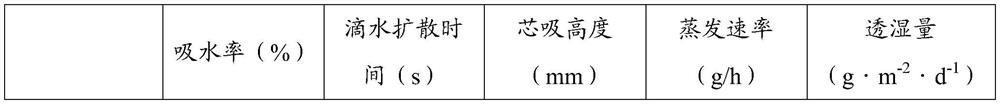

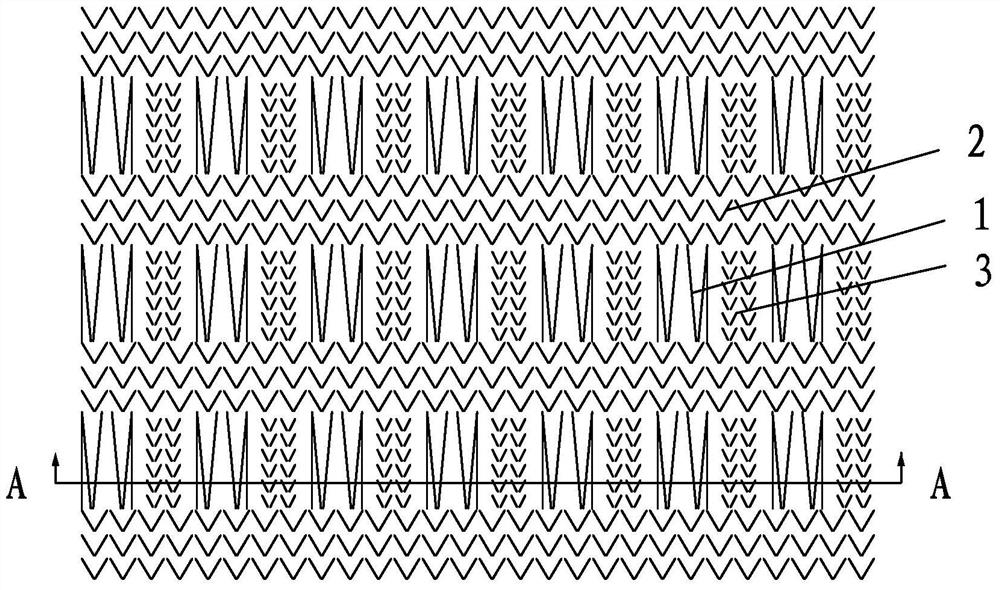

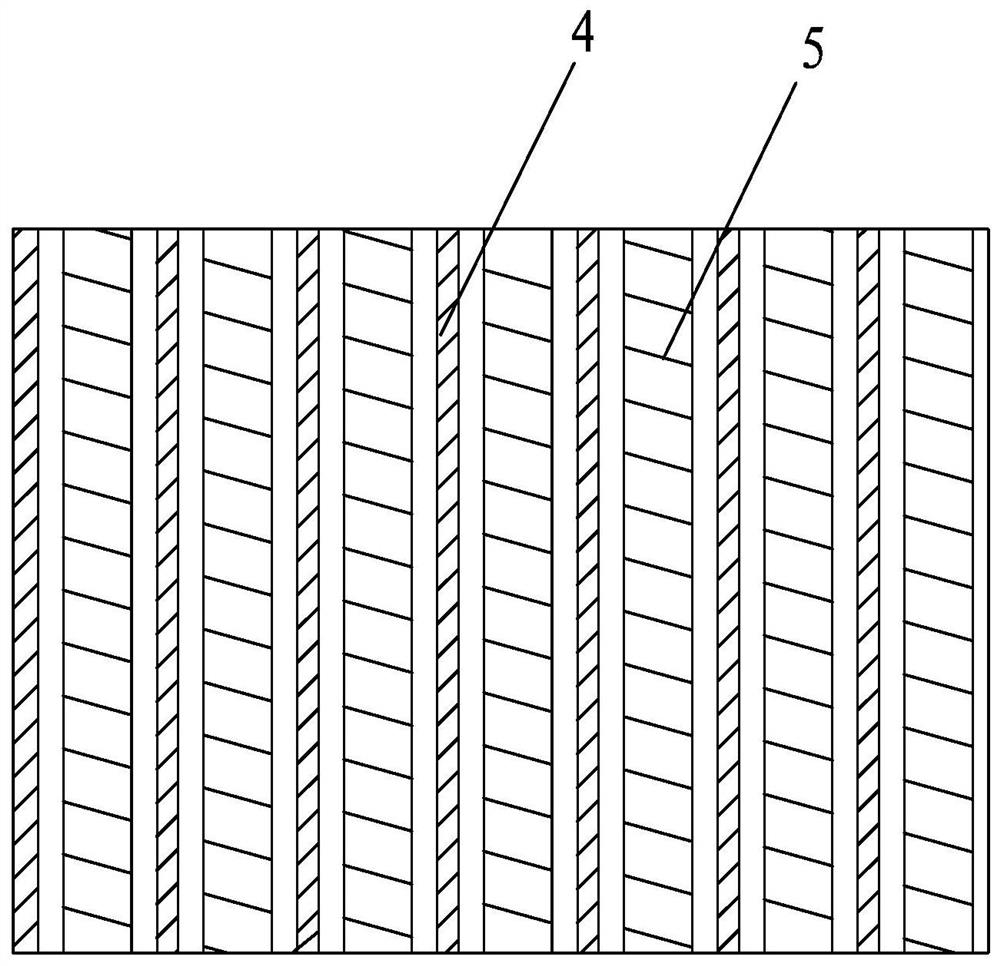

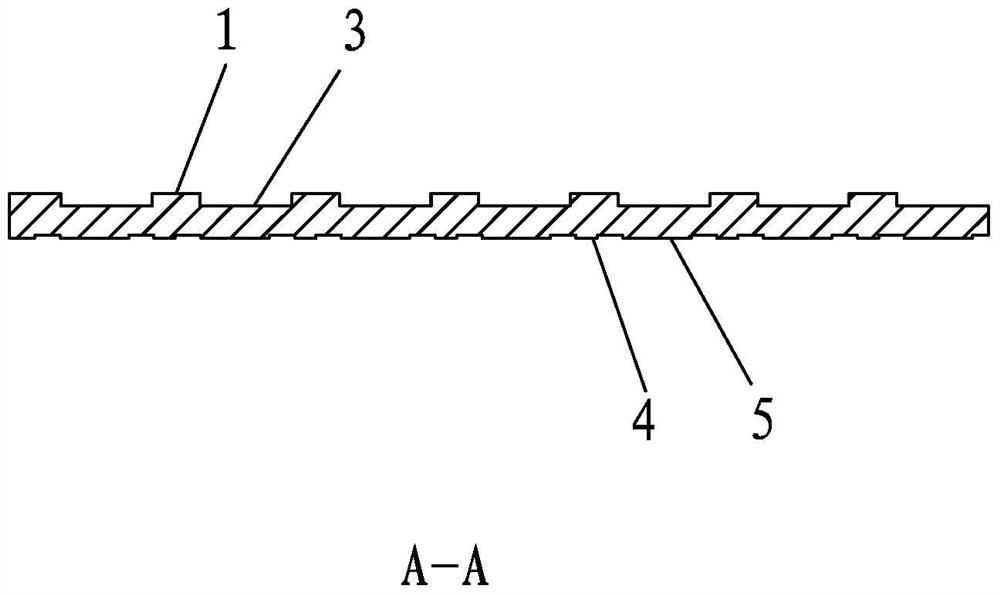

Spinning method adopting core spun yarn and fabric

InactiveCN110144659AGood physical and mechanical propertiesGood moisture wicking functionFilament/thread formingContinuous wound-up machinesMoisture permeabilityMoisture absorption

The invention discloses a spinning method adopting core spun yarn and fabric. The method comprises steps as follows: polyester filaments with multiple special-shaped sections are subjected to vortex spinning, and the core spun yarn is obtained, wherein polyester staple fibers with a cross section constitute a skin layer of the core spun yarn and the polyester filaments with other special-shaped sections constitute a core layer of the core spun yarn; the core spun yarn is subjected to sizing treatment; the core spun yarn after sizing is woven according to preset conditions, and fabric grey cloth is obtained; the fabric grey cloth is subjected to desizing and drying setting, and a finished fabric product is prepared. The spinning method adopts a simple process, the prepared fabric has good moisture absorption and moisture permeability, and the core spun yarn has excellent physical and mechanical properties of both filament core yarn and covered staple fibers.

Owner:SUZHOU UNIV +1

Moisture-absorbing quick-drying fabric and preparation method thereof

InactiveCN112410986AReduce touch pointsImprove performanceWeft knittingGrip property fibresPolymer scienceCombing

The invention provides moisture-absorbing quick-drying fabric and a preparation method thereof. The fabric comprises a hydrophilic inner layer and a quick-drying outer layer, wherein the hydrophilic inner layer is composed of bottom yarn, the quick-drying outer layer is composed of surface yarn, the bottom yarn is combed cotton yarn or twisted yarn of the combed cotton yarn and polyester filamentyarn, the surface yarn is special-shaped superfine denier polyester filament yarn, and the D value and the F value in specification of the bottom yarn are both larger than those in specification of the surface yarn. The preparation method of the fabric comprises the steps that the bottom yarn and the surface yarn are woven into gray fabric, and then after-treatment is carried out on the fabric toobtain the moisture-absorbing and quick-drying fabric; wherein the fabric after-treatment comprises alkali treatment and softening treatment; alkali treatment conditions are as follows: a 1wt.%-2wt.%sodium hydroxide solution is adopted, the bath ratio is 1:50, and the treatment is carried out at 90-100 DEG C for 30-40 minutes; softening treatment conditions are as follows: a silicon-free softening finishing agent is adopted, dipping is performed for 20-30 min at the temperature of 20-30 DEG C, then drying is performed for 3-4 min at the temperature of 100 DEG C, and finally baking is performed for 1-2 min at the temperature of 170-180 DEG C. The fabric has excellent moisture-absorbing and quick-drying properties and good durability.

Owner:义乌市鼎莎针织有限公司

Bamboo fabric raw material production technology

InactiveCN105463673AImprove breathabilityImprove wear resistanceWeft knittingVegetable materialFiberEngineering

A bamboo fabric raw material production technology can provide bamboo fabric raw material having wet-absorbing and ventilating performance as flax and a characteristic of bright color such as chemical fibers and the bamboo fabric raw material can maintain features of bamboo fiber textile. With cooperation between the raw material and other raw material with various performance, weaving raw material having different styles can be produced, so weaving product raw material can be diversified and performance of various fabric raw material can be utilized; and fabric with bright color, great hand feeling and velvet feeling, great elasticity and wet-absorbing and ventilating performance, excellent anti-wrinkling performance, low shrinkage rate and great wearability.

Owner:WUJIANG CITY JUNDA TEXTILE

High-elasticity extinction TSF composite fiber chip fabric and preparation method for same

InactiveCN107385528AIncrease elasticityPermanentArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsYarnFiber

The invention discloses a high-elasticity extinction TSF composite fiber chip fabric which is characterized in that the high-elasticity extinction TSF composite fiber chip fabric is made through extrusion, metering, yarn recombination, filament spraying, cooling, oiling, stretching and shaping, and winding of an extinction PTT constituent melt and an extinction PET constituent melt; the ratio of the extinction PTT constituent to the extinction PET constituent is 6:4-4:6; the extinction PET constituent contain PET and ash; the ratio of PET to ash is 98:2; the extinction PTT constituent contains PTT and ash; and the ratio of PTT to ash is 98.5:1.5. According to the invention, elasticity of the high-elasticity extinction TSF composite fiber chip fabric can be enhanced; certain light shielding effects can be achieved; production efficiency and production quality can be increased; and production cost can be reduced.

Owner:WUJIANG JIALI ADVANCED FIBER CO LTD

Hollow fiber blended fabric

InactiveCN103610248AGood moisture wicking functionWarm and breathableProtective garmentSpecial outerwear garmentsHollow fibrePolymer science

The invention discloses hollow fiber blended fabric. The hollow fiber blended fabric is formed by blended weaving of four kinds of hollow fibers which are Y-shaped cross section recycled polyester filament fibers, viscose hollow fibers, kapok fibers and apocynum venetum fibers. The hollow fiber blended fabric comprises, by weight, 23%-27% of Y-shaped cross section recycled polyester filament fibers, 14%-18% of viscose hollow fibers, 30%-34% of kapok fibers and 21%-33% of apocynum venetum fibers. Due to the fact that the fabric is formed by blended weaving of the four kinds of hollow fibers which are the Y-shaped cross section recycled polyester filament fibers, the viscose hollow fibers, the kapok fibers and the apocynum venetum fibers, the woven fabric has the advantages of being excellent in dry fit function, easy to clean, capable of being dried soon, cool, comfortable, capable of keeping warm, and breathable.

Owner:SUZHOU IND PARK YOUSHUN CLOTHING FACTORY

Cool fiber warp-knitted car seat cushion and preparation method thereof

InactiveCN109518353ACool and comfortableImprove ductilitySeat coveringsWarp knittingTextile fiberPolyester

The invention discloses a cool fiber warp-knitted car seat cushion and a preparation method thereof. The cushion is of a warp-knitted weave, and is formed by performing composite interweaving on polyester drawn textured yarn serving as a skeleton base and cool fiber blended yarn serving as lining yarn, wherein the mass fraction of the lining yarn is 15-45%; the lining yarn is blended yarn of coolfiber and conventional textile fiber, the yarn count is 30 S-50 S, the mass friction of the cool fiber in the lining yarn is 30-70%, and the conventional textile fiber is one or more of tencel, modal,viscose, cotton, bamboo fiber and polyester. By using the cool fiber for spinning and warp knitting, the car seat cushion made by sewing fabric integrates the special functions of the fiber, and in combination with the stable consolidation structure of the warp-knitted fabric and the through hole wicking effect, the car seat cushion has the effects of refreshing, cooling and antibacterial healthcare.

Owner:SHANGHAI DEFULUN CHEM FIBER

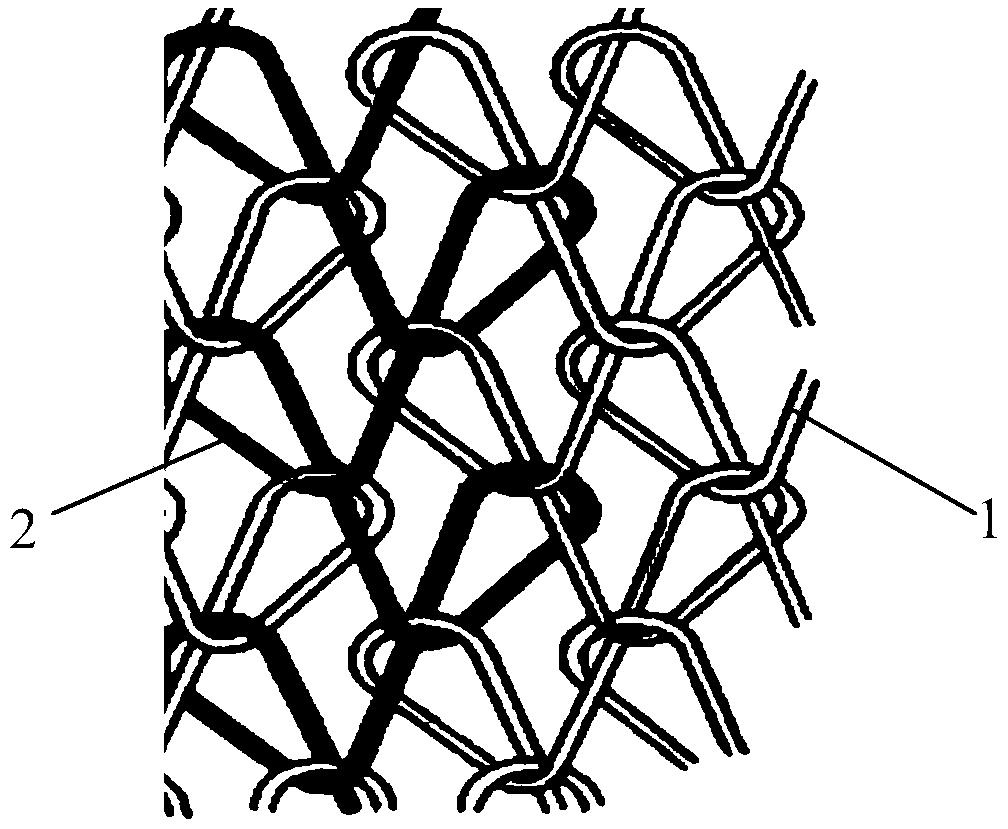

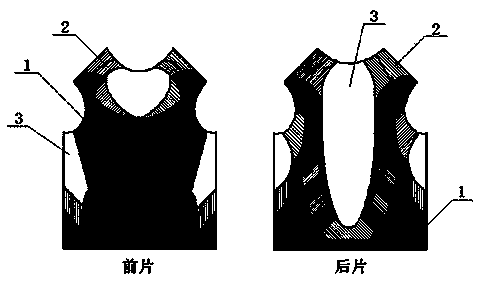

Novel warp-knitted sport suit

InactiveCN103462238AStrong moisture wickingBroad market application prospectsWarp knittingProtective garmentBiomedical engineeringWhite area

The invention discloses a novel warp-knitted sport suit. The novel warp-knitted sport suit consists of a dark area, a light-colored area and a white area, and is made of a warp-knitted fabric which is woven by a Jacquard warp knitting machine and has moisture-absorbing and sweat-releasing functions, wherein the warp-knitted fabric comprises a mesh Jacquard tissue structure, a thin Jacquard tissue structure and a thick Jacquard tissue structure; the dark area is made of a thick Jacquard tissue fabric; the light-colored area is made of a thin Jacquard tissue fabric; the white area is made of a mesh Jacquard tissue fabric. By the adoption of different fabric tissue structures, the novel warp-knitted sport suit disclosed by the invention has good moisture-absorbing and sweat-releasing functions, has uniquely styled patterns, is a high-performance sport suit with integrated properties of comfort, functionality and fashion, and has a wide market application prospect.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

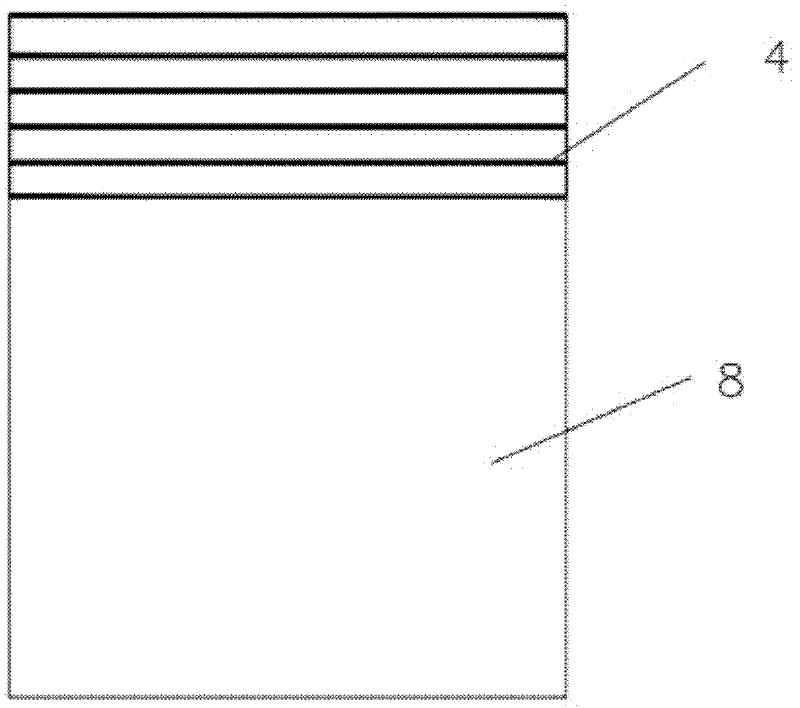

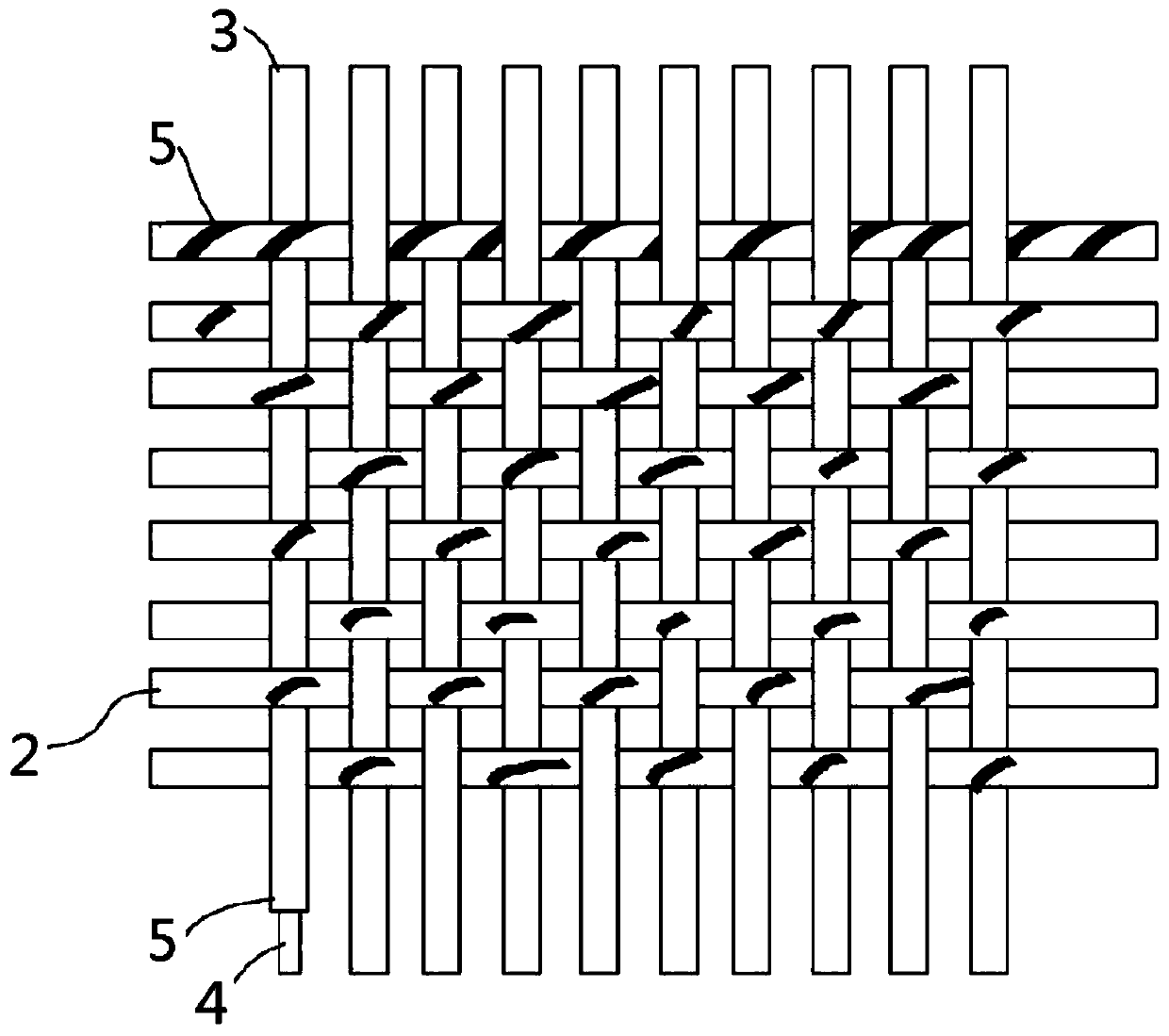

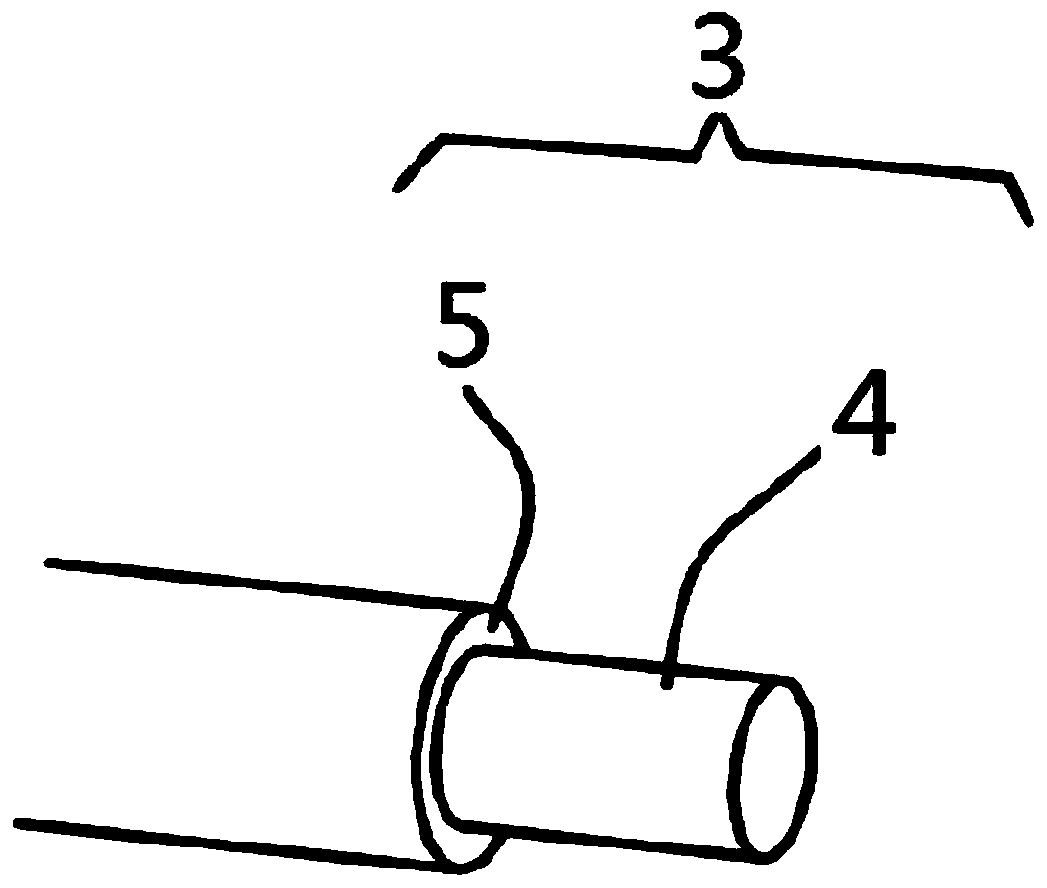

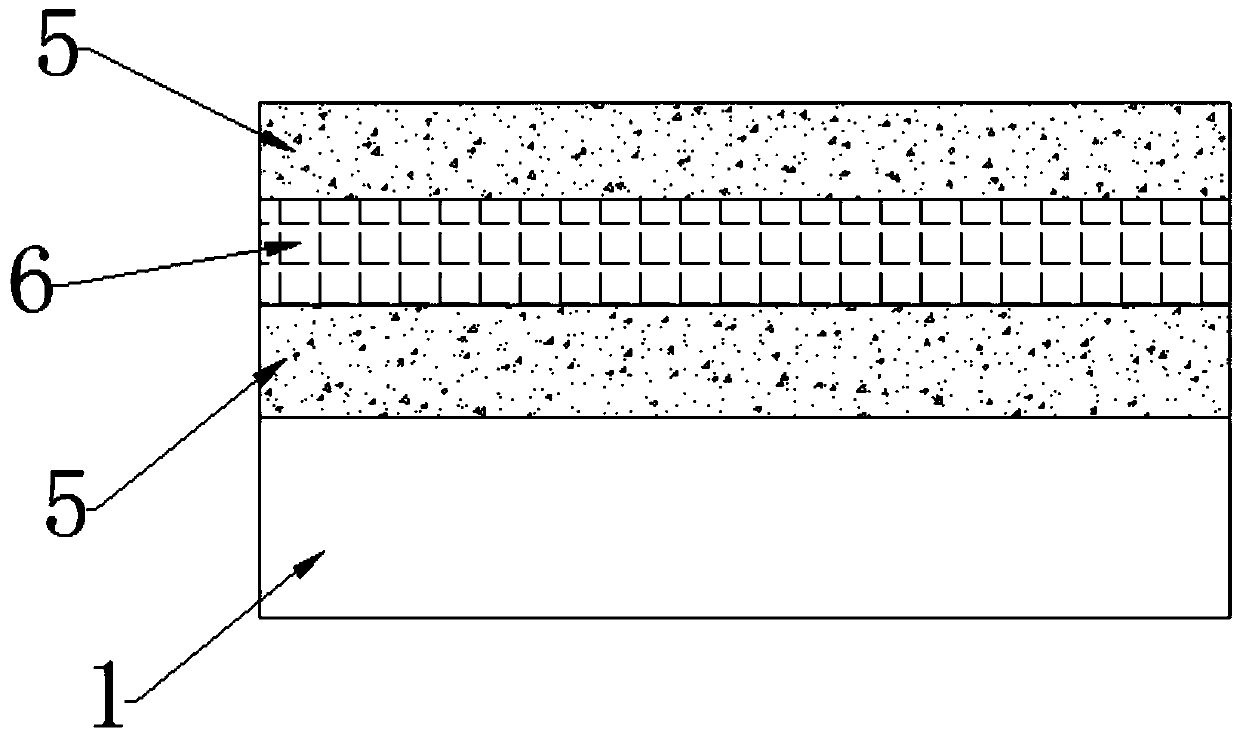

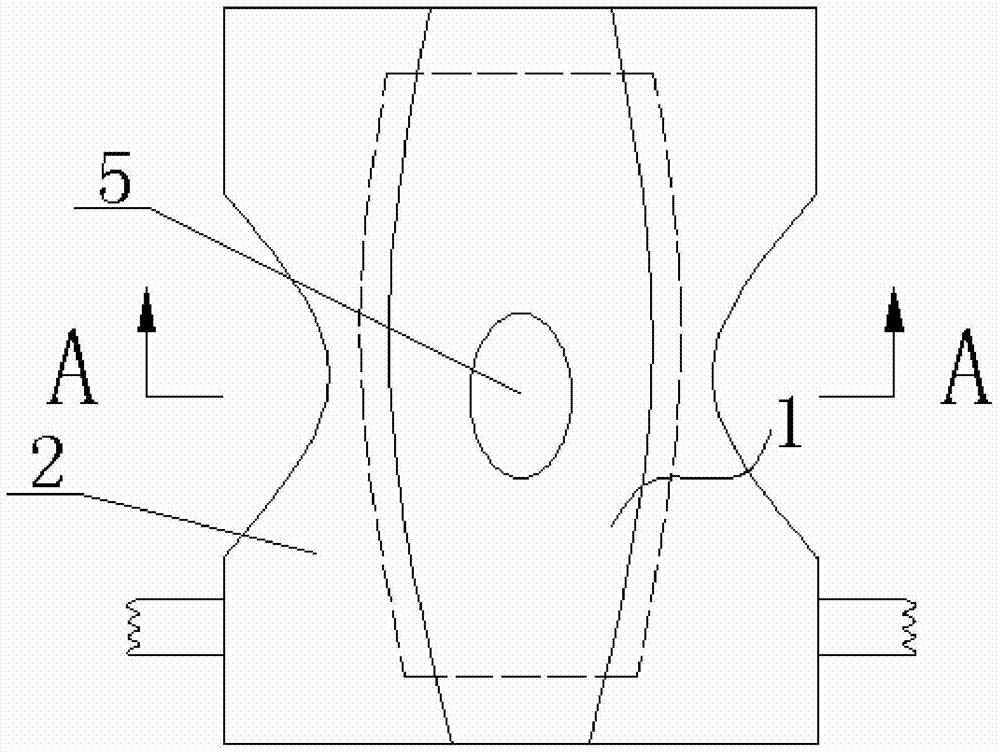

Safety lining cloth with excellent moisture transferring and heat conducting performance and production process thereof

InactiveCN110284333AImprove cooling effectGuaranteed breathabilityGarment special featuresFibre typesSurface layerHeat conducting

The invention discloses safety lining cloth with excellent moisture transferring and heat conducting performance and a production process thereof. The safety lining cloth comprises base layer safety lining cloth, wherein the base layer safety lining cloth is formed through plain weave of warp and weft yarns, the weft yarn is an elastic monofilament, the outer surface of the monofilament is also covered with a composite adhesive layer, and the composite adhesive layer comprises 70-80 parts of a hot melt adhesive, 5-10 parts of Teflon and 3-5 parts of nano-graphene oxide; the safety lining cloth also comprises hygroscopic fiber cloth arranged at the upper side face of the base layer safety lining cloth, wherein the lower side face of the hygroscopic fiber cloth is bonded with the base layer safety lining cloth through the composite adhesive layer on the upper side face of the base layer safety lining cloth, and the upper side face of the hygroscopic fiber cloth is also provided with a point-shaped or strip-shaped or grid-shaped composite adhesive layer. The lining cloth has the excellent moisture transferring, sweat discharging and heat conducting performance, the process comprises preparation of a composite adhesive, yarn making, preparation of the base layer safety lining cloth, improvement of moisture absorbing and transferring and heat conducting performance of the base layer safety lining cloth, preparation of an initial safety lining cloth product and surface layer sizing, the process is simple, and the practicability is strong.

Owner:张家港市杨舍镇美捷配饰设计工作室

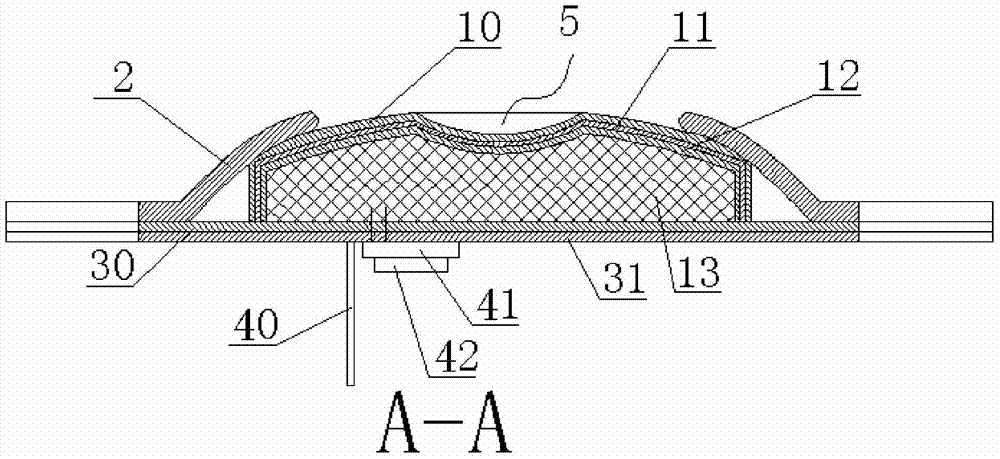

Paper diaper

InactiveCN103800131AGood for skin protectionProtect the skinAbsorbent padsBandagesSurface layerPulp and paper industry

The invention relates to daily supplies, in particular to a paper diaper. The paper diaper comprises a paper diaper body, water-repellency non-woven fabric layers, a bottom film, bottom-layer non-woven fabric, a fixing belt, a humidity sensor and a buzzer, wherein the water-repellency non-woven fabric layers are arranged on the two wings of the top of the paper diaper body; the bottom film is sticked to the bottom face of the paper diaper body; the bottom-layer non-woven fabric is sticked to the bottom face of the bottom film; the paper diaper body is formed by sequentially overlapping a non-woven fabric surface layer, an anti-bacteria guide layer, a cotton core coating layer and a cotton core from top to bottom; the middle of the top of the paper diaper body is concave to form a testis containing groove; one end of the fixing belt is fixedly connected with the bottom-layer non-woven fabric; the other end of the fixing belt is detachably connected with the bottom face of the bottom-layer non-woven fabric through hoop and loop fasteners; the humidity sensor and the buzzer are fixedly connected; the receiving end of the humidity sensor is located in the cotton core. The paper diaper can be used comfortably, has the good moisture guide function, protects skins of infants or patients, and has the automatic prompting function.

Owner:SHINAN BRANCH OF QINGDAO BLUEPRINT CULTURE COMM

Plain woven flash textile fabric

InactiveCN102011248ASimplify the weaving processWith flash visual effectsWoven fabricsEngineeringPlain weave

The invention discloses a plain woven flash textile fabric, which is formed by interweaving warps and wefts, wherein the warps and the wefts are interwoven into a plain woven unit, and diamond wires are adopted as the warps. Flash visual effect of tiny spots is formed on the surface of the plain woven flash textile fabric disclosed by the invention, and the fabric is compact and has simple weaving process.

Owner:WU JIANG TIANXIN QINFENG TEXTILE

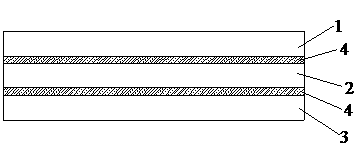

Novel portable outdoor garment material

InactiveCN103101267AMeet the requirements of outdoor activitiesGood moisture wicking functionSynthetic resin layered productsWhole bodyMoisture absorption

The invention discloses novel portable outdoor garment material. The novel portable outdoor garment material comprises a silicon resin film layer, an outer waterproof breathable film and a fiber layer, wherein the outer waterproof breathable film is arranged between the silicon resin film layer and the fiber layer; antibacterial composite nano particle ZnO / TiO2 is evenly coated in a gap between the silicon resin film layer and the fiber layer; and the silicon resin film layer, the outer waterproof breathable film and the fiber layer are bonded and pressed into a whole body through a binder. The novel portable outdoor fabric can completely meet the requirements of outdoor activities, and is good in moisture absorption and sweat releasing functions, good in waterproof permeability and good in comfort.

Owner:SUZHOU ZUNYUAN TEXTILE

Antibacterial moisture-transfer chinlon 6 and preparation method thereof

ActiveCN102677215BReduce contentStrong ability to load copper ionsBiocideFilament forming substance formingPolyamideMoisture absorption

Owner:TAICANG HONGYI CHEM FIBER

A kind of elastic fiber and preparation method thereof

ActiveCN103882538BGood moisture wicking functionSimple preparation processMelt spinning methodsFiberPolyester

Owner:TAICANG RONGWEN SYNTHETIC FIBER

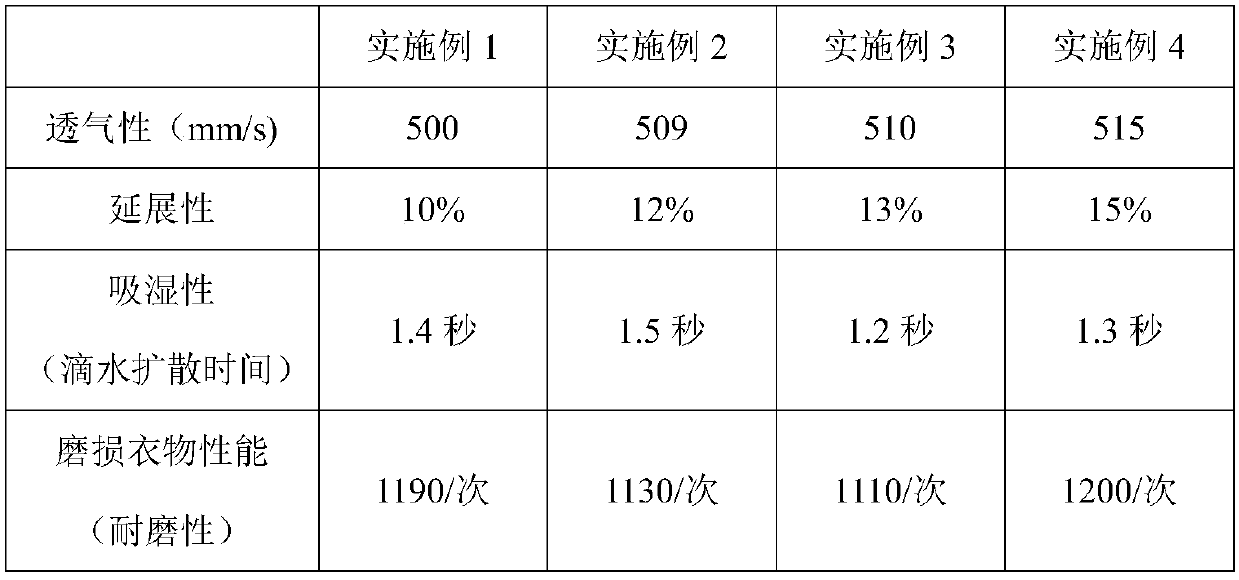

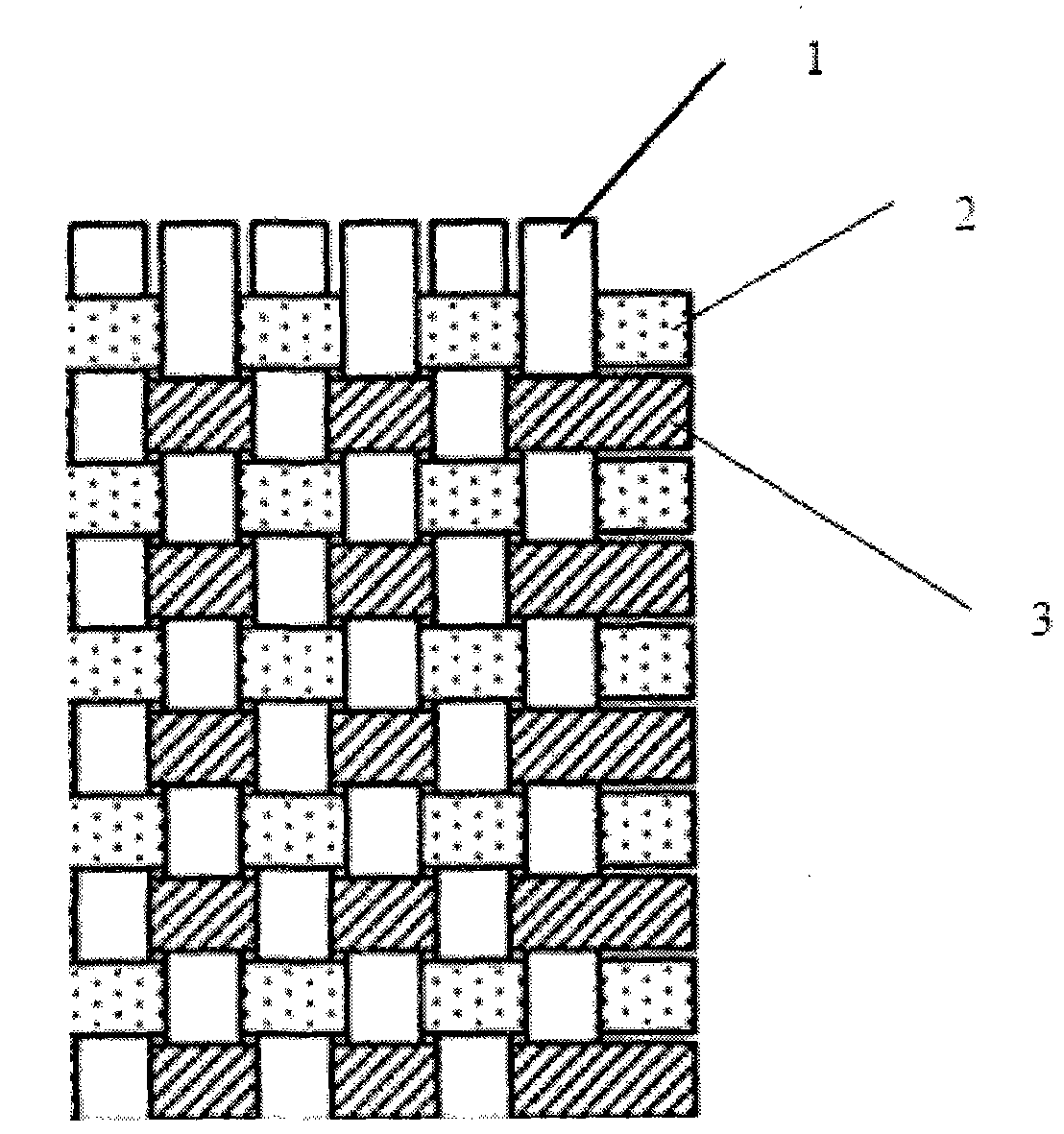

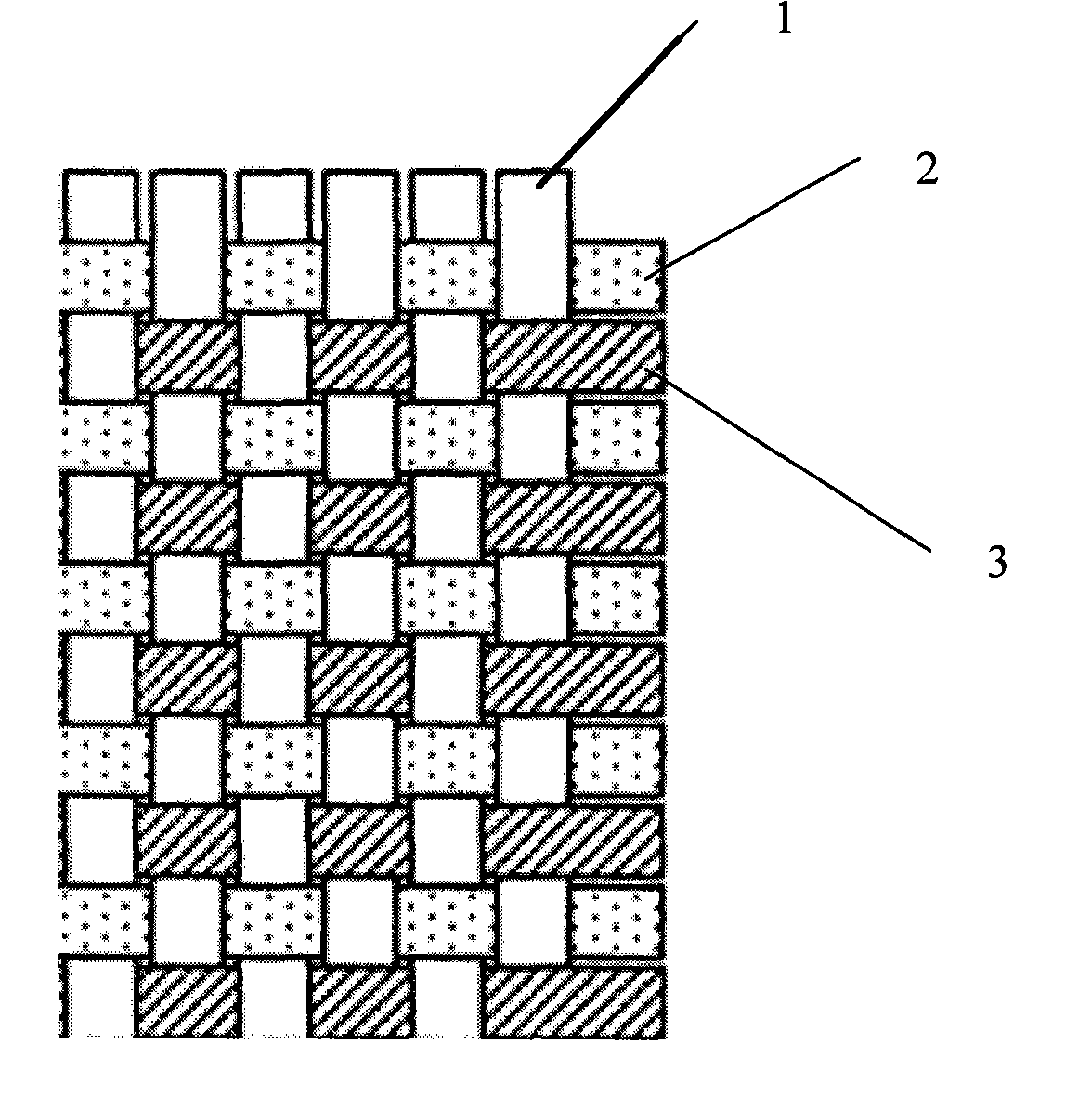

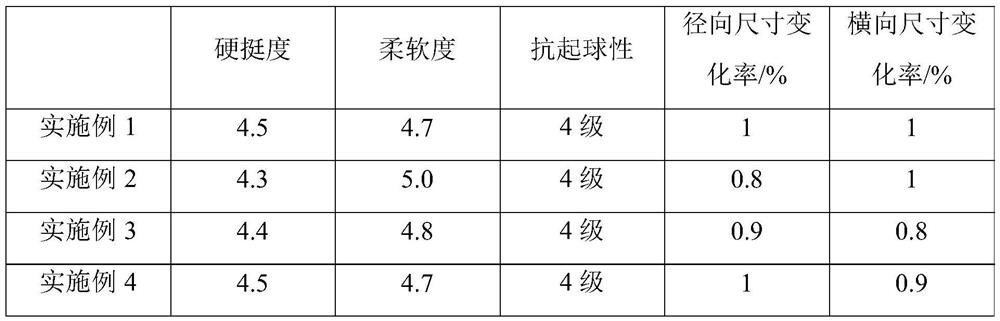

A kind of ultra-light moisture-absorbing and sweat-wicking double-sided weft-knitted square fabric and its production method

The invention provides an ultra-light moisture-absorbing and sweat-wicking double-sided weft-knitted checkered fabric, which is made of 50D / 48F fine denier polyester filament and 50D / 48F fine-denier polyester The polyester elastic yarn is interwoven and processed through moisture absorption and sweat absorption, and the mass ratio of fine denier polyester filament to fine denier polyester elastic yarn is 65%:35%. The invention also provides a production method of an ultra-light moisture-absorbing and sweat-wicking double-sided weft-knitted square fabric, which includes a knitting and weaving process and a post-finishing process. The use of fine denier polyester filaments and fine denier polyester elastic yarns for looping and non-working weaving not only makes the fabric light, but also has a concave-convex three-dimensional effect and good air permeability; by controlling the fine denier polyester filaments and fine denier The mass ratio of polyester elastic yarn is 65%:35%, which can realize the good elasticity of the woven fabric, which is convenient for people to exercise; the moisture-absorbing and sweat-wicking function is used for finishing and reduction cleaning, pickling process, so that the fabric has a good moisture-wicking and sweat-wicking function and soft touch.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Gauze

InactiveCN109811452AImprove protectionNatural antibacterial and antibacterialLayered productsMulti-ply fabricsYarnFiber

The invention discloses gauze. The gauze is interwoven by warp yarns and weft yarns, wherein the warp yarns and the weft yarns are both bamboo-linen-cotton blended yarns; the bamboo-linen-cotton blended yarns are prepared in percentage by mass: 30% to 60% of bamboo fibers, 10% to 20% of linen fibers, and 20% to 50% of cotton fibers; and the warp yarns and the weft yarns are both 10<S> to 60<S> bamboo-linen-cotton single yarns or 21<S> / 2 to 80S / 2 ply yarns. The gauze has natural antibacterial and bacteriostatic functions and good moisture absorption and sweat releasing functions which has goodprotection effect on the human body.

Owner:湖南瑞亚高科集团有限公司

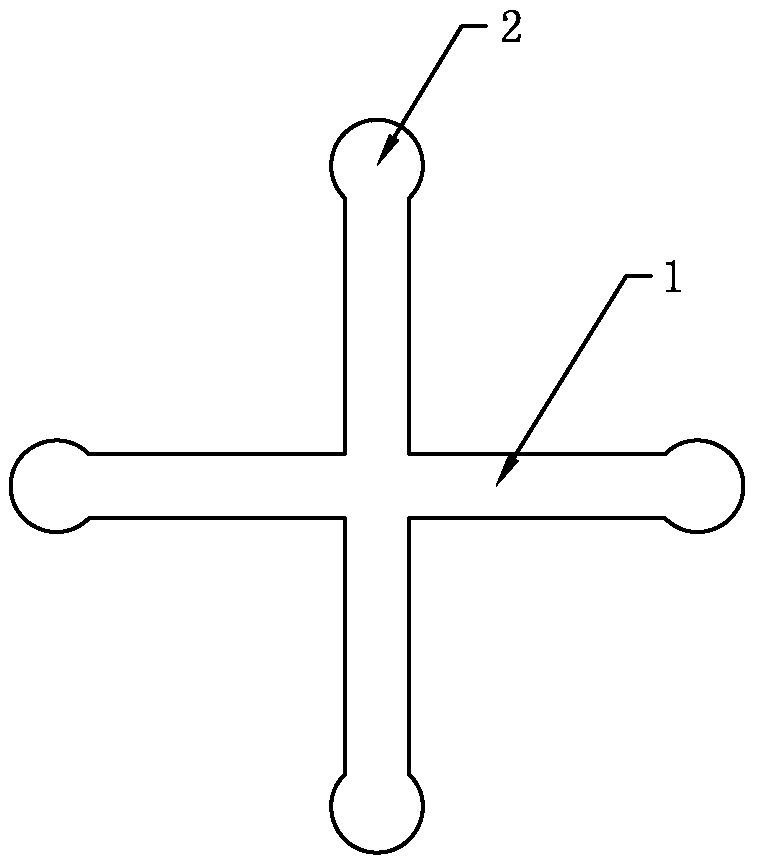

Moisture absorbing and sweat releasing fiber and preparation method thereof

InactiveCN105506760AHigh moisture absorptionImprove moisture removal rateArtificial filament heat treatmentMelt spinning methodsPolyesterMoisture absorption

The invention discloses a moisture absorbing and sweat releasing fiber and a preparation method thereof. The fiber is provided with a polygonal cross section, wherein each corner of a polygon is provided with a strip-shaped body and an expanded top end; a tubular cavity is formed between two adjacent included angles of the polygon in the longitudinal direction of the fiber. The preparation method comprises the following steps of by adopting a melt spinning method, performing spinning forming on a polyester melt at the spinning temperature of 280 to 290DEG C through a special-shaped spinneret plate arranged in a spinning manifold, wherein the spinning speed is 1,100 to 1,200m / min; then performing cooling, drafting, heat setting and drying at the temperature of 90 to 110DEG C to obtain the moisture absorbing and sweat releasing fiber. According to the fiber disclosed by the invention, the moisture absorption rate and the moisture exhaust rate are greatly improved; in addition, the surface smoothness of the fiber is high, and the hand feeling and the softness of the fiber are improved.

Owner:SHANDONG HUA HONG FIBER TECH CO LTD

A moisture-wicking and sweat-wicking school uniform fabric and its preparation method

ActiveCN111267428BMaintain moisture permeabilityGuaranteed amountWeft knittingSynthetic resin layered productsPolyesterYarn

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Canvas for health-care double-layer shoes and production method thereof

The invention discloses canvas for health-care double-layer shoes and a production method of the canvas. The canvas is produced through the following steps that warp yarns and weft warns are formed by combining 16s rotor spinning single yarns, 32s rotor spinning single yarns and 10s rotor spinning single yarns into two strands and twisted through a short yarn two-for-one twister, and raw materials are blended through long stapled cotton, sheep wool and coolplus (moisture absorption and sweat releasing polyester fibers), wherein the blending ratio is 40-50 / 10 / 50-40. Binder warps are adopted to conduct double-layer weaving, particles on the outer layer protrude, the outer layer is attractive and elegant, the inner layer has good air permeability, wear resistance and moisture absorption, and the good moisture absorption and sweat releasing function is achieved. Compared with traditional canvas for shoes, the canvas has the health-care function, the shoes are comfortable to wear, sweating is relieved, and foot odors, beriberi and like of the feet of a user are relieved.

Owner:SHANDONG LICHANG TEXTILE TECH

Anti-wrinkle imitated silk fabric and processing technology thereof

The invention discloses an anti-wrinkle imitated silk fabric and a processing technology thereof. The anti-wrinkle imitated silk fabric is prepared from composite filament of anti-wrinkle PET fiber filament and spandex core-spun yarn and real silk yarn; the composite filament of the anti-wrinkle PET fiber filament and the spandex core-spun yarn is located on the outer side of the fabric; the real silk yarn is located on the inner side of the fabric; and the real silk yarn is completely covered with the composite filament of the anti-wrinkle PET fiber filament and the spandex core-spun yarn. The anti-wrinkle PET fiber filament is prepared after spinning pulp of PET fiber filament and anti-wrinkle finishing liquid are mixed, so that the anti-wrinkle performance of the fabric can be remarkably improved, and the washing resistance and wearability of the fabric are improved. The anti-wrinkle imitated silk fabric is stable in size, smooth in hand feeling, soft and comfortable, has the texture like real silk, and has the characteristics of good moisture penetrability, air permeability, wrinkle resistance and the like.

Owner:铭锋(福建)织造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com