One-step pattern different dyeing cool composite fiber and preparation method thereof

A composite fiber and color technology, applied in fiber processing, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve the problem of increased fiber wool, broken ends, decreased fiber spinnability, and difficult heat conduction paths Formation and other problems, to achieve the effect of high breaking strength, obvious cooling effect, and meet individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

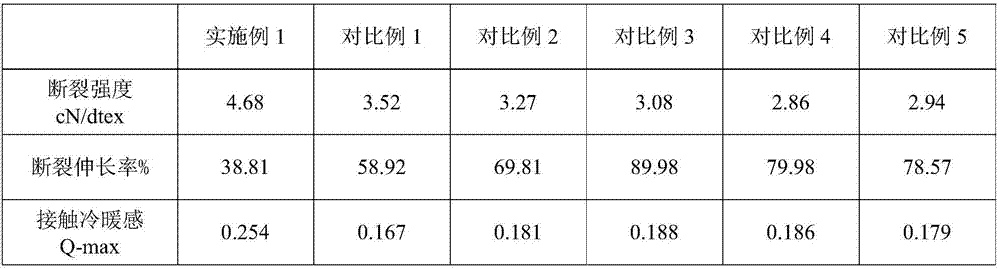

Examples

Embodiment 1

[0030] (1) Add the polyethylene slices of the polyethylene slice skin layer and the polyamide slices of the polyamide slice core layer into the A and B feed bins of the composite spinning machine respectively, and enter the dryer for drying. The water content of the polyethylene slices reaches below 20ppm, The water content of polyamide slices is below 200ppm;

[0031] The dried polyethylene chips and polyamide chips are respectively fed into the screw extruder for heating and plasticizing. The plasticizing temperature of polyethylene chip screw extrusion is 168°C-175°C, and the plasticizing temperature of polyamide chip screw extrusion is 253 ℃-260℃;

[0032] After polyethylene chips and polyamide chips are melted and plasticized by the screw, they are metered by two metering pumps according to the weight ratio of 30:70, and the melts are extruded into the same composite component to form the cross-sectional structure required by the design, and then pass through the spinnere...

Embodiment 2

[0036] On the basis of Example 1, the plasticizing temperature of polyethylene chip screw extrusion was changed to 210° C.-220° C., the draw ratio was 2.94, and other process parameters and conditions were the same as in Example 1.

[0037] The obtained one-step color-differentiated cool-feeling composite fiber has a cortex structure with a bare core layer in the length direction of the fiber, and the length of the structure in the length direction of the fiber is 1-10 mm, and every two adjacent The spacing between the structures is 1-10mm, the linear density is 70D, the breaking strength is 4.21cN / dtex, the elongation at break is 59.02%, and the Q-max of contact cold and warm feeling is 0.268, which has obvious contact cold feeling. The performance can well meet the requirements of use.

Embodiment 3

[0039] On the basis of Example 2, only the weight ratio of polyethylene chips and polyamide chips was changed to 40:60, and other process parameters and conditions were the same as in Example 2.

[0040]The obtained one-step color-differentiated cool-feeling composite fiber has a cortex structure with a bare core layer in the length direction of the fiber, and the length of the structure in the length direction of the fiber is 1-10 mm, and every two adjacent The distance between the structures is 1-10mm, the linear density is 70D, the breaking strength is 4.05cN / dtex, the elongation at break is 65.23%, and the Q-max of contact cold and warm feeling is 0.249, which has a relatively obvious contact cold feeling. The performance can well meet the requirements of use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com