Patents

Literature

36results about How to "Natural antibacterial and antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Germanium viscose fiber and preparation method thereof

ActiveCN102011205ASmall particle sizeHigh strengthArtificial filament washing/dryingArtificial filaments from viscoseHuman environmentZinc

The invention relates to a germanium viscose fiber, which is prepared from hemp pulp and nano germanium ores serving as raw materials, wherein the content of the nano germanium ores is 1 to 30 percent of the weight of the finished germanium viscose fiber product; the germanium viscose fiber is prepared by preparation of the germanium ore pulp, preparation of soluble viscose, preparation of germanium pulp, preparation of viscose spinning stock solution, spinning, post treatment and drying process; the hemp pulp and the nano germanium ores are used as the raw materials, the hemp pulp and the nano germanium ores serving as the raw materials are renewable resources, and the discarded fabrics of viscose fiber can be biologically degraded, so accumulative influence on the environment is not caused, and the environment is protected; the nano germanium has small grain diameter and is dispersed uniformly in the fiber; the prepared fiber product has high strength and good textile processing performance by adopting viscose and coagulating bath composite denaturation technology; and zinc sulfate with high pollution to the human environment is not used any more, so the harm to the environment is reduced in the fiber production process.

Owner:潍坊欣龙生物材料有限公司

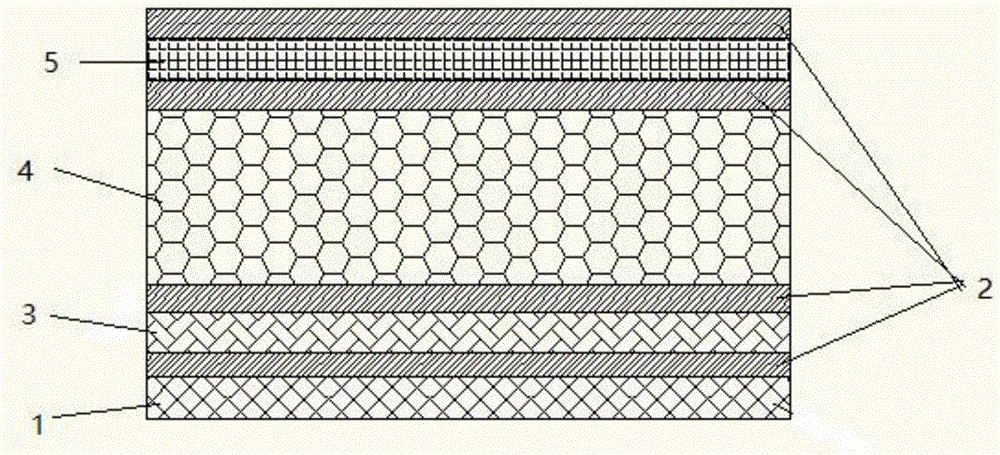

Waterproof and environment-friendly paper honeycomb composite board for automotive interior, and preparation method of composition board

The invention discloses a waterproof and environment-friendly paper honeycomb composite board for automotive interior, and a preparation method of the composition board. The waterproof and environment-friendly paper honeycomb composite board is formed by compounding a piece of non-woven fabric, a hot melt adhesive membrane, a bamboo fiber felt, another hot melt adhesive membrane, a paper honeycomb core, another hot melt adhesive membrane, a GMT felt and another hot melt adhesive membrane from bottom to top; each hot melt adhesive membrane is prepared from the following raw materials in parts by weight: 20-30 parts of ternary co-polypropylene, 10-20 parts of a vinyl-propylene copolymer, 5-10 parts of C5 / C9 copolymer resin, 2-4 parts of high molecular weight polypropylene (PP) wax and 1-2 parts of an antioxidant; the bamboo fiber felt is prepared from the following raw materials in parts by weight: 40-50 parts of bamboo fiber, 5-10 parts of brucite powder, 5-8 parts of sepiolite powder, 10-15 parts of a urea-formaldehyde resin adhesive, 7-12 parts of silicone acrylic emulsion, 1-2 parts of nano titanium dioxide and 4-6 parts of castor oil. The waterproof and environment-friendly paper honeycomb composite board has the characteristics of being less in odor and less in volatile organic compounds (VOC), resisting low temperature and heat aging, being permanent in moisture resistance, mould-proof and free from undesirable odor, and the like, and is non-toxic and environmentally-friendly.

Owner:合肥杰迈特汽车新材料有限公司

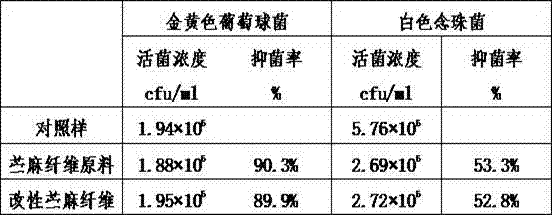

Modification method of ramie fibers

InactiveCN107447516AChange orientationImprove finenessBiochemical fibre treatmentGrip property fibresState of artMildew

The invention relates to a modification method of ramie fibers. The modification method comprises the following steps: step 1, proportioning cottonseed shell ash, rice straw ash and sodium hydroxide according to a weight ratio of 10 to (5-8) to (1-2) to obtain a mixture, adding the mixture into water which is 10-15 times the total weight of the mixture, boiling and preparing a modified solution; step 2, adding the ramie fibers into the modified solution to be completely immersed, and cooking for 2-4 hours; and step 3, taking the ramie fibers out of the modified solution, washing the ramie fibers with clear water, and naturally drying the ramie fibers in air. Compared with the prior art, the method disclosed by the invention has the advantages that characteristics such as degree of crystallinity and degree of orientation of the ramie fibers are improved, a prodding and itching feeling generated when the ramie fibers are in contact with a human body is eliminated to certain extent, unique fiber hole cavity structures of the ramie fibers are not damaged, and grooved cavities in the middle of the fibers are not damaged, so that characteristics such as bacteria resistance and bacteriostasis, deodorization and adsorption, moisture absorption and ventilation, mildew prevention and wear resistance of the ramie fibers can be kept.

Owner:厦门盛方生态技术集团有限公司

Ramie fiber mattress production method

InactiveCN107326532AChange in crystallinityChange orientationBiochemical fibre treatmentAbrasion resistant fibresPunchingThermoforming

The invention relates to a ramie fiber mattress production method which includes the steps: firstly, quantitatively feeding and carding ramie fibers; secondly, performing mesh laying, needle punching and thermoforming; finally, cutting the ramie fibers. The ramie fibers adopt modified ramie fibers, a modified method of the ramie fibers includes the steps: firstly, matching cotton seed shell ash, rice straw ash and sodium hydroxide according to the weight ratio of 10:(5-8):(1-2), adding the cotton seed shell ash, the rice straw ash and the sodium hydroxide into water with the weight accounting for 10-15 times of the total weight of the cotton seed shell ash, the rice straw ash and the sodium hydroxide, and boiling mixture to prepare modified solution; secondly, adding the ramie fibers into the modified solution, enabling the ramie fibers to be completely immersed by the modified solution, and stewing mixture for 2-4h; thirdly, taking out the ramie fibers from the modified solution, washing the ramie fibers by the aid of clear water, and naturally air-drying the ramie fibers. According to the method, characteristics such as crystallizing degree and orientation degree of the ramie fibers are changed, prodding and itching sensation is removed when the ramie fibers contact with human bodies to some extent, and unique pore cavity structures and middle ditch-shaped cavities of the ramie fibers cannot be broken, so that a prepared ramie fiber mattress keeps characteristics such as natural bacterium resistance, bacterium inhibition, odor removal, adsorption, moisture absorption, permeability, mildew resistance and abrasion resistance of the ramie fibers.

Owner:厦门盛方生态技术集团有限公司

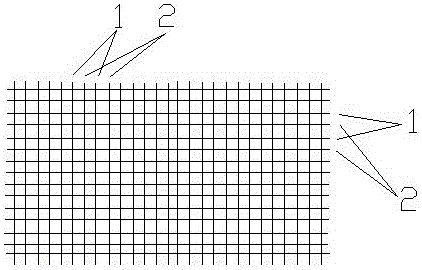

Bamboo fiber gauze kerchief deodorization, sterilization and anti-radiation fabric

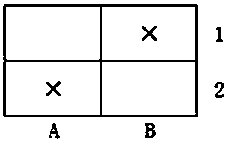

InactiveCN106003867AStable supportAnti-electromagnetic radiationSynthetic resin layered productsWoven fabricsPolyesterYarn

The invention relates to a bamboo fiber gauze kerchief deodorization, sterilization and anti-radiation fabric. The fabric is formed by interweaving cotton fiber yarns (1) as warps and bamboo fiber yarns (2) as wefts, several core-spun yarns (3) are embedded into the cotton fiber yarns (1) and formed in the mode that wavy metal ion fiber is wrapped with silk. A lining layer is combined to the back face of the fabric. A fiber face layer and a waterproof layer are fixedly arranged on the upper surface and the lower surface of the lining layer respectively. An inflaming retarding layer formed through adhesion of inflaming retarding powder is fixed to the surface of the outer side of the waterproof layer, the lining layer is formed by interweaving polyester yarns, breathable holes are evenly arrayed in the lining layer, the fiber face layer is formed by interweaving warps and wefts, and soybean fiber is interwoven in the warps and the wefts. The fabric achieves deodorization, sterilization and radiation resistance.

Owner:JIANGYIN BEIYE TEXTILE

Germanium viscose fiber and preparation method thereof

ActiveCN102011205BHave a cumulative effectSmall particle sizeArtificial filament washing/dryingArtificial filaments from viscoseSulfateHuman environment

Owner:潍坊欣龙生物材料有限公司

Bamboo fiber gauze kerchief fabric good in use performance and resistant to radiation

The invention relates to a bamboo fiber gauze kerchief fabric good in use performance and resistant to radiation. The fabric is formed by interweaving cotton fiber yarn (1) as the warp and bamboo fiber yarn (2) as the weft. A plurality of core-spun yarns (3) are embedded in the cotton fiber yarn (1) and formed by wrapping metal ion fiber by silk, and the metal ion fiber is wavy. A lining layer is compounded on the back side of the fabric, the lining layer is formed by weaving weft, kapok fiber and ramie are adopted as warp and weft respectively, the diameter of the kapok fiber is 4.16 micron, the diameter of the ramie is 18.32 micron, the warp density is 16.9 pieces per centimeter, and the weft density is 26.7 pieces per centimeter. The fabric is good in use performance and resistant to radiation.

Owner:JIANGYIN ZEWAN TRADE

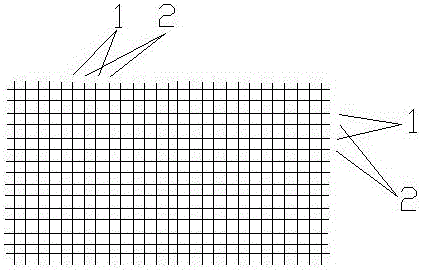

Gauze

InactiveCN109811452AImprove protectionNatural antibacterial and antibacterialLayered productsMulti-ply fabricsYarnFiber

The invention discloses gauze. The gauze is interwoven by warp yarns and weft yarns, wherein the warp yarns and the weft yarns are both bamboo-linen-cotton blended yarns; the bamboo-linen-cotton blended yarns are prepared in percentage by mass: 30% to 60% of bamboo fibers, 10% to 20% of linen fibers, and 20% to 50% of cotton fibers; and the warp yarns and the weft yarns are both 10<S> to 60<S> bamboo-linen-cotton single yarns or 21<S> / 2 to 80S / 2 ply yarns. The gauze has natural antibacterial and bacteriostatic functions and good moisture absorption and sweat releasing functions which has goodprotection effect on the human body.

Owner:湖南瑞亚高科集团有限公司

Reflective sparkled anti-radiation shell fabric of bamboo-fiber gauze kerchief

InactiveCN105919192AStable supportAnti-electromagnetic radiationProtective fabricsSynthetic resin layered productsEngineeringIon

The invention relates to a reflective sparkled anti-radiation shell fabric of bamboo-fiber gauze kerchief. The shell fabric is interwoven from cotton fiber yarns (1) as warps and bamboo-fiber yarns (2) as wefts; multiple core-spun yarns (3) are embedded in the cotton-fiber yarns (1); each of the core-spun yarns (3) is formed by coating a wavy metal-ion fiber with silk. The back of the shell fabric is composited with a liner layer which is interwoven from warps and wefts by an inter-drift weaving method; the warps and the wefts are made of nylon filaments, and specifically, each warp is composed of 36 fibers with fiber number of 40 deniers and each weft is composed of 24 fibers with fiber number of 70 denier, and the warps are characterized in that every four warps are controlled by one reed. The shell fabric is reflective, sparkled and anti-radiation.

Owner:JIANGYIN SHANGFENG TEXTILE

Bamboo fiber gauze scarf anti-radiation fabric with far infrared radiating function

The invention relates to bamboo fiber gauze scarf anti-radiation fabric with a far infrared radiating function. The fabric is formed by interweaving cotton fiber yarn (1) serving as warp and bamboo fiber yarn (2) serving as weft, several cored wires (3) are embedded in the cotton fiber yarn (1), each cored wire (3) is formed by coating metal ion fiber with silk, and the metal ion fiber is wavy. A lining layer is composited on the back of the fabric and formed by interweaving warp and weft which are arranged in a mutually perpendicular manner, the warp is common fiber yarn, and the weft is far infrared fiber yarn. The fabric has the far infrared radiating function and is resistant to radiation.

Owner:JIANGYIN YIFAN IND & TRADE

A kind of bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556260BEvenly dispersedImprove spinnabilityArtificial filaments from viscoseWet spinning methodsPolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber and a preparation method thereof. The fiber is obtained by spinning after mixing bamboo charcoal slurry and viscose, and the content of the nano-bamboo charcoal is 0.1% to 10% of the weight of the finished fiber. The specific indicators of bamboo charcoal viscose fiber finished products include: dry breaking strength of 1.6~3.5cN / dtex, dry breaking elongation of 16~20%, dry strength coefficient of variation CV≤18%, dry breaking elongation coefficient of variation CV≤8 %, defect ≤ 4mg / 100, bamboo charcoal content 0.1-10%, antibacterial rate > 99.9%, ammonia adsorption > 50%, color fastness to washing 4-5. The finished fiber produced by the invention has the characteristics of high strength, good adsorption performance, excellent antibacterial effect, uniform color and strong color fixation, and provides high-quality bamboo charcoal viscose fiber raw materials for making textiles.

Owner:YIBIN HIEST FIBER +1

Reasonable-structure anti-irradiation fabric for bamboo fiber gauze kerchief

The invention relates to a radiation-resistant fabric with reasonable structure of bamboo fiber gauze. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. The back of the fabric is compounded with a lining layer, the lining layer is woven from warp threads and weft threads, the warp threads are made of protein fibers, and the weft threads are made of acrylic fibers, wherein the diameter of the protein fibers is 42.1 μm, the fineness is 189 dtex, and the diameter of the acrylic fibers is 6.52 μm , the fineness is 189dtex, the warp density is 54.8 threads / cm, the weft density is 54.1 threads / cm, and the weft double weave structure is adopted. The invention has reasonable structure and anti-radiation.

Owner:JIANGYIN JIANGZHOU PRINTING & DYEING CO LTD

Free-static irradiation-resistant fabric of bamboo fiber gauze kerchief

InactiveCN107518478AStable supportAnti-electromagnetic radiationWeft knittingProtective equipmentFiberWave shape

The invention relates to a non-static anti-radiation fabric of bamboo fiber gauze. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. A lining layer is compounded on the back of the fabric, and printing is printed on the lining layer. The lining layer is composed of 75D / 36F plain stitch loops and 75D / 144F elongated sinker arc loop loops through weft knitting. As a result, a layer of antistatic agent is attached to the printed lining layer. The invention has no static electricity and anti-radiation.

Owner:JIANGYIN HAOZHOU TEXTILE CO LTD

Bamboo fiber gauze kerchief elegant and non-deformation radiation resistant fabric

InactiveCN107541835AStable supportAnti-electromagnetic radiationWoven fabricsYarnRadiation resistantCotton fibre

The invention relates to an elegant and non-deformed anti-radiation fabric of bamboo fiber gauze. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. A lining layer is compounded on the back of the fabric, and the lining layer is composed of a velvet layer, a sponge layer and a base cloth layer sequentially from top to bottom. The invention is elegant, non-deformable and anti-radiation.

Owner:黄磊

Anti-radiation fabric with good heat-preservation effect for bamboo-fiber gauze kerchief

InactiveCN106079706AStable supportAnti-electromagnetic radiationGarment special featuresLayered productsFiberEngineering

The invention relates to an anti-radiation fabric with good heat-preservation effect for bamboo-fiber gauze kerchief. The anti-radiation fabric is interweaved by using cotton-fiber yarns (1) as warps and using bamboo-fiber yarns (2) as wefts; a plurality of core spun yarns (3) are embedded in the cotton-fiber yarns (1) and are formed by wrapping silks on metal-ion fibers which are in a wavy shape. The back surface of the fabric is compounded with a lining layer which comprises a lining layer body weaved by warp yarns and weft yarns; the warp yarns and the weft yarns are interweaved into a three-up and three-down tabby structure; a jacquard layer is arranged on the upper surface of the lining layer body. The anti-radiation fabric is good in heat-preservation effect and is anti-radiation.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Multifunctional anti-radiation bamboo-fiber gauze kerchief fabric

InactiveCN106079705AStable supportAnti-electromagnetic radiationGarment special featuresLayered productsCotton fibreWave shape

The invention relates to multifunctional anti-radiation bamboo-fiber gauze kerchief fabric. The fabric is formed by interweaving cotton fiber yarns (1) serving as warps and bamboo fiber yarns (2) serving as wefts, wherein a plurality of core-spun yarns (3) are embedded in each cotton fiber yarn (1), the core-spun yarns (3) are obtained by coating metal ion fibers with silk, and the metal ion fibers are wave-shaped. A lining layer is compounded in the back surface of the fabric, the lining layer comprises a lining layer body formed by weaving the wefts and the warps, the wefts and the warps are interweaved to form a plain structure with three upper layers and three lower layers, a jacquard weave layer is formed on the upper surface of the lining layer body, a patch layer is arranged on the upper surface of the jacquard weave layer, and a plurality of patches are arranged on the patch layer. The multifunctional anti-radiation bamboo-fiber gauze kerchief fabric has abundant functions and is anti-radiation.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

Overall compact, firm and anti-radiation fabric for bamboo fiber gauze kerchief

The invention relates to overall compact, firm and anti-radiation fabric for a bamboo fiber gauze kerchief. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft, several pieces of core-spun yarn (3) are inlaid in each piece of cotton fiber yarn (1) and formed by coverage of metal ion fibers with silk, and the metal ion fibers are wave-shaped. A lining layer is composited on the back surface of the fabric, and the weave structure of the lining layer comprises sixty-eight weft-faced weave or warp-faced weave from left to right. The fabric is compact, firm and anti-radiation overall.

Owner:JIANGYIN YASHUN GARMENT

Bamboo fiber gauze kerchief touch strong radiation-resistant fabric

InactiveCN107541837AHigh transparencyImprove breathabilityLayered productsWoven fabricsRadiation resistantSurface layer

The invention relates to a bamboo fiber gauze kerchief touch strong radiation-resistant fabric. The fabric is formed by weaving warps and wefts using cotton fiber yarns (1) as warps and bamboo fiber yarns (2) as wefts. A plurality of core-spun yarns (3) are embedded in the cotton fiber yarn (1). The core-spun yarn (3) is formed by wrapping silk on a metal ion fiber, and the metal ion fiber is wavy. A lining layer is composited on the back surface of the fabric. The lining layer comprises a lining layer body formed by weaving warps and wefts. The warps and the wefts interweave to form a three-up-three-down plain weave. The upper surface of the lining layer body is provided with a jacquard layer. The upper surface of the jacquard layer is provided with a flocking layer. The lower surface ofthe lining layer body is provided with a ventilating layer. The fabric has good touch and is resistant to radiation.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

Dry, comfortable and anti-radiation fabric of bamboo fiber gauze kerchief

InactiveCN106113744AStable supportAnti-electromagnetic radiationLayered productsClothingsIonWave shape

The invention relates to a dry, comfortable and anti-radiation fabric of bamboo fiber gauze. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. A lining layer is compounded on the back of the fabric, and the lining layer includes a pure cotton lining layer, a bamboo charcoal fiber lining layer, and a soybean fiber / cotton fiber blended lining layer compounded in sequence. The invention is dry, comfortable and anti-radiation.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

Bamboo fiber gauze kerchief triple-inflaming-retarding and anti-radiation fabric

InactiveCN106003901AHigh transparencyImprove breathabilityLayered productsWoven fabricsYarnCotton fibre

The invention relates to a bamboo fiber gauze kerchief triple-inflaming-retarding and anti-radiation fabric. The fabric is formed by interweaving cotton fiber yarns (1) as warps and bamboo fiber yarns (2) as wefts, several core-spun yarns (3) are embedded into the cotton fiber yarns (1) and formed in the mode that wavy metal ion fiber is wrapped with silk. A lining layer is combined to the back face of the fabric. Micropores are formed in the two faces of the lining layer respectively, an inflaming retarding sizing agent leaks into the micropores, and one face of the lining layer is coated with a waterproof inflaming retarding layer. The fabric achieves triple-inflaming retarding and radiation resistance.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Highly-layered radiation-resistant fabric of bamboo fiber gauze kerchief

InactiveCN106113741AImprove support performanceExpand the scope of useLayered productsClothingsWoven fabricWave shape

The invention relates to a bamboo fiber gauze scarf which has a strong sense of hierarchy and is an anti-radiation fabric. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. A lining layer is compounded on the back of the fabric, and the lining layer includes a lining layer. The surface of the lining layer is provided with a non-woven fabric surface layer, and several small lining layers are arranged between the lining layer and the non-woven fabric surface layer. block, and the small lining layer block is compounded on the lining layer through an adhesive. The invention has a strong sense of layering and anti-radiation.

Owner:JIANGYIN JIAYI GIFT

Radiation-shielding fabric with high expansion-contraction force for bamboo fiber gauze kerchief

InactiveCN106113742AStable supportAnti-electromagnetic radiationWeft knittingLayered productsFiberYarn

The invention relates to a radiation-shielding fabric with high expansion-contraction force for a bamboo fiber gauze kerchief. The fabric is formed by longitudinally and laterally interweaving cotton fiber yarn (1) taken as the wrap and bamboo fiber yarn (2) taken as the weft. The cotton fiber yarn (1) is internally provided with a little core-spun yarn (3) which is made from silk-coated metal ion fibers, and the metal ion fibers are wave-shaped. The back of the fabric is provided with a lining layer, which is made from 150D / 48F flat stitches, 32 ST / A terry stitches with elongated sinker loops, and 150D / 96F terry stitches with elongated sinker loops, which are sequentially inter-looped through weft knitting. A layer of a warming medicine is attached to the dual-color lining layer. The fabric is high in expansion-contraction force and can resist radiation.

Owner:JIANGYIN CHUNLAN TEXTILE

Bamboo charcoal cellulose fiber and manufacturing method thereof

ActiveCN100558954CImprove solubilityHarm reductionArtificial filaments from cellulose solutionsProduction rateCellulose fiber

The invention discloses a method for manufacturing bamboo charcoal cellulose fiber, which is to dissolve cellulose through ionic liquid to make spinning stock solution, then add nano-bamboo charcoal to make denatured spinning stock solution, and then pass through a coagulation bath made of ionic liquid aqueous solution It is made by spinning, and the content of nano-bamboo charcoal is 4% to 30% of the weight of the finished fiber. The manufacturing method of the invention is simple in operation, high in productivity, less in environmental pollution and less harmful to operators, and the prepared bamboo charcoal cellulose fiber has excellent adsorption performance, antibacterial performance and antibacterial performance.

Owner:潍坊欣龙生物材料有限公司

Preparation method of tea shell carbon fibers

InactiveCN112482021ASolve technical problems of preparationCreate pollutionBiochemical fibre treatmentTextile treatment machine arrangementsFiberCarbon fibers

The invention provides a preparation method of tea shell carbon fibers. The preparation method is characterized by comprising the following steps of (1) preparing tea shell carbon powder; (2) preparing a tea shell carbon aqueous dispersion liquid; (3) performing pretreatment of fibers; and (4) coating the fibers with tea shell carbon. Tea shells are prepared into tea shell carbon aqueous dispersion liquid, and the tea shell carbon aqueous dispersion liquid is added into a dipping barrel, so that the surfaces of fibers are evenly coated with the tea shell carbon aqueous dispersion liquid to prepare the tea shell carbon fibers, the technical problem of preparation of the tea shell carbon fibers is solved, and the whole preparation method operates at low temperature, is safe and environmentally friendly and cannot pollute the environment. The tea shell carbon fiber prepared by the novel preparation method has natural functions of resisting and inhibiting bacteria, generating negative ions, emitting far infrared rays and removing peculiar smell, and textiles prepared from the tea shell carbon fibers have the characteristics of smoothness, fineness, good hygroscopicity and the like. Thetea shell carbon fiber can be applied to the field of textile products such as clothes, household textiles, underwear and masks, and has a wide market prospect.

Owner:郑州诺肯新材料科技有限公司

Anti-radiation fabric for preventing heat of human body from being dissipated outwards of bamboo fiber gauze kerchief

InactiveCN106042490AStable supportAnti-electromagnetic radiationLayered productsClothingsFiberEngineering

The invention relates to a bamboo fiber gauze to prevent the temperature of the human body from flowing out and anti-radiation fabric. The fabric is interwoven with cotton fiber yarn (1) as warp and bamboo fiber yarn (2) as weft. Several core-spun threads (3) are embedded in the cotton fiber yarn (1). The cored wire (3) is formed by silk covering metal ion fibers, and the metal ion fibers are wavy. A lining layer is compounded on the back of the fabric, and the surface of the lining layer is coated with a fluorine monomer waterborne polyurethane coating layer. The invention prevents the temperature of the human body from flowing out and resists radiation.

Owner:JIANGYIN ZHONGMA PACKING MATERIAL

Bamboo, hemp and cotton health-care socks

InactiveCN109549256ANatural antibacterial and antibacterialGood moisture wicking functionHandkerchiefsBaby linensHemp fiberStaphylococcus aureus bacteria

The invention provides bamboo, hemp and cotton health-care socks. Each sock is composed of a sock heel, a sock bottom, a sock vamp, a sock toe and a sock welt, wherein the sock heel, the sock bottom,the sock vamp and the sock toe are formed by knitting bamboo, hemp and cotton blended yarns. The obtained product has the natural antibacterial and bacteriostatic functions and good moisture absorption and sweat releasing functions, the detection of the Guangzhou microbiological analysis testing center shows that the antibacterial rate for staphylococcus aureus is 99%, the antibacterial rate for escherichia coli is 90%, and the antibacterial rate for candida sporogenes is 89%; and meanwhile, the defect that the socks purely made of bamboo fibers and hemp fiber blended yarns have fluffing and pilling easily is overcome, and the service life is greatly prolonged.

Owner:湖南瑞亚高科集团有限公司

Bamboo fiber gauze scarf antibacterial mildewproof anti-radiation fabric

InactiveCN105942634AStable supportAnti-electromagnetic radiationProtective fabricsSynthetic resin layered productsYarnSurface layer

The invention relates to bamboo fiber gauze scarf antibacterial mildewproof anti-radiation fabric which is formed by interweaving cotton fiber yarn (1) serving as warp and bamboo fiber yarn (2) serving as weft. Several cored wires (3) are embedded in the cotton fiber yarn (1), each cored wire (3) is formed by coating metal ion fiber with silk, and the metal ion fiber is wavy. A lining layer is composited on the back of the fabric and comprises a PU film surface layer, a flax fiber core layer and a ramie fiber bottom layer which are sequentially composited. The fabric is antibacterial, mildewproof and resistant to radiation.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Bamboo fiber gauze kerchief fabric resistant to water, high in breathability and resistant to radiation

The invention relates to a bamboo fiber gauze kerchief fabric resistant to water, high in breathability and resistant to radiation. The fabric is formed by interweaving cotton fiber yarn (1) as the warp and bamboo fiber yarn (2) as the weft. A plurality of core-spun yarns (3) are embedded in the cotton fiber yarn (1) and formed by wrapping metal ion fiber by silk, and the metal ion fiber is wavy. A lining layer is compounded on the back side of the fabric, and the surface of the lining layer is coated with a fluorine monomer waterborne polyurethane coating. The fabric is resistant to water, high in breathability and resistant to radiation.

Owner:JIANGYIN DUJUAN BEADED

RICh-color good-rebound resilience anti-irradiation fabric for bamboo fiber gauze kerchief

InactiveCN107518477ARich in colorIncrease elasticityProtective equipmentLayered productsFiberWave shape

The invention relates to rich-color good-rebound resilience anti-irradiation fabric for a bamboo fiber gauze kerchief. The fabric is formed by cotton fiber yarns (1) as warp yarns and bamboo fiber yarns (2) as weft yarns in a longitudinal and latitudinal interweaving mode. Several core-spun yarns (3) are embedded into the cotton fiber yarns (1), metal ion fibers are wrapped by silk to form the core-spun yarns (3), and the metal ion fibers are in a wave shape. A lining layer is compounded on the back face of the fabric, and warp yarns composed of bi-color threads and single-color threads and bi-color weft yarns are woven to form the lining layer. The fabric is rich in color, good in rebound resilience and resistant to irradiation.

Owner:苏光明

Bamboo fiber anti-radiation shell fabric with good flexibleness and good comfortability for gauze kerchief

InactiveCN106113743AStable supportAnti-electromagnetic radiationSynthetic resin layered productsWoven fabricsFiberTectorial membrane

The invention relates to a bamboo fiber anti-radiation shell fabric with good flexibleness and good comfortability for a gauze kerchief. The shell fabric is made by interweaving warp yarns and weft yarns in a manner that using cotton fiber yarns (1) as the warp yarns and using bamboo fiber yarns (2) as the weft yarns, several core-spun yarns (3) are nested in the cotton fiber yarns (1), each core-spun yarn (3) is formed by cladding metal ion fibers through natural silks, and the metal ion fibers are wavy; and a liner layer is compounded on the back of the shell fabric, and comprises a liner layer body, a PTFE film and a protective film, wherein the PTFE film is arranged on the liner layer body, and the protective film is arranged on the surface of the PTFE film and is used for protecting the PTFE film. The bamboo fiber anti-radiation shell fabric disclosed by the invention has good flexibleness and comfortability, and is resistant to radiation.

Owner:JIANGYIN HANXIN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com