Waterproof and environment-friendly paper honeycomb composite board for automotive interior, and preparation method of composition board

A technology for automobile interior decoration and paper honeycomb, which is applied in the field of automobile interior decoration materials, can solve the problems of poor moisture resistance, bacteria-prone mildew, easy deformation, etc., and achieve the effects of good dispersion, fatigue reduction, and firm composite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

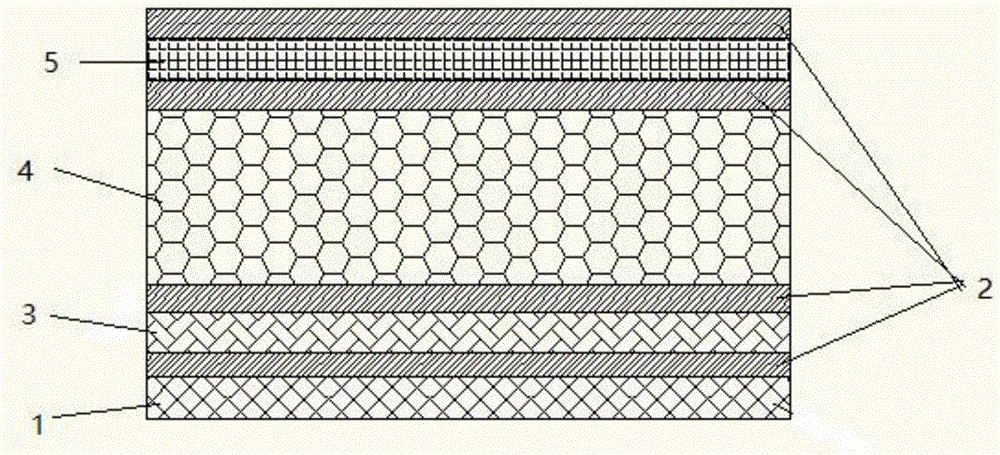

[0021] See attached figure 1 , a waterproof, flame-retardant and environmentally friendly paper honeycomb composite board for automotive interiors, the composite board is composed of non-woven fabric 1, hot-melt adhesive film 2, bamboo fiber felt 3, hot-melt adhesive film 2, paper honeycomb composite board from bottom to top Composite core 4, hot melt adhesive film 2, GMT felt 5, hot melt adhesive film 2;

[0022] The hot melt adhesive film raw material includes 20 parts of terpolymerized polypropylene, 20 parts of ethylene-propylene copolymer, 5 parts of C5 / C9 copolymer resin, 2 parts of high molecular weight PP wax, and 1 part of antioxidant in parts by weight;

[0023] The bamboo fiber felt comprises 40 parts by weight of bamboo fiber, 5 parts of brucite powder, 8 parts of sepiolite powder, 10 parts of urea-formaldehyde resin adhesive, 7 parts of silicon-acrylic emulsion, 1 part of nano-titanium dioxide, and 4 parts of castor oil. Parts; preparation method: mix brucite pow...

Embodiment 2

[0030] A waterproof, flame-retardant and environment-friendly paper honeycomb composite board for automobile interior decoration, the composite board is composed of non-woven fabric, hot melt adhesive film, bamboo fiber felt, hot melt adhesive film, paper honeycomb core, hot melt adhesive Composite film, GMT felt and hot melt adhesive film;

[0031] The hot melt adhesive film raw material includes 25 parts of terpolymer polypropylene, 15 parts of ethylene-propylene copolymer, 8 parts of C5 / C9 copolymer resin, 3 parts of high molecular weight PP wax, and 2 parts of antioxidant in parts by weight;

[0032] The bamboo fiber felt comprises 45 parts by weight of bamboo fiber, 8 parts of brucite powder, 6 parts of sepiolite powder, 12 parts of urea-formaldehyde resin adhesive, 10 parts of silicon-acrylic emulsion, 2 parts of nano-titanium dioxide, 5 parts of castor oil Parts; preparation method: mix brucite powder, sepiolite powder, and nano-titanium dioxide, add castor oil, stir at...

Embodiment 3

[0039] A waterproof, flame-retardant and environment-friendly paper honeycomb composite board for automobile interior decoration, the composite board is composed of non-woven fabric, hot melt adhesive film, bamboo fiber felt, hot melt adhesive film, paper honeycomb core, hot melt adhesive Composite film, GMT felt and hot melt adhesive film;

[0040] The hot melt adhesive film raw material includes 30 parts of terpolymerized polypropylene, 20 parts of ethylene-propylene copolymer, 10 parts of C5 / C9 copolymer resin, 4 parts of high molecular weight PP wax, and 2 parts of antioxidant in parts by weight;

[0041]The bamboo fiber felt comprises 50 parts by weight of bamboo fiber, 10 parts of brucite powder, 8 parts of sepiolite powder, 15 parts of urea-formaldehyde resin adhesive, 12 parts of silicon-acrylic emulsion, 2 parts of nano-titanium dioxide, and 6 parts of castor oil. Parts; preparation method: mix brucite powder, sepiolite powder, and nano-titanium dioxide, add castor oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com