Preparation method of tea shell carbon fibers

A technology of carbon fiber and tea shell, which is applied in the field of preparation of tea shell carbon fiber, to achieve the effect of good hygroscopicity and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

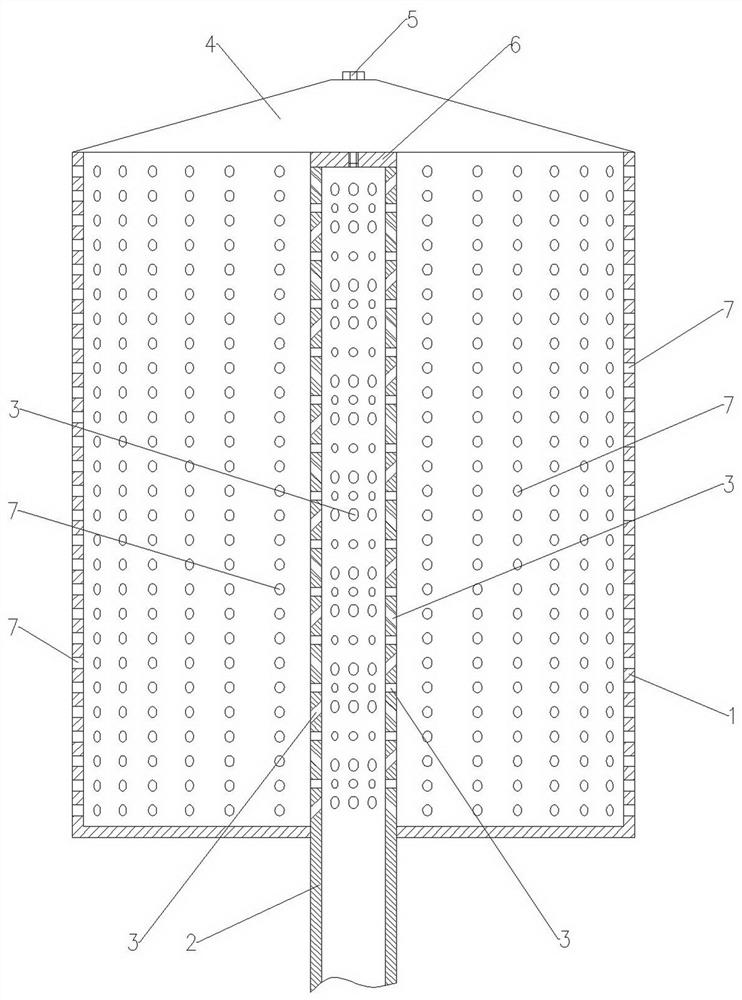

Image

Examples

Embodiment

[0028] Embodiment: A kind of preparation method of tea shell charcoal fiber, it is characterized in that: described preparation method comprises the following steps:

[0029] (1) Production of tea shell charcoal powder

[0030] First, mix the tea husk with 92# gasoline, the mixing ratio is 1:1 by weight, then ignite and burn the tea husk obtained after burning to 400 mesh with an airflow mill, and put the obtained tea husk powder into the muffle furnace Medium heating to 800°C, heating rate 25°C / min, heat preservation for 2 hours, tea husk powder is fully carbonized, and tea husk charcoal powder is obtained;

[0031] (2) Preparation of tea shell charcoal water dispersion

[0032] Add water and a thickener, and then add the tea shell charcoal powder prepared in step (1). The weight ratio of tea shell charcoal powder to water is 1:4, and the ratio of tea shell charcoal powder to thickener is 1:0.6. Grind three times with a fine ball mill, then pressurize and filter three times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com