Metal rubber roller forming equipment

A metal rubber and roll forming technology, which is applied in metal rolling and other directions, can solve the problems of stamping die design and processing difficulties, low tensile strength of metal rubber components, high scrap rate, etc., to improve strength and anti-delamination ability, The effect of improving technical performance and service life, and improving hooking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

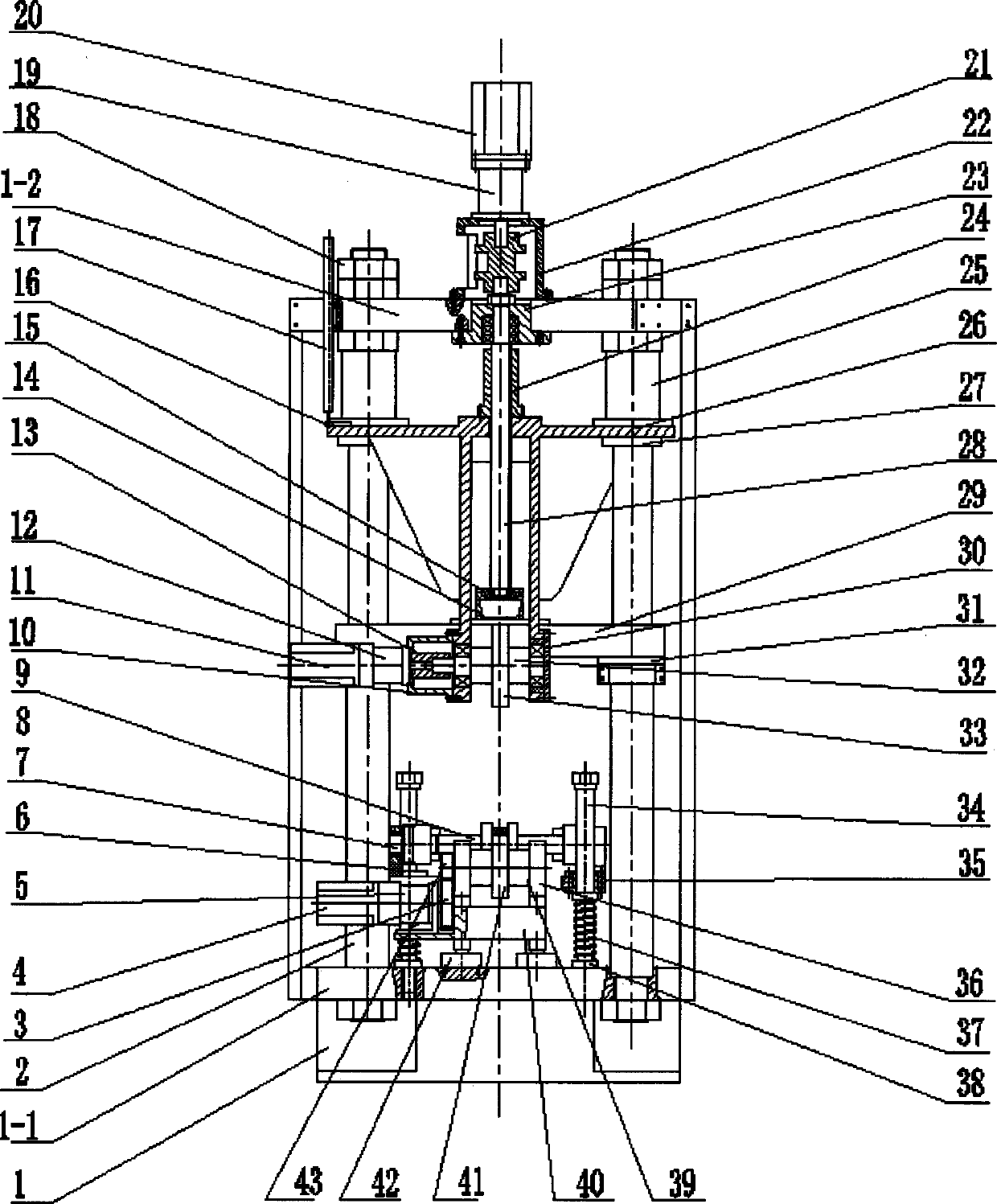

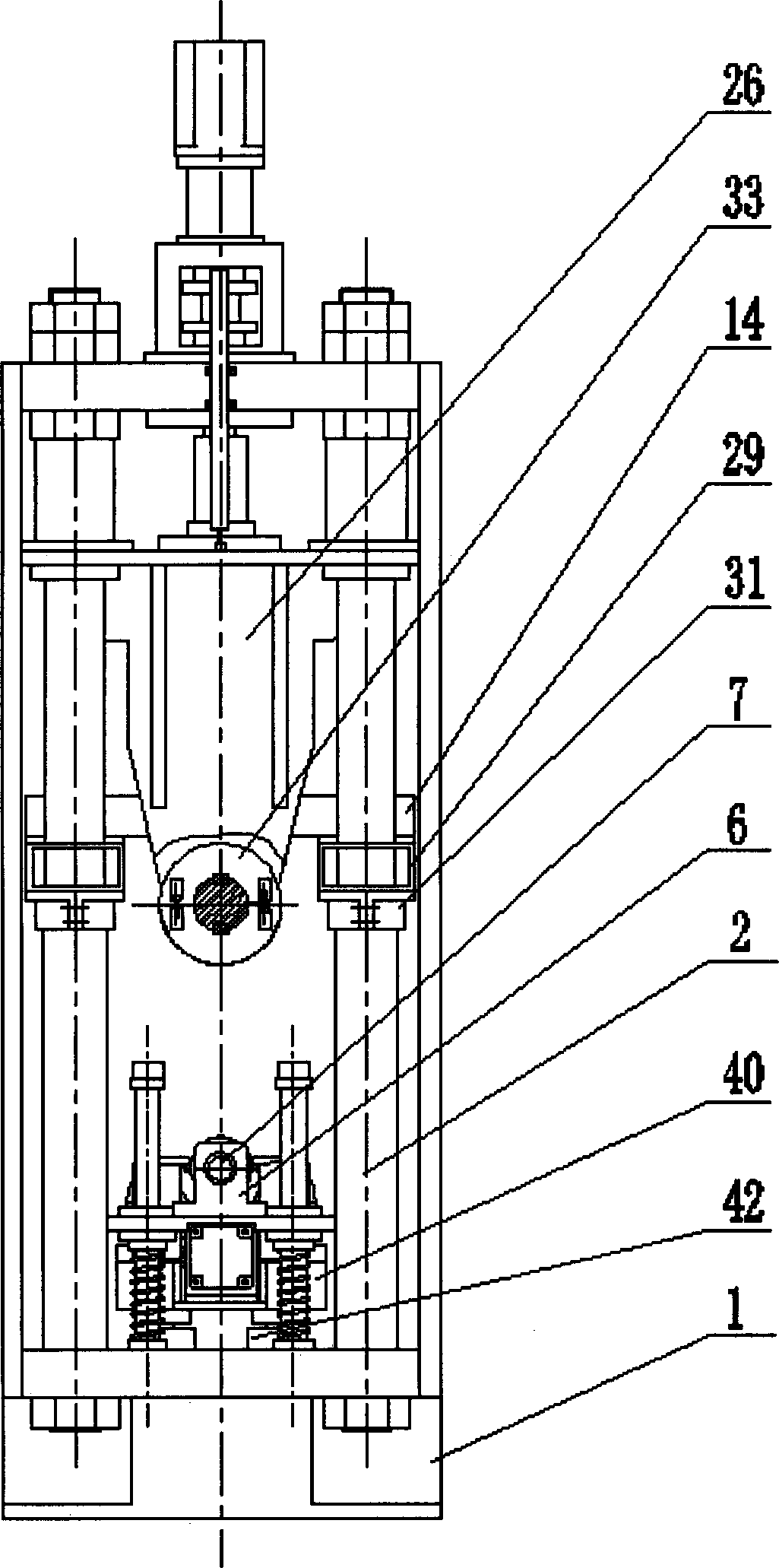

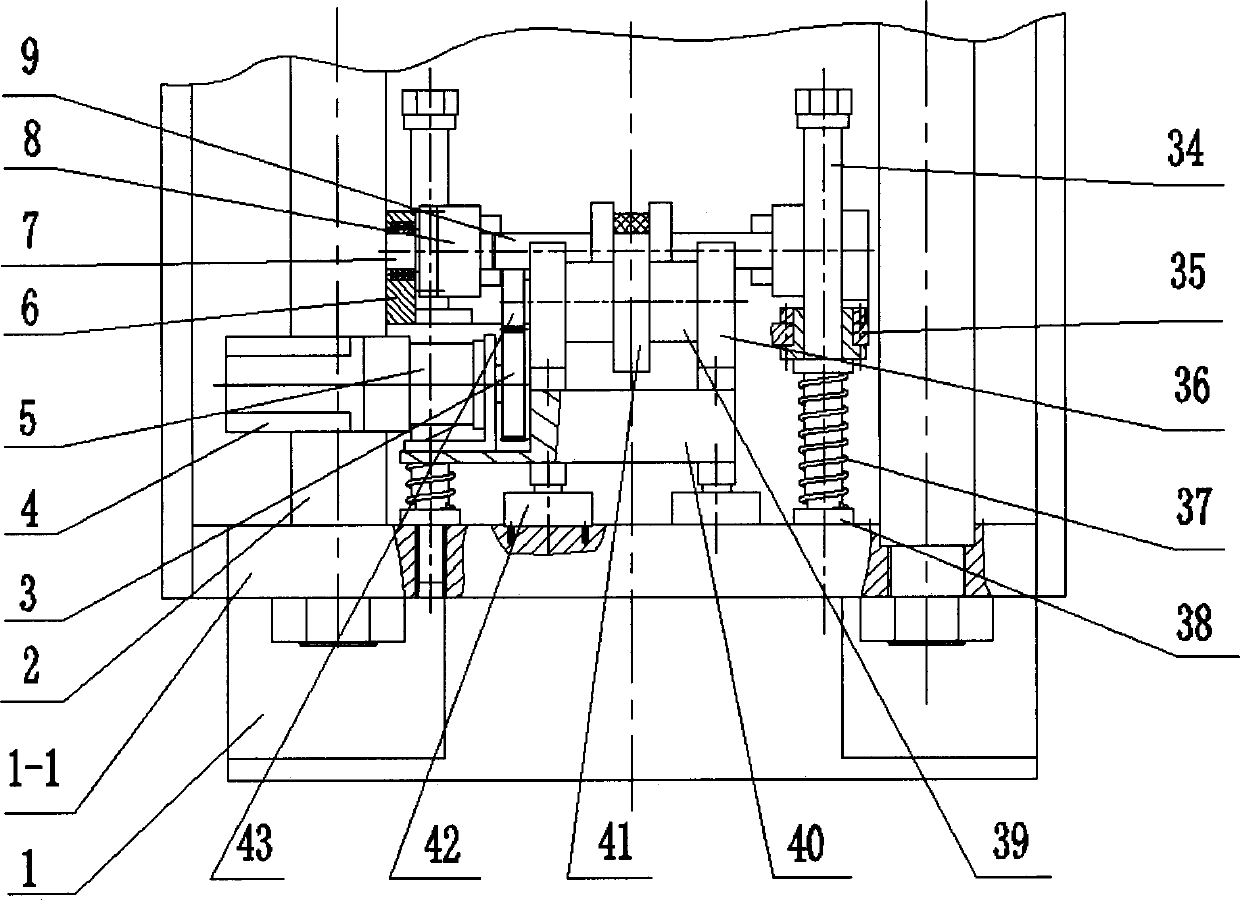

[0038] like Figure 1 ~ Figure 3 Shown, the present invention comprises frame 1, lifting mechanism, rolling mechanism, control system.

[0039] like figure 1 and figure 2 As shown, the frame 1 is a welded assembly of steel plates, square pipes and angle steels, which installs and supports each component of the equipment.

[0040] like figure 1 and figure 2 As shown, the lifting mechanism includes: lead screw motor 20, lead screw motor reducer 19, lead screw coupling 21, lead screw motor support 22, lead screw 28, lead screw nut 24, lead screw bearing seat, angular contact Ball bearing, moving roller seat 26, support seat 14, middle beam 29, positioning sleeve 31, column 2, column nut 18.

[0041] like figure 1 As shown, the lead screw motor 20 and the lead screw motor reducer 19 are supported on the lead screw motor support 22, the lead screw motor reducer 19 is a planetary reducer, and the lead screw coupling 21 is a friction disc coupling.

[0042] After the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com