Ramie fiber mattress production method

A technology of ramie fiber and production method, which is applied in the field of ramie fiber mattress production, can solve the problems of itchy skin, easy wrinkling and fluffing of fabrics, affecting the application of ramie fiber, etc., and achieve the effect of improving fineness and eliminating itching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments.

[0014] A kind of production method of ramie fiber mattress, at first combing ramie fiber quantitative feeding, then laying a net, combining with acupuncture, hot-pressing setting, finally cutting, described ramie fiber adopts modified ramie fiber, and this modified ramie fiber The modification method comprises the steps:

[0015] Step 1, mix cottonseed hull ash, straw ash and sodium hydroxide in a weight ratio of 10:6:1.5, add water 12 times the total weight of the three, and boil to prepare a modified solution;

[0016] Step 2, adding ramie fibers into the modified solution, completely submerging, and cooking for 3 hours;

[0017] In step 3, the ramie fiber is taken out from the modified solution, washed with clear water, and air-dried naturally.

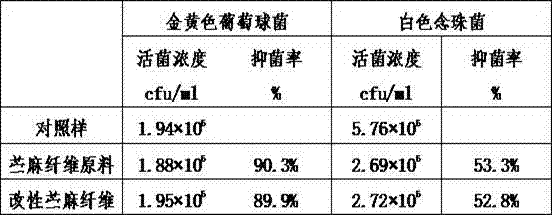

[0018] The prepared modified ramie fiber and the raw material ramie fiber were tested for physical properties under the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com