In-mold self-reinforced co-injection molding method for single polymer composites

A technology of composite materials and molding methods, which is applied in the field of injection molding molds, can solve problems such as damage to the overall performance of composite materials, and achieve the effect of flexible and convenient regulation and wide selection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

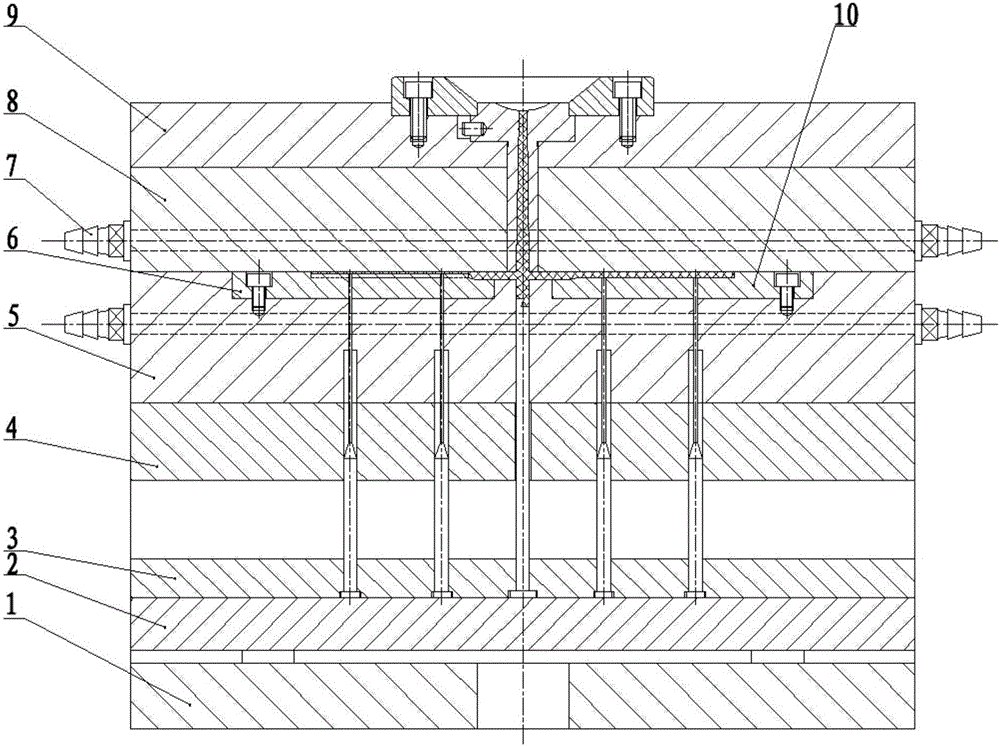

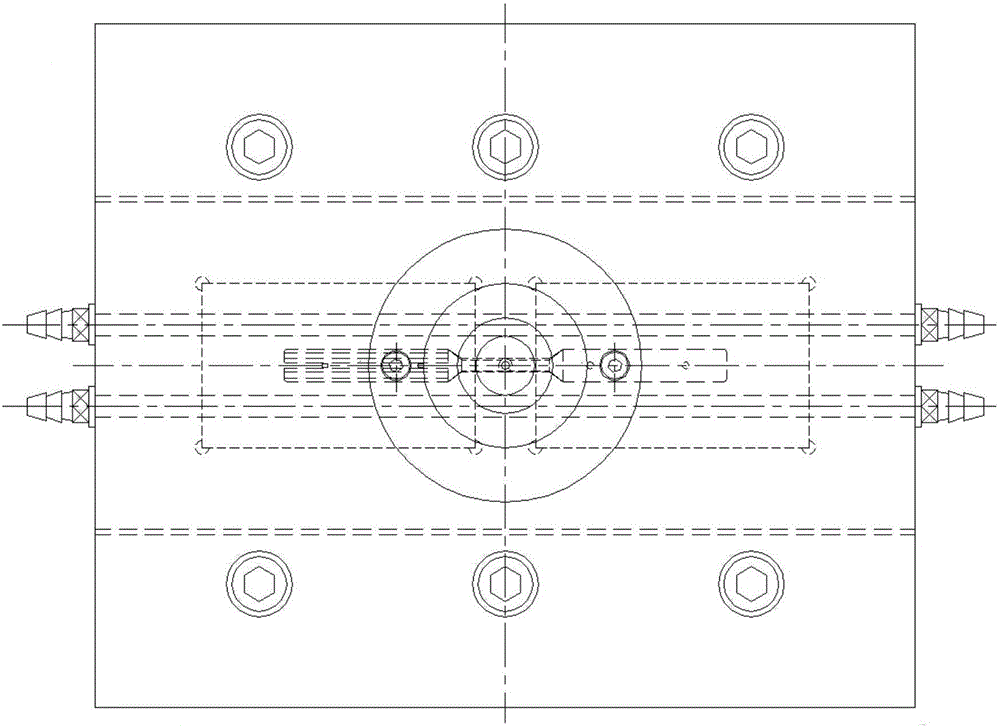

[0022] Below in conjunction with technical scheme and accompanying drawing 1 (a), (b) and 2 (a), (b) describe the technological process of preparing SPC of the present invention in detail.

[0023] 1) Install the matrix cavity insert 6 and the reinforced molding insert 10 in the accompanying drawing 2 on the movable template 5 through positioning pins and socket head cap screws; Water hole, use the mold temperature machine to control the temperature of the mold during the molding process, which constitutes the mold for self-reinforced co-injection molding SPC in the mold;

[0024] 2) Set the molding parameters of the injection molding machine, inject the plasticized polymer into the mold cavity, and when forming the first mold, because there is no matrix in the reinforced phase insert, only one SPC matrix can be obtained, the first mold The amount of plasticizing should be increased appropriately;

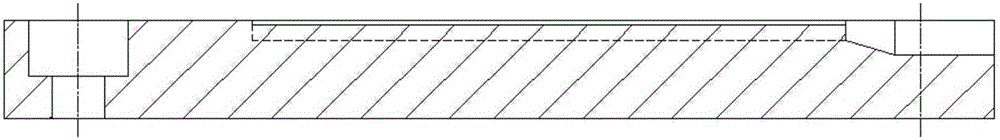

[0025] 3) Cut off the handle of the formed SPC matrix sample, and place the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com