Erasable printing technology for plasmon colors

A plasmonic and color technology, applied in the field of erasable printing technology of plasmonic color, to achieve the effect of high-efficiency color printing and simple operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

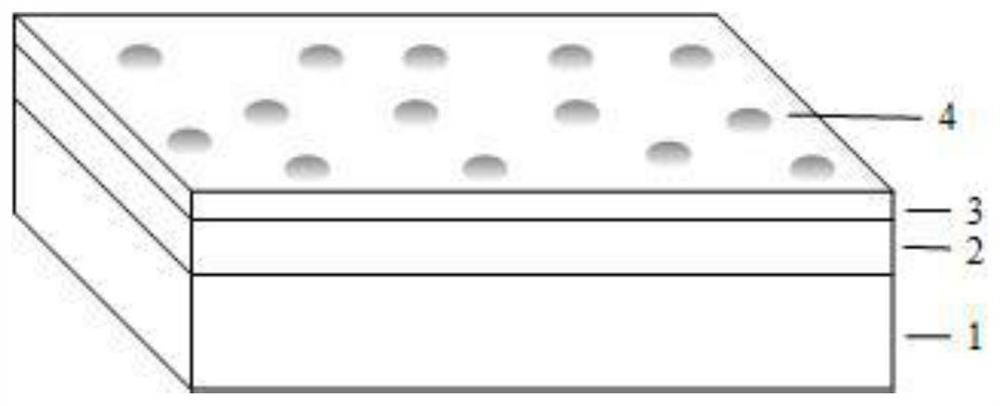

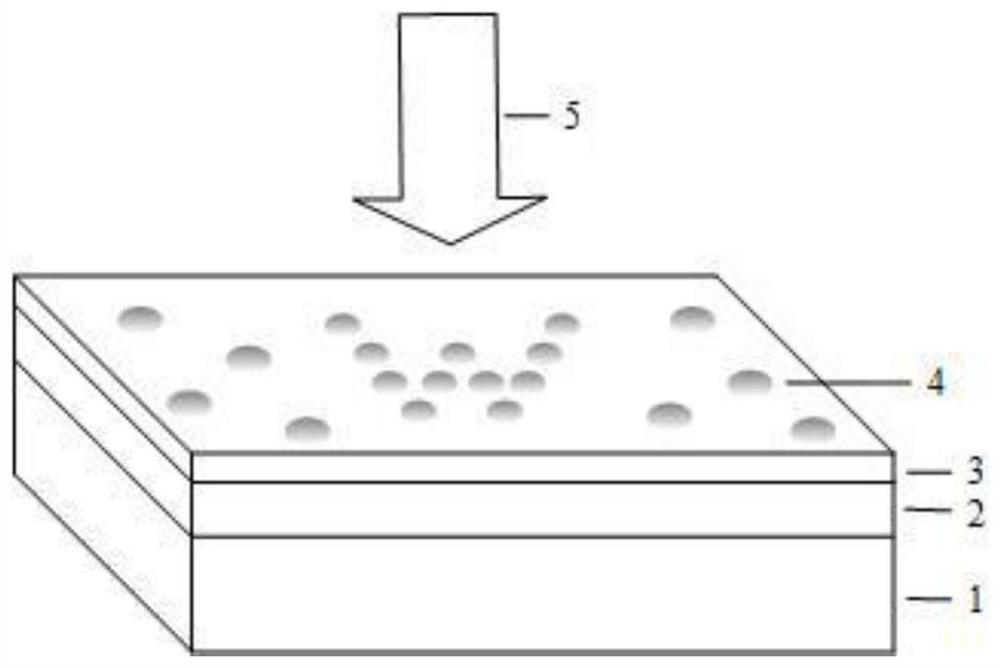

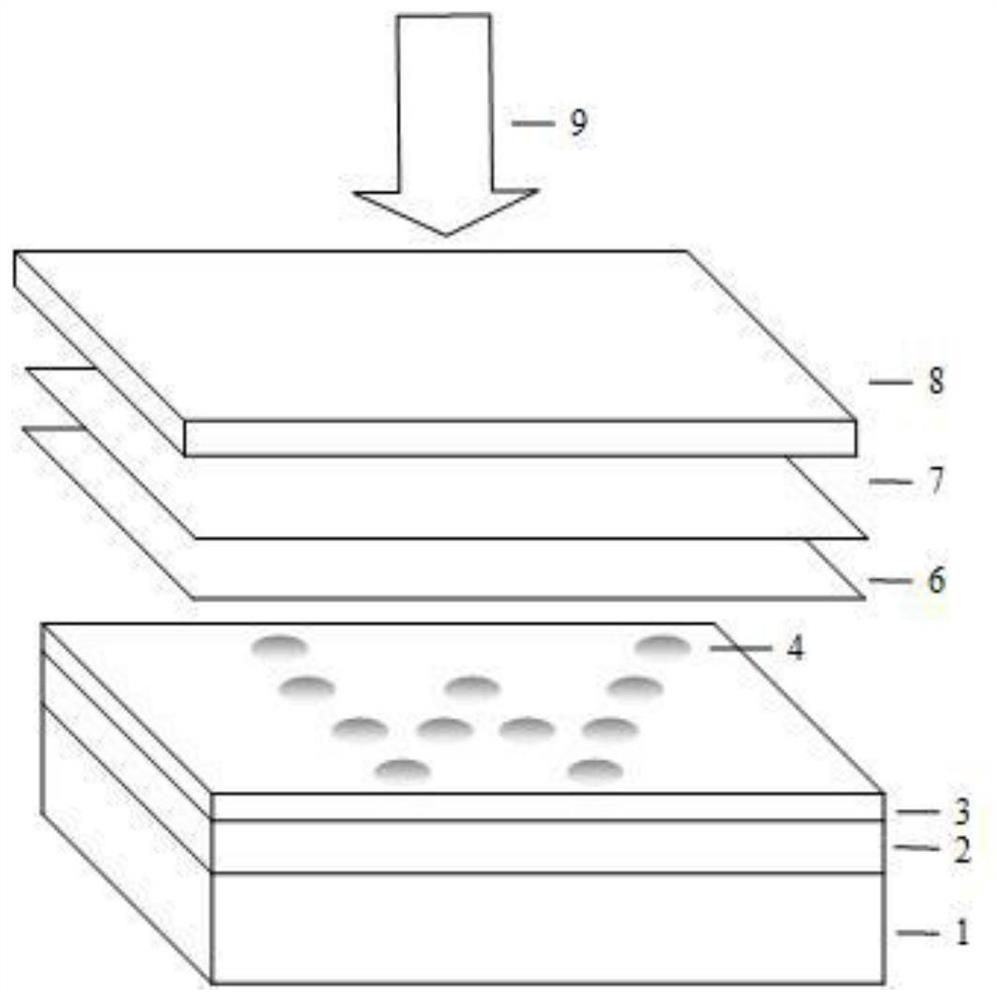

[0029] Figure 1-4 It is a schematic diagram of the steps of the erasable printing technology of plasmonic color according to the present invention. 100nm thick reflective metal Ag was deposited on the glass slide; 30nm thick SiO was deposited on the surface of Ag metal by plasma-enhanced chemical vapor deposition (PECVD) 2 Dielectric, as the spacer layer; deposit 10nm thick Ag on the surface of the spacer layer, such as figure 1 As shown; use a 405nm laser with a power of 100% and a burning time of 6ms to scan the surface of metal Ag, and write the letter "W", such as figure 2 shown. The Ag was observed to turn green under the light microscope, and the SEM image showed that the Ag nanoparticles were reduced in size, such as Figure 5 As shown; lay a layer of graphite-coated aluminum foil on the surface of the scanned sample with a thickness of 4 μm, and then cover it with transparent glass (the thickness of the transparent glass is 0.5 mm) as a transparent solid layer; us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com