Energy conversion hydraulic plant and method for controlling such plant

An energy conversion and hydraulic technology, used in pump control, mechanical equipment, hydropower, etc., can solve the problems of inconsistent shape and flow direction, incomplete filling of guides, separation of guide surfaces, etc., to optimize performance , Improve the stability, reduce the effect of fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

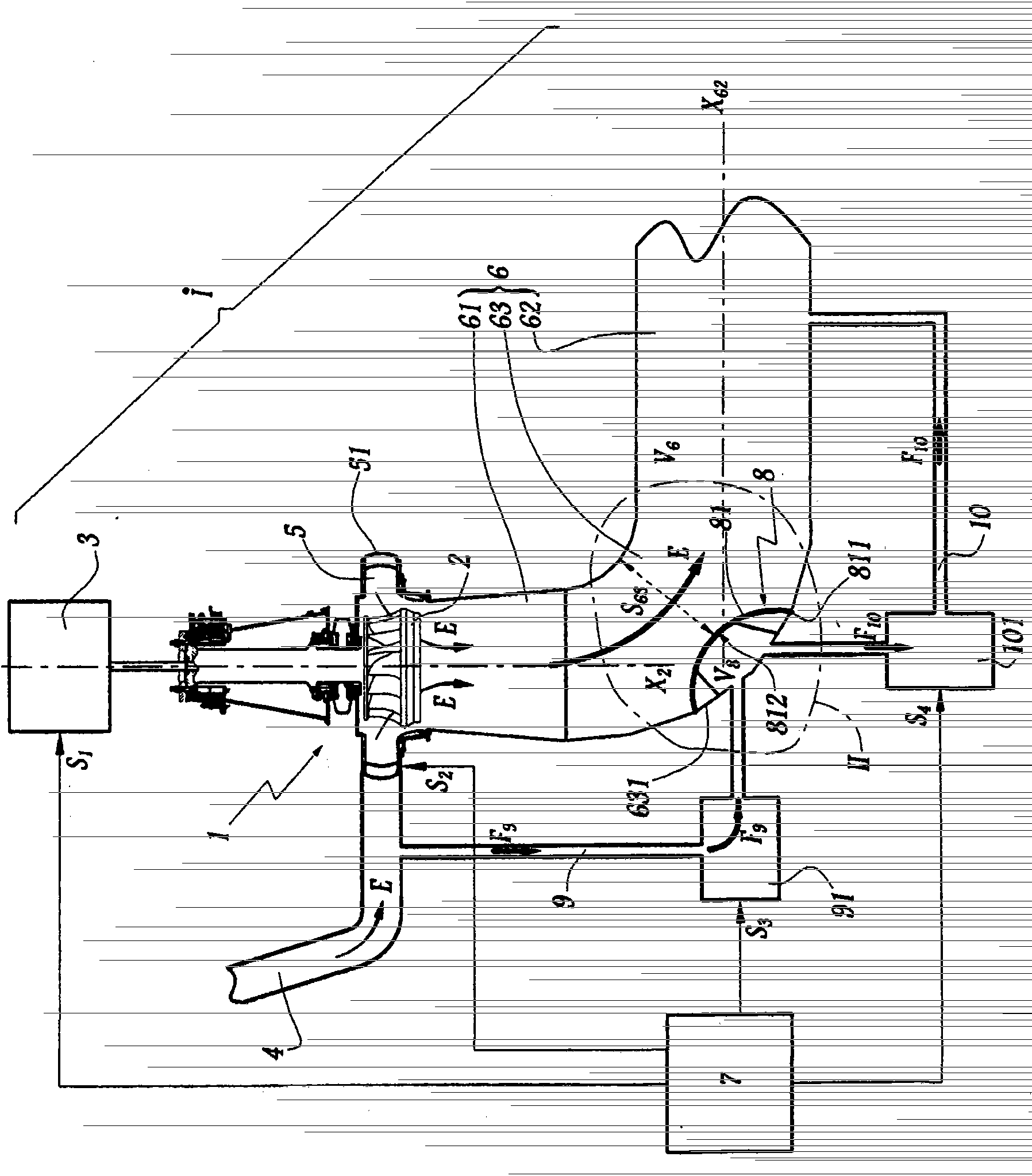

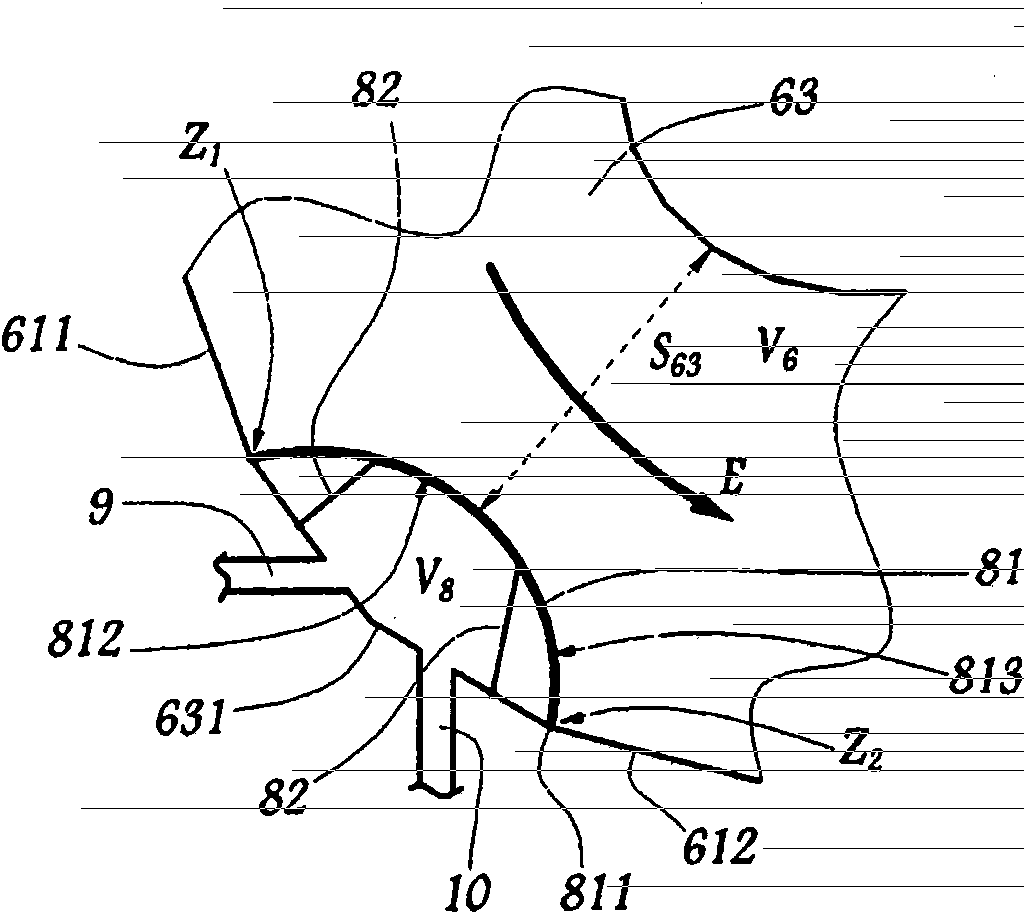

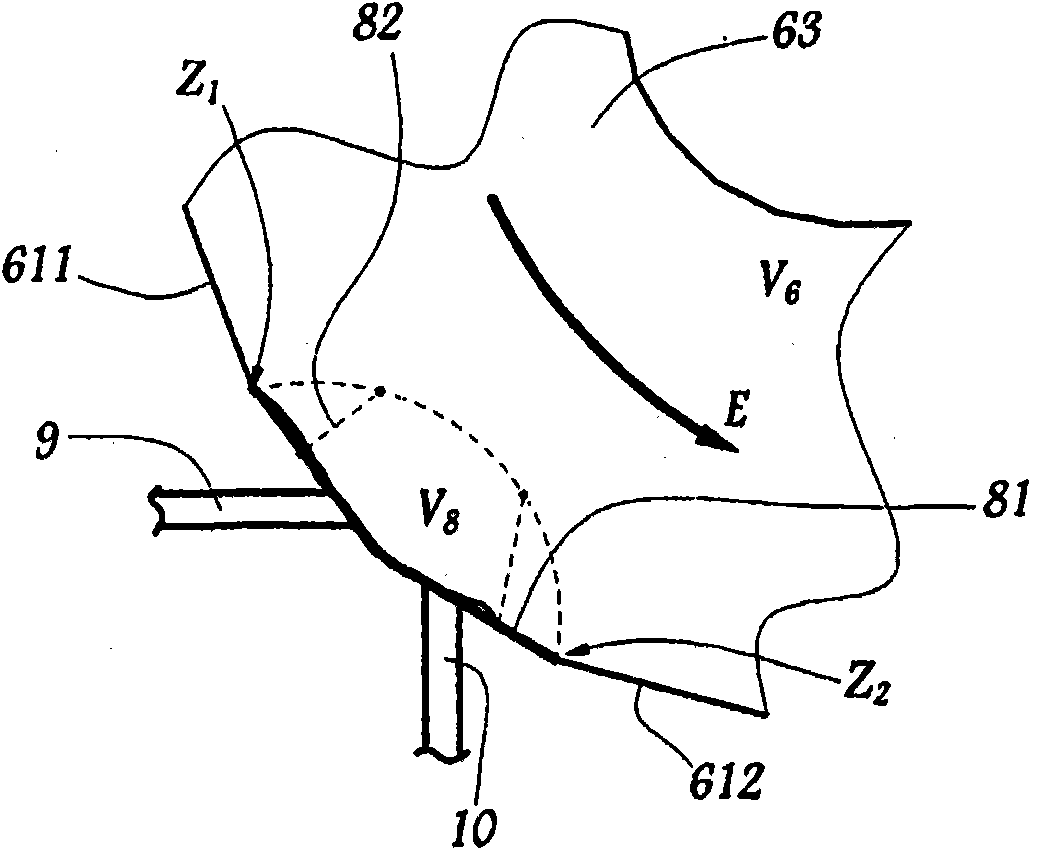

[0029] Figures 1 to 3 The plant I shown has a Francie-type turbine 1 whose wheel 2 is intended to be driven in rotation by a forced flow E from a reservoir not shown. The wheel body 2 constitutes a rotating part of the turbine 1 . The turbine 1 is connected to a generator 3 which, in response to the rotation of the wheel body 2, supplies alternating current to a grid not shown. Thus, the device I can convert the hydraulic energy of the flow E into electrical energy. The flow E is conveyed to the wheel body 2 by a forced channel 4 which extends between the water reservoir and a tank 5 equipped with guide vanes 51 which locally regulate the flow E. A channel 6 is provided downstream of the wheel body 2 for discharging the flow E downstream of the installation I and retransmitting it to the river from which it is drawn.

[0030] The components 4, 5 and 6 together define the hydraulic path of the flow E.

[0031] A control unit 7 is used to operate the turbine 1 , in particul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com