Patents

Literature

41results about How to "Change geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

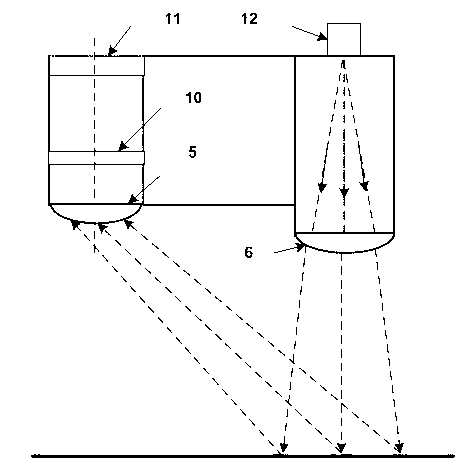

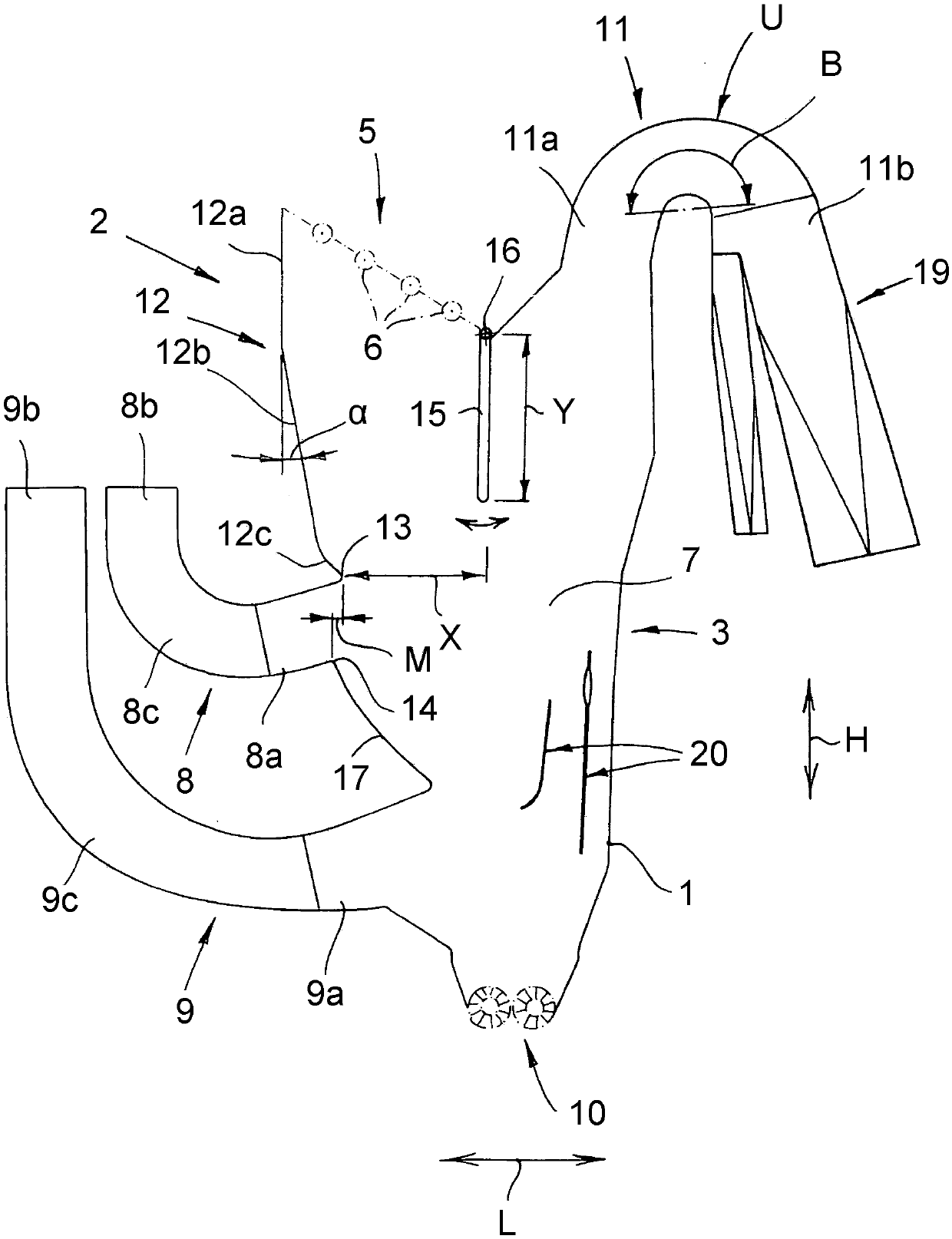

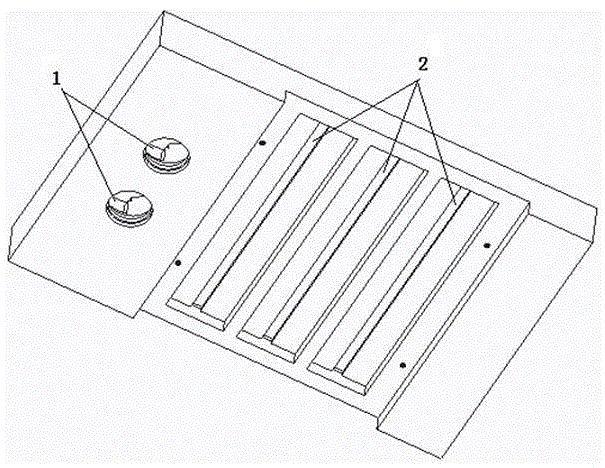

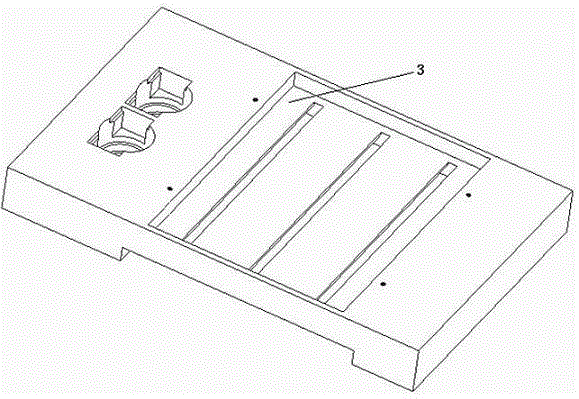

Initiative light source type crop canopy reflection spectral measurement device and method

InactiveCN103293113AOptical path parameters are adjustableChange geometryColor/spectral properties measurementsMeasurement deviceSpectral response

The invention provides an initiative light source type crop canopy reflection spectral measurement device and method and belongs to the field of geometrical optics and agricultural information nondestructive testing. A driving light source is a double-channel narrow-band LED (Light Emitting Diode) light source and adopts a special structure with adjustable light path parameters; the change of initiative light source irradiation characteristic parameters is realized according to measurement requirements so that spectral reflectance measurement of canopies with different scales can be met; a light path structure of a measurement system can guarantee that a constant value proportion relation can be kept when the height change is measured by a double-channel reflection spectral response value, so that measurement values of specific value type spectral indexes including NDVI (Normalized Difference Vegetation Index), RVI (Ratio Vegetation Index) and the like are theoretically not changed along with the measurement height.

Owner:NANJING AGRICULTURAL UNIVERSITY

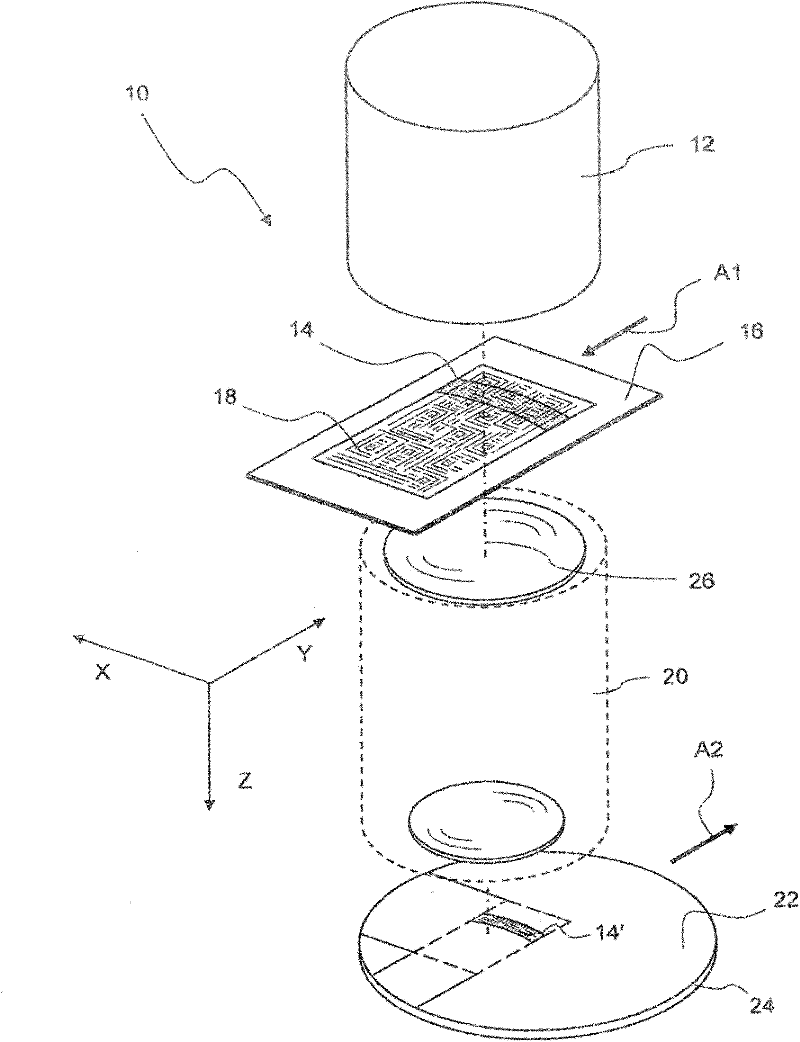

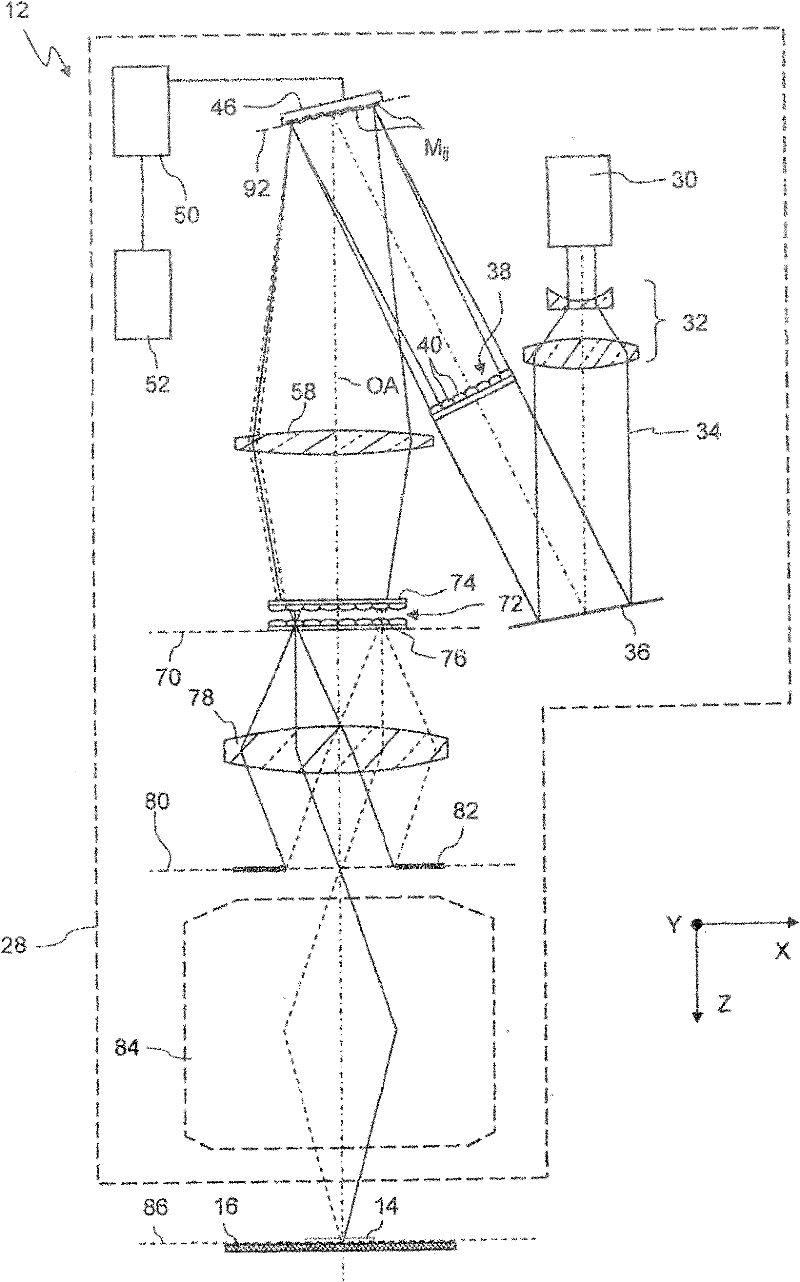

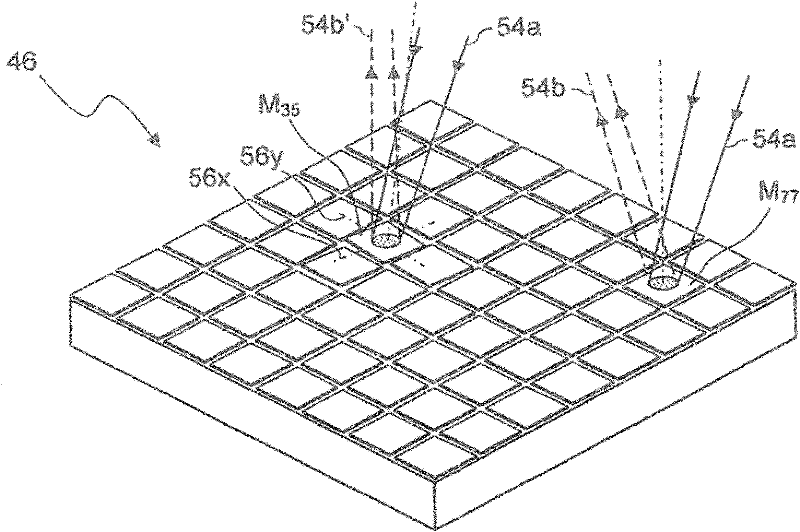

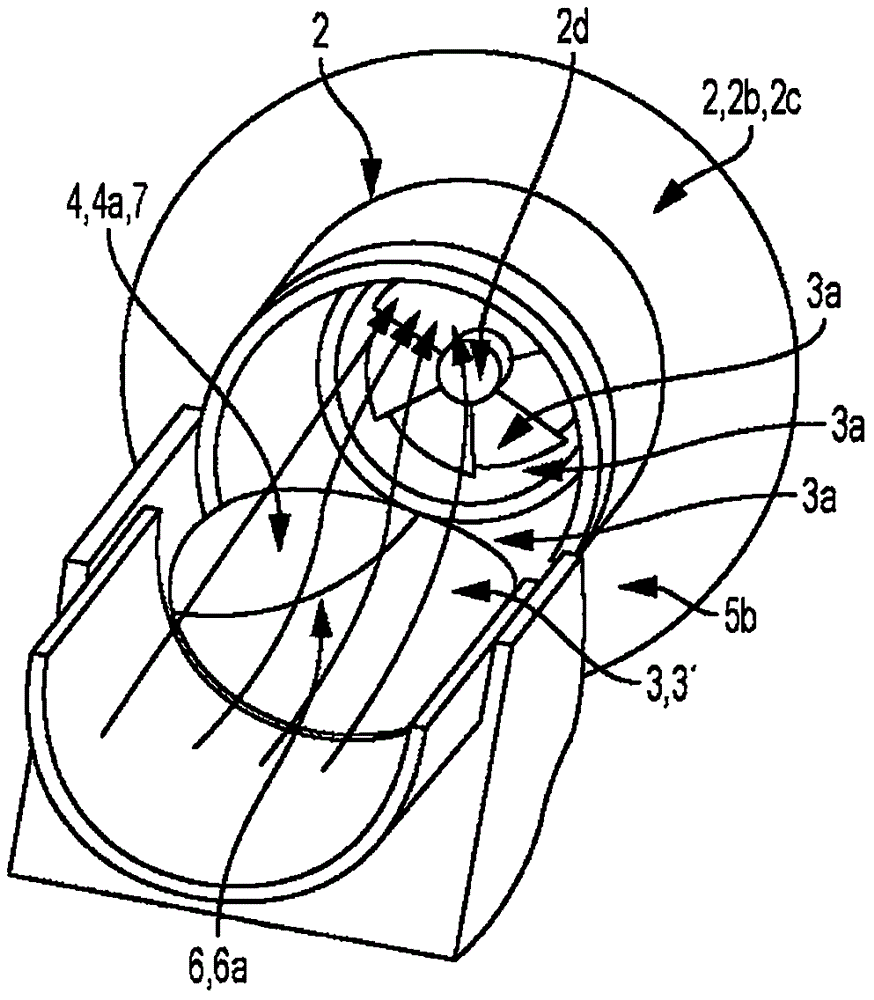

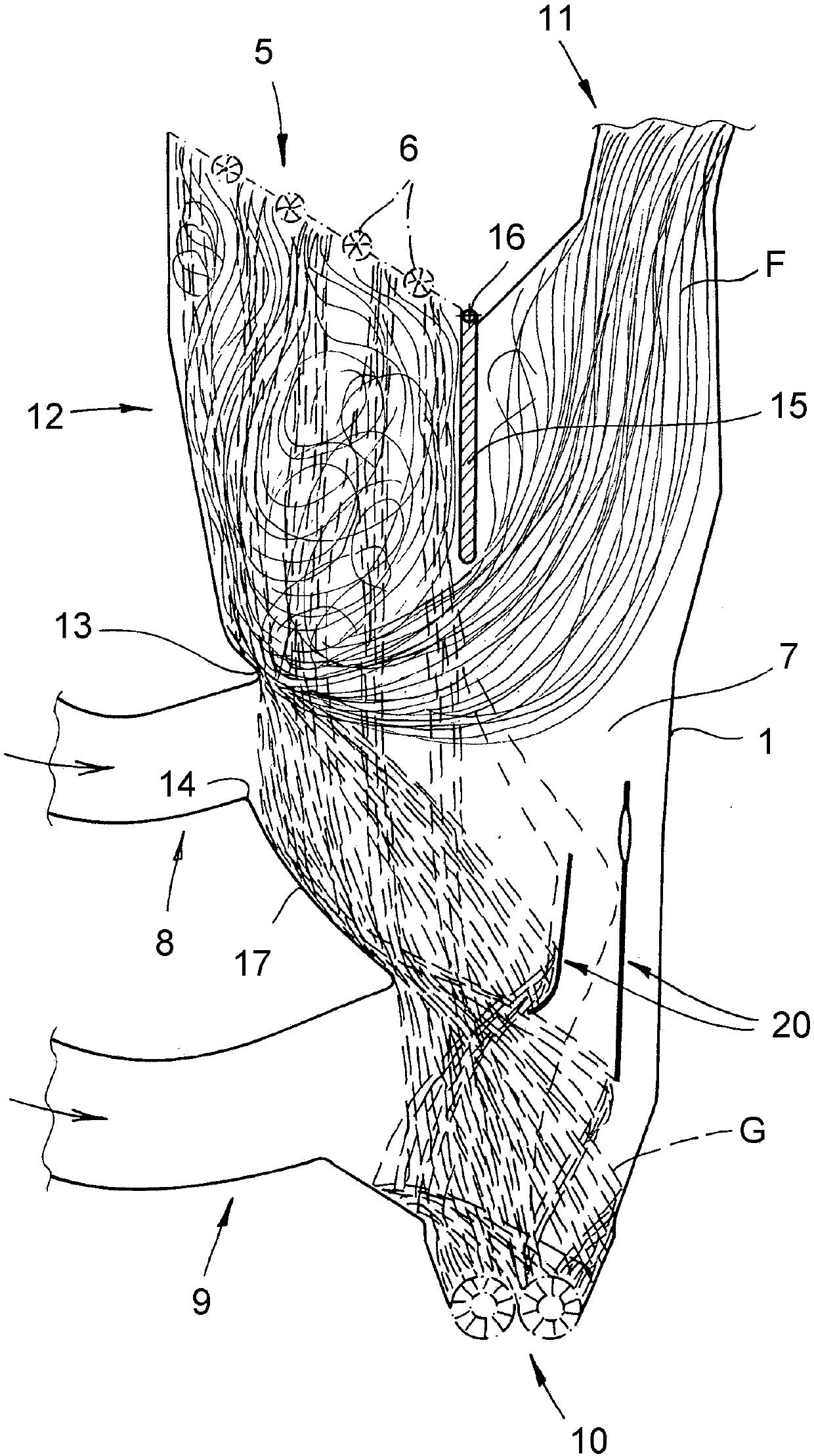

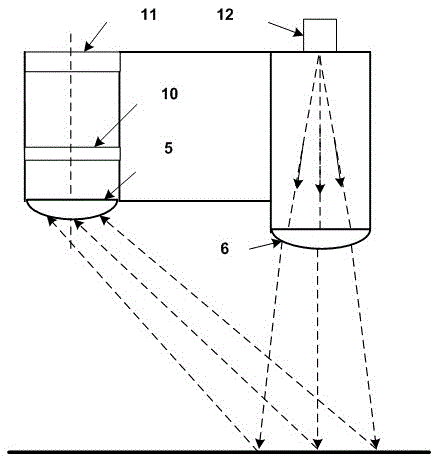

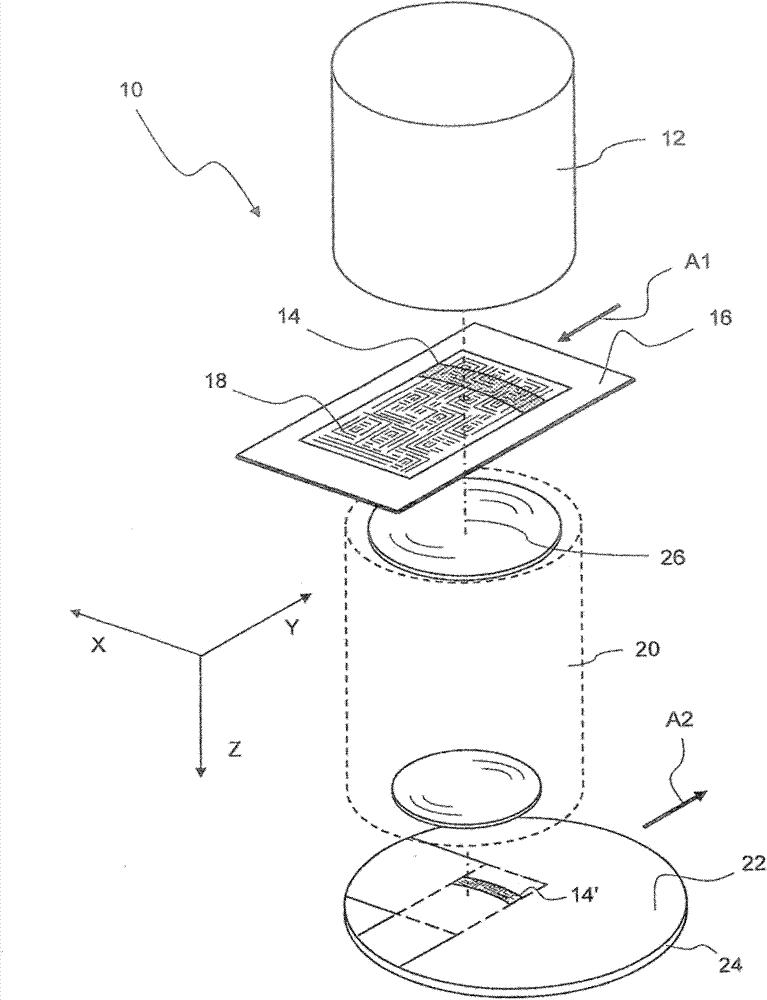

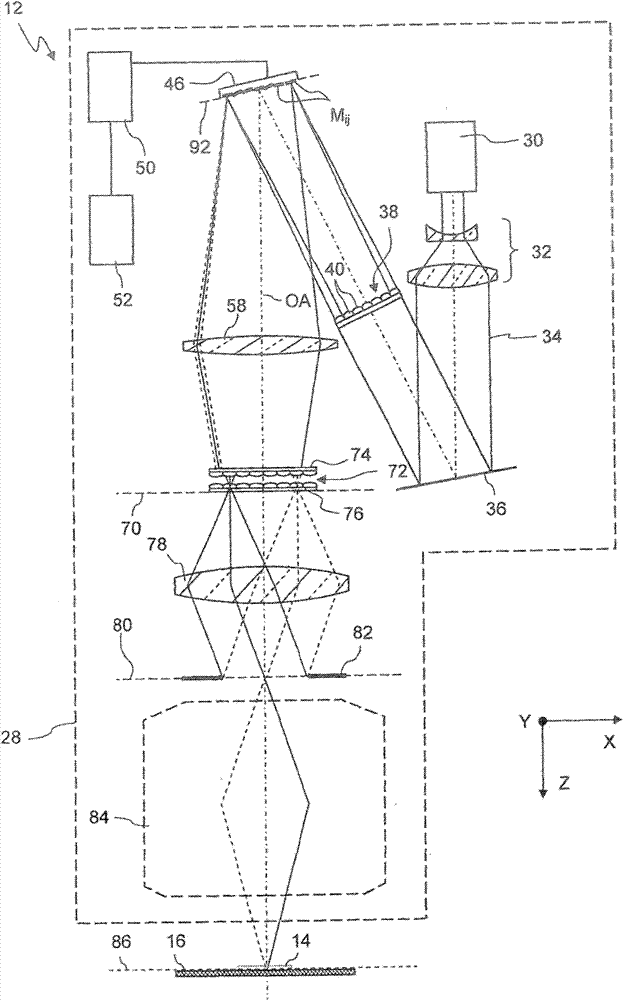

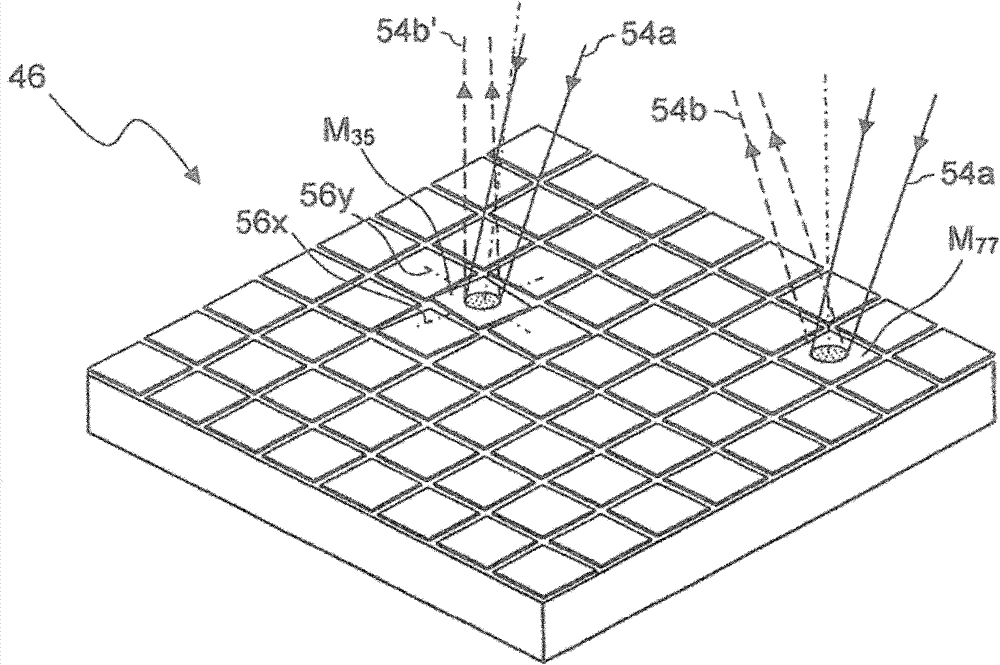

Illumination system of a microlithographic projection exposure apparatus

ActiveCN102099743AChange geometryPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingLight beam

An illumination system of a microlithographic projection exposure apparatus (10) comprises an optical raster element (72) configured to produce a plurality of secondary light sources (95) located in a system pupil surface (70). The optical raster element (72) has a plurality of light entrance facets (92) each being associated with one of the secondary light sources (95). A beam deflecting device comprises a beam deflection array (46) of reflective or transparent beam deflecting elements (Mij) each being configured to illuminate a spot (90) on one of the light entrance facets (92) at a position that is variable by changing a deflection angle produced by the beam deflecting element (Mij). A control unit (50) is configured to control the beam deflection elements (Mij) such that variable light patterns (LP) assembled from the spots (80) can be formed on at least one of the plurality of light entrance facets (92).

Owner:CARL ZEISS SMT GMBH

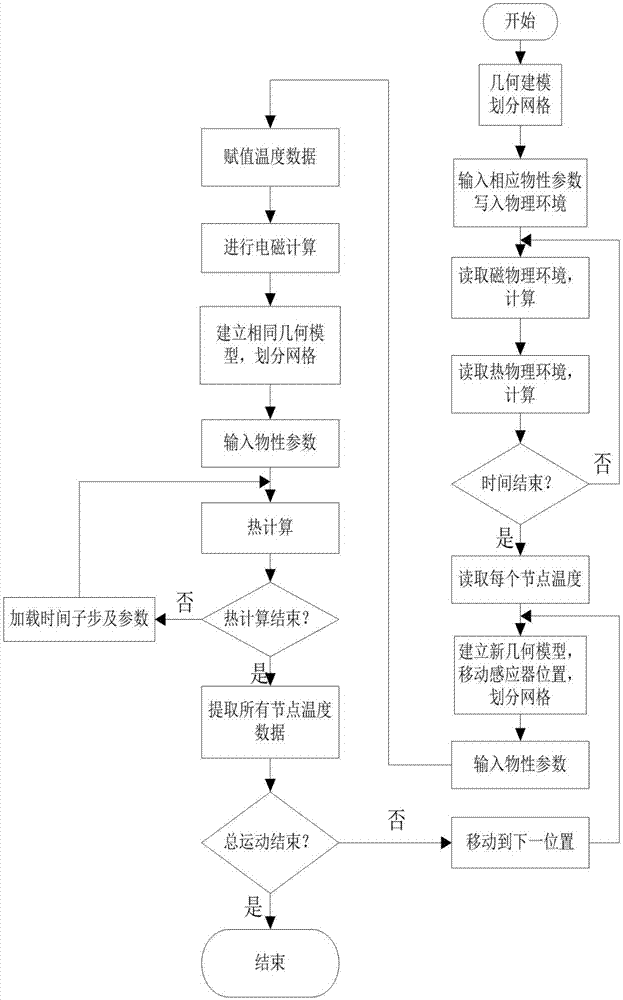

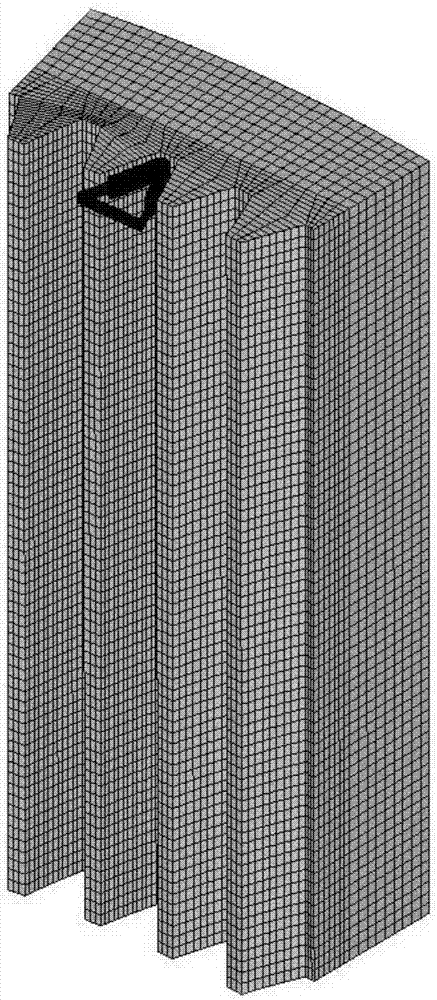

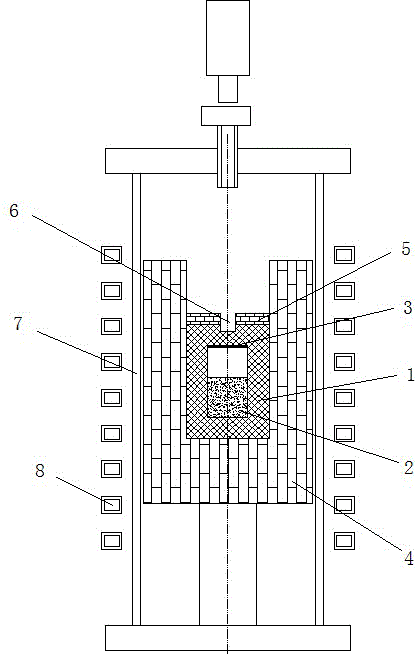

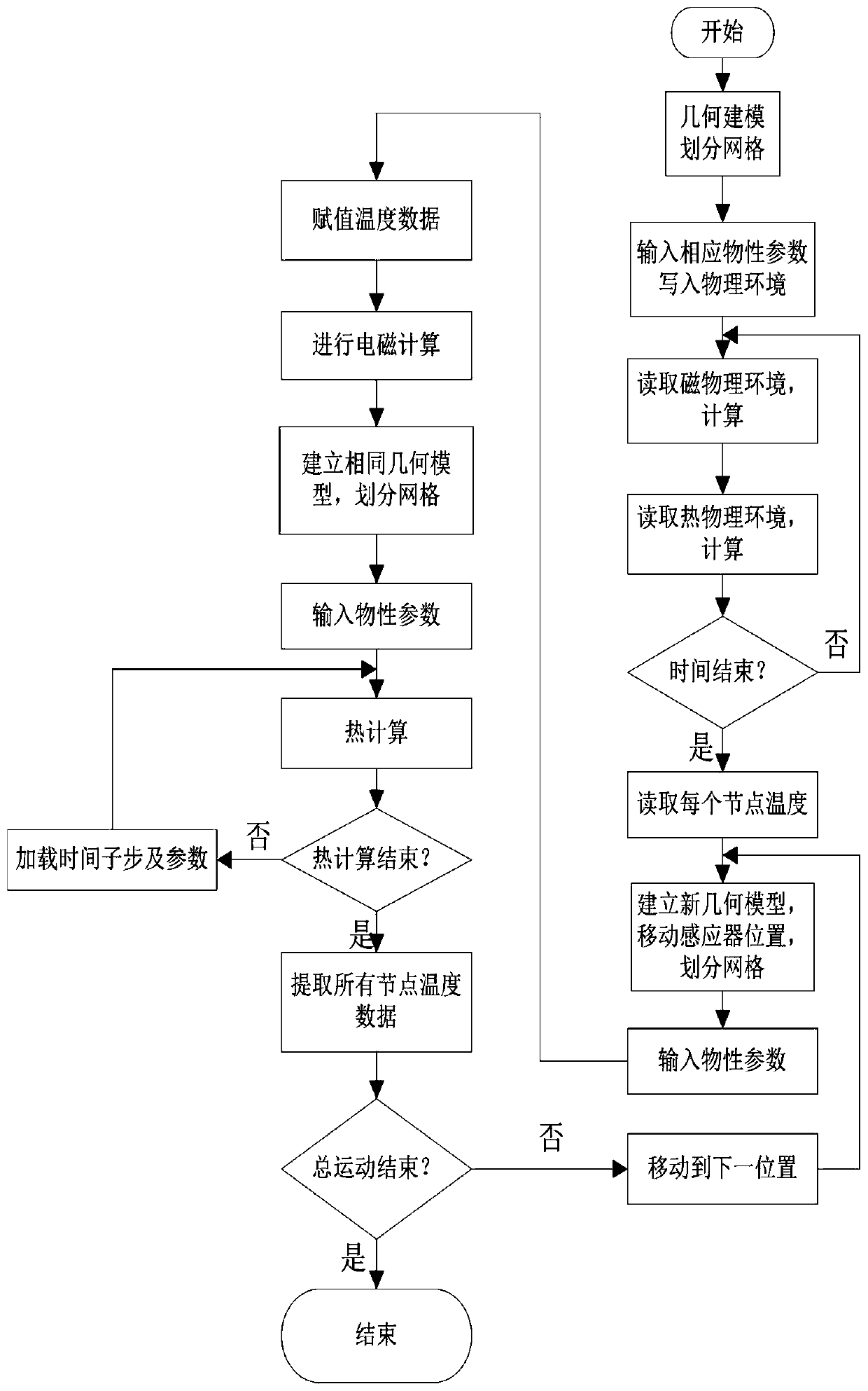

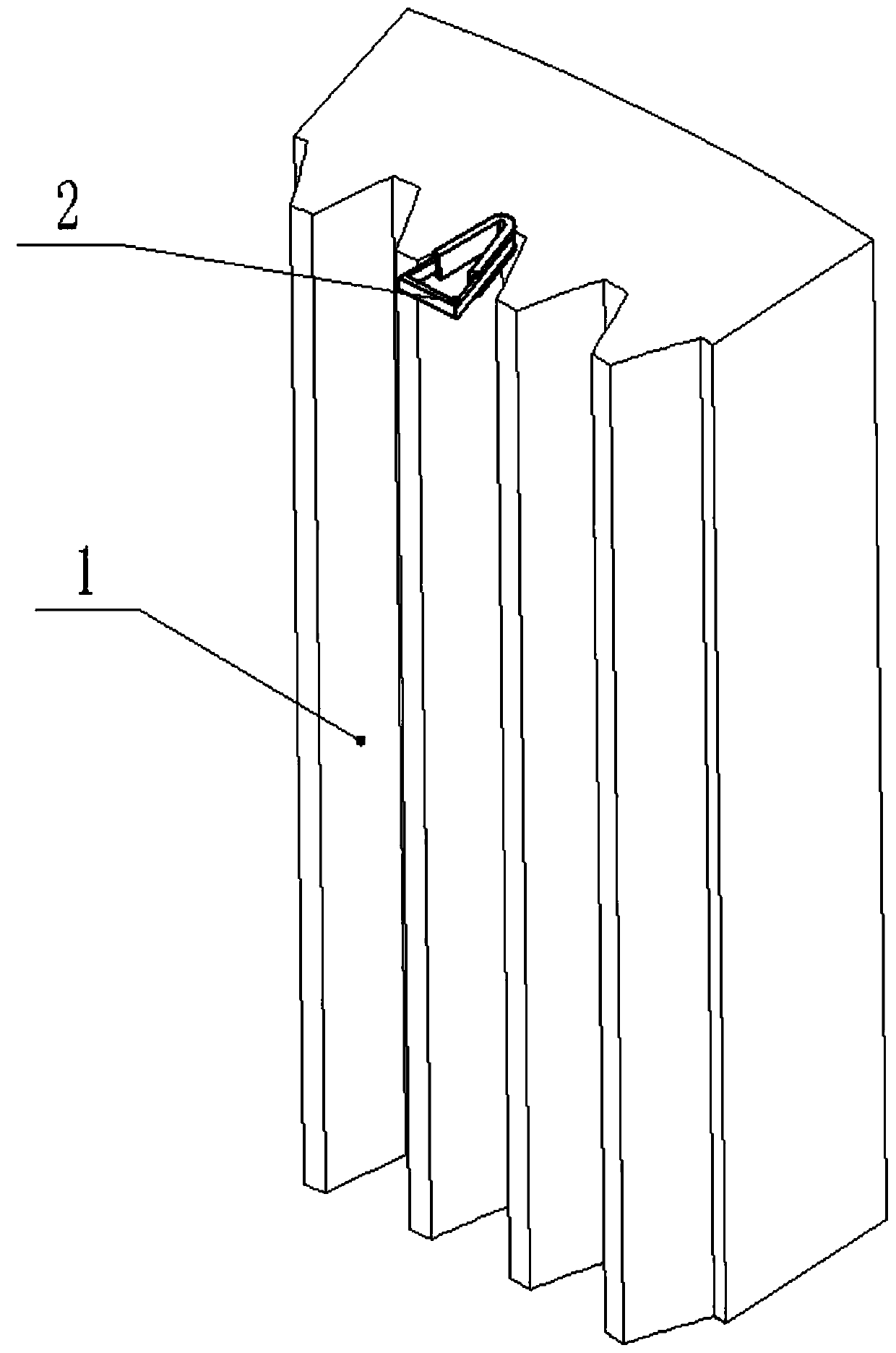

ANSYS simulation platform-based method for calculating movable induction heating of big gear rings

ActiveCN107169166AChange geometryChange the speed parameterDesign optimisation/simulationSpecial data processing applicationsCouplingEngineering

The invention discloses an ANSYS simulation platform-based method for calculating movable induction heating of big gear rings. The method comprises the following steps of: determining a modeling-required parameter according to main equipment and workpieces used in an induction heating process of big gear rings; determining a software-recognizable equivalent parameter according to an induction heating process parameter used in a production process; establishing an initial analysis geometric model according to the determining parameters, adding physical property parameters of used materials, and dividing grids; applying a boundary condition and a corresponding load, and carrying out initial electromagnetic heating coupling calculation; extracting all the node temperatures of the analyzed workpieces; moving an inductor, establishing a movement analysis geometric model according to the determined parameters, adding material attributes, dividing grids, endowing nodes in one-to-one correspondence with the workpieces with the node temperatures extracted in the electromagnetic calculation, applying a boundary condition and a load, and carrying out continuous electromagnetic heating coupling calculation; and controlling the movement speed of the inductor through realizing the distance of each movement of the inductor and a corresponding induction heating time until the whole calculation is completed.

Owner:YANSHAN UNIV

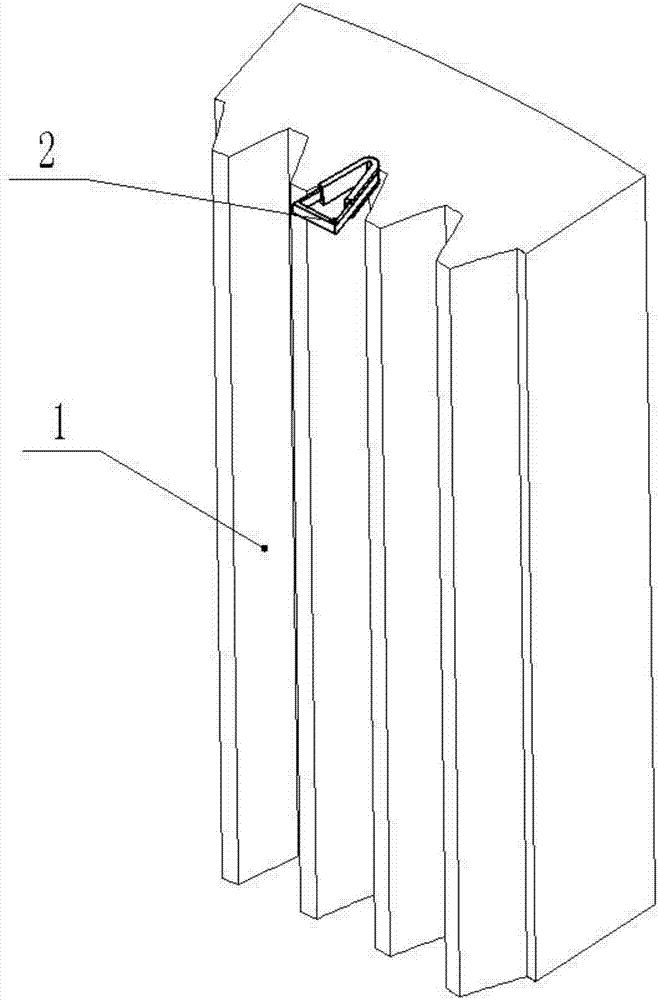

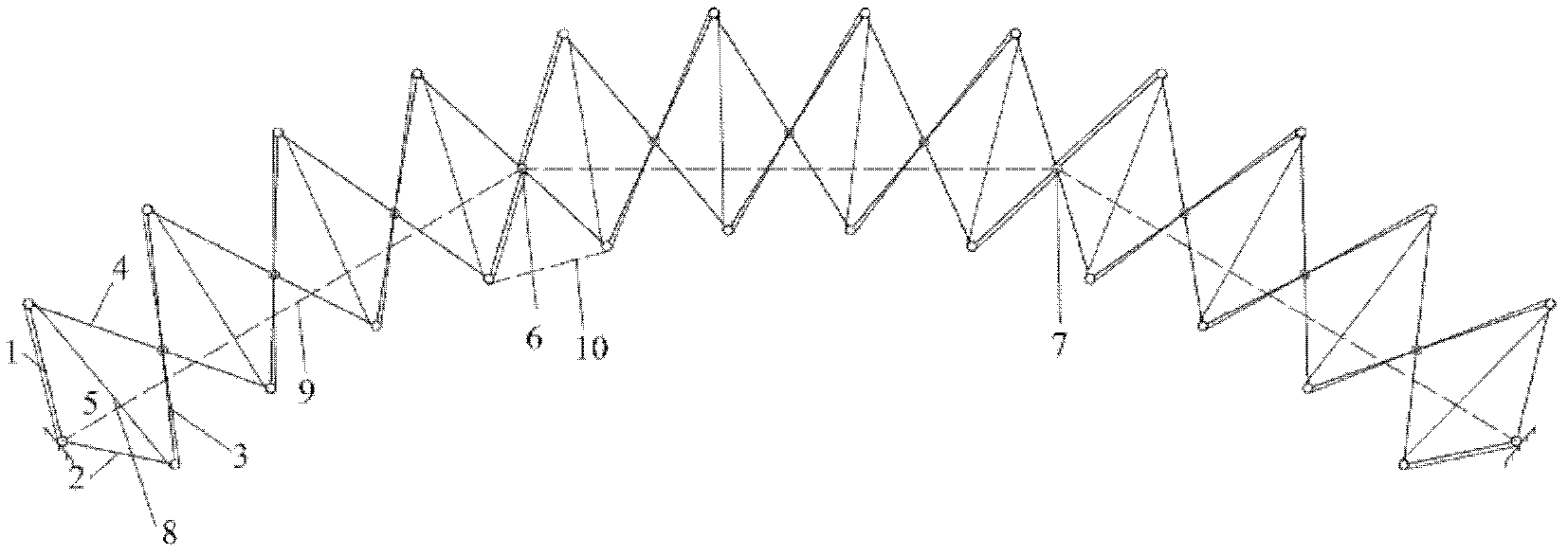

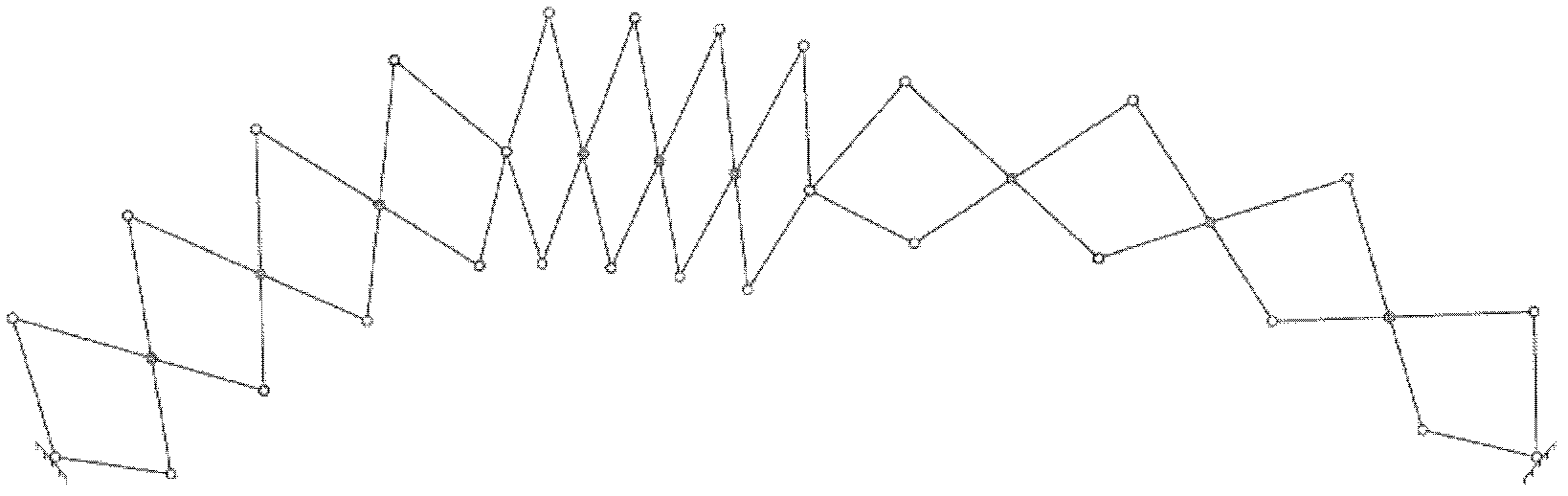

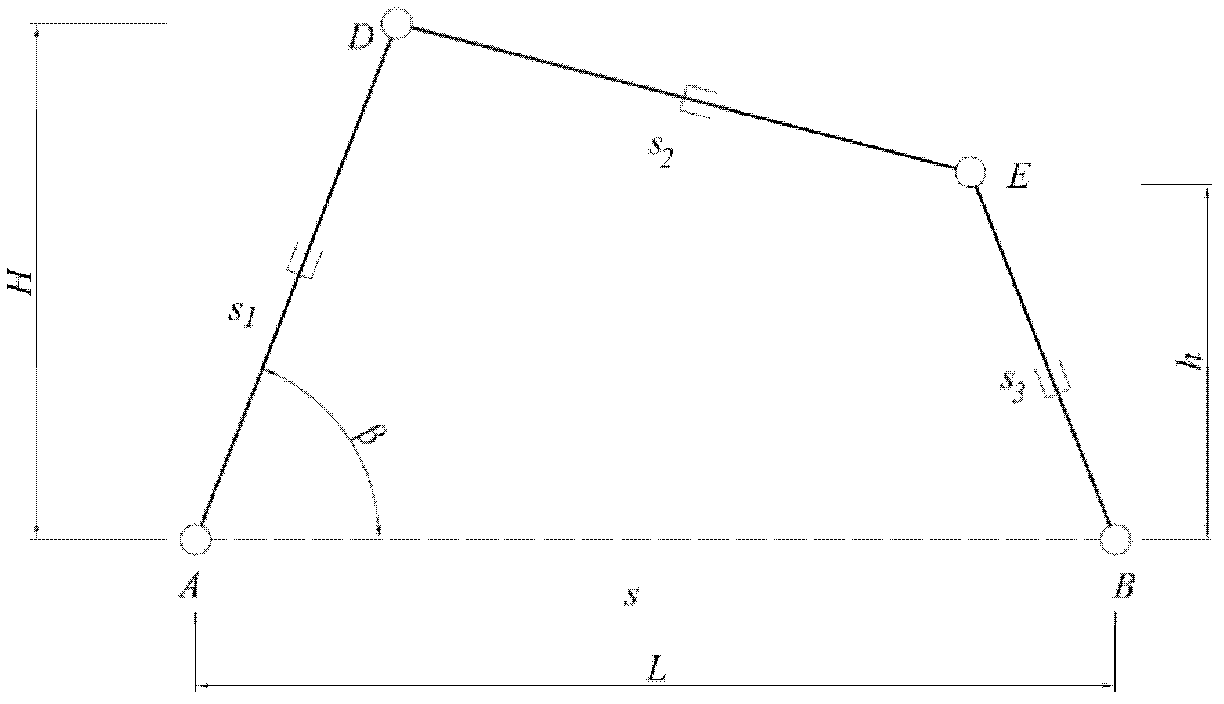

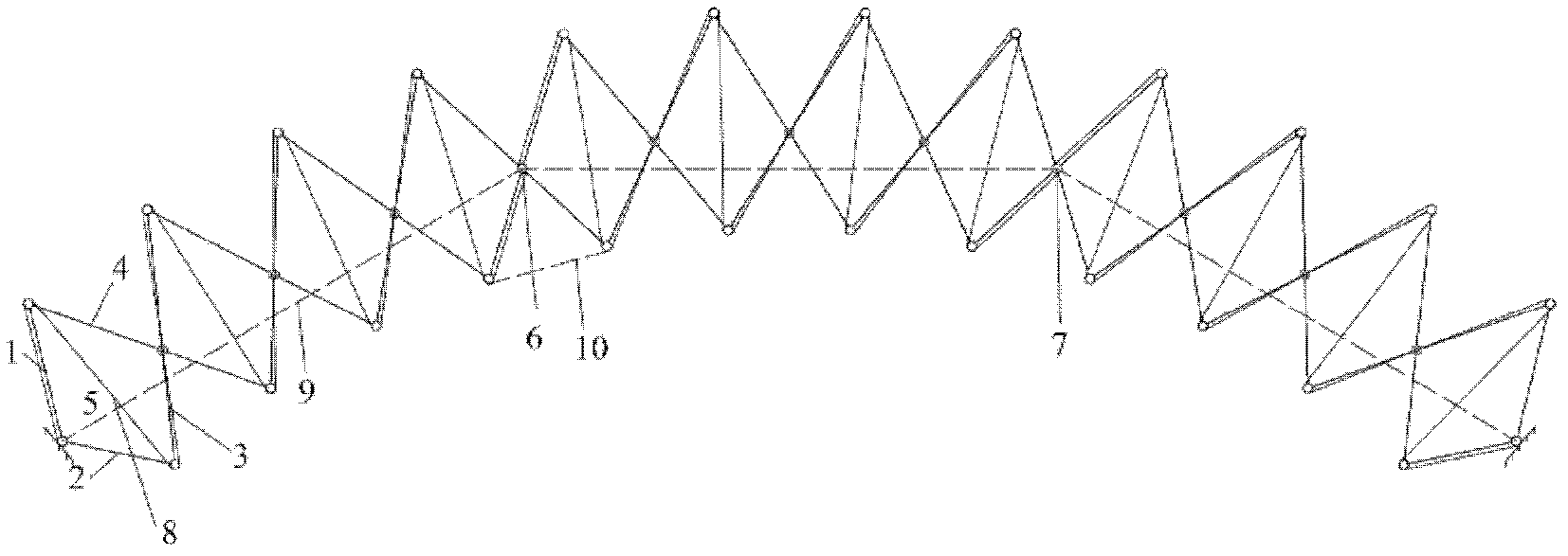

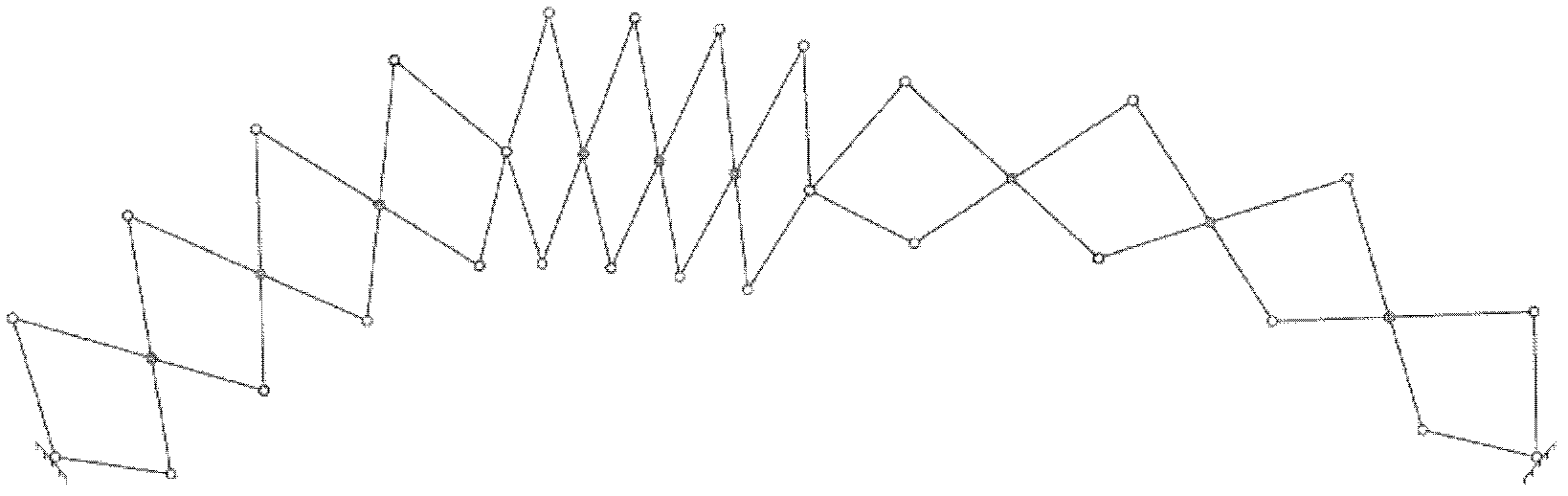

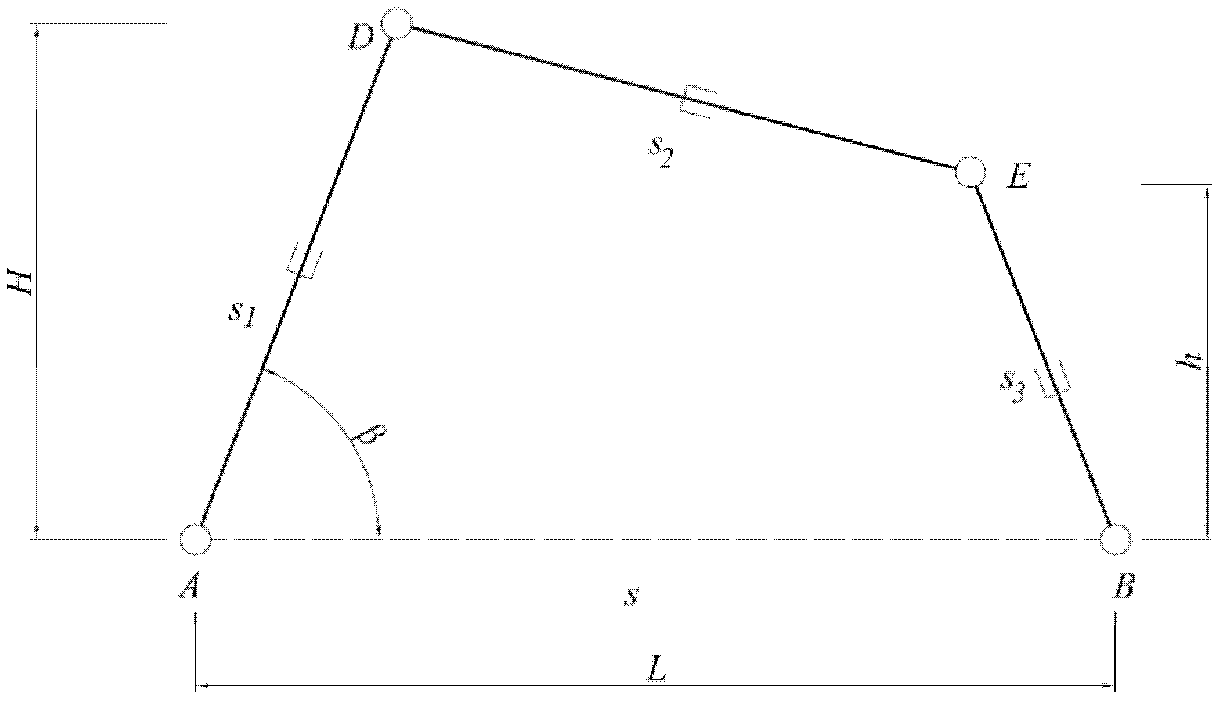

Movable truss with high-order curve shape

ActiveCN102605891AMeet the requirements of the opening and closing functionMeet functional requirementsBuilding roofsCurve shapeInterconnection

The invention discloses a truss structure with a high-order curve shape, comprising a connecting bar mechanism and an inhaul cable, wherein the connecting bar mechanism is obtained by interconnection of n four-connecting bar mechanisms by n-1 joints; the four-connecting bar mechanism is obtained by rotary connection of a first connecting bar, a second connecting bar, a third connecting bar and a fourth connecting bar; lengths of the first connecting bar and the fourth connecting bar are the same; lengths of the second connecting bar and the third connecting bar are the same; and lengths of the first connecting bar and the fourth connecting bar are longer than those of the second connecting bar and the third connecting bar. Because lengths of the first connecting bar and the second connecting bar in the connecting bar mechanism are different, in the movable truss, the joint of each sub connecting bar mechanism becomes arc during deformation; the corresponding geometrical shape is arc; and curvatures of the arcs change during the movement of the truss, so that the movable truss can form a geometrical shape with high-order curve.

Owner:SOUTHEAST UNIV

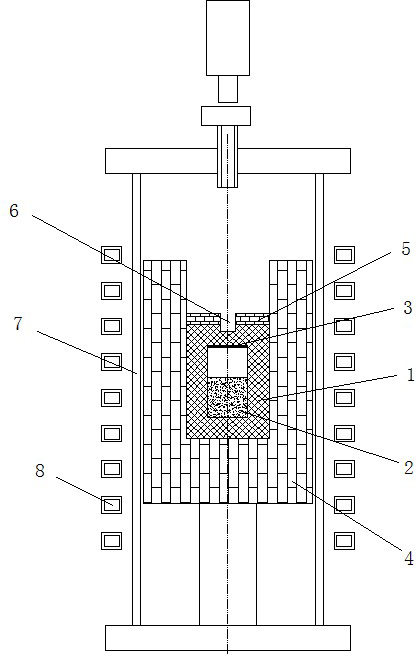

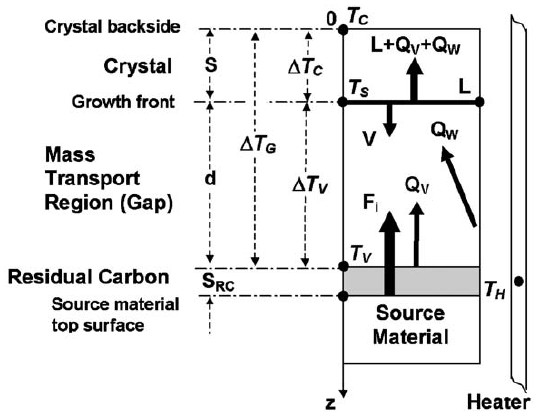

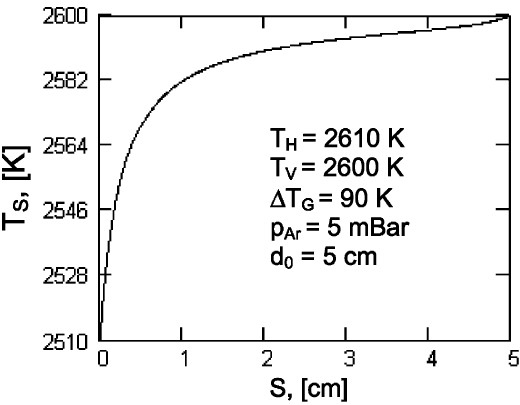

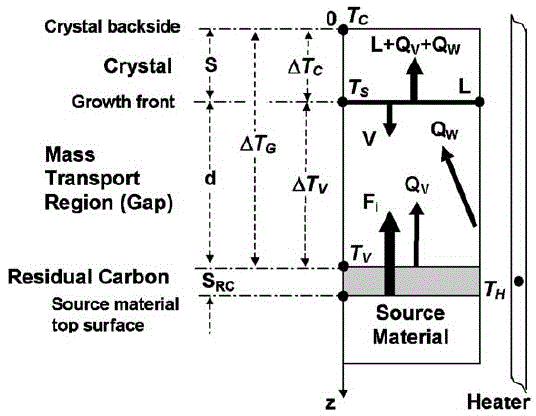

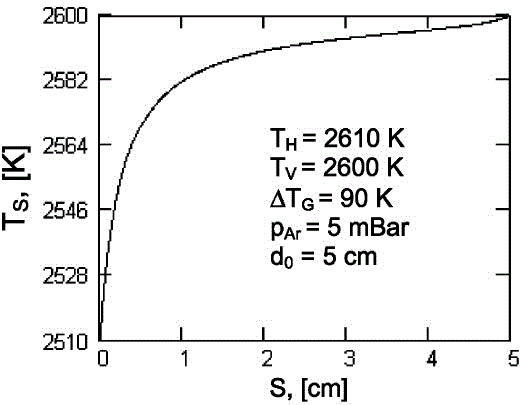

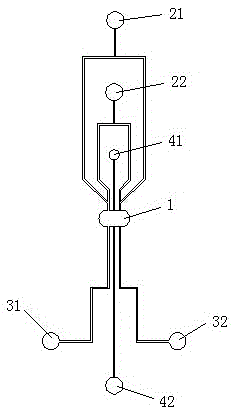

Method and device for growing silicon carbide crystal according to PVT (Physical Vapor Transport) method

InactiveCN102644105AChange geometryEliminate changes in temperature fieldPolycrystalline material growthFrom condensed vaporsDynamic balanceCrystal growth

The invention relates to a method and a device for growing a silicon carbide crystal according to a PVT (Physical Vapor Transport) method. A moveable heat-insulating adjusting element is arranged above a crucible; when the silicon carbide crystal grows, with the thickening of the crystal on a crucible cover, a distance D between the moveable heat-insulating adjusting element and the crucible cover is gradually increased, wherein the thermal resistance Rc of the crystal to thermal flux Q is increased, with the increasing of the thickness of the crystal; the equivalent thermal resistance Rb of the moveable heat-insulating adjusting element to the thermal flux Q is reduced while the distance D is increased; and the temperature of a crystal interface is kept unchanged by keeping the dynamic balance between the increment of Rc and the reduction of Rb. According to the method, a heat-insulating adjusting element on the crucible cover is changed into the heat-insulating adjusting element which can move according to the technical demand during the growing process of the crystal. A geometric structure of a heat-insulating system and the energy output of a graphite crucible are changed by changing the distance between the moveable heat-insulating adjusting element and the crucible cover, so that the purpose of adjusting the temperature field in the graphite crucible during the growing process of the crystal is achieved.

Owner:吴晟

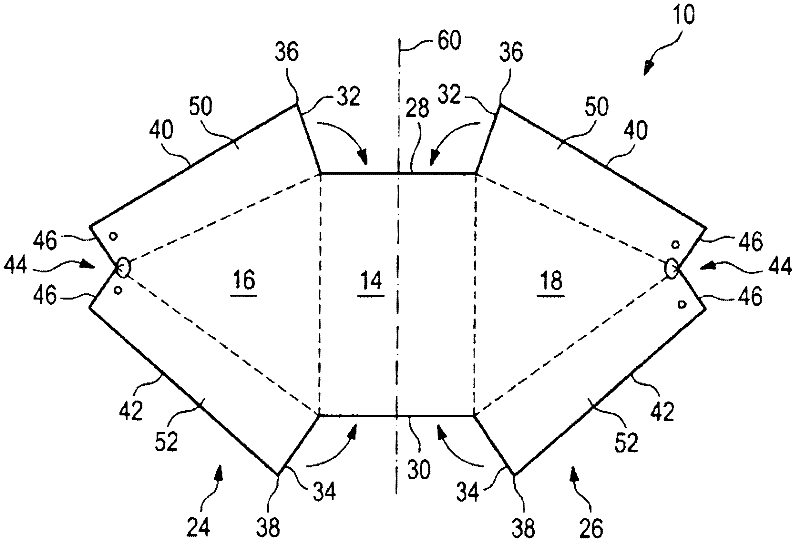

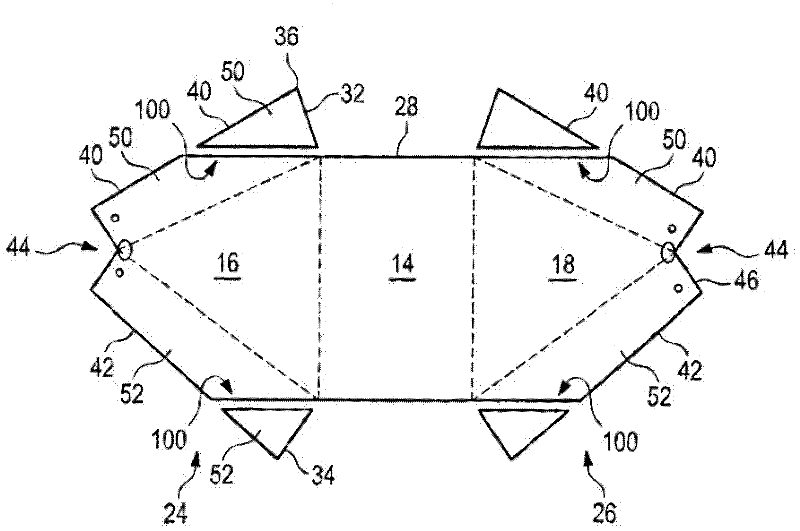

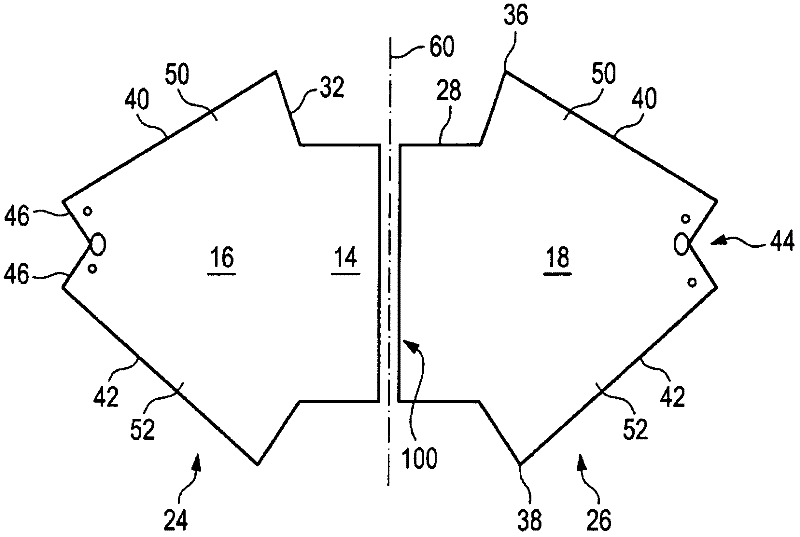

Airbag

The invention relates to an airbag, especially a passenger airbag, comprises a rear injection orifice, a front wall (14) for the impact of the occupant as well as two opposed sidewalls (16, 18) and an upper wall and a lower wall. Each of the upper and lower walls is split and consists of side portions (50, 52) which are juxtaposed and are connected to each other along opposite margins (40, 42), wherein the margins (40, 42) of the side portions which are juxtaposed and are connected to each other of the upper wall and / or the lower wall are extended in a nonlinear form. Thus the airbag can be easily and advantageously manufactured and the structure design can be fast adapted to different indoor contour.

Owner:TRW AUTOMOTIVE GMBH

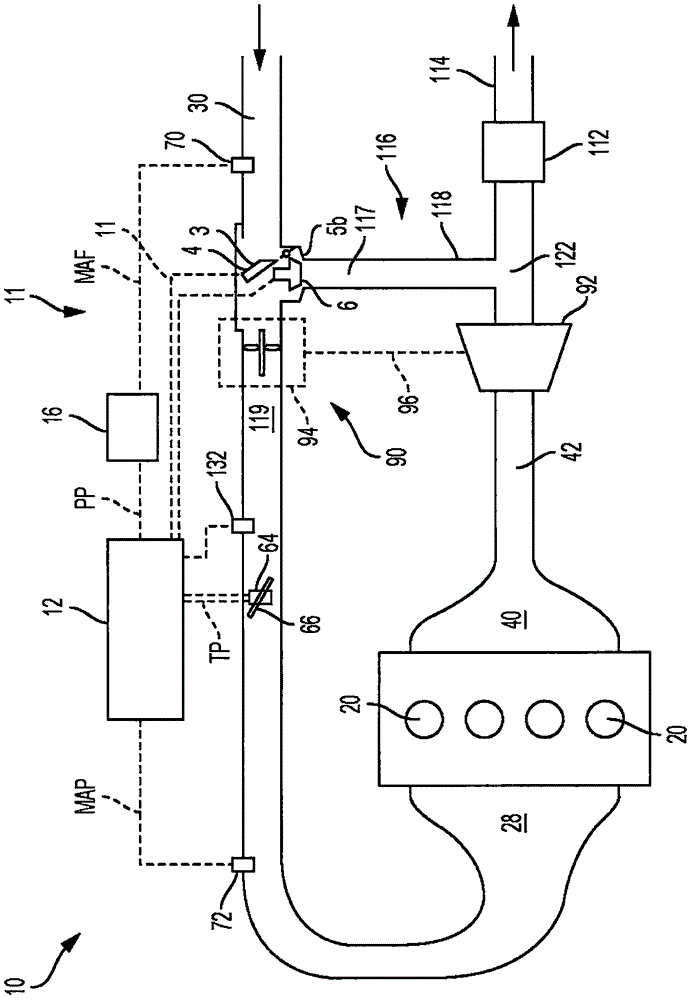

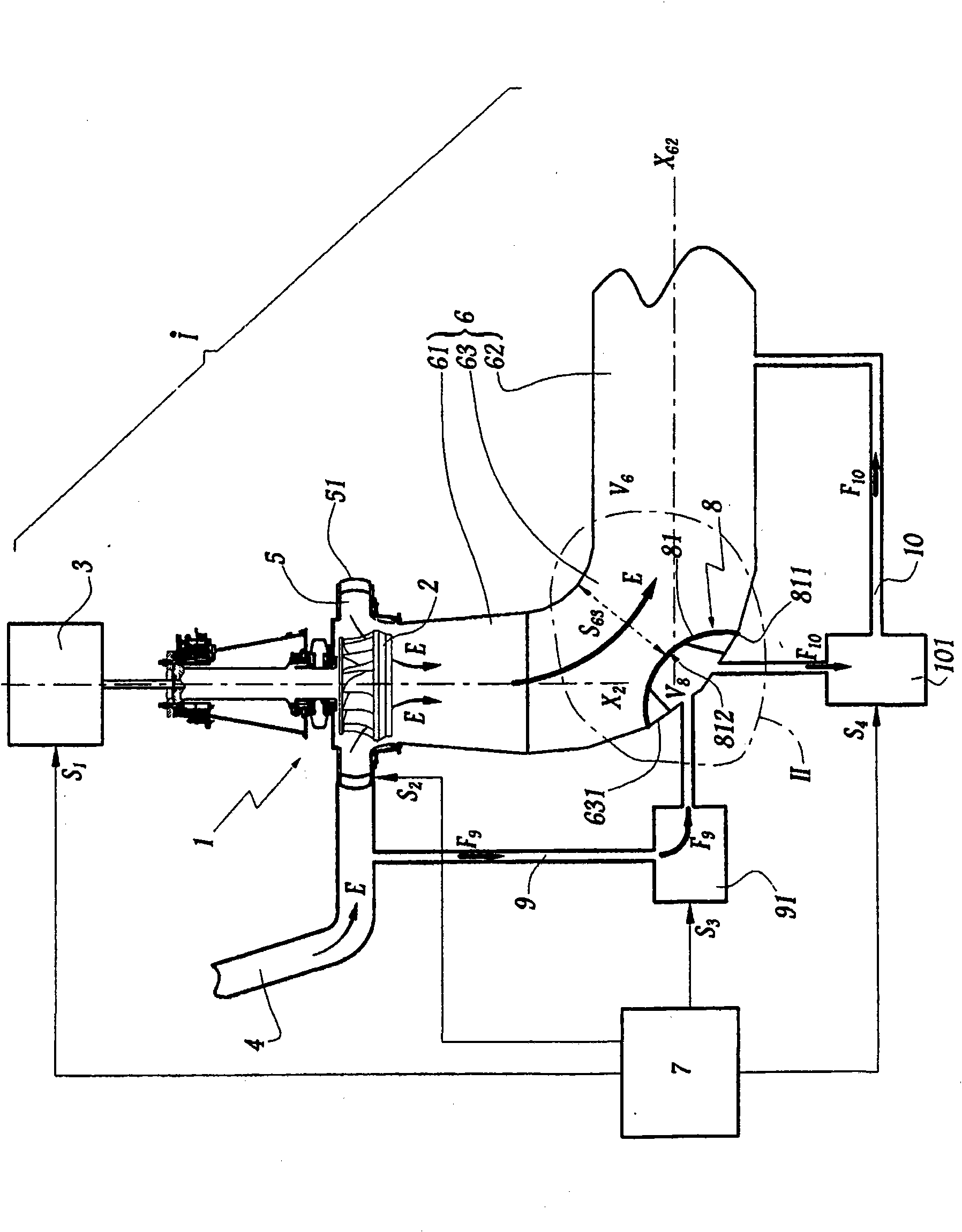

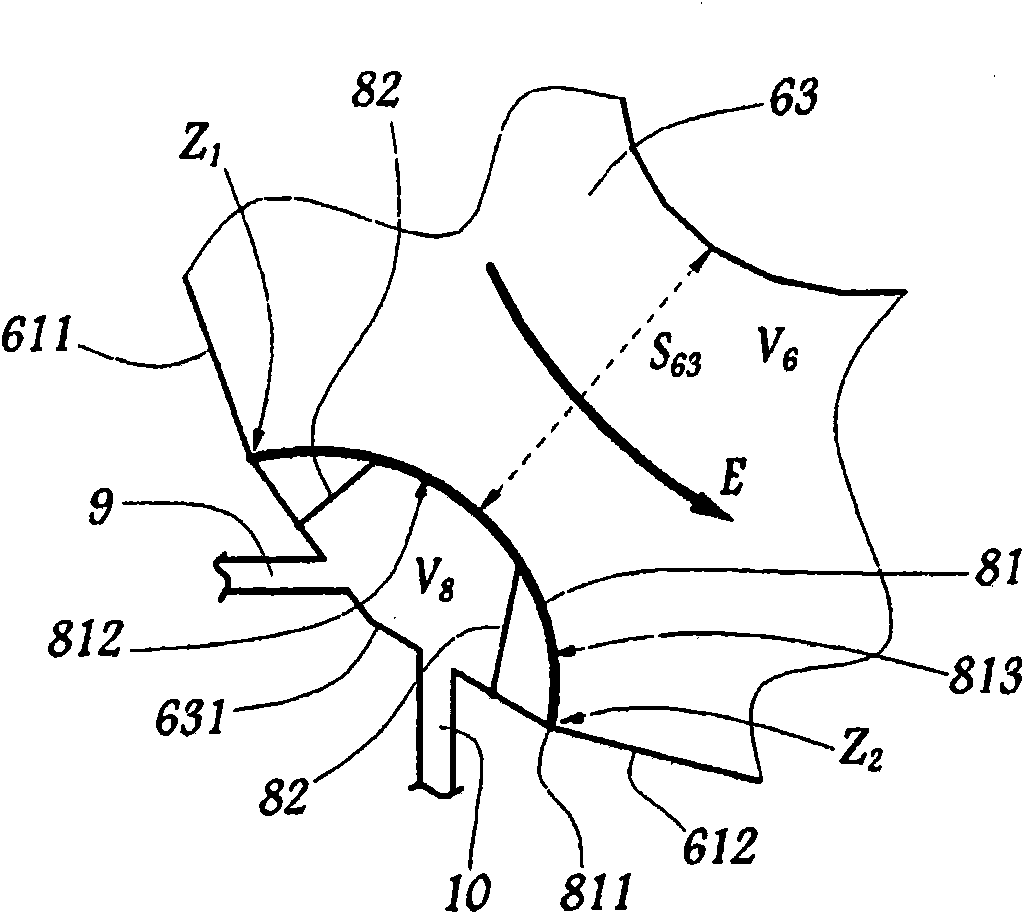

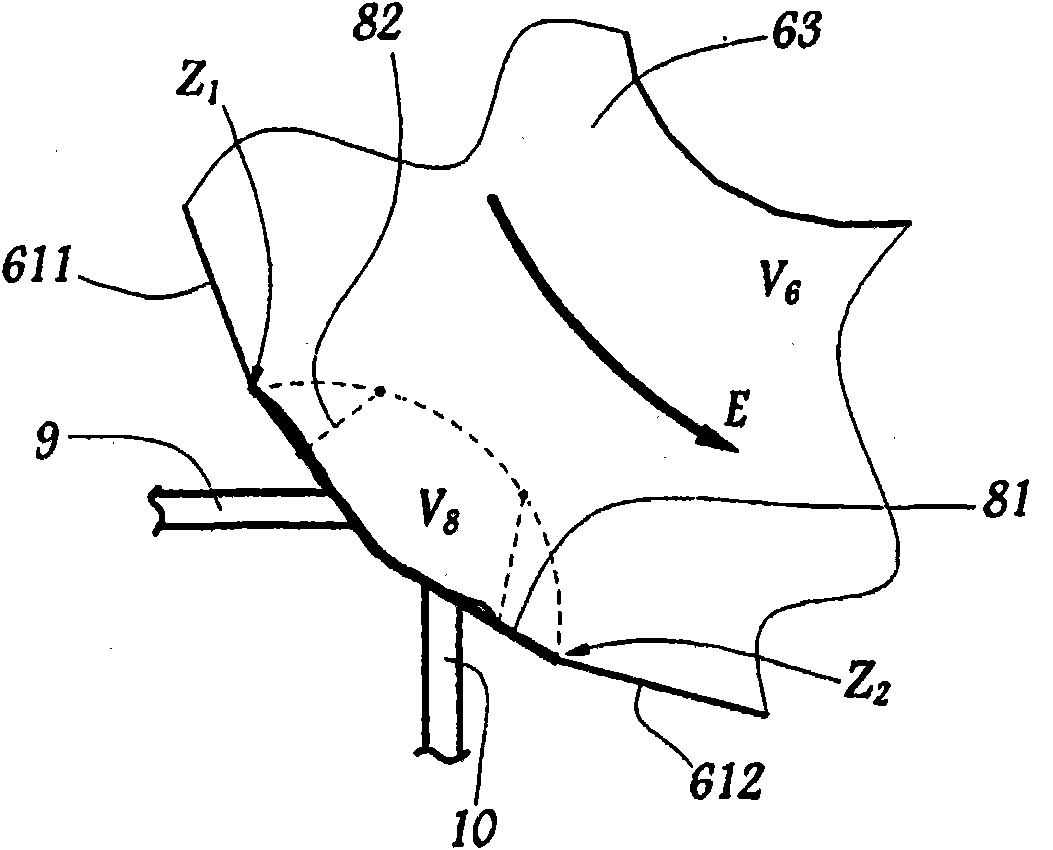

Supercharger with exhaust gas recirculation

ActiveCN106401762AImprove torque characteristicsHigh boost pressure ratioElectrical controlInternal combustion piston enginesImpellerJunction point

The invention relates to a supercharger with exhaust gas recirculation. An engine, methods and systems are provided for supercharging charge air for internal combustion engines. The engine having an intake, and a blower with at least one impeller in the intake mounted on a rotatable shaft. An EGR line opens into the intake system upstream of the at least one impeller to form a junction point. A flap, pivotable about an axis running transversely with respect to the intake air flow, has: a first position which blocks the intake by way of a front side, and which opens up the EGR line; and a second position to cover the EGR line and open intake system wherein the flap is not planar, and has, at least on the front side thereof, at least one deformation as an unevenness.

Owner:FORD GLOBAL TECH LLC

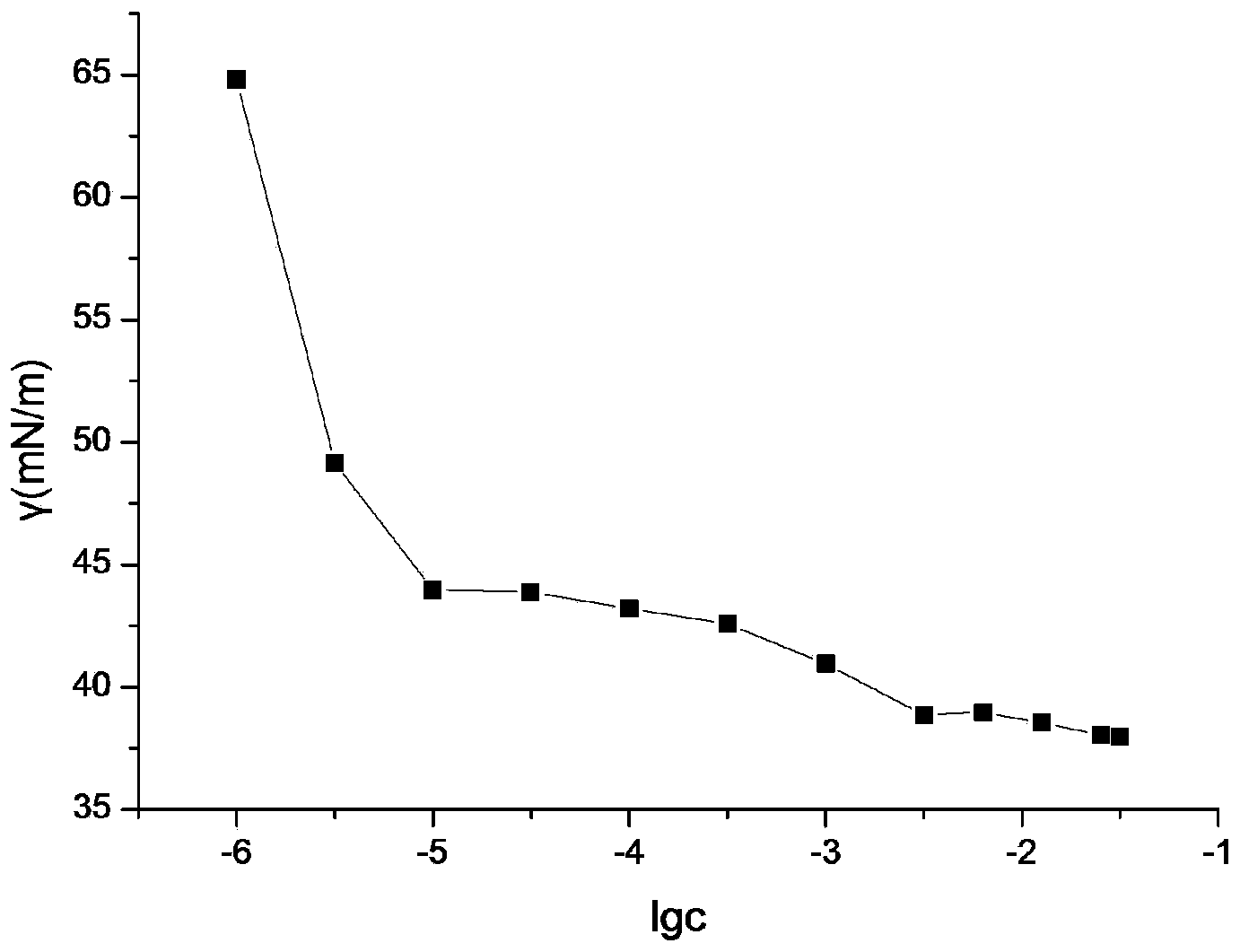

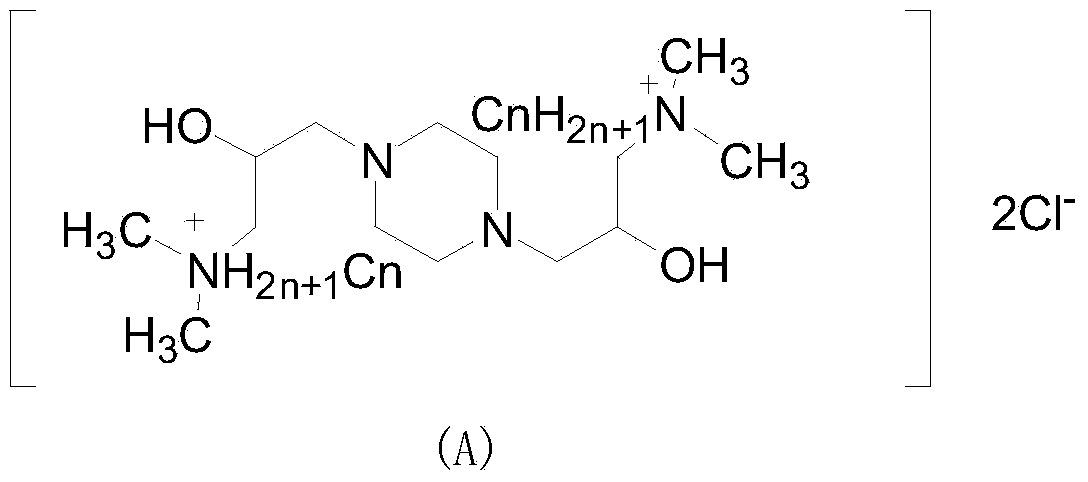

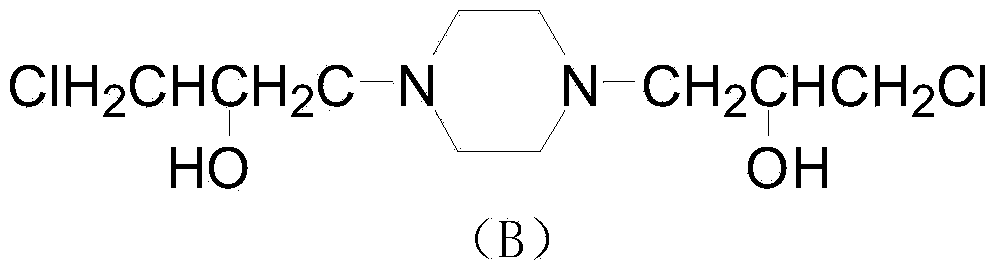

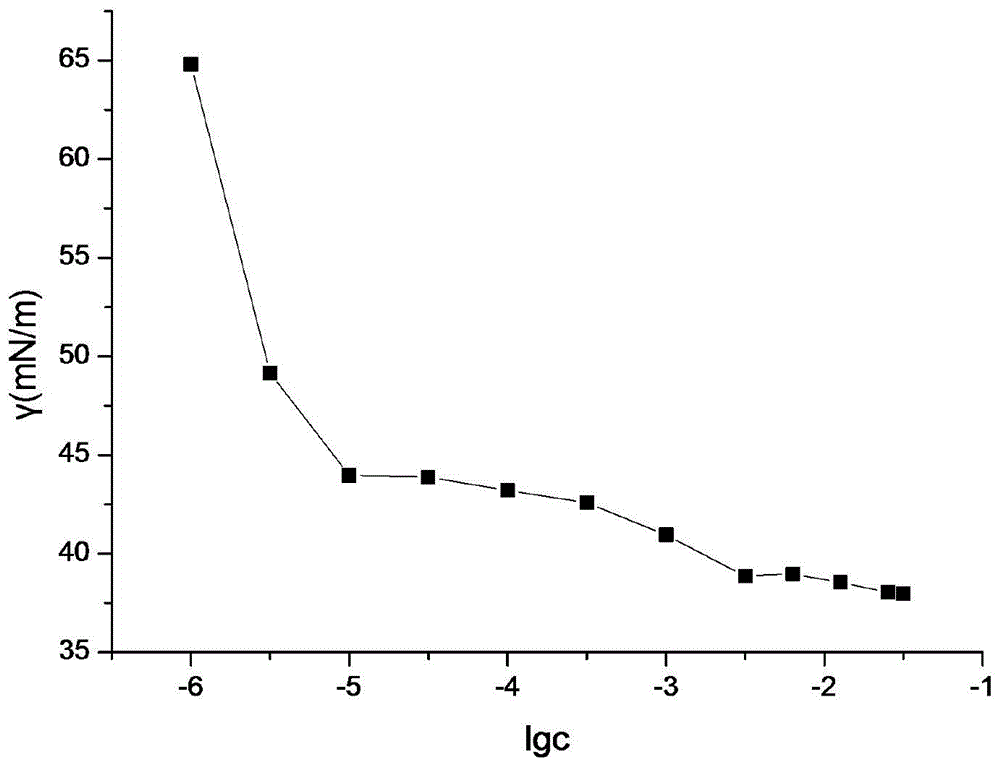

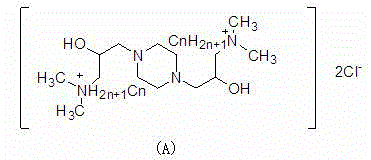

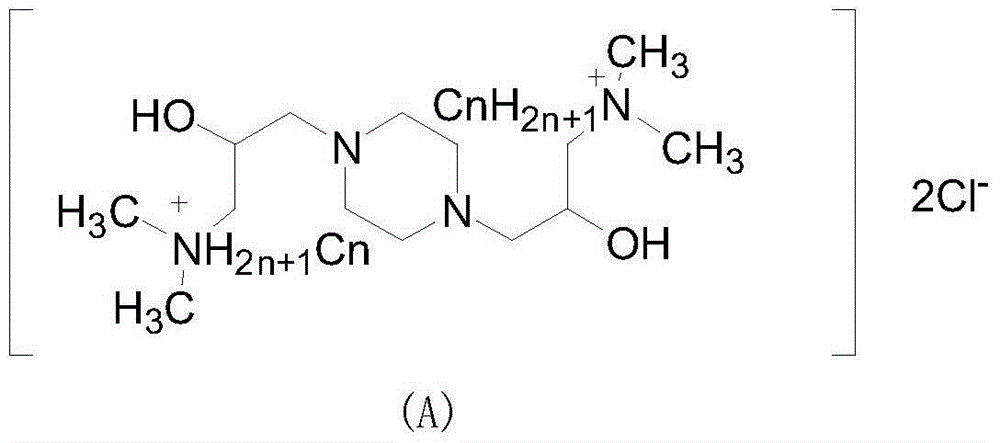

Novel dimeric cationic surfactant and preparation method thereof

InactiveCN103920415APositive and effective effectGood water solubilityOrganic chemistryTransportation and packagingSolubilityElectrical polarity

The invention relates to a novel dimeric cationic surfactant. The structural formula of the surfactant is indicated as formula (A). The dimeric cationic surfactant introduces groups at a polar head to reach chemical bonding, restrain separating force among the original single-chain single heads and improve appetency among carbon chains, thereby improving surface activity and opening a brand new pathway for practical application. The surfactant has good water solubility. Compared with the general single-head surfactant, the surfactant has low surface tension and a cmc value and is a novel surfactant with a wide application prospect. As shown in the specification, wherein, n=18, 16, 14 or 12.

Owner:HEBEI UNIV OF TECH

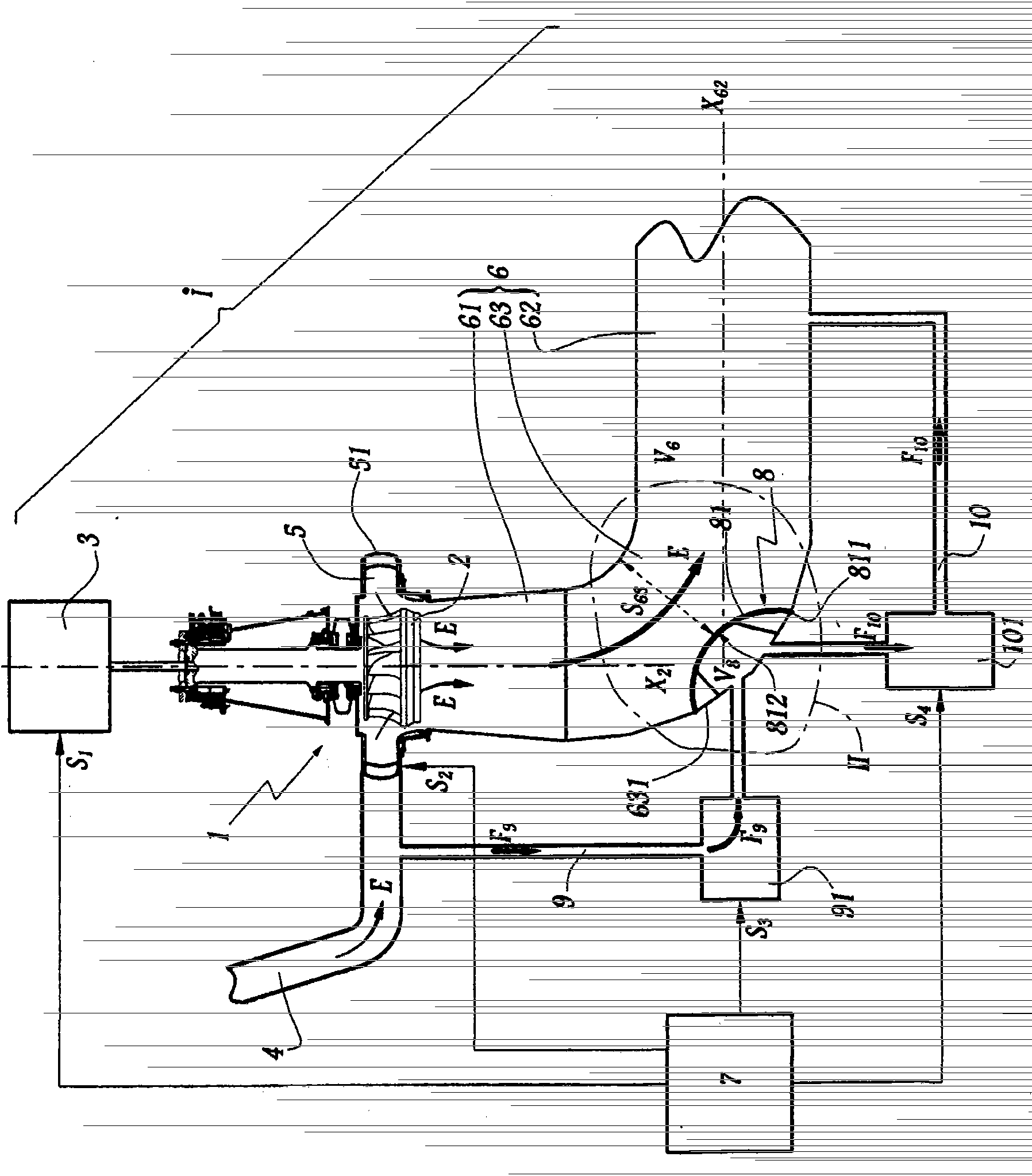

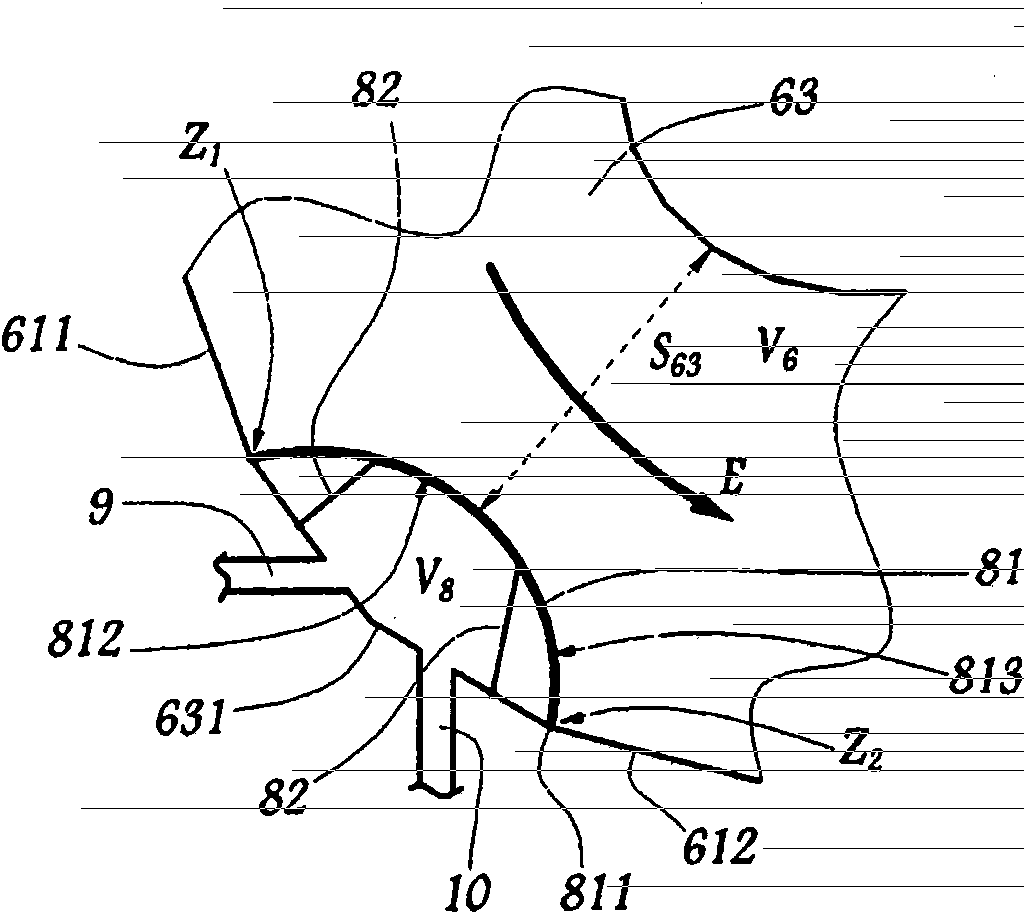

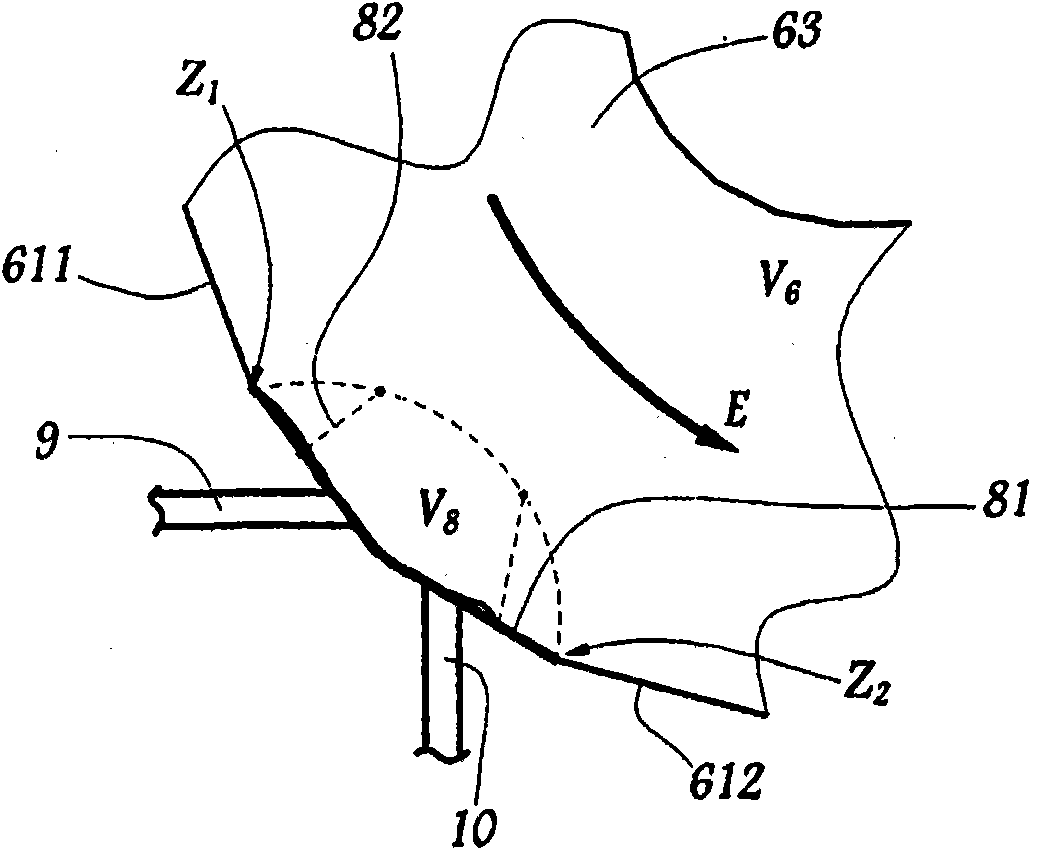

Energy conversion hydraulic plant and method for controlling such plant

InactiveCN101910618AImprove efficiencyImprove stabilityHydro energy generationPump controlEngineeringTurbine

The invention relates to a hydraulic plant (I) that defines a path (4, 5, 6) for a forced water flow (E), and comprises at least one machine (1) of the turbine, pump or turbine-pump type, a member (8) provided with at least one deformable wall (81) and defining at least one closed volume (V8) with variable dimensions. The plant also includes means (9, 91) for supplying (Fg) the closed volume with a pressurised fluid. The member with a deformable wall (81) is mounted in a hydraulic duct (6) located downstream from a rotary portion (2) of the machine (1). The deformable wall defines, locally and downstream from the rotary portion (2), a modular section (S63) for the flow (E) passage in the hydraulic duct (6). According to the method of the invention, a pressurised fluid is injected (F9) into a closed volume having variable dimensions (V8) and defined by a member (8) provided in a hydraulic duct (6) located downstream from the rotary portion (2), in order to modulate the passage section (S63).

Owner:GE RENEWABLE TECH

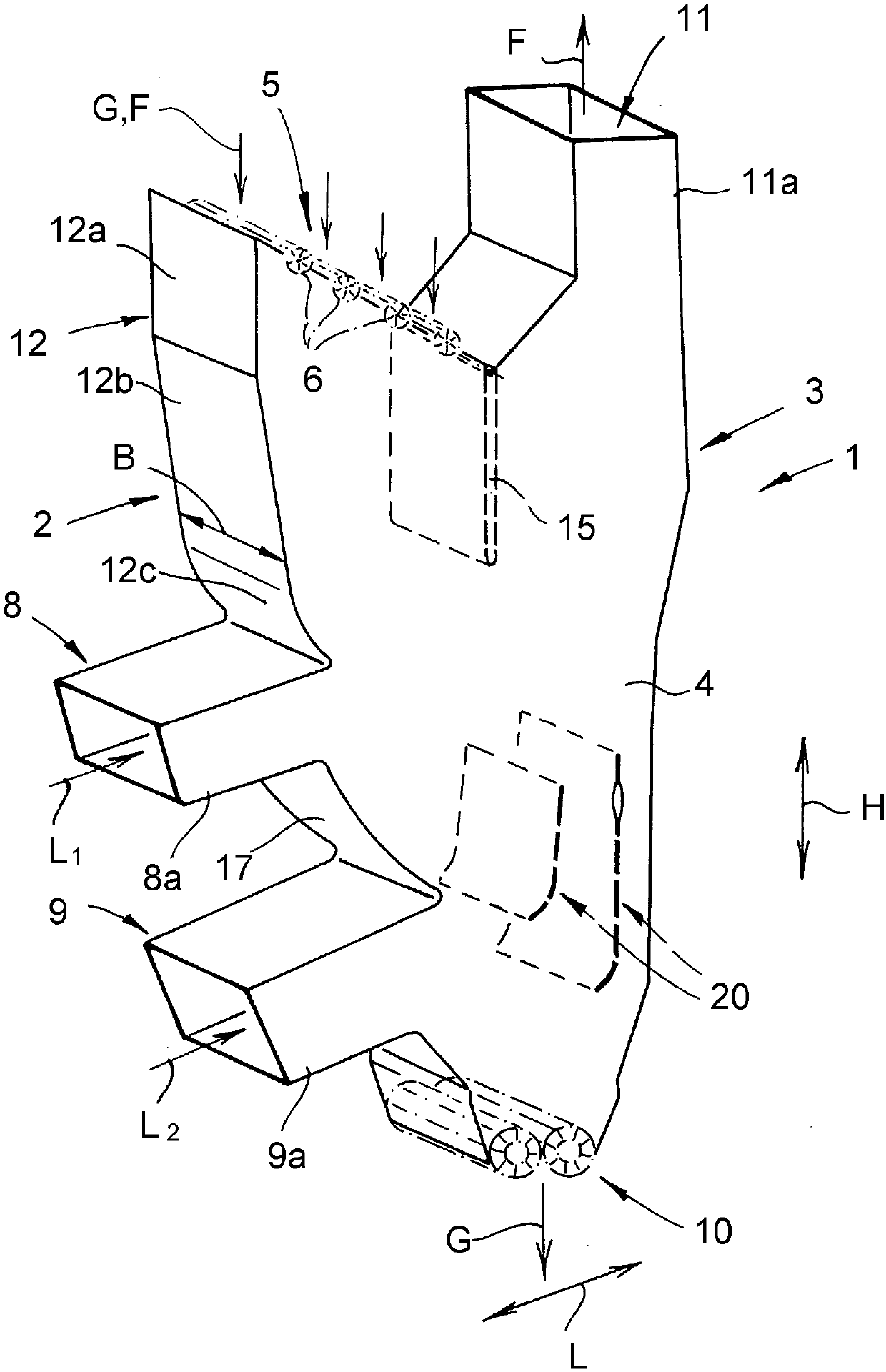

Sifter

InactiveCN107824450APrevent intrusionPrevent fallingGas current separationDomestic articlesFiberMechanical engineering

The invention relates to a sifter serves for separating coarse particles from a particle-carrying stream during the manufacture of wood material panels, in particular wood fiber panels. The sifter comprises at least one sifter housing having a feed inlet, at least one air inlet, an air outlet, and a coarse feed outlet disposed below the feed inlet. The upper front wall of the screen housing, whichis arranged above the air inlet, is oriented obliquely with respect to the vertical line at least in partial regions. The screening machine is characterized in that the upper edge of the air inlet isaligned in side view above the lower edge of the air inlet or protrudes by an amount (M) from the lower edge.

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

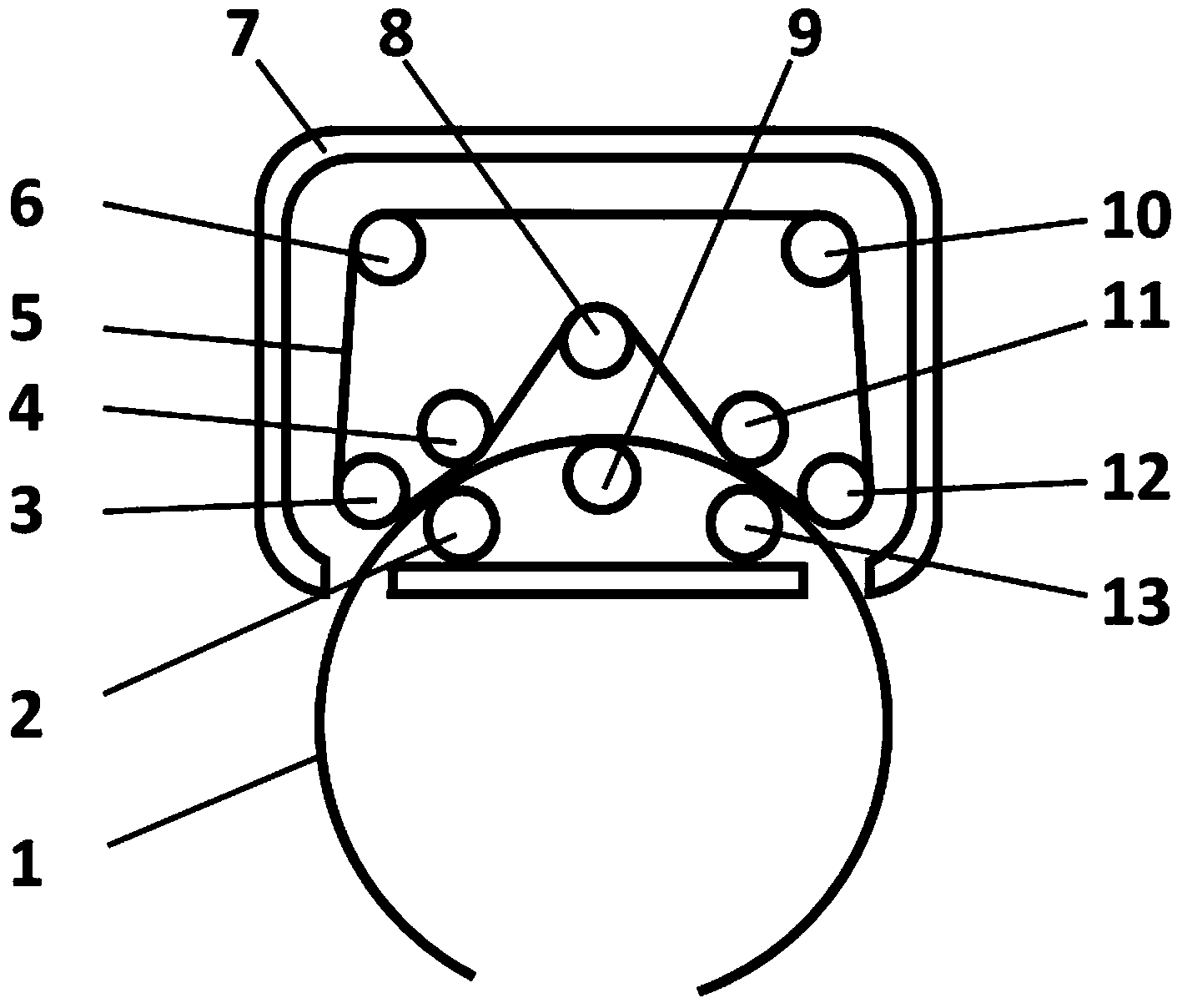

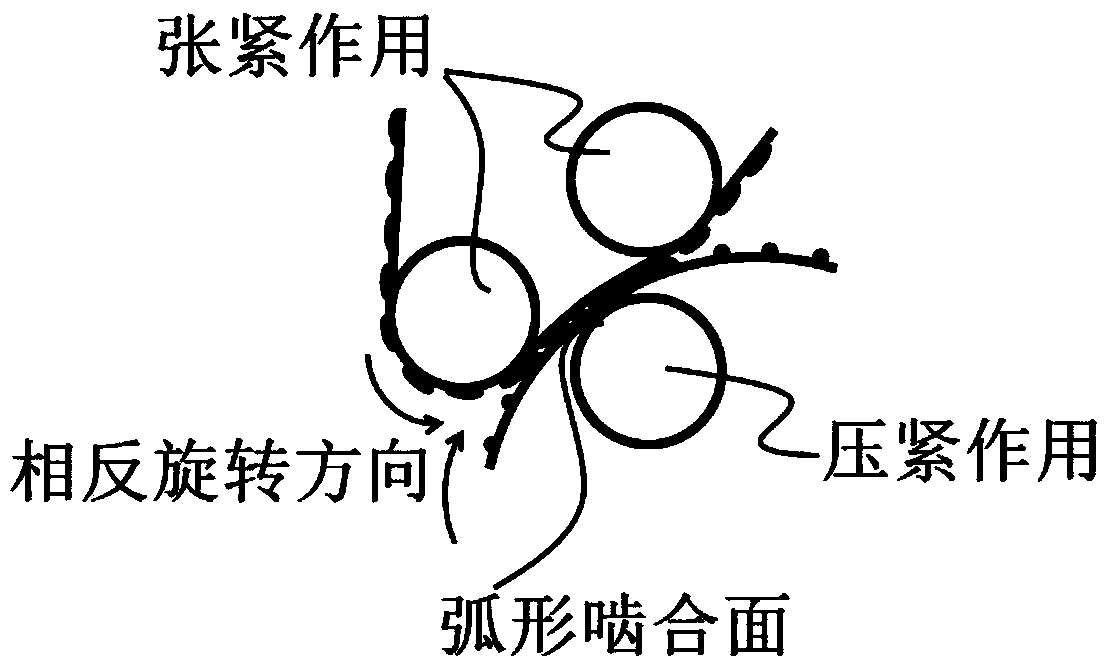

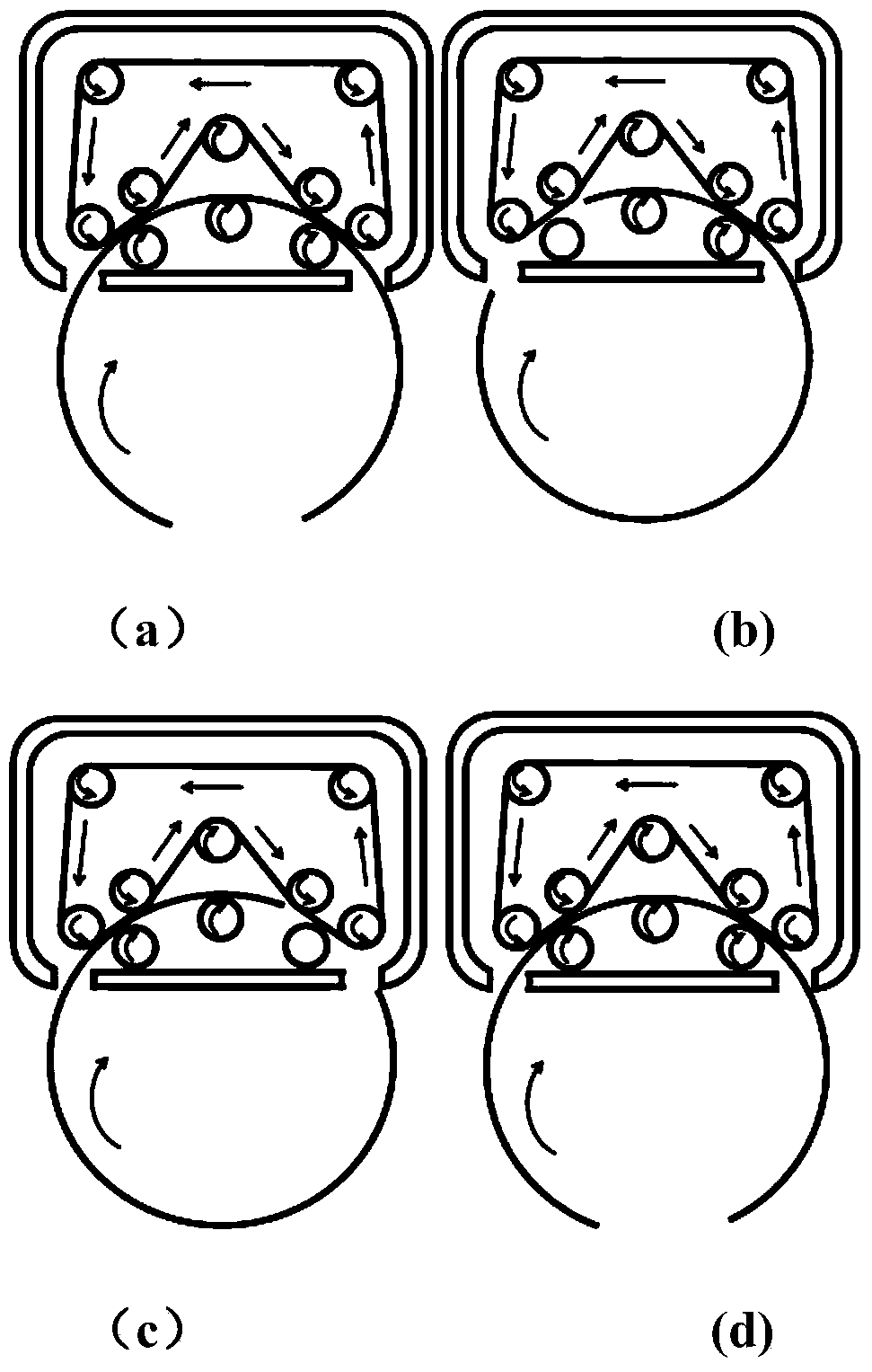

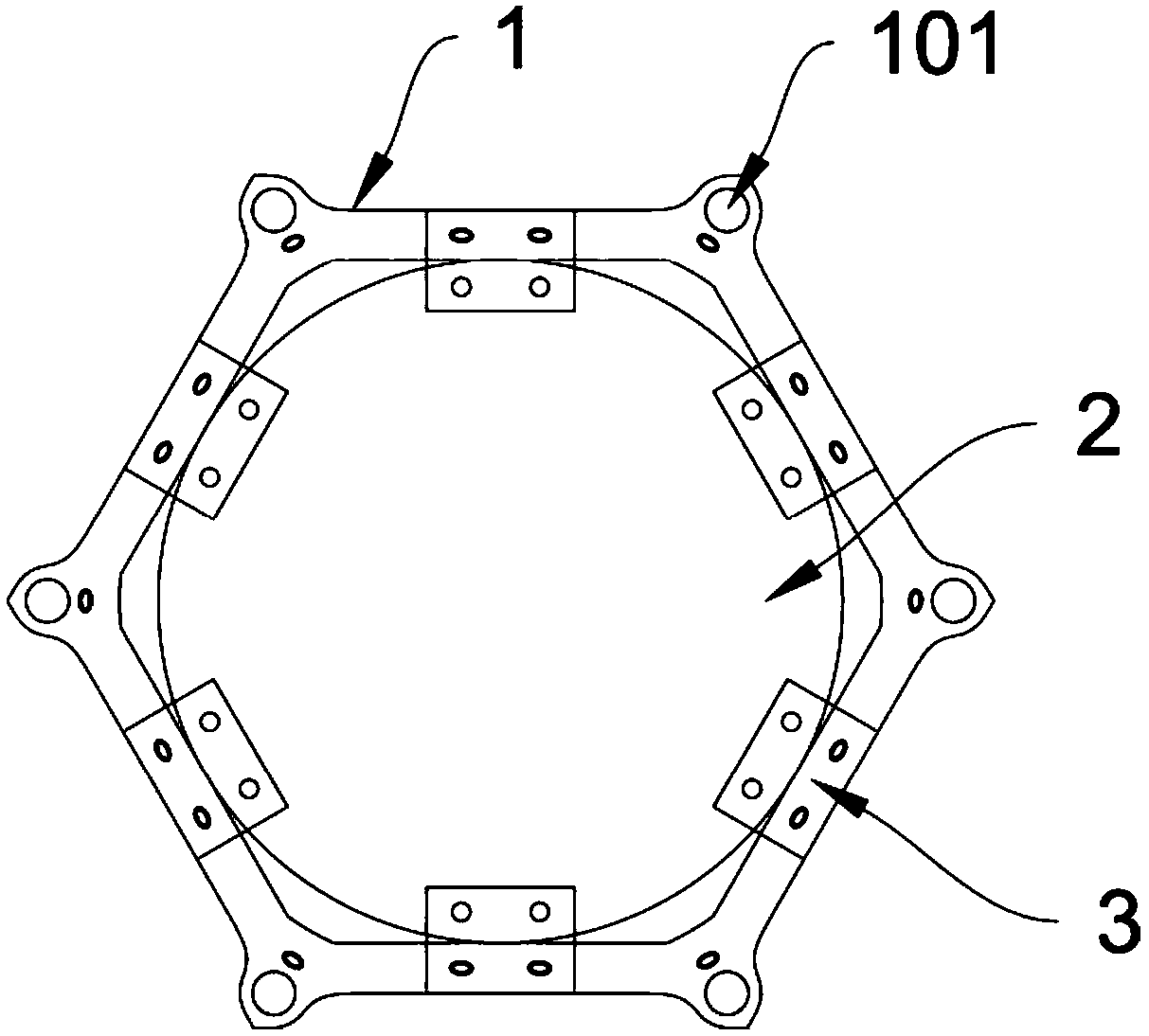

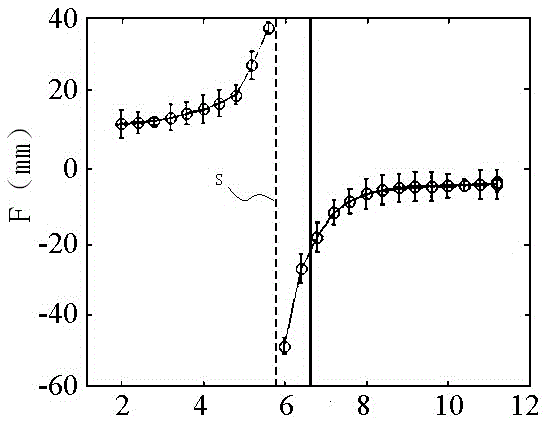

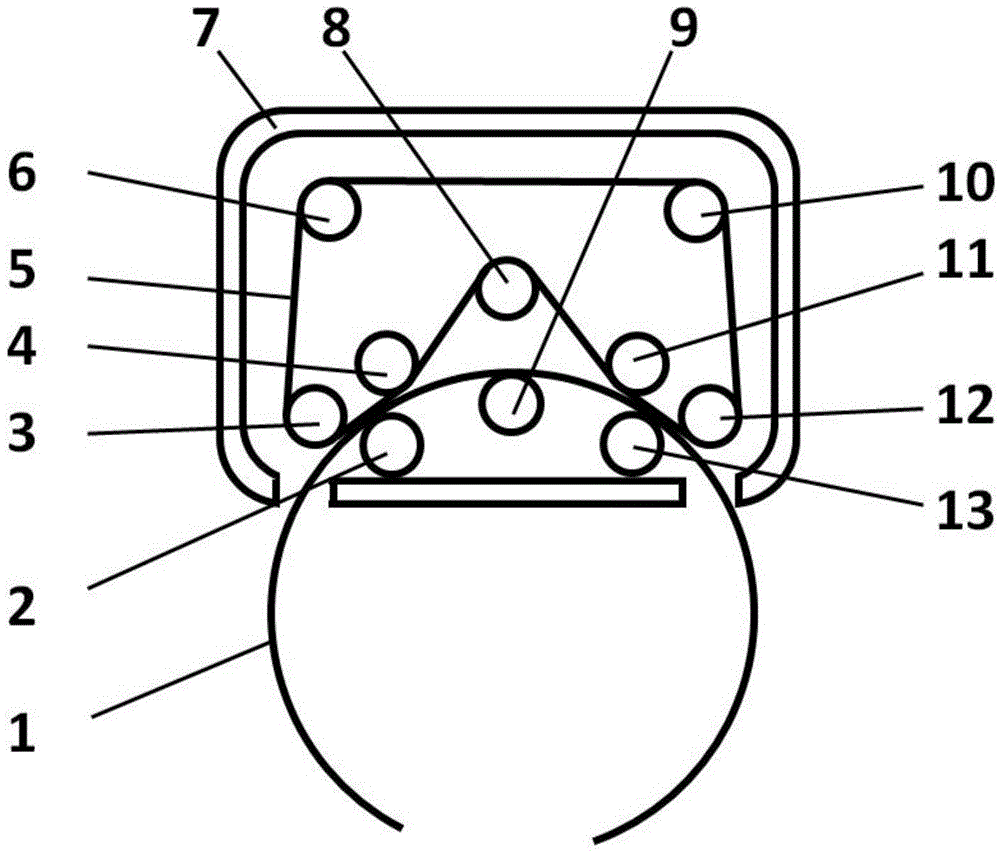

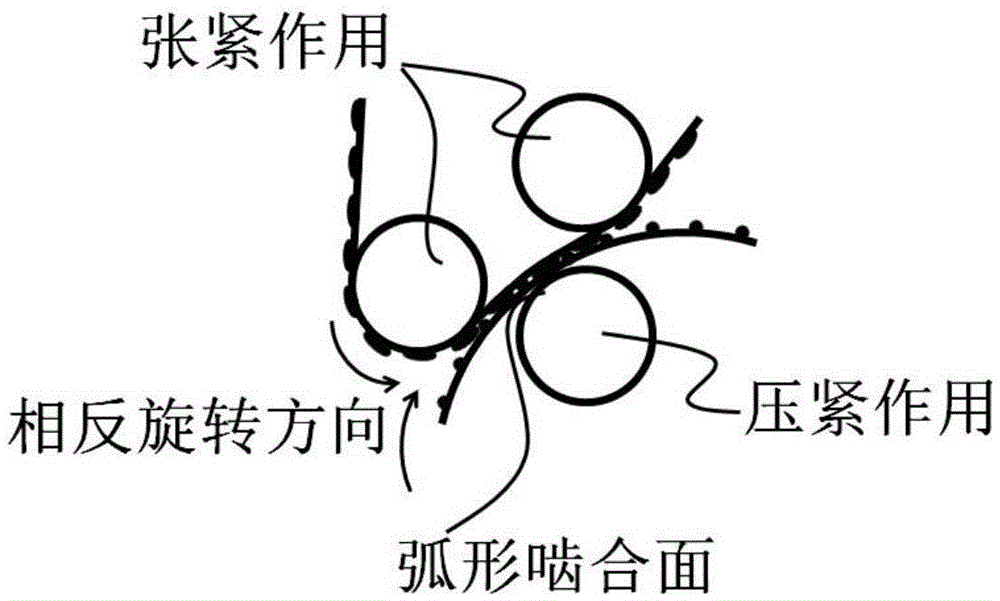

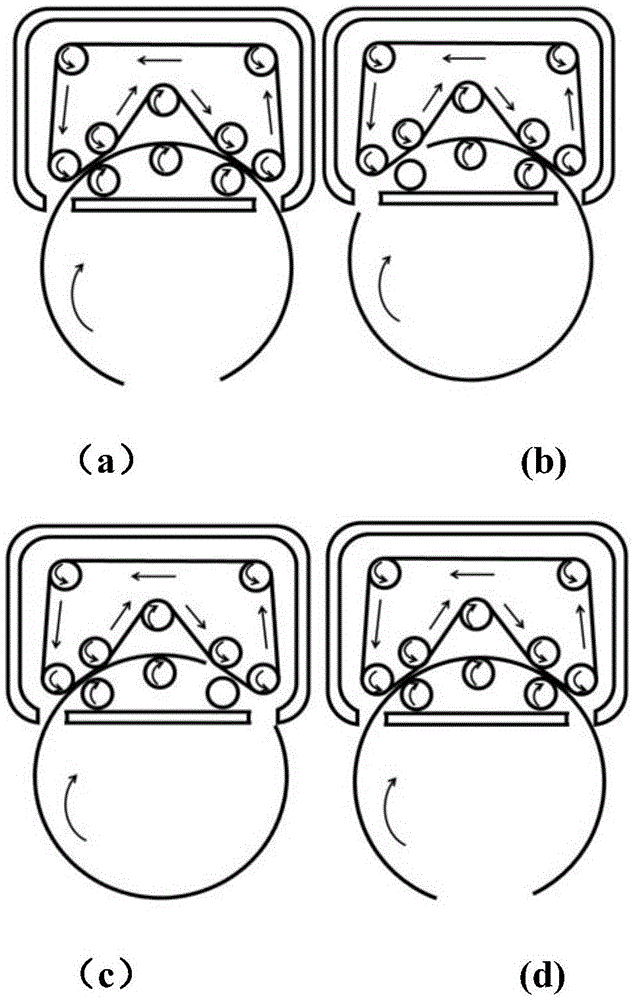

Flexible transmission mechanism of non-closed type annular rotator and application method of flexible transmission mechanism

The invention discloses a flexible transmission mechanism of a non-closed type annular rotator and an application method of the flexible transmission mechanism. The flexible transmission mechanism comprises the non-closed type annular rotator, three pinch rollers, six tensioning wheels, a toothed belt, a housing and a gear, wherein the pinch rollers, the tensioning wheels and a central spindle of the gear are fixed on a base plate of the housing; the gear, the second tensioning wheel, the first tensioning wheel, the third tensioning wheel, the fourth tensioning wheel, the sixth tensioning wheel and the fifth tensioning wheel are arranged clockwise; the inner side of the toothed belt is fitted with the outer sides of the five tensioning wheels to form a closed ring; the outer side of the toothed belt is meshed with the gear and the outer tooth shape of the non-closed type annular rotator; the three pinch rollers are fitted with the inner side of the non-closed type annular rotator. The flexible transmission mechanism of the non-closed type annular rotator and the application method of the flexible transmission mechanism, disclosed by the invention, can enlarge the meshing area of the flexible transmission mechanism, the gear and the non-closed type annular rotator, so as to increase the meshing force, and meanwhile avoid interference and clamping between the flexible transmission mechanism, the gear and the rigid tooth shape of the non-closed type annular rotator.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

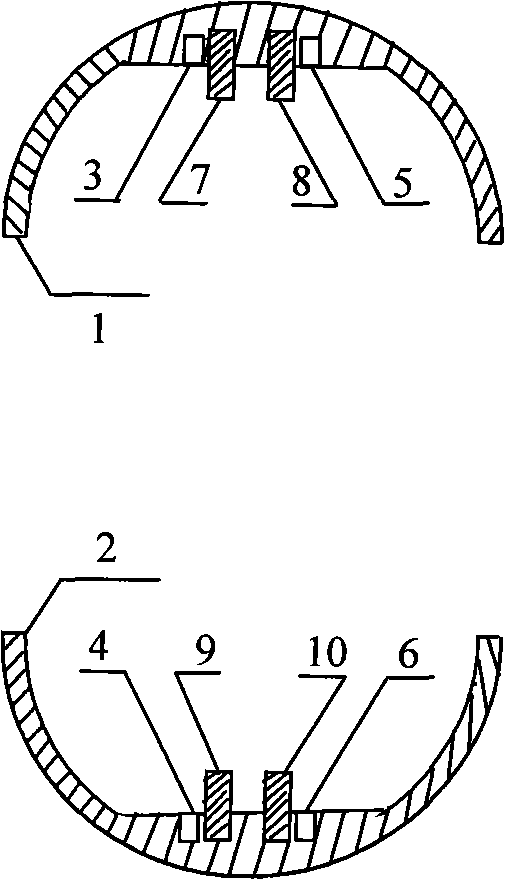

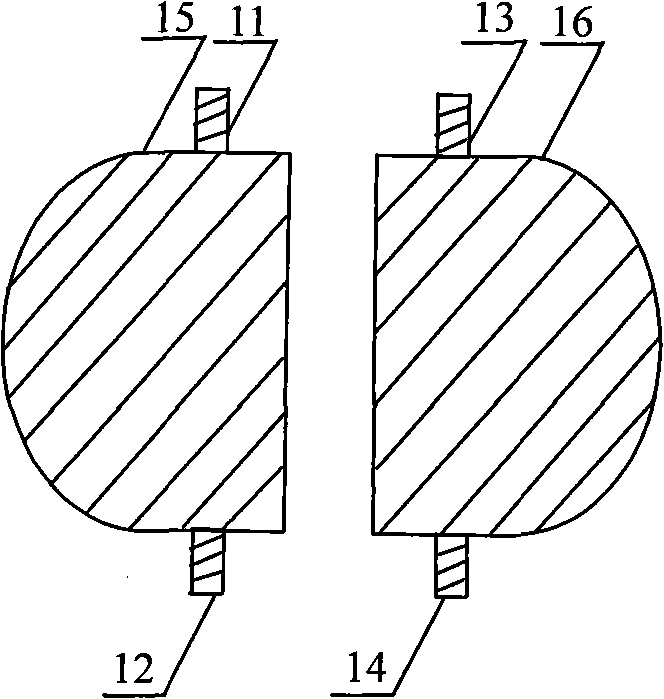

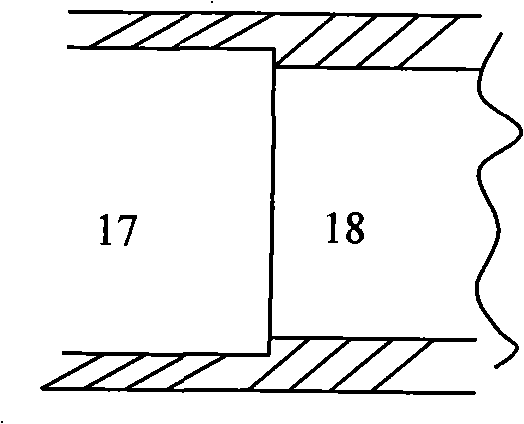

Detachable double-leaf artificial mechanism heart valves

The invention relates to a detachable two-bladed artificial mechanical cardiac valve, which consists of a circular valve support and two symmetrical semilunar valve blades, wherein the circular valve support is divided into two symmetrical semilunar valve supports; each valve support has a pair of shaft journals and chock blocks; the upper part and the lower part of each of the two symmetrical semilunar valve blades are respectively provided with two valve axes; the two pairs of valve axes are corresponding to the two pairs of shaft journals and can be conveniently inserted in and pulled out; and the two pairs of chock blocks respectively control the maximum opening angle of the two symmetrical semilunar valve blades. The two-bladed artificial mechanical cardiac valve is detachable and can conveniently change the geometrical shapes of certain parts of the mechanical cardiac valve according to design requirements while keeping other design structures unchanged, thereby ensuring lower cost and research data with more comparability.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

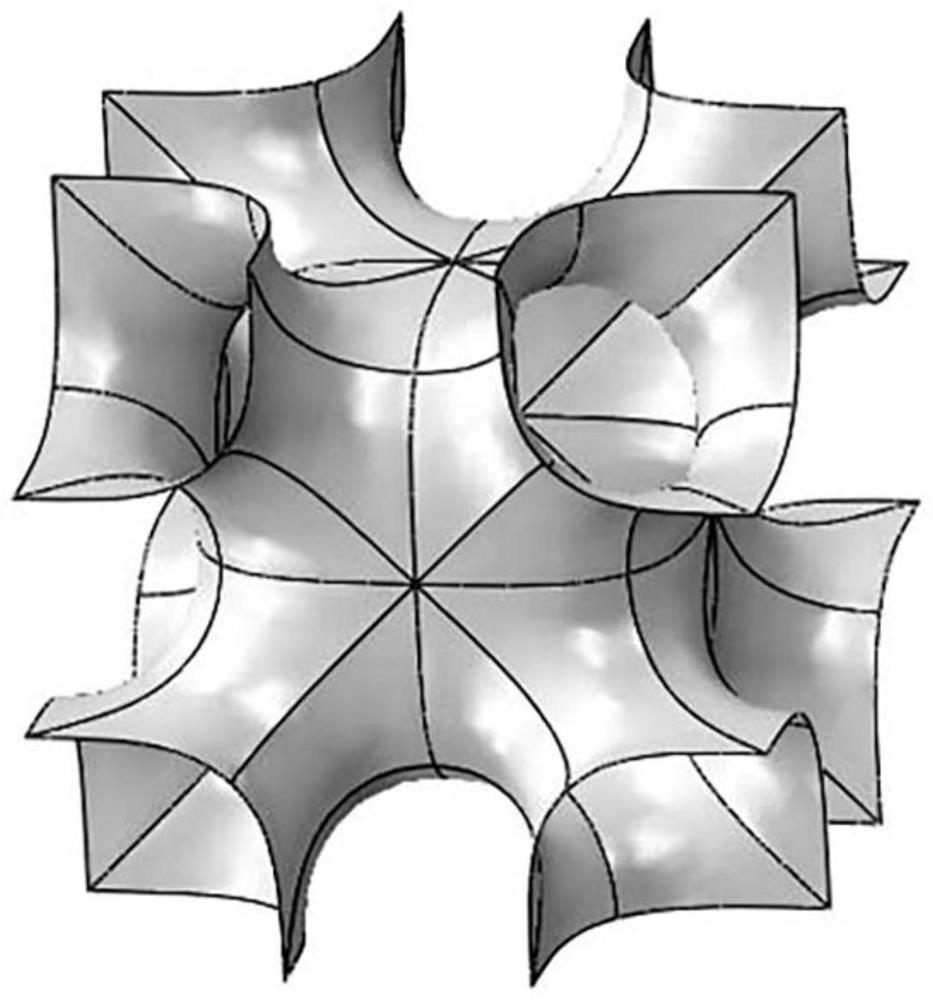

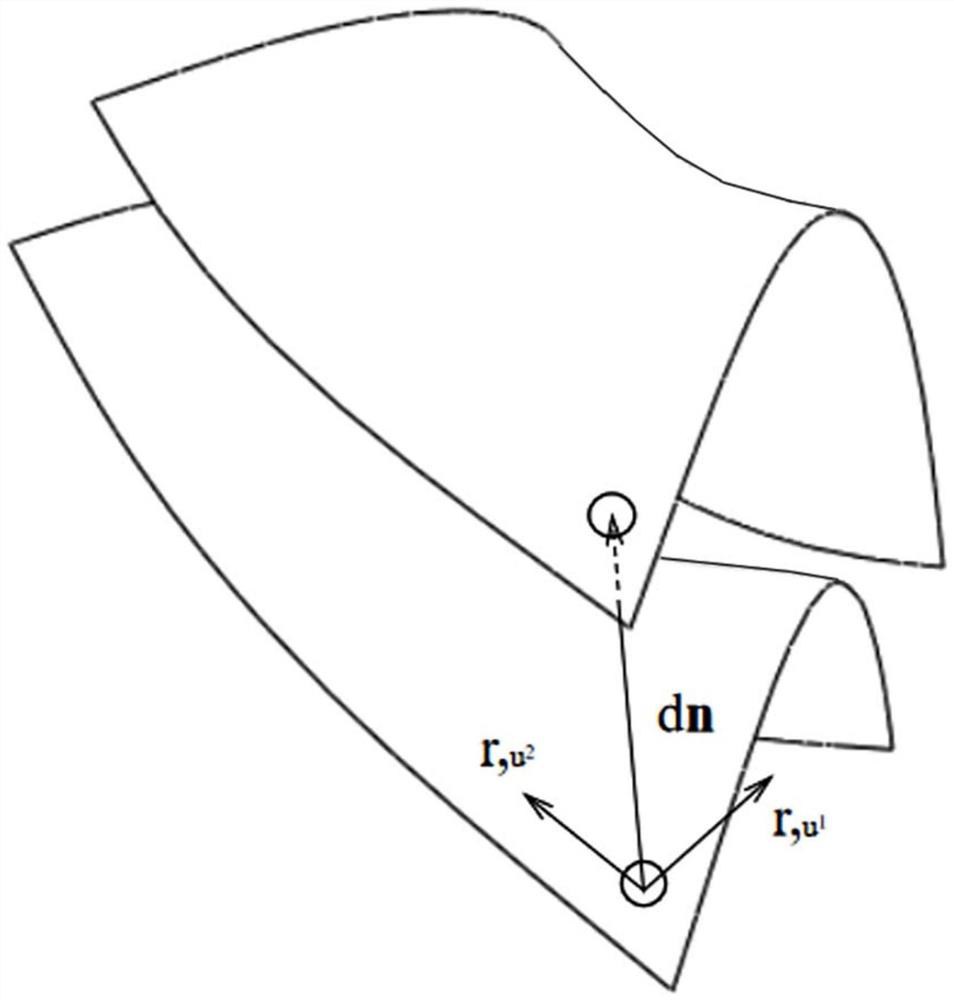

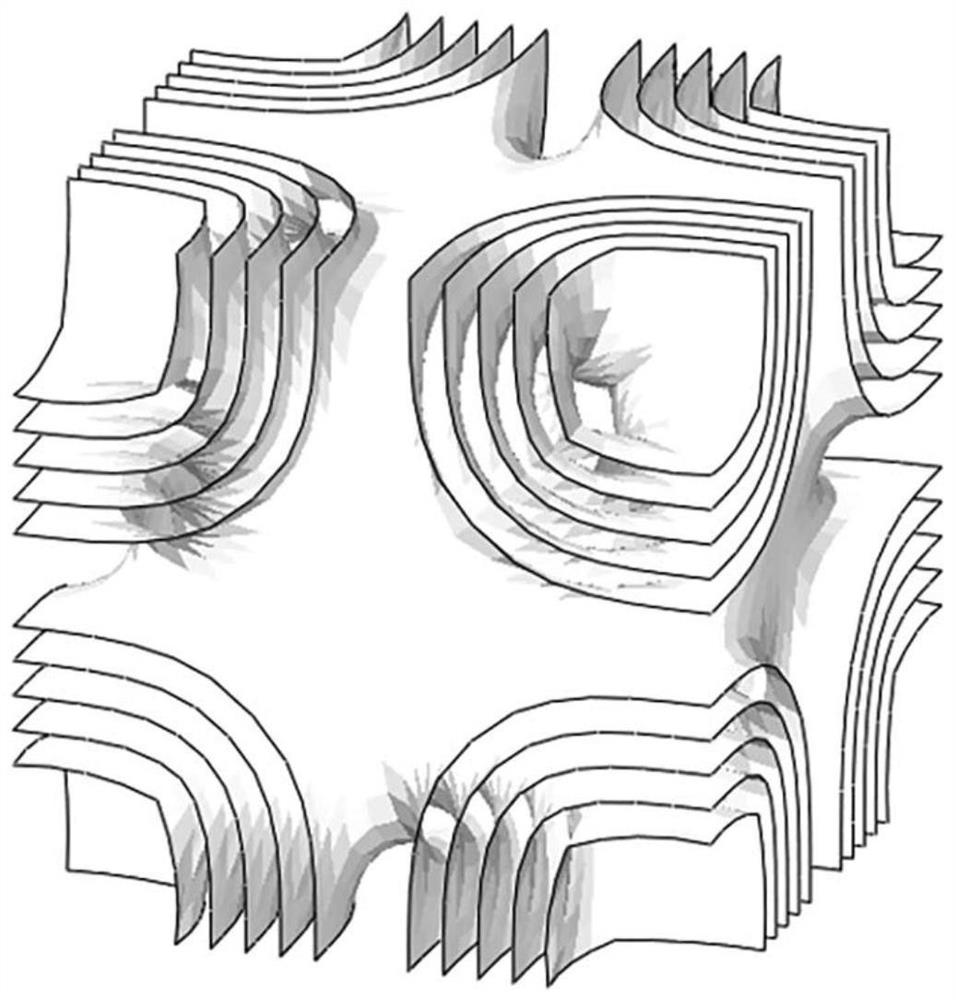

Three-dimensional smooth curved surface dot matrix cell element, design method, dot matrix structure and part

PendingCN114329775AChange geometryGuaranteed smooth continuous propertiesGeometric CADDot matrixEngineering

The invention relates to the technical field of material lightening, in particular to a three-dimensional smooth curved surface dot matrix cell element, a design method, a dot matrix structure and a part. According to the design method, an original lattice cell curved surface is discretized and deviated to obtain an equidistant deviation curved surface corresponding to each grid unit curved surface, new lattice cell elements in different shapes are formed through the equidistant deviation curved surfaces, the smooth and continuous characteristics of the equidistant deviation curved surfaces are guaranteed, and a non-dimensional deviation parameter is introduced to achieve the design of the lattice cell elements in different shapes. The geometric configuration of the curved surface dot matrix cell element can be conveniently changed, so that the mechanical property is regulated and controlled, the dot matrix cell element meeting the requirement is obtained, and the application of the three-dimensional smooth curved surface dot matrix cell element is wider. According to the dot matrix structure formed by distributing the multiple three-dimensional smooth curved surface dot matrix cell element arrays, dot matrix cell element configurations of different shapes can be selected according to needs, and the dot matrix structure meeting the needs is obtained. At least one part of the parts is of a lattice structure, and the parts have the mechanical property meeting the requirement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

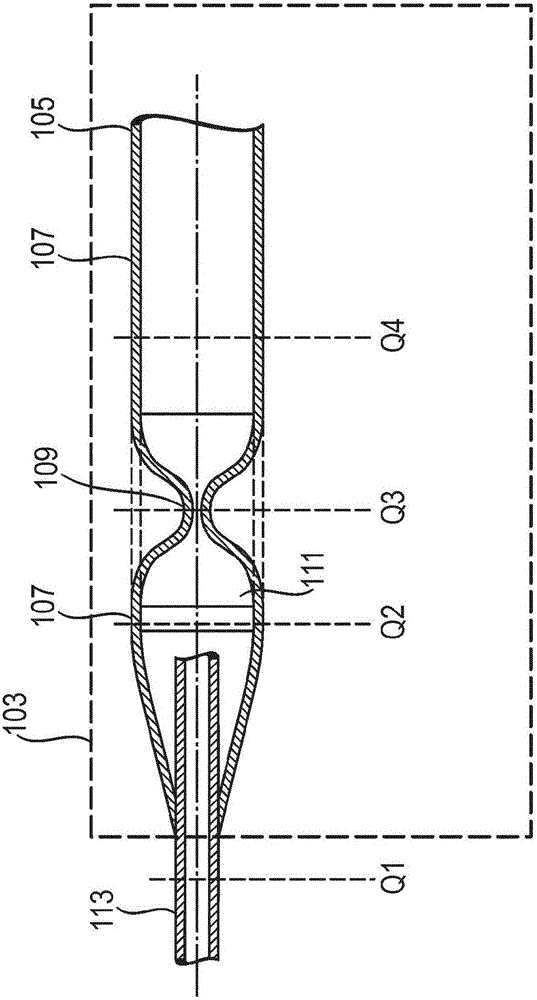

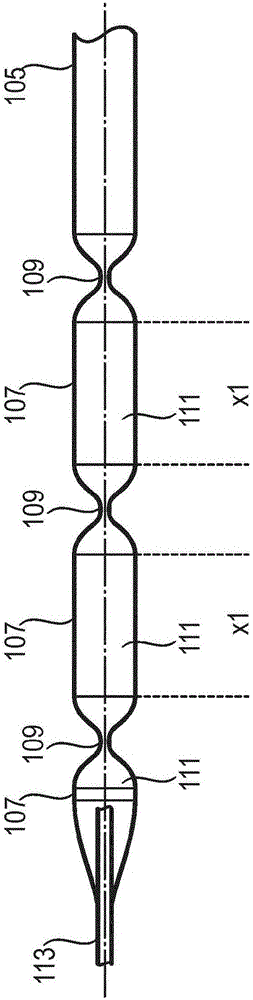

Refrigeration device comprising an evaporator

InactiveCN105102906AMaintain stiffnessHold bending momentSafety devices for heat exchange apparatusEvaporators/condensersRefrigerantEvaporator

The present invention relates to a refrigeration device having an evaporator (103) for evaporating a refrigerant, which evaporator comprises an inlet pipe (105) for the admission of the refrigerant, in which inlet pipe there is formed a pipe region (107), which has a first flow cross section, and a constriction region (109), which has a second flow cross section smaller than the first flow cross section, and to a method for producing an evaporator of said type.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

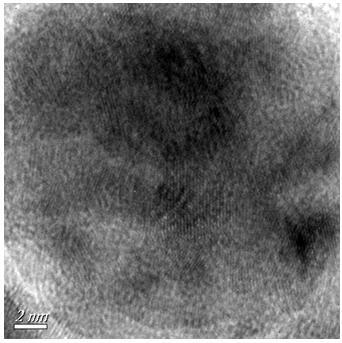

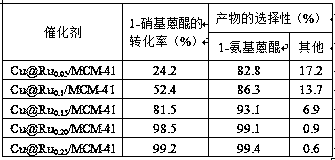

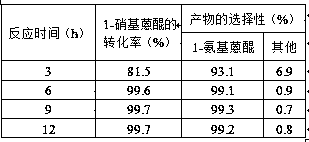

Cu@Ru/MCM-41 nanocatalyst, and preparation method and application thereof

InactiveCN110252383AReduce dosageHigh catalytic activityMaterial nanotechnologyOrganic chemistryHeterojunctionNano catalyst

The invention relates to a Cu@Ru / MCM-41 nanocatalyst, and a preparation method and an application thereof, and belongs to the field of nanocatalyst studies. A full-silicon MCM-41 mesoporous molecular sieve and nano-Cu particles are synthesized, and the Cu@Ru / MCM-41 nanocatalyst is prepared in the presence of an organic modifier. The surface of large-grain nano-Cu is wrapped with nano-Ru to form a heterojunction type Cu@Ru shell-core structure, and the Cu@Ru shell-core structure is loaded on a porous component MCM-41, so the dispersiveness of the active component Ru is greatly increased, thereby the active component Ru exposes many active sites, and the catalyst has a good hydrogenation performance; the Cu@Ru / MCM-41 nanocatalyst prepared in the invention has high catalytic activity and stability when catalyzing the hydrogenation of 1-nitroanthraquinone to produce 1-aminoanthraquinone; and the preparation method has the advantages of simple process route, small dosage of the catalyst, greenness and environmental friendliness, and meets industrialization requirements.

Owner:JIANGSU UNIV

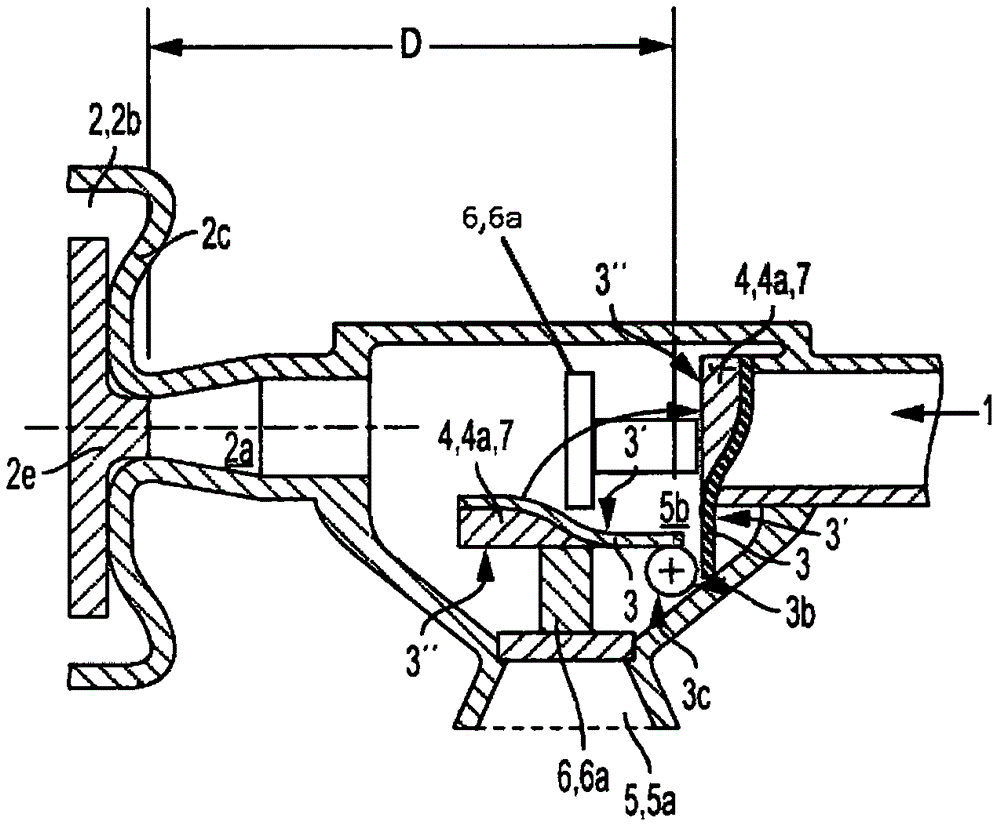

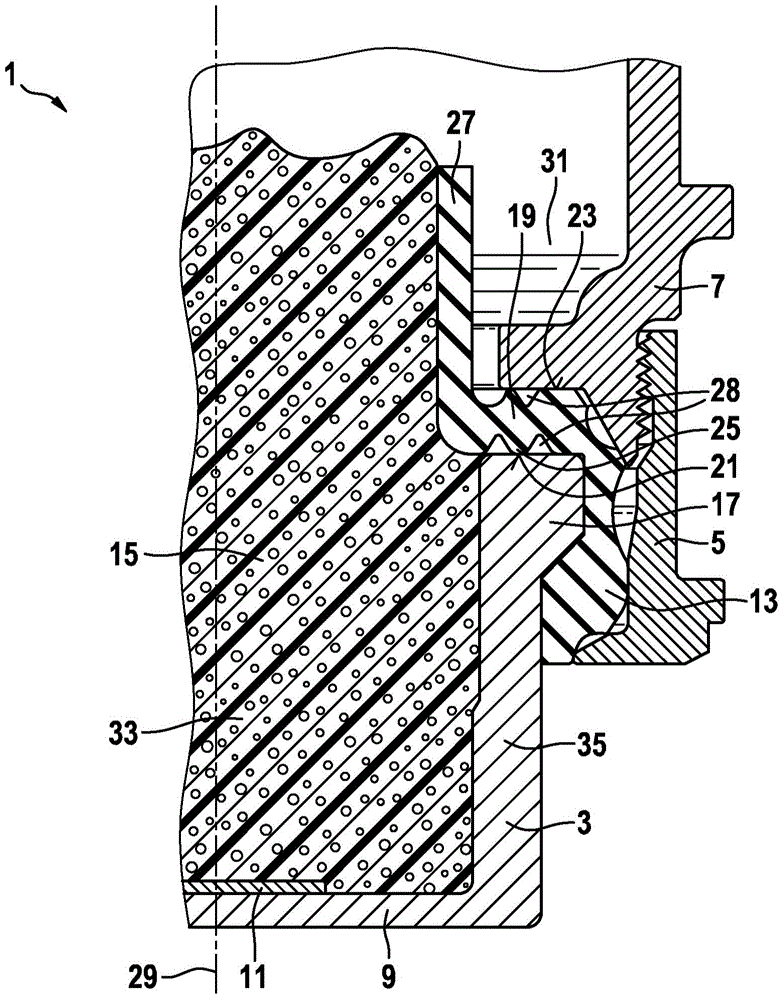

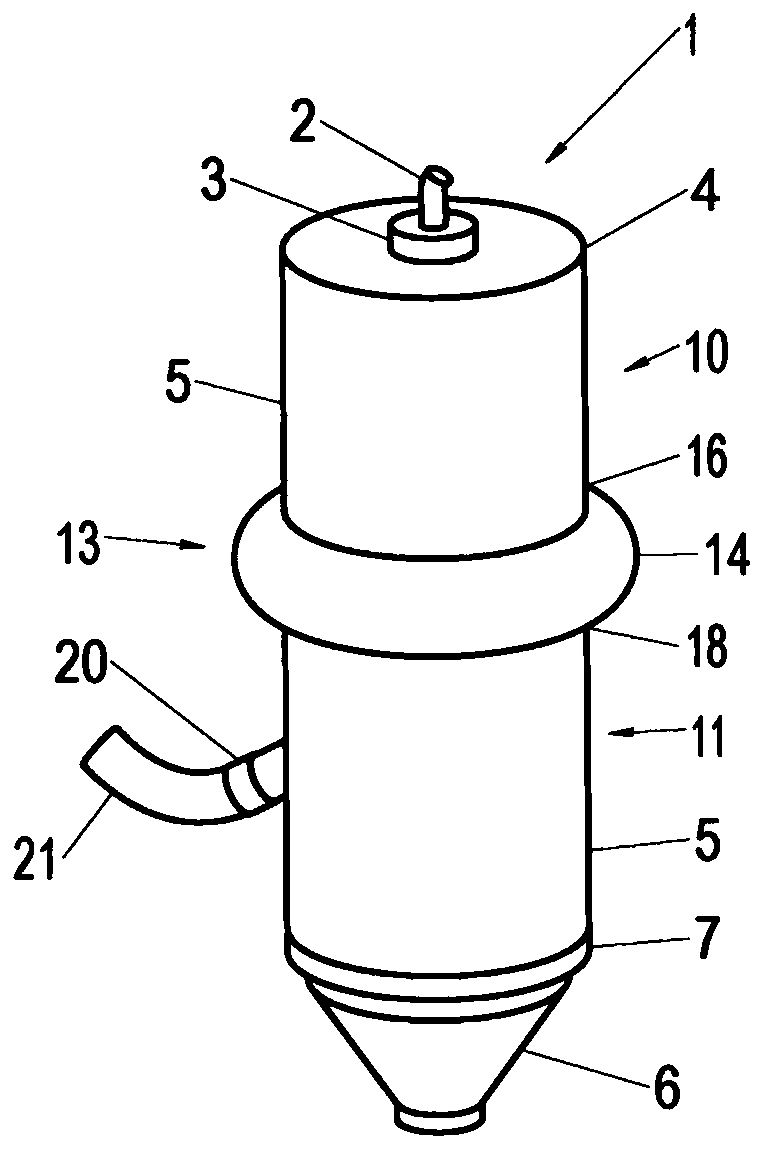

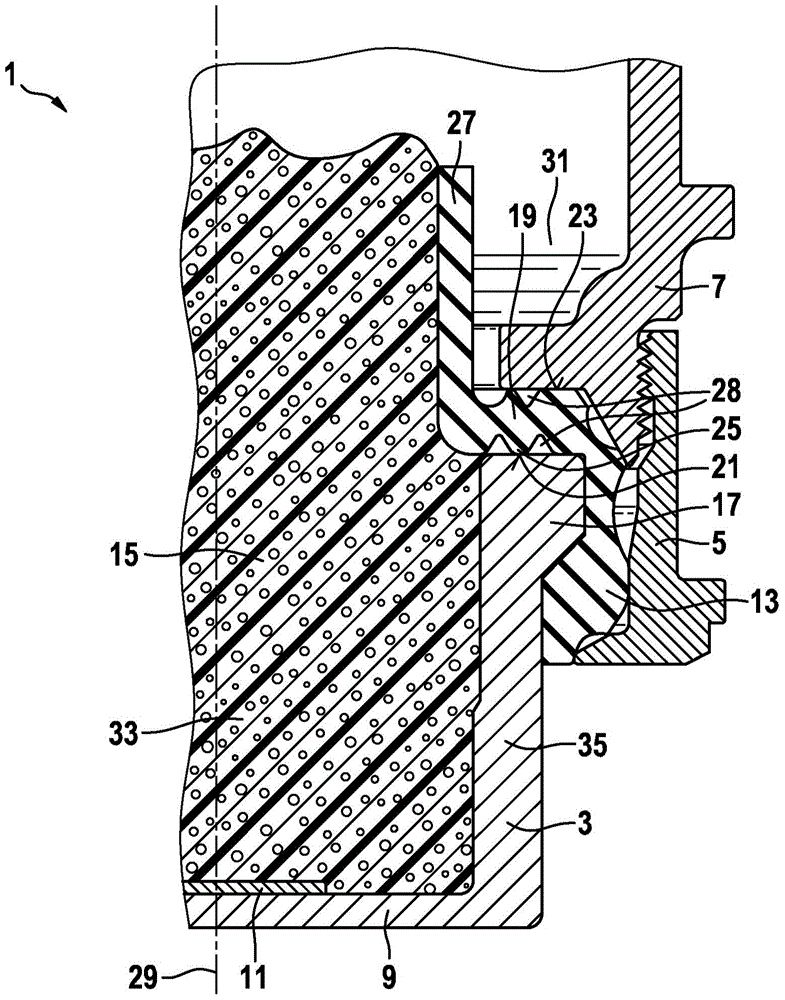

Ultrasound Sensor

ActiveCN104040619AChange geometryPreserve the manufacturing processSound producing devicesFilling materialsTransducer

The invention relates to an ultrasound sensor for sending and / or receiving ultrasound signals, comprising a diaphragm cup (3) having a transducer (11) and a housing (7), wherein the diaphragm cup (3) is releasably connected to the housing (7), a decoupling ring (13) is accommodated between the membrane cup (3) and the housing (7), and the membrane cup (3) is filled with a filling material (15). The decoupling ring (13) comprises a lip (27) that is designed in such a way that a gap (31) is formed between the lip (27) and the housing inner wall and the filling material (15) is accommodated in a space at the decoupling ring (13), which space is enclosed by the membrane cup (3) and the lip (27). The invention further relates to a use of the ultrasound sensor.

Owner:ROBERT BOSCH GMBH

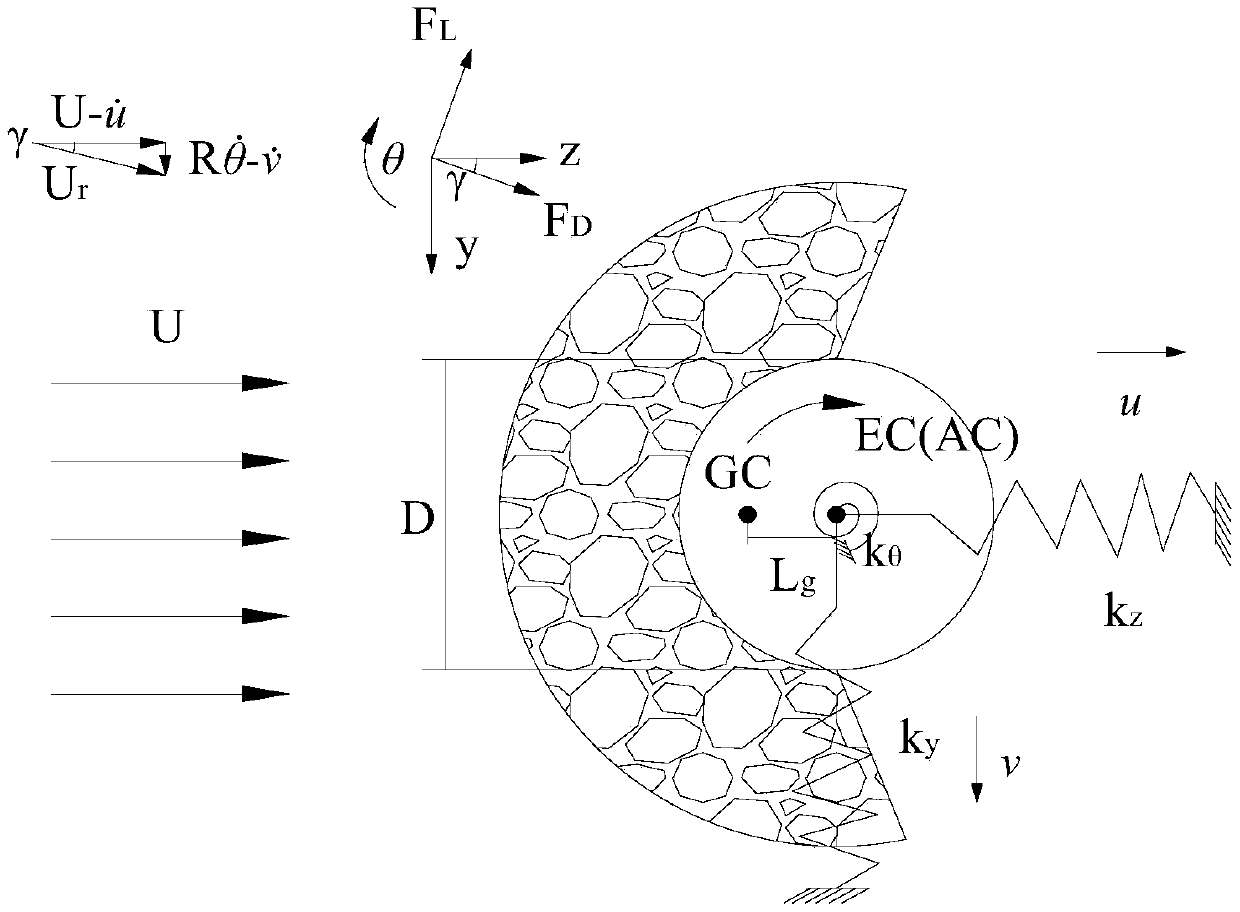

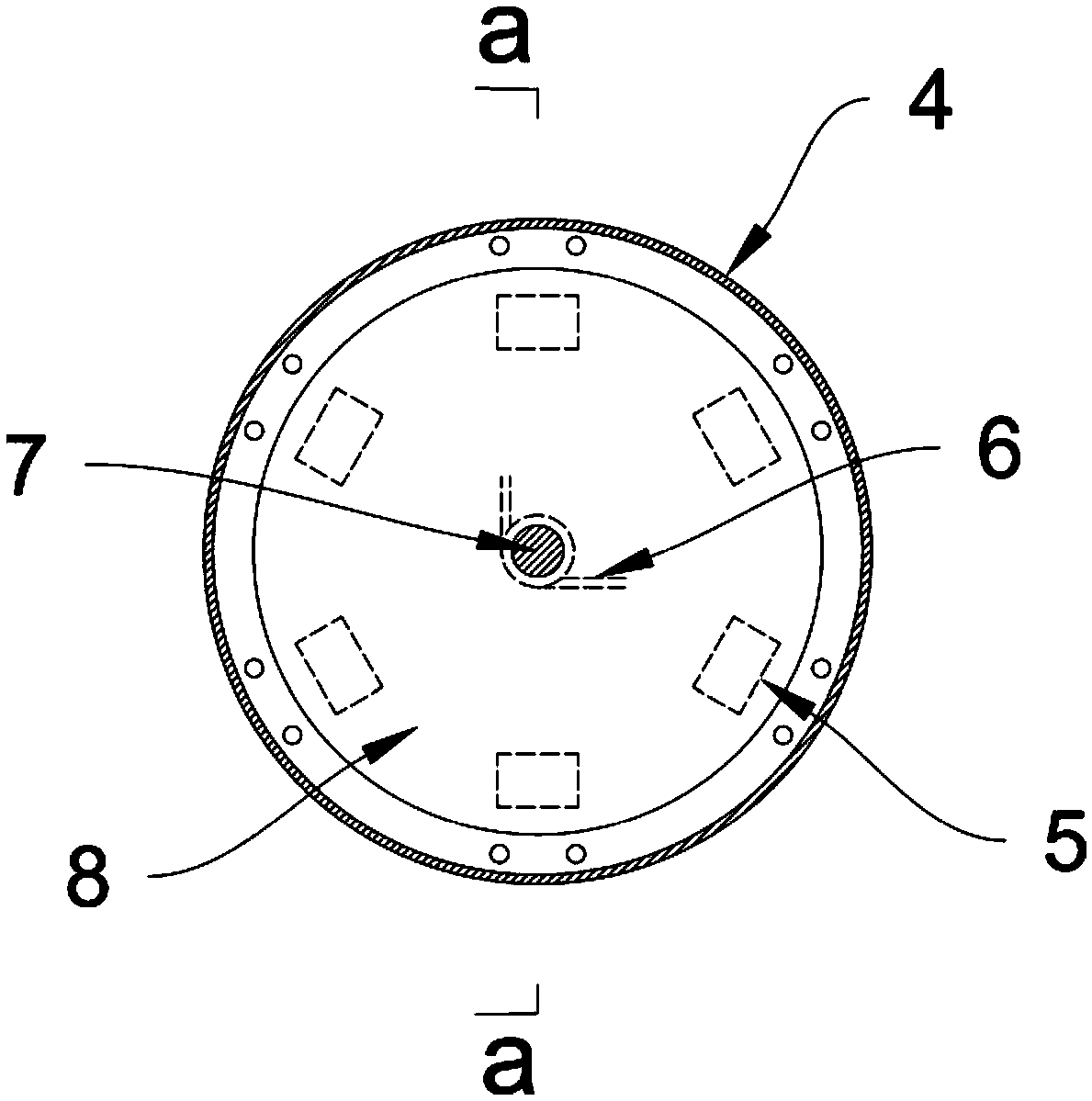

Anti-dancing torsional eddy current mass damper and optimization method thereof

ActiveCN109599820AImprove fatigue resistanceInsensitive to ambient temperature changesMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsCircular discVertical vibration

The invention belongs to the technical field of overhead transmission lines, and particularly relates to an anti-dancing torsional eddy current mass damper and an optimization method thereof. The scheme of the invention is based on the in-depth study of the three-degree-of-freedom dancing of wires and the mass damper, passively controls the torsional vibration of the wires by using the mass damper, uses a metal disk as a mass unit, uses a torsional spring as a stiffness unit, and uses a permanent magnet as a damping unit. The scheme of the invention fully utilizes the characteristics of the three-degree-of-freedom dancing of split wires, well avoids the problem that the vertical vibration control needs to provide a large amount of motion space of the mass unit by adopting a method of controlling the torsional vibration, and can control the low-frequency dancing of the lines in a small size.

Owner:ZHEJIANG UNIV

Novel dimeric cationic surfactant and preparation method thereof

InactiveCN103920415BInhibition of separation abilityHigh affinityOrganic chemistryTransportation and packagingSolubilityCarbon chain

The invention relates to a novel dimeric cationic surfactant. The structural formula of the surfactant is indicated as formula (A). The dimeric cationic surfactant introduces groups at a polar head to reach chemical bonding, restrain separating force among the original single-chain single heads and improve appetency among carbon chains, thereby improving surface activity and opening a brand new pathway for practical application. The surfactant has good water solubility. Compared with the general single-head surfactant, the surfactant has low surface tension and a cmc value and is a novel surfactant with a wide application prospect. As shown in the specification, wherein, n=18, 16, 14 or 12.

Owner:HEBEI UNIV OF TECH

Movable truss with high-order curve shape

ActiveCN102605891BChange geometryMeet the requirements of the opening and closing functionBuilding roofsCurve shapeInterconnection

Owner:SOUTHEAST UNIV

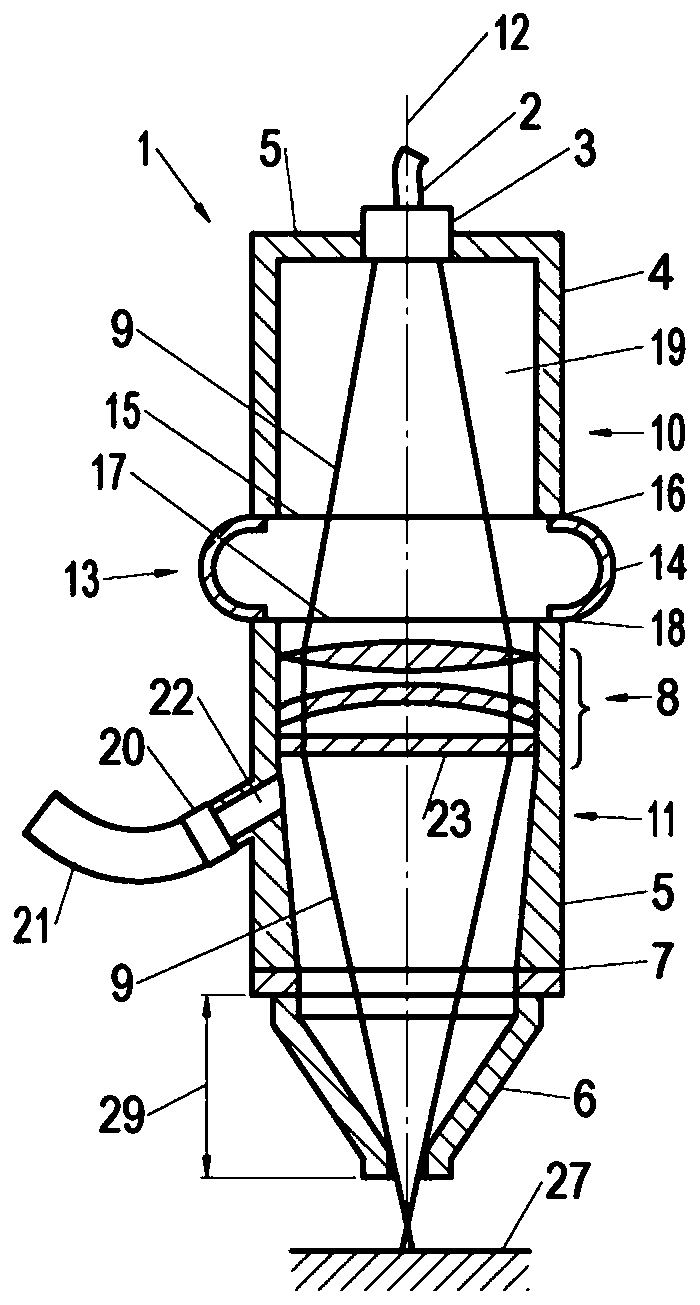

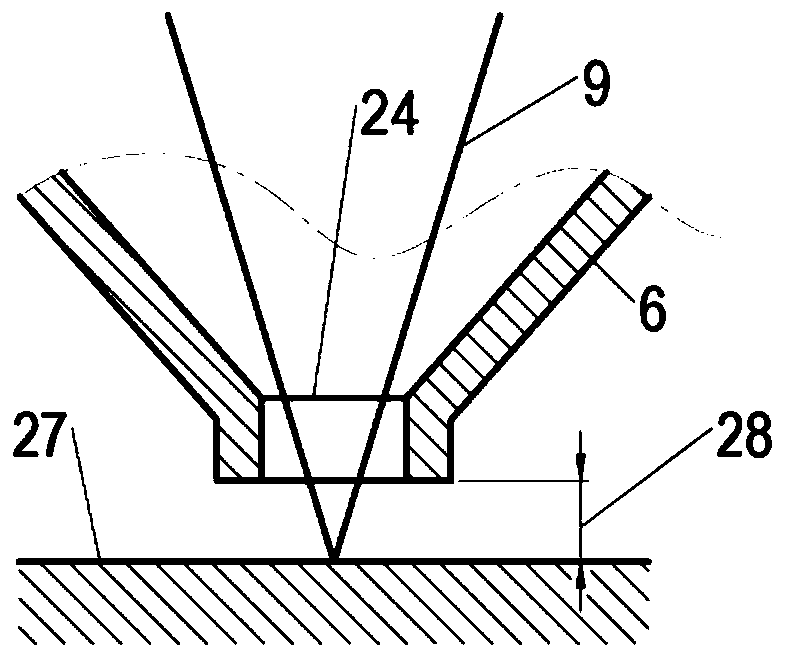

Laser cutting head comprosing a body made of two parts, being linked together by a flexible member

PendingCN109906130AChange geometryEnsure range of movementWelding/cutting auxillary devicesAuxillary welding devicesLaser lightMutual position

The present application relates to a laser cutting head (1), which comprises a body (2), a laser light source (3) located at a first end (4) of the body (5), a nozzle (6) located at a other end (7) ofthe body (5), an optical system (8) located inside the body (5) between the laser light source (3) and the nozzle (6). The body (2) comprises at least two parts (10, 11), which are slidable relativeto each other in such a way that, due to their reciprocal displacement, the mutual position of the laser light source (3) and / or the nozzle (6) and / or the optical system (12) can be changed, so that the geometry of the laser beam (9) inside the body (2) can be changed during use to achieve the desired parameters of the focus of the laser beam (9) on the surface of the workpiece (27).

Owner:EJMA JANUSZ MARCIN POWER TECH

A method and device for growing silicon carbide crystals by PVT method

InactiveCN102644105BChange geometryEliminate changes in temperature fieldPolycrystalline material growthFrom condensed vaporsCrystal growthCrystallization

The invention relates to a method and a device for growing a silicon carbide crystal according to a PVT (Physical Vapor Transport) method. A moveable heat-insulating adjusting element is arranged above a crucible; when the silicon carbide crystal grows, with the thickening of the crystal on a crucible cover, a distance D between the moveable heat-insulating adjusting element and the crucible cover is gradually increased, wherein the thermal resistance Rc of the crystal to thermal flux Q is increased, with the increasing of the thickness of the crystal; the equivalent thermal resistance Rb of the moveable heat-insulating adjusting element to the thermal flux Q is reduced while the distance D is increased; and the temperature of a crystal interface is kept unchanged by keeping the dynamic balance between the increment of Rc and the reduction of Rb. According to the method, a heat-insulating adjusting element on the crucible cover is changed into the heat-insulating adjusting element which can move according to the technical demand during the growing process of the crystal. A geometric structure of a heat-insulating system and the energy output of a graphite crucible are changed by changing the distance between the moveable heat-insulating adjusting element and the crucible cover, so that the purpose of adjusting the temperature field in the graphite crucible during the growing process of the crystal is achieved.

Owner:吴晟

An active light source type crop canopy reflection spectrum measuring device and method thereof

InactiveCN103293113BOptical path parameters are adjustableChange geometryColor/spectral properties measurementsSpectral responseMeasurement device

Owner:NANJING AGRICULTURAL UNIVERSITY

ultrasonic sensor

ActiveCN104040619BIncrease sound pressureShorten transient oscillation timeSound producing devicesUltrasonic sensorFilling materials

The invention relates to an ultrasound sensor for sending and / or receiving ultrasound signals, comprising a diaphragm cup (3) having a transducer (11) and a housing (7), wherein the diaphragm cup (3) is releasably connected to the housing (7), a decoupling ring (13) is accommodated between the membrane cup (3) and the housing (7), and the membrane cup (3) is filled with a filling material (15). The decoupling ring (13) comprises a lip (27) that is designed in such a way that a gap (31) is formed between the lip (27) and the housing inner wall and the filling material (15) is accommodated in a space at the decoupling ring (13), which space is enclosed by the membrane cup (3) and the lip (27). The invention further relates to a use of the ultrasound sensor.

Owner:ROBERT BOSCH GMBH

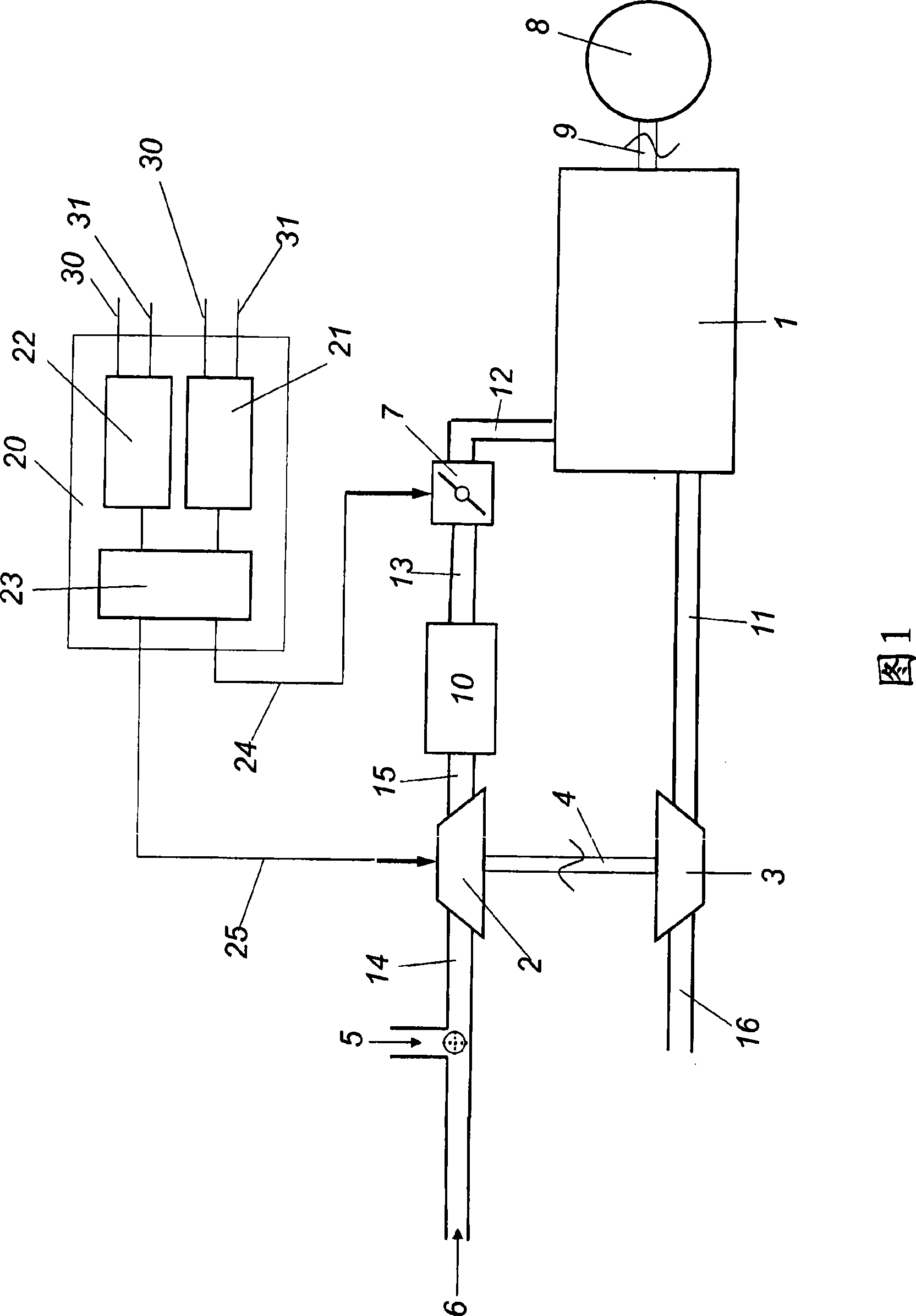

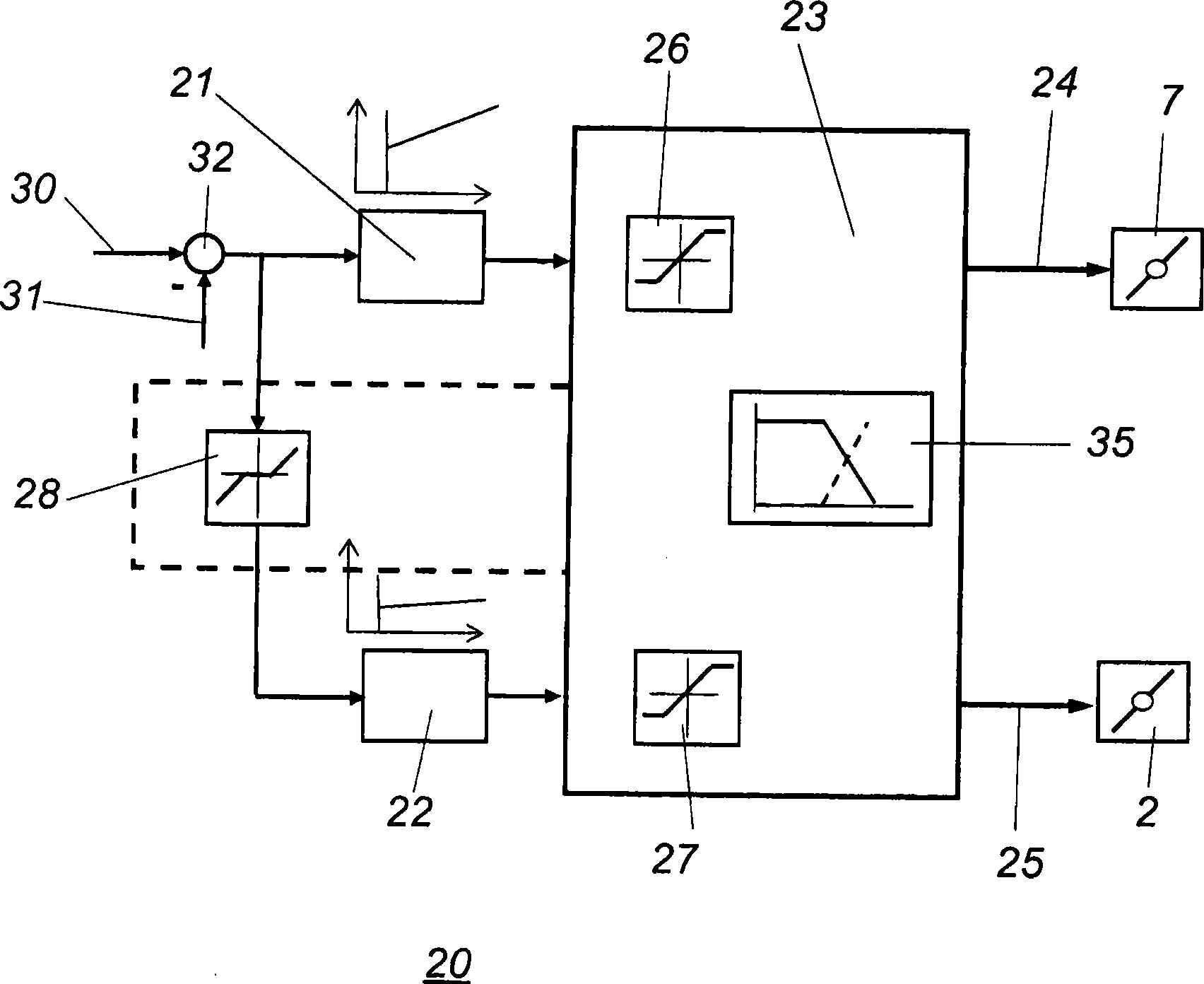

Combustion machines and motor regulating device

InactiveCN101392696AChange geometryChange the amount of gasElectrical controlInternal combustion piston enginesCombustionEngineering

A method of operating a stationary internal combustion machine comprising a compressor device of variable compressor geometry which compresses gas fed to the internal combustion machine, and a throttle device which is connected downstream of the compressor device and with which the amount of compressed gas fed to the internal combustion machine is variable, wherein the internal combustion machine is regulated by way of the actuation of at least two adjusting members, wherein the internal combustion machine is regulated to a-preferably substantially constant-engine regulating value, and upon a deviation in the engine regulating value from a reference value the amount of gas fed to the internal combustion machine is altered by the actuation of the throttle device as the first adjusting member and by the variation in the geometry of the compressor device as the second adjusting member so that the engine regulating value is re-set to the reference value.

Owner:GE JENBACHER

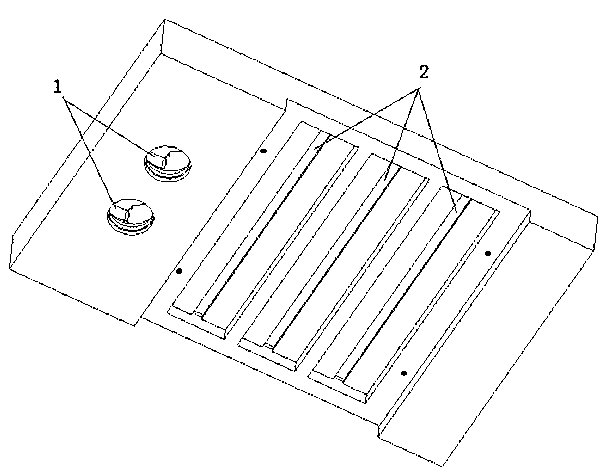

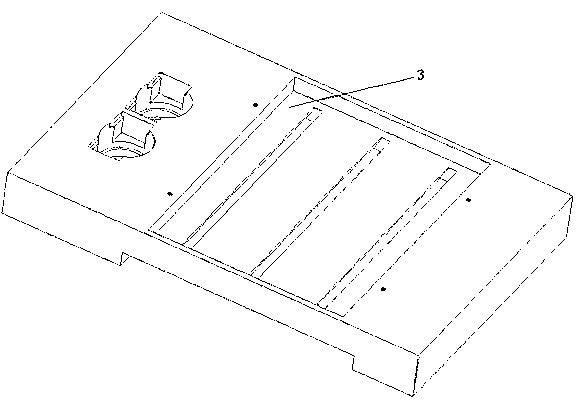

Liquid double lens set construction method based on micro fluidic chip

InactiveCN105629357AContinuously adjustable divergenceLarge adjustment rangeLensMicro fluidicMicrofluidic chip

The invention discloses a liquid double lens set construction method based on a micro fluidic chip, relating to the optical device technology field and solving the problem that the regulation range of the prior art is small. The liquid double lens set construction method comprises steps of choosing two fluids which have two different refractive indexes and are not dissolved with each other, enabling the two fluids to pass through one lens cavity in a laminar flow, enabling the two fluids to form a three-layer structure, in which a high refractive fluid is clamped between two low refractive fluids in the cavity of the lens and enabling the three-layer structure to commonly constitute a lens assembly. The invention can control the curvature of the interface of the high refractive fluid and the low refractive fluid through controlling the speed rate of the two fluids and enables the lens assembly to take on the working form. The method disclosed by the invention can perform convergence, collimation and divergence continuous adjustment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A flexible transmission mechanism of a non-enclosed annular rotating body and its application method

The invention discloses a flexible transmission mechanism of a non-closed type annular rotator and an application method of the flexible transmission mechanism. The flexible transmission mechanism comprises the non-closed type annular rotator, three pinch rollers, six tensioning wheels, a toothed belt, a housing and a gear, wherein the pinch rollers, the tensioning wheels and a central spindle of the gear are fixed on a base plate of the housing; the gear, the second tensioning wheel, the first tensioning wheel, the third tensioning wheel, the fourth tensioning wheel, the sixth tensioning wheel and the fifth tensioning wheel are arranged clockwise; the inner side of the toothed belt is fitted with the outer sides of the five tensioning wheels to form a closed ring; the outer side of the toothed belt is meshed with the gear and the outer tooth shape of the non-closed type annular rotator; the three pinch rollers are fitted with the inner side of the non-closed type annular rotator. The flexible transmission mechanism of the non-closed type annular rotator and the application method of the flexible transmission mechanism, disclosed by the invention, can enlarge the meshing area of the flexible transmission mechanism, the gear and the non-closed type annular rotator, so as to increase the meshing force, and meanwhile avoid interference and clamping between the flexible transmission mechanism, the gear and the rigid tooth shape of the non-closed type annular rotator.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

A Calculation Method for Mobile Induction Heating of Large Ring Gear Based on ANSYS Simulation Platform

ActiveCN107169166BChange geometryChange the speed parameterDesign optimisation/simulationSpecial data processing applicationsThermodynamicsInductor

The invention discloses an ANSYS simulation platform-based method for calculating movable induction heating of big gear rings. The method comprises the following steps of: determining a modeling-required parameter according to main equipment and workpieces used in an induction heating process of big gear rings; determining a software-recognizable equivalent parameter according to an induction heating process parameter used in a production process; establishing an initial analysis geometric model according to the determining parameters, adding physical property parameters of used materials, and dividing grids; applying a boundary condition and a corresponding load, and carrying out initial electromagnetic heating coupling calculation; extracting all the node temperatures of the analyzed workpieces; moving an inductor, establishing a movement analysis geometric model according to the determined parameters, adding material attributes, dividing grids, endowing nodes in one-to-one correspondence with the workpieces with the node temperatures extracted in the electromagnetic calculation, applying a boundary condition and a load, and carrying out continuous electromagnetic heating coupling calculation; and controlling the movement speed of the inductor through realizing the distance of each movement of the inductor and a corresponding induction heating time until the whole calculation is completed.

Owner:YANSHAN UNIV

Energy conversion hydraulic plant and method for controlling such plant

InactiveCN101910618BImprove efficiencyImprove stabilityHydro energy generationPump controlWater flowEngineering

The invention relates to a hydrodynamic device (I) defining a path (4, 5, 6) of forced water flow (E), having at least one machine (1) of turbine, pump or turbopump type and a component (8) , said part (8) is provided with at least one deformable wall (81) defining at least one enclosed space (V8) of variable size. The device also has means (9, 91) for supplying (F9) pressurized fluid to the enclosed space. The part with deformable walls (81) is installed in a hydraulic channel (6) downstream of a rotating part (2) of the machine (1). The deformable wall locally defines an adjustable passage section (S63) of the flow (E) in the hydraulic channel (6) downstream of the rotating part (2). According to the method of the invention, the pressurized fluid is injected (F9) into a closed space (V8) of variable dimensions delimited by a part (8) arranged downstream of the rotating part (2) In a hydraulic channel (6), to adjust the passing section (S63).

Owner:GE RENEWABLE TECH

Illumination system of a microlithographic projection exposure apparatus

ActiveCN102099743BChange geometryPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingLight beam

An illumination system of a microlithographic projection exposure apparatus (10) comprises an optical raster element (72) configured to produce a plurality of secondary light sources (95) located in a system pupil surface (70). The optical raster element (72) has a plurality of light entrance facets (92) each being associated with one of the secondary light sources (95). A beam deflecting device comprises a beam deflection array (46) of reflective or transparent beam deflecting elements (M ij ) each being configured to illuminate a spot (90) on one of the light entrance facets (92) at a position that is variable by changing a deflection angle produced by the beam deflecting element (M ij ). A control unit (50) is configured to control the beam deflection elements (M ij ) such that variable light patterns (LP) assembled from the spots (80) can be formed on at least one of the plurality of light entrance facets (92).

Owner:CARL ZEISS SMT GMBH

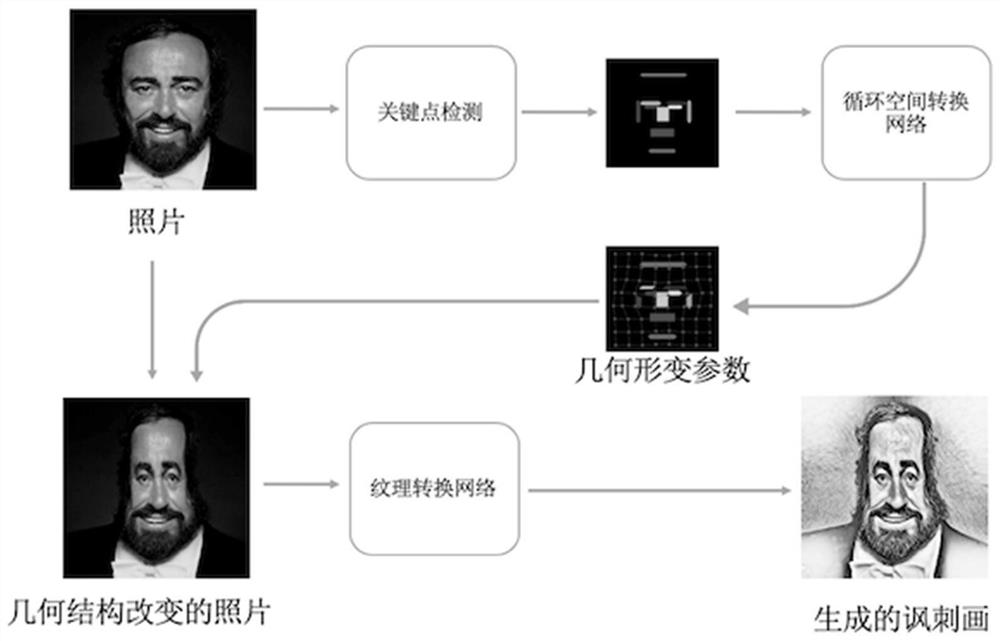

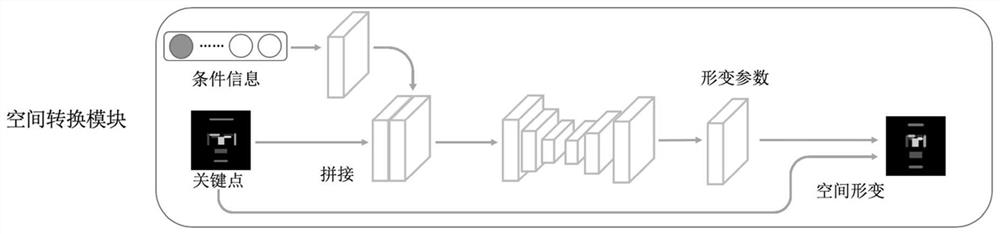

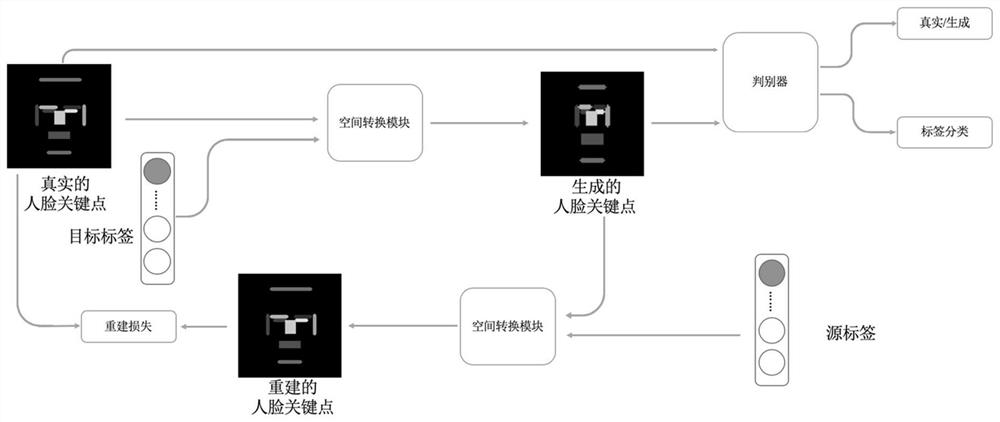

A Face Caricature Generation Method Based on Recurrent Space Transformation Network

ActiveCN110415308BChange geometryAvoid the problem of not being able to generate exaggerated face caricaturesTexturing/coloringCharacter and pattern recognitionData setComputer graphics (images)

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com