Sifter

A technology of screening machine and wood fiber board, which is applied in the direction of solid separation, separation of solids from solids by air flow, pretreatment of molding materials, etc., can solve problems such as unfavorable screening, and achieve the goal of improving screening quality and increasing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

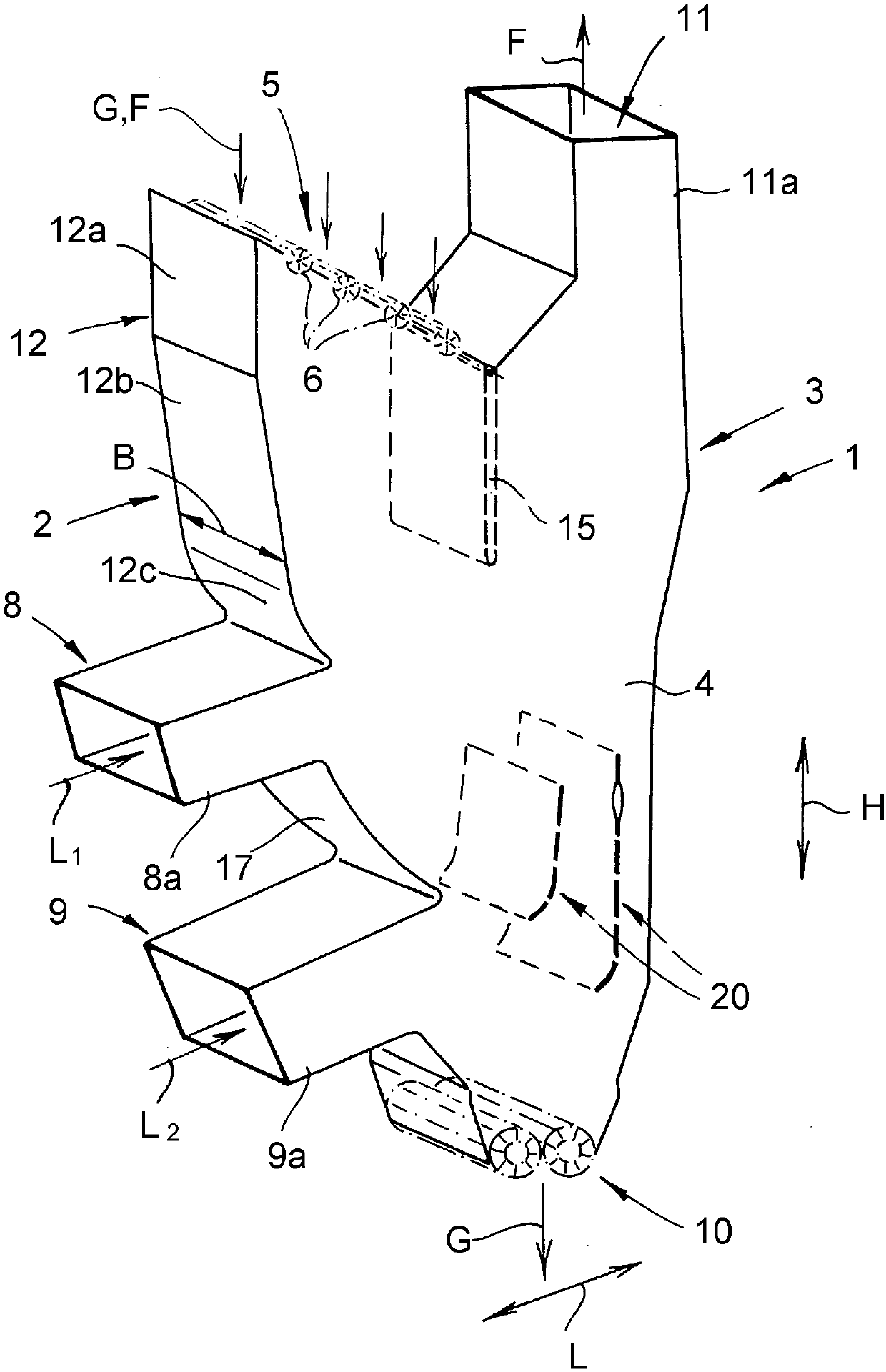

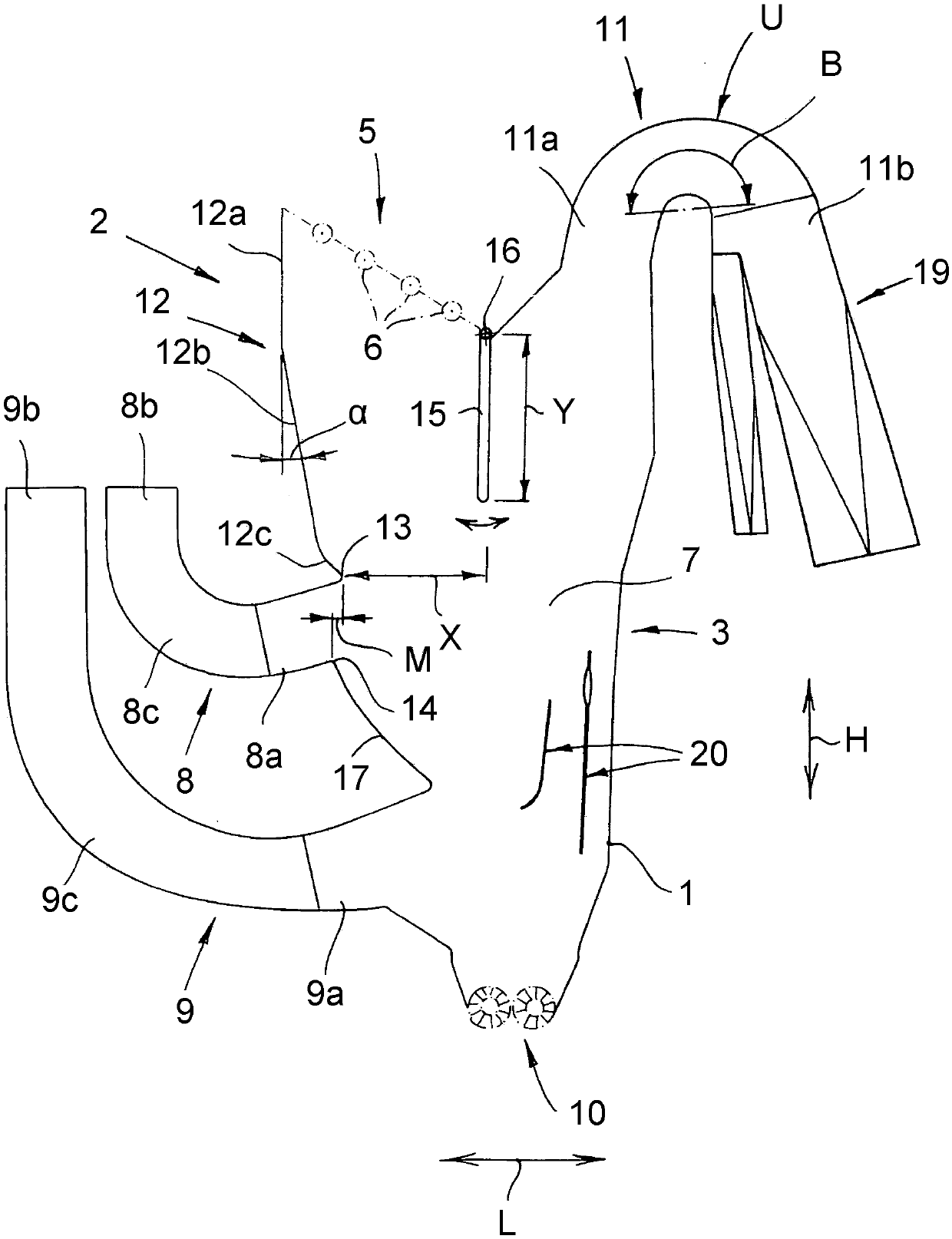

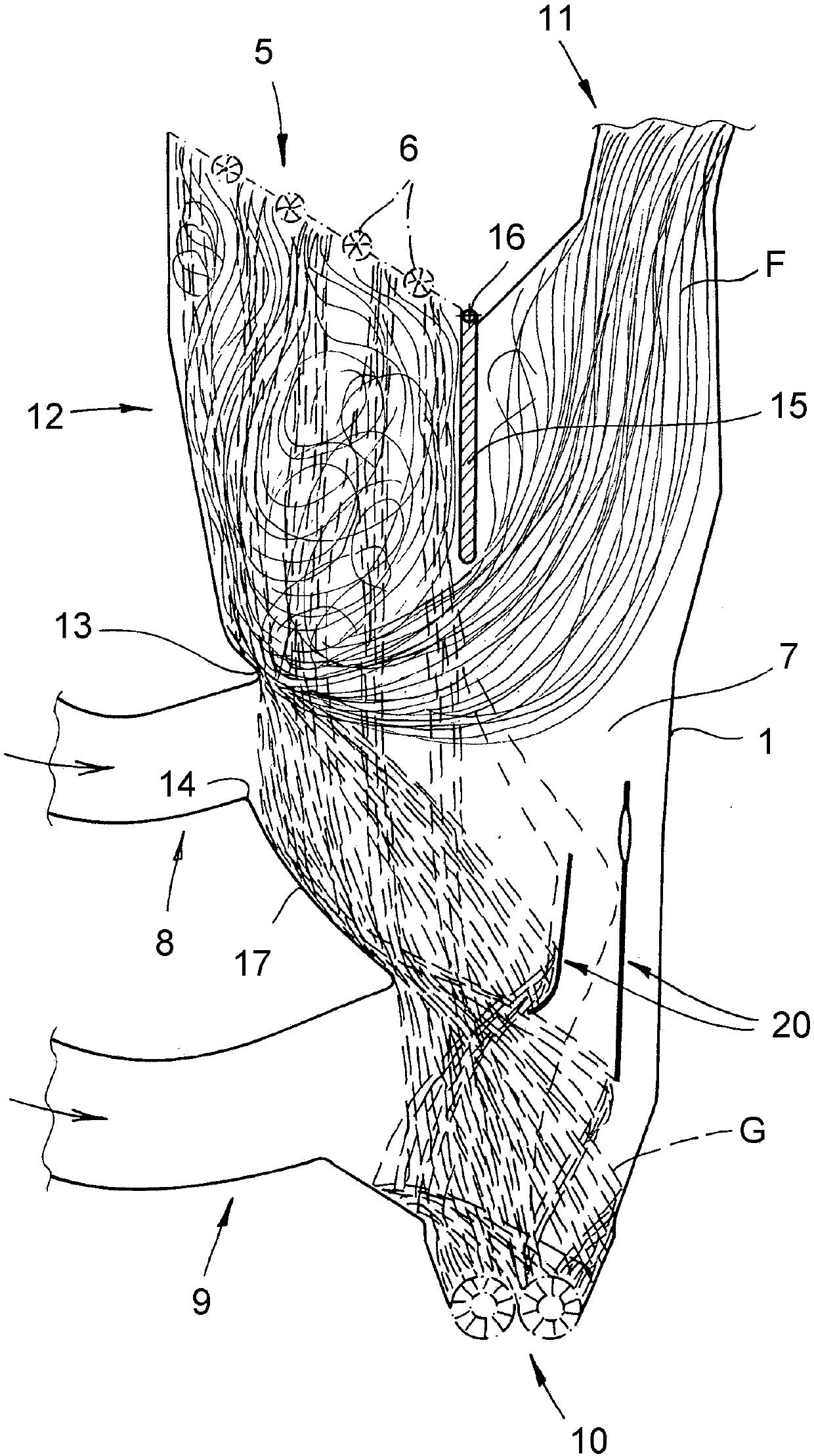

[0023] The drawing shows a sieving machine for separating coarse particles from a particle flow, especially a fiber flow, during the production of wood-based boards, especially wood-fibre boards. Such a sieving machine is preferably integrated in a plant for the production of wood-based material boards, in particular in order to remove undesired components (such as metal parts, adhesive clumps, coarse fibers, rust flakes or the like) from the material flow (such as glued fibers) objects), more precisely in particular in order to protect downstream equipment or equipment components (such as the steel belt of a continuously operating wood-based material panel press) from damage.

[0024] The screening machine has a screening machine housing 1 which in its basic structure comprises a front wall 2 , a rear wall 3 and two side walls 4 . The designations “front wall 2 ” and “rear wall 3 ” refer here to the main flow direction of the incoming sieving air. The screen housing 1 has on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com