Liquid double lens set construction method based on micro fluidic chip

A technology of a microfluidic chip and a construction method, applied in the directions of lenses, optics, instruments, etc., can solve the problems of limited adjustment range, inability to achieve continuous adjustment of beam convergence, collimation, and divergence, etc., to achieve a wide adjustment range and divergence. Continuously adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the scope of protection of the present invention. The commas in all indicate the relationship between and.

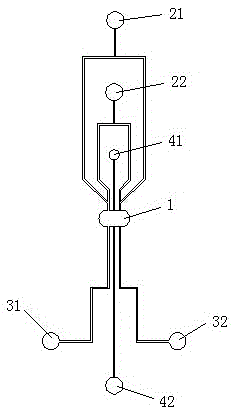

[0010] A method for constructing a liquid double-lens group based on a microfluidic chip provided by an embodiment of the present invention is characterized in that two fluids with different refractive indices and immiscibles are selected, and the two fluids are brought together in a laminar flow Flow through the same lens cavity, and make the two fluids form a three-layer structure with a layer of high refractive index fluid sandwiched between two layers of low refractive index fluid in the lens cavity (that is, the low refractive index fluid is used as the high refractive in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com