Patents

Literature

80results about How to "Reduce temperature unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

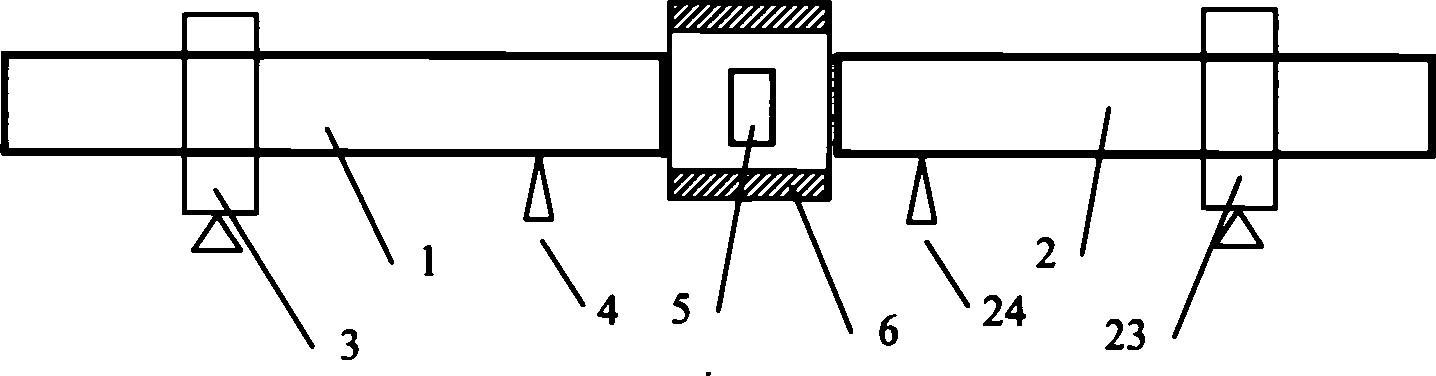

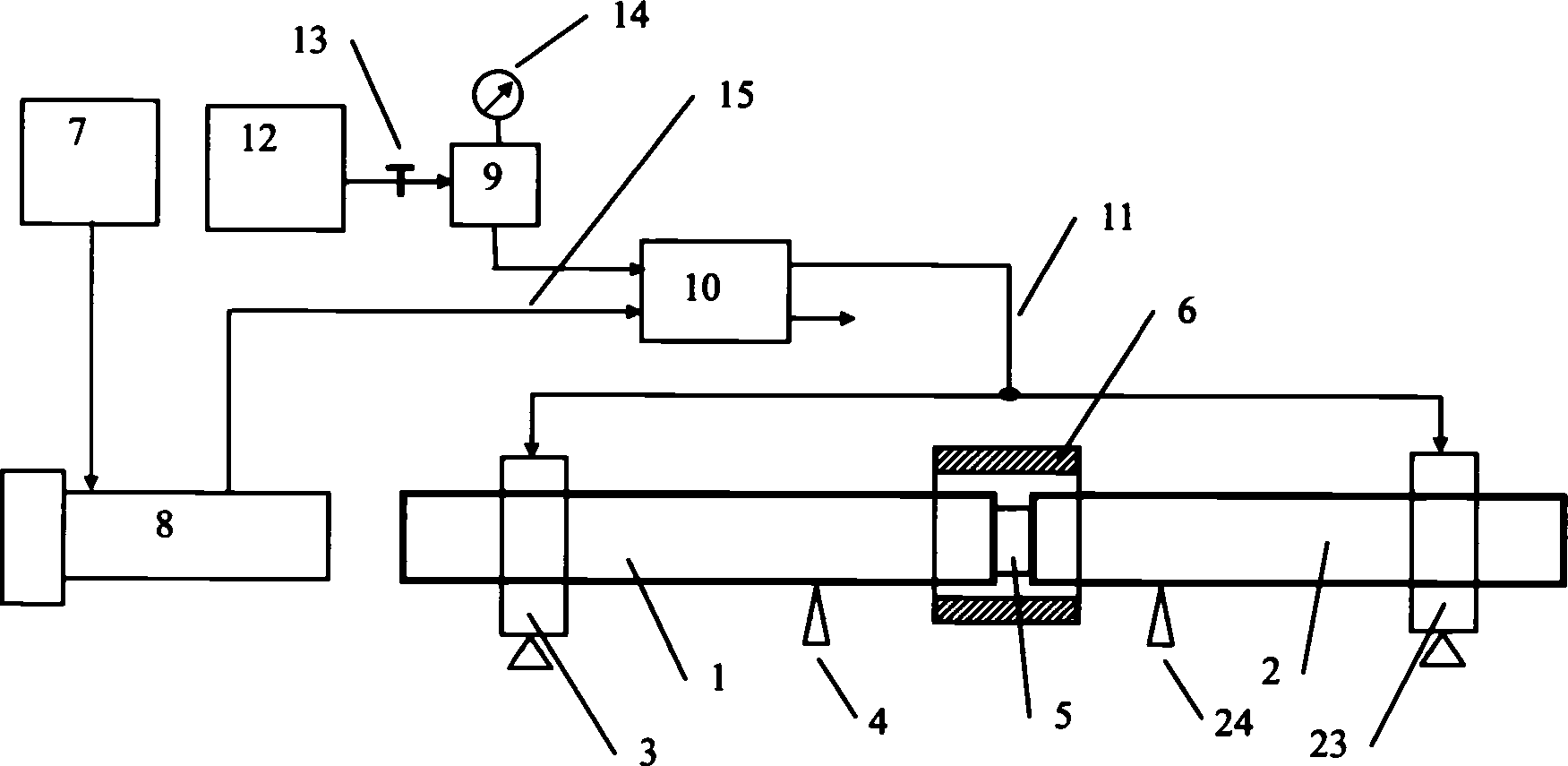

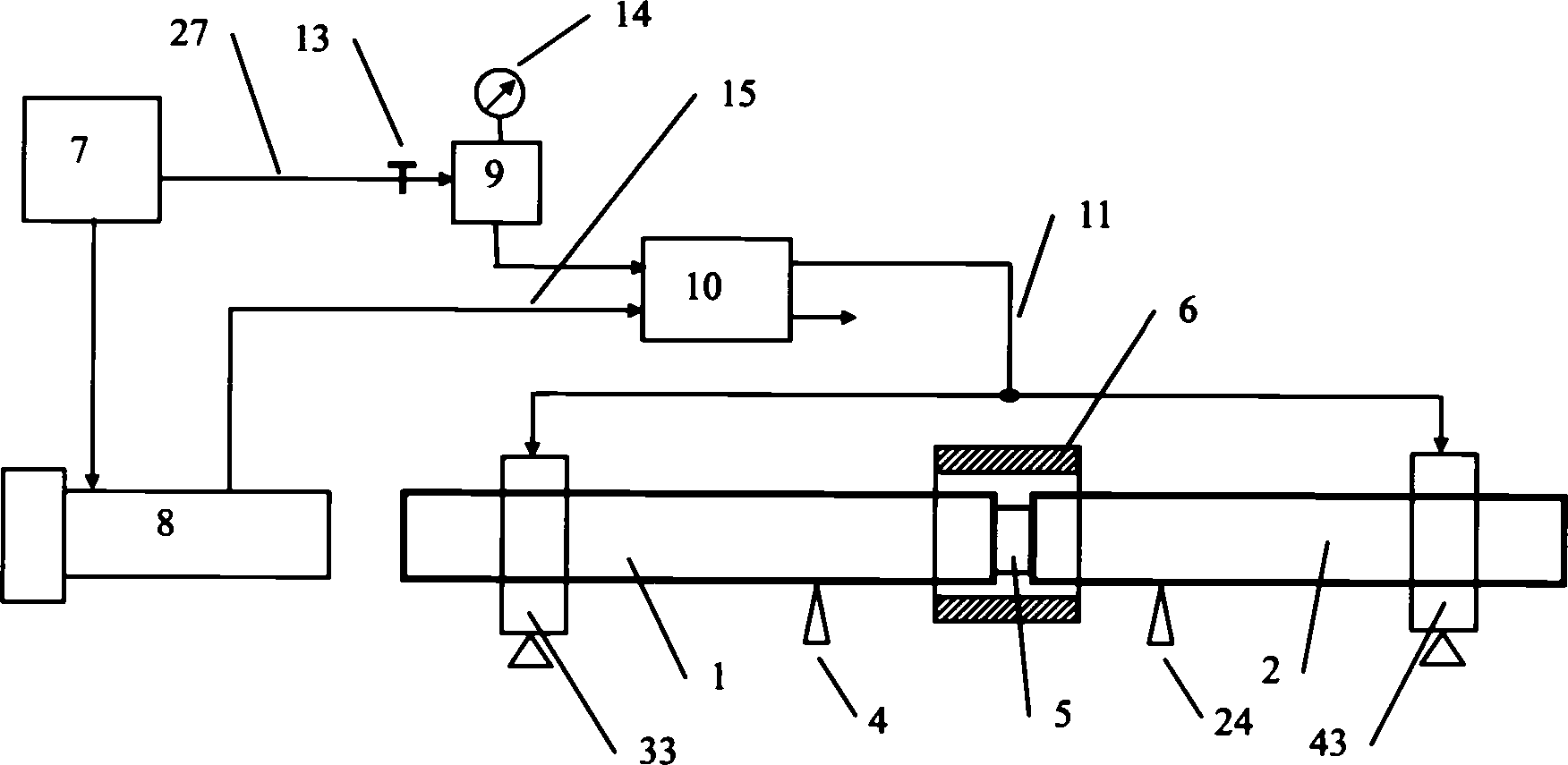

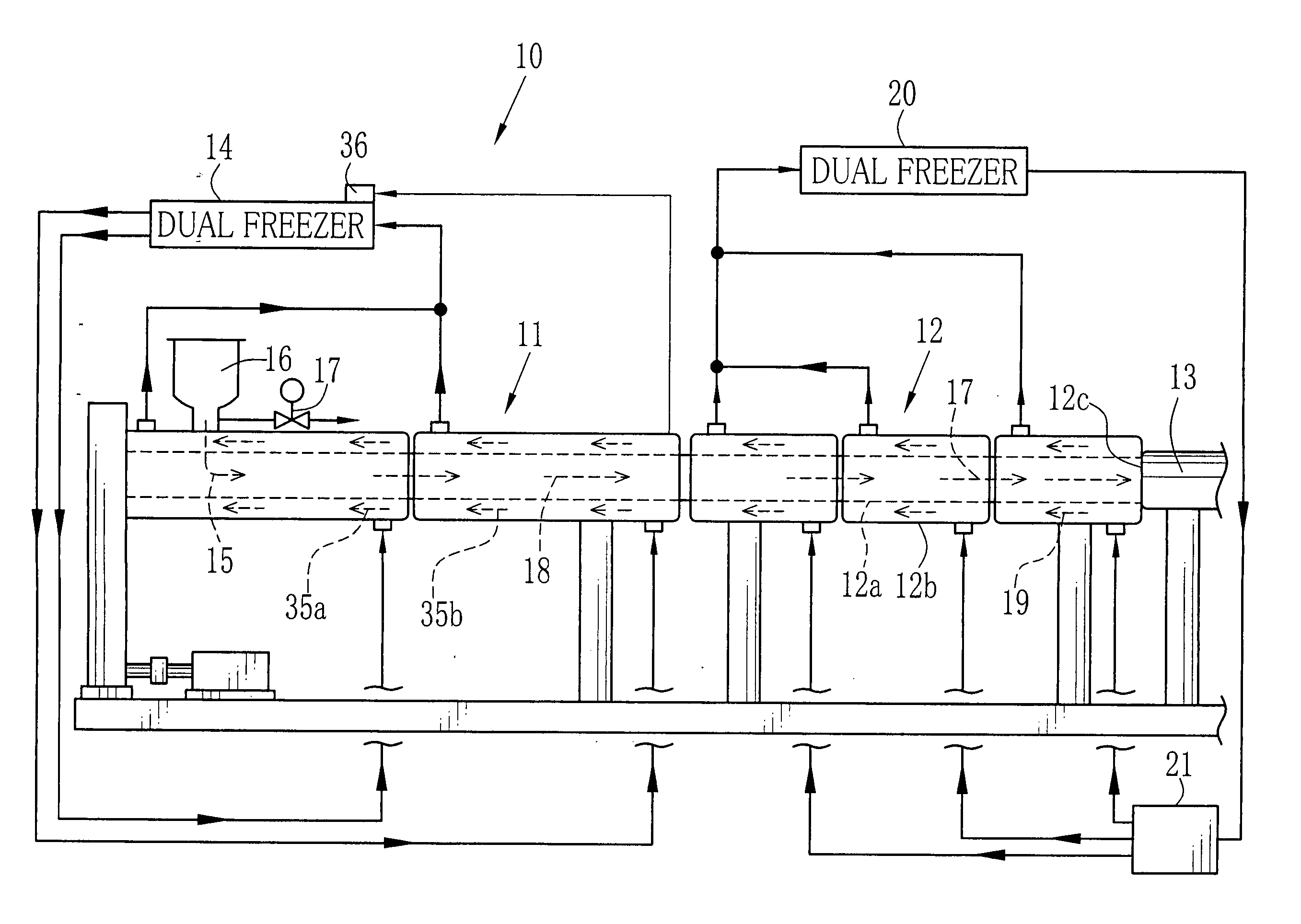

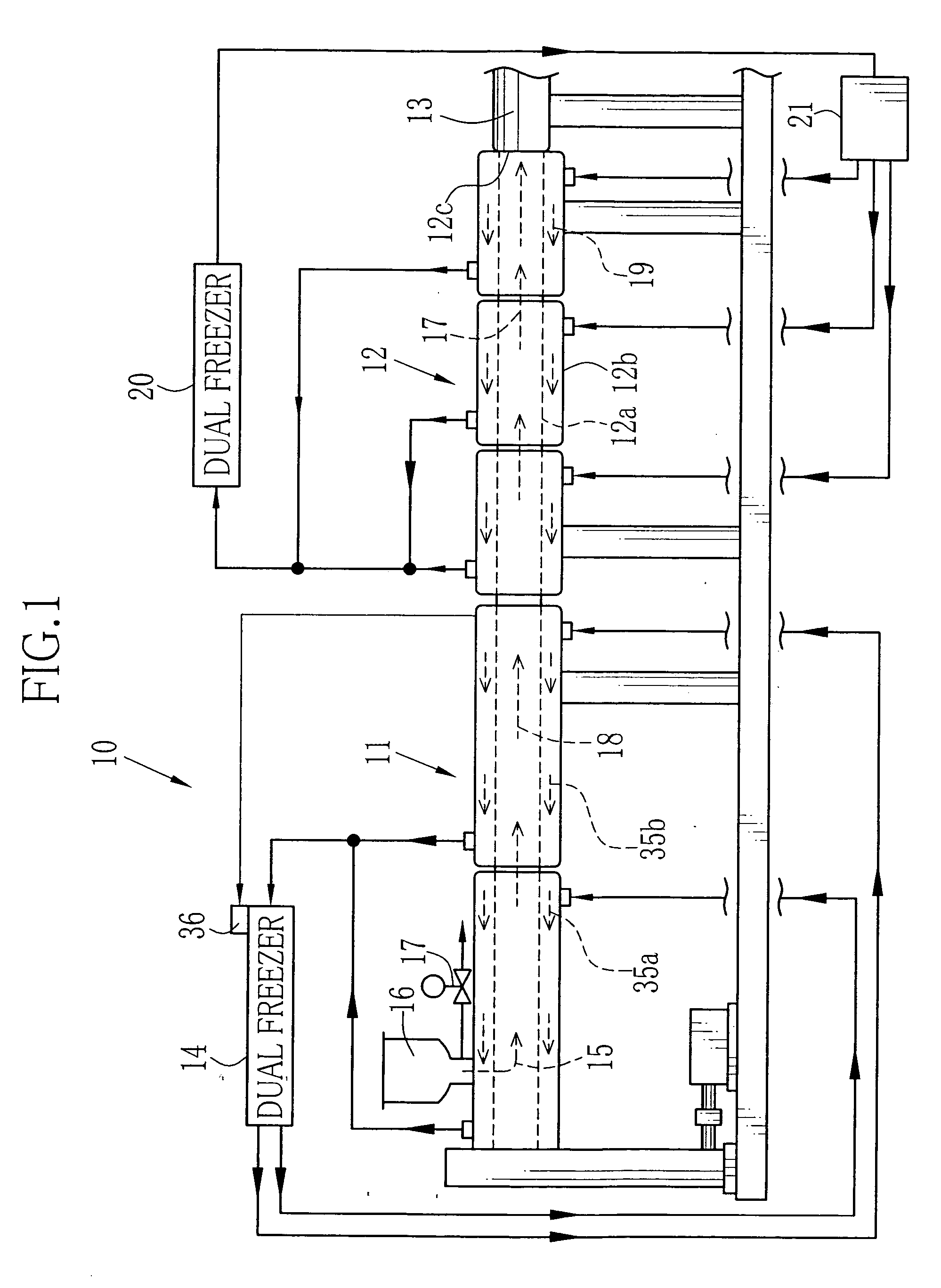

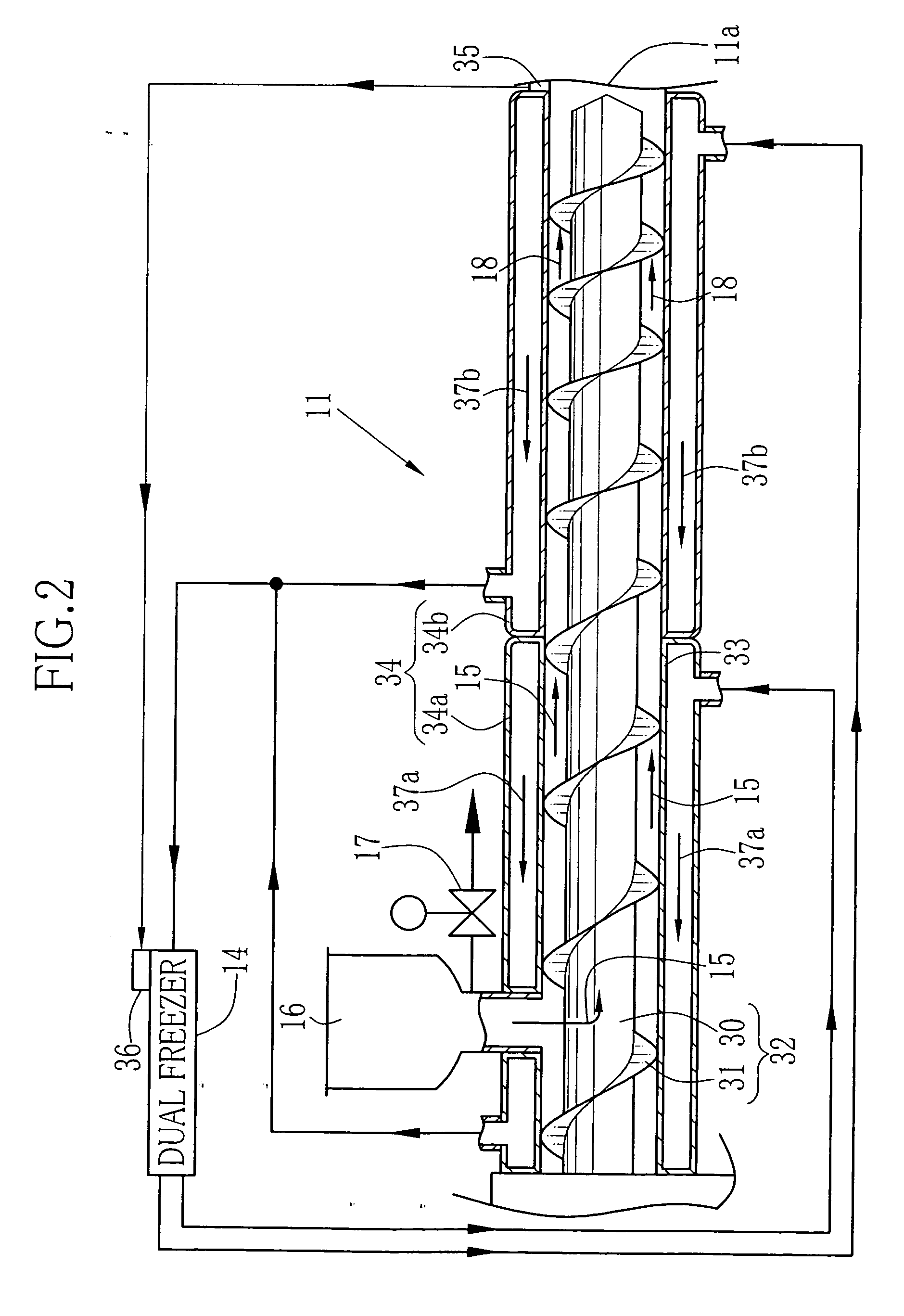

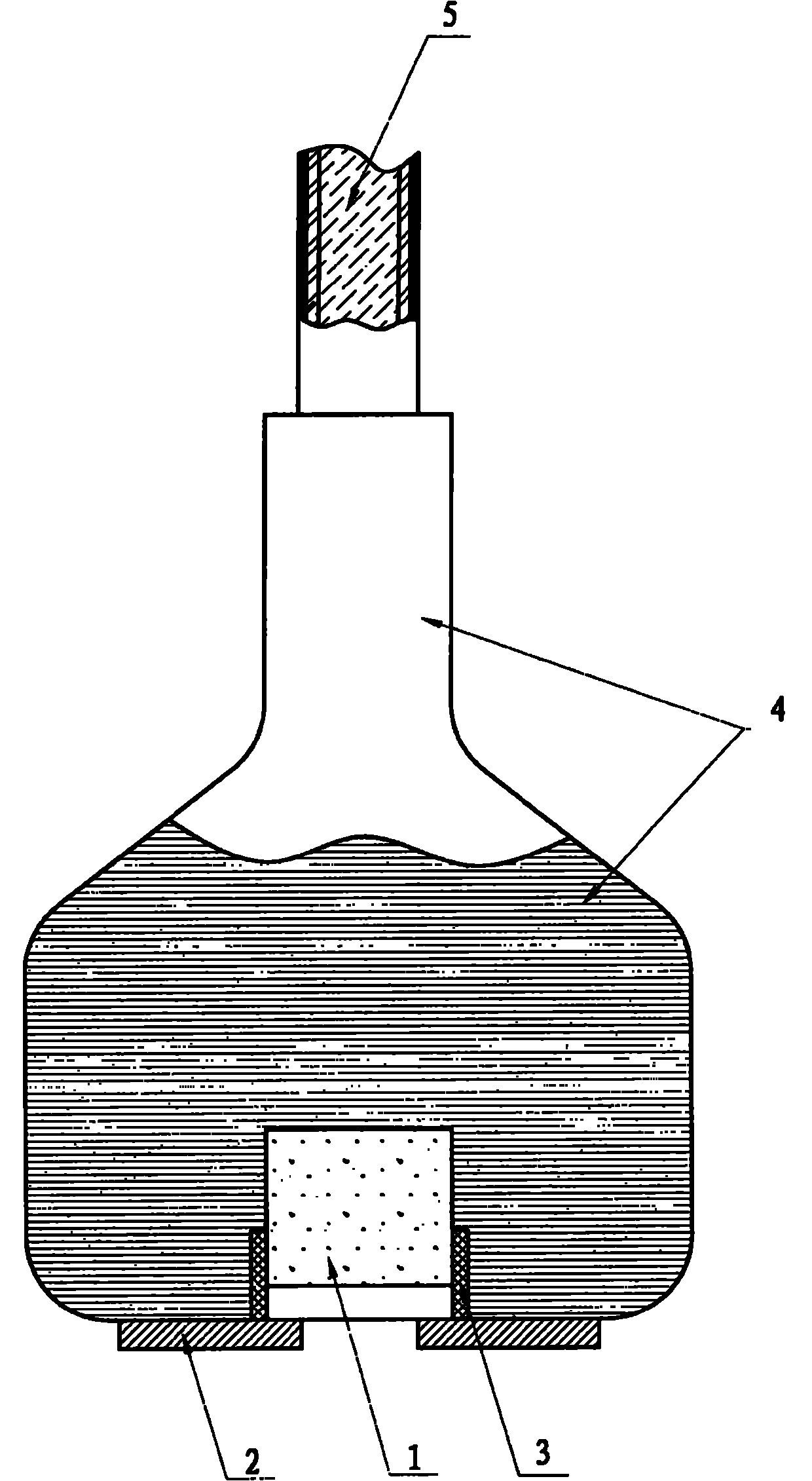

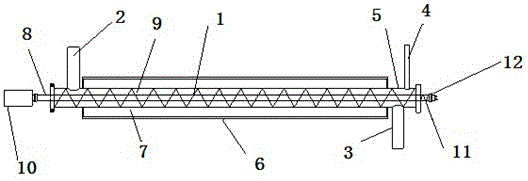

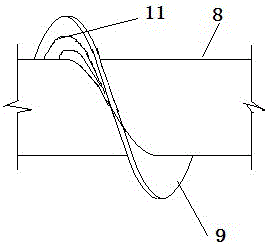

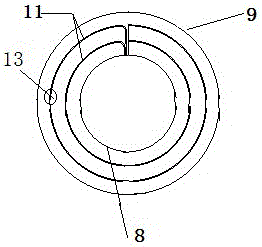

Double-air path bidirectional automatic assembling device for high-temperature Hopkinson pressure bar experiment

InactiveCN1888851AGuaranteed synchronicityReduce temperature unevennessStrength propertiesEngineeringAtmospheric pressure

Two-way double steam paths self-motion assembled equipment for high temperature Hopkinson pressure-bar experiment belongs to material high temperature dynamic mechanics capability research field. Each gas driving rack set on incidence perch and transmission perch and push them towards specimen in assembling to form two-way assemble in order to keep specimen in the availability heating range. Push the driving gas path of rack and separate setting of air cannon startup gas path and set gas chief valve control the switch of driving gas path and air cannon startup gas path. It makes the driving rack and air cannon startup linkage without influence. Set small gas storage tin as driving gas source and control its air pressure to control the driving speed of the driving rack. It can keep the assembled stability of the equipment and enhance assembled success probability. It assures the synchronism of assembled equipment when the stress wave arrives to specimen to avoid the temperature of specimen rapidly drop for leaving heat fountain.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

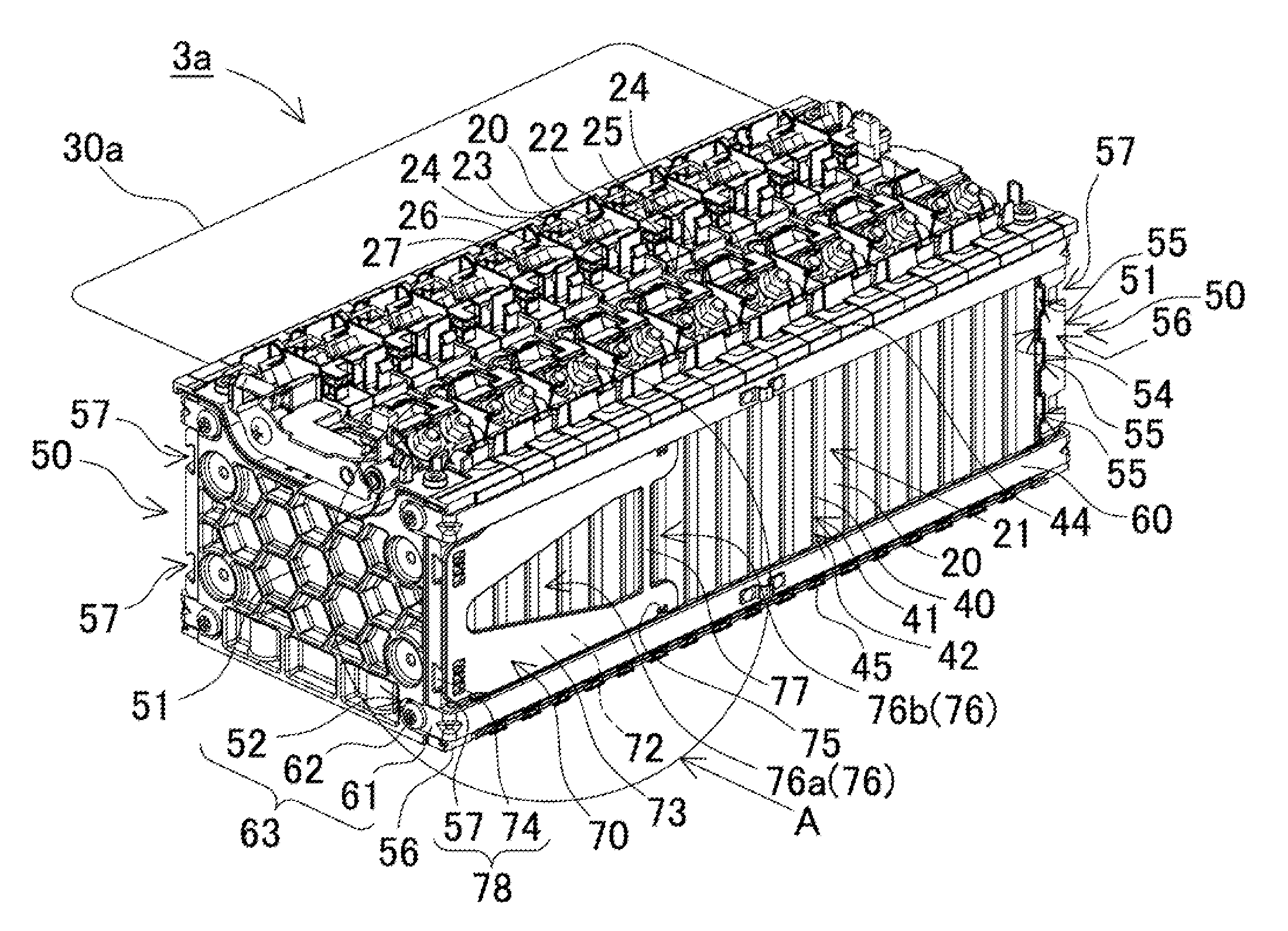

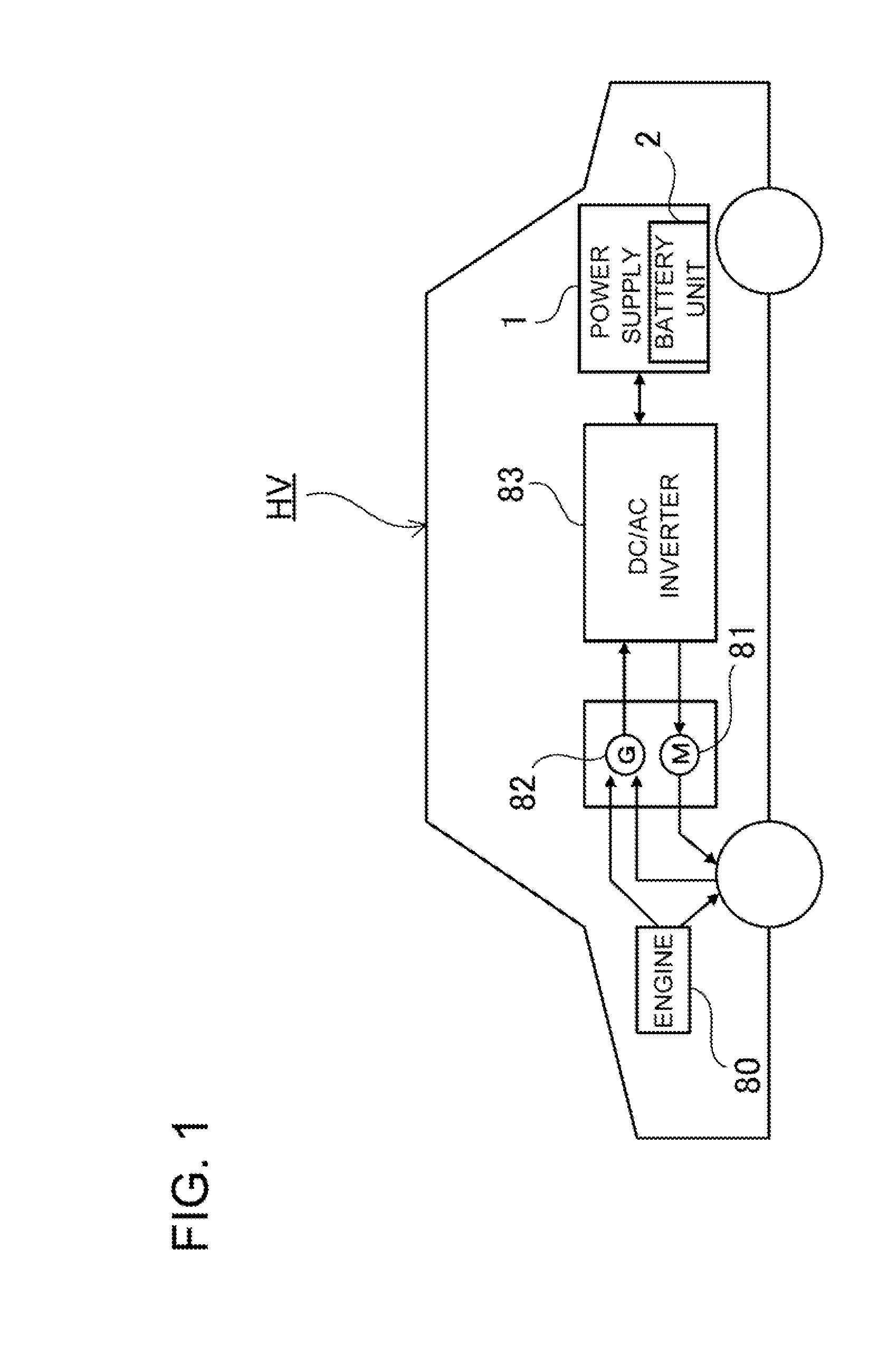

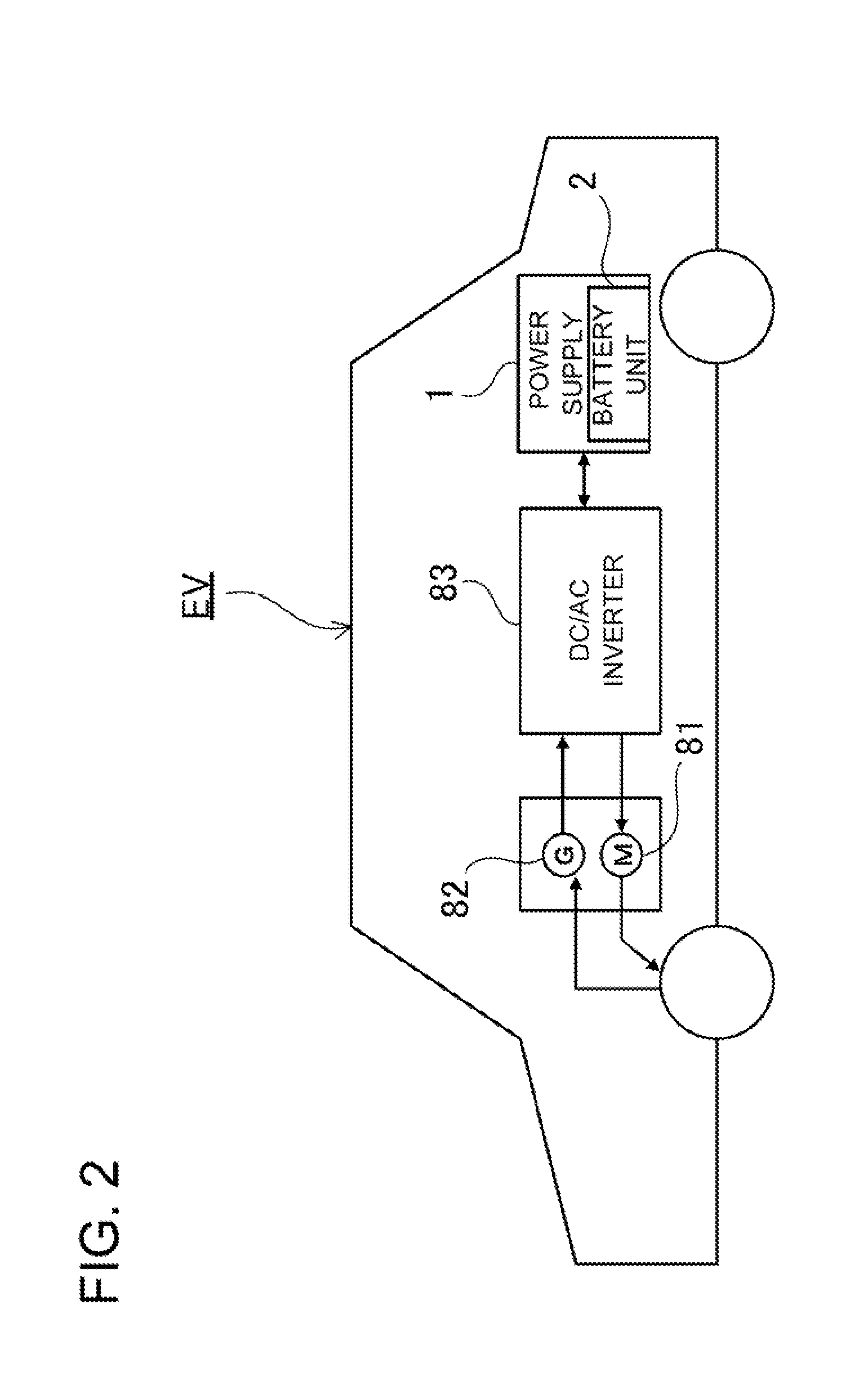

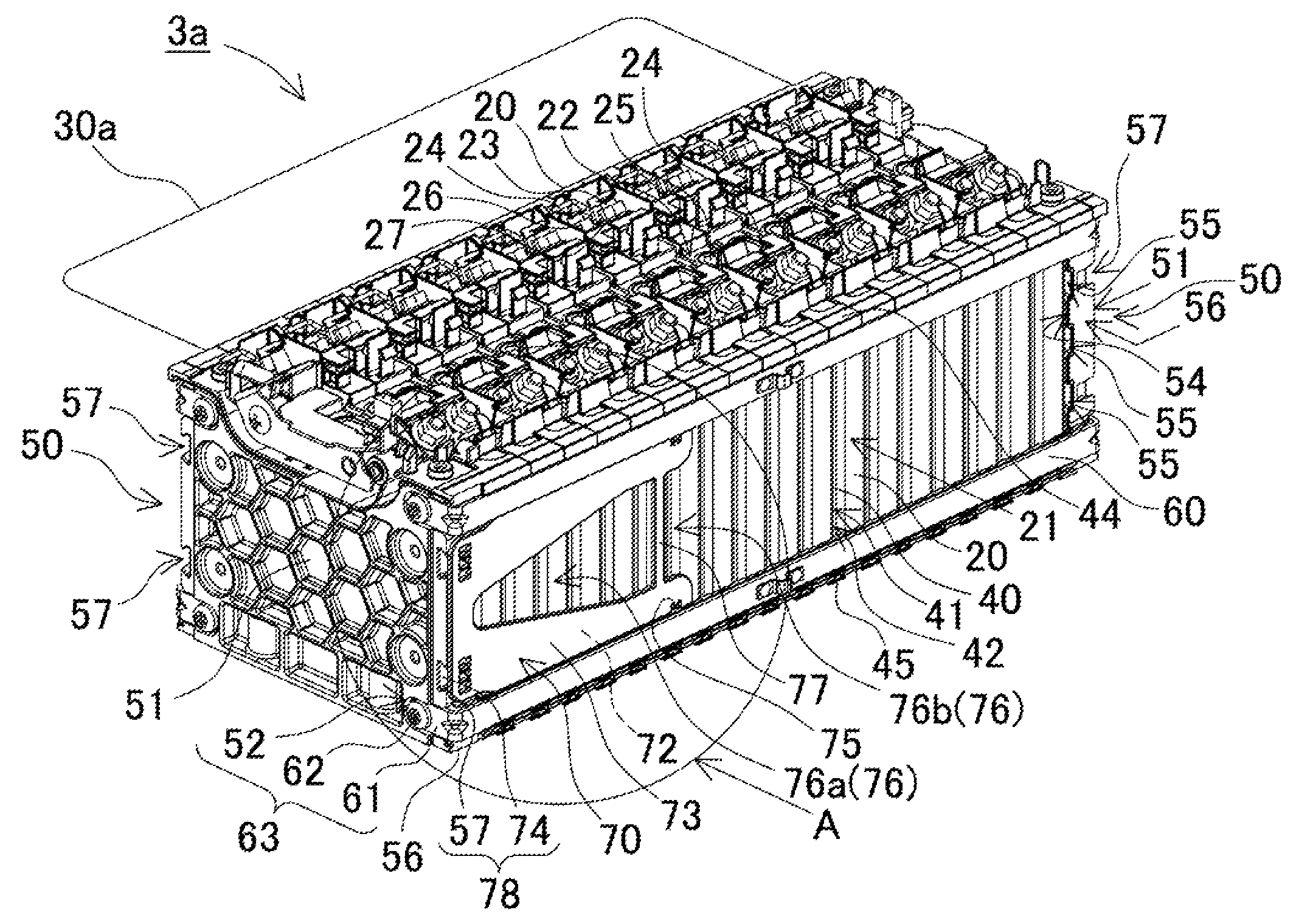

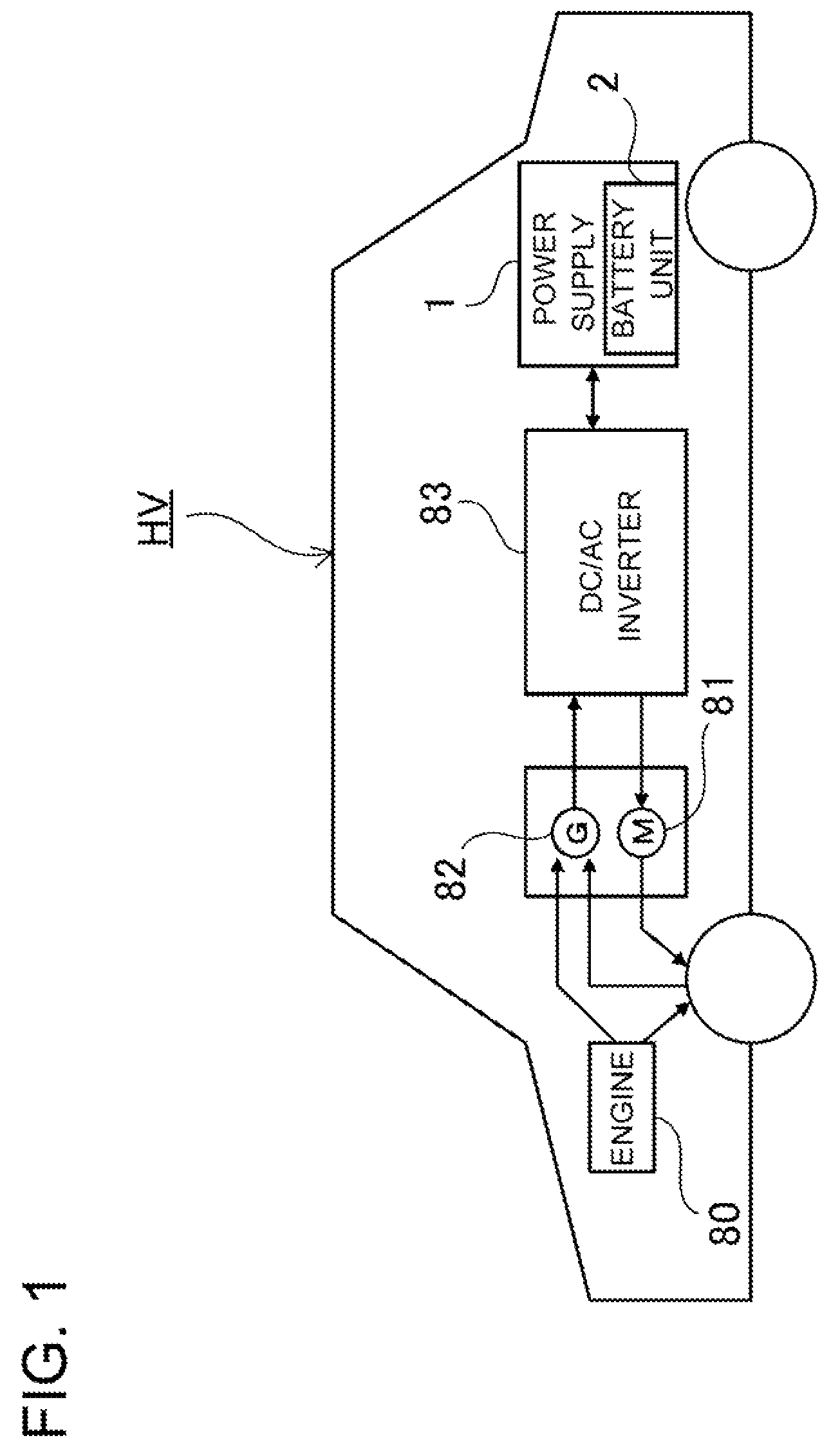

Battery temperature unevenness suppressing power supply

ActiveUS20110104547A1Securely and stably attachCost reductionElectric devicesCell temperature controlEngineeringElectrical and Electronics engineering

Owner:SANYO ELECTRIC CO LTD

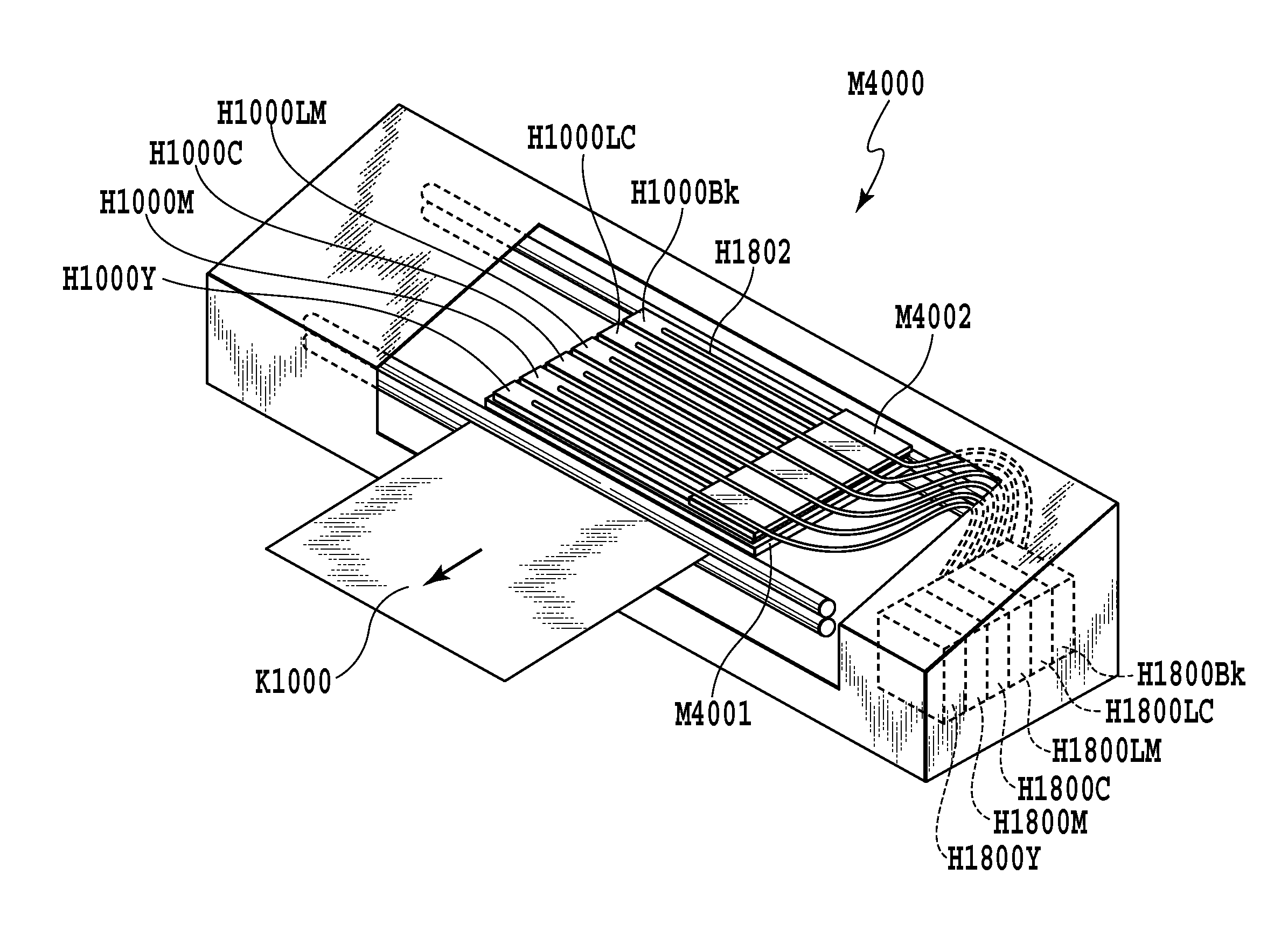

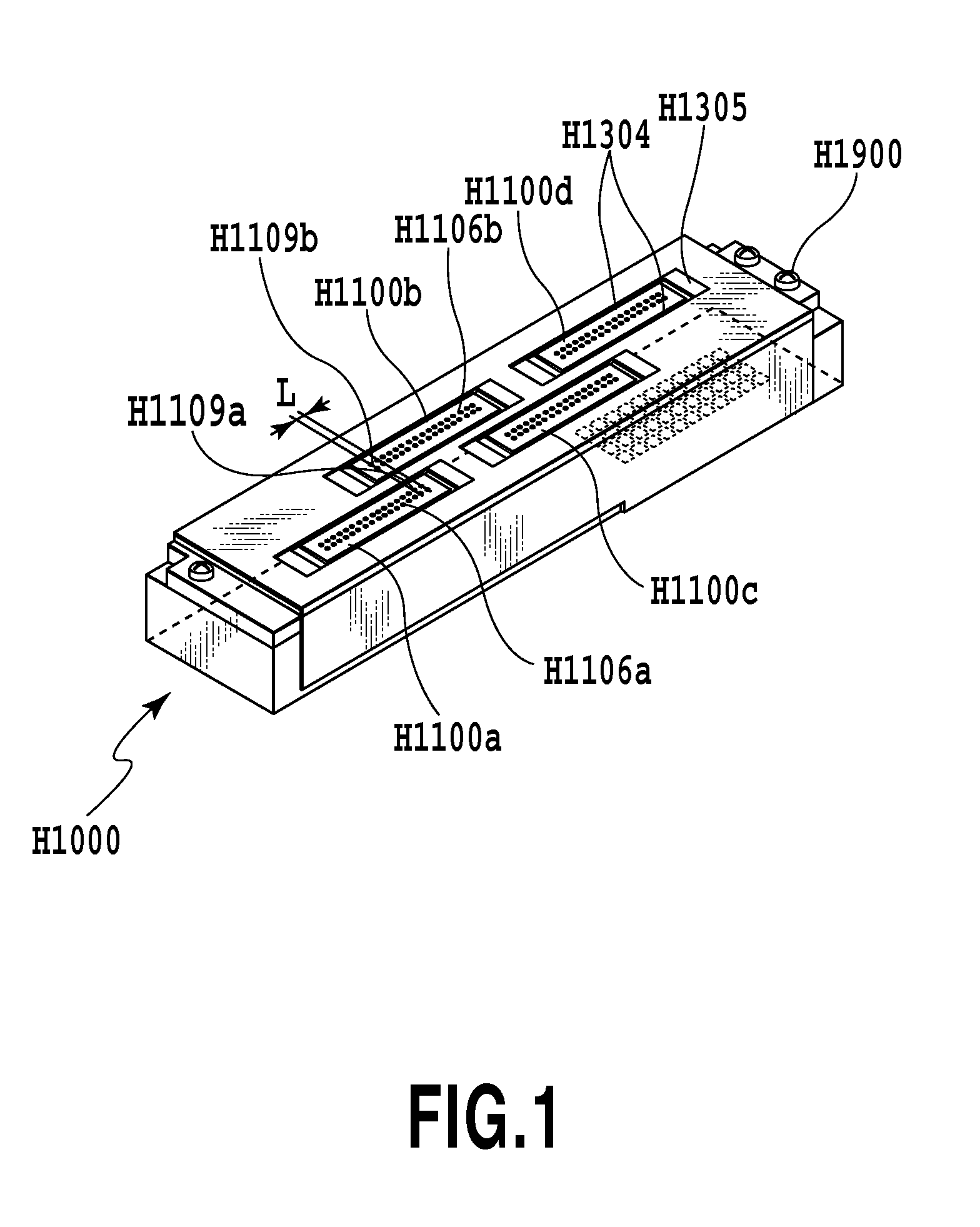

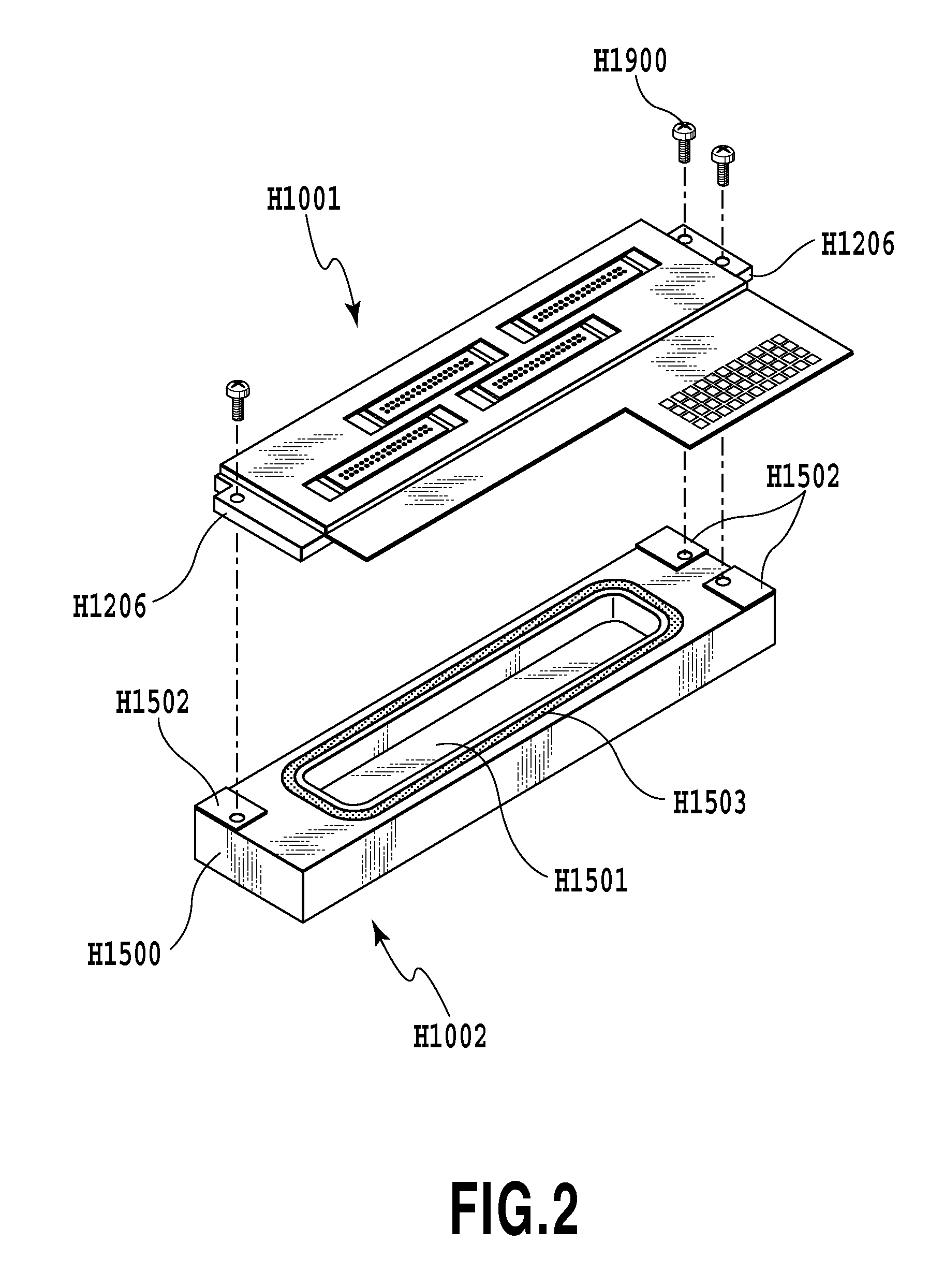

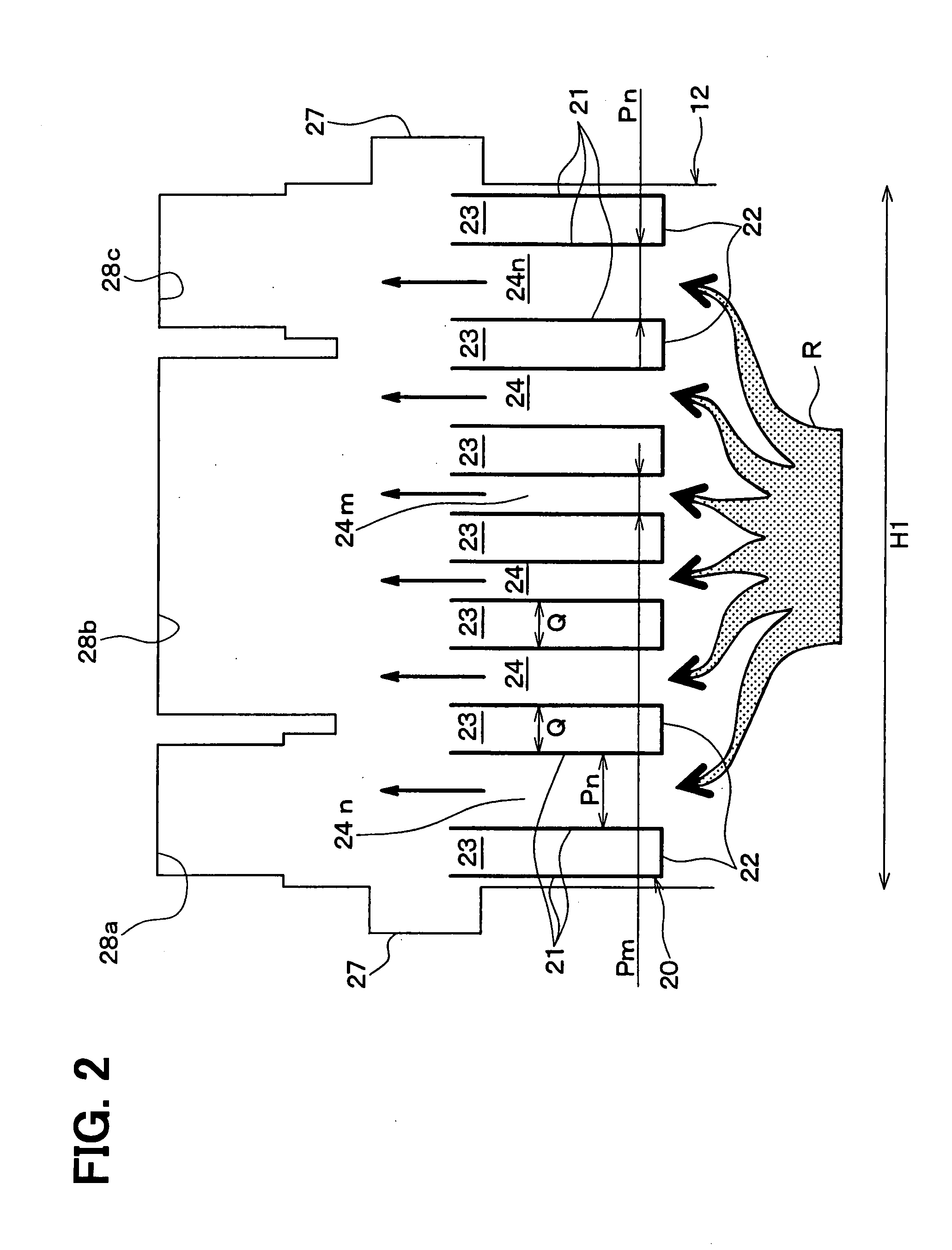

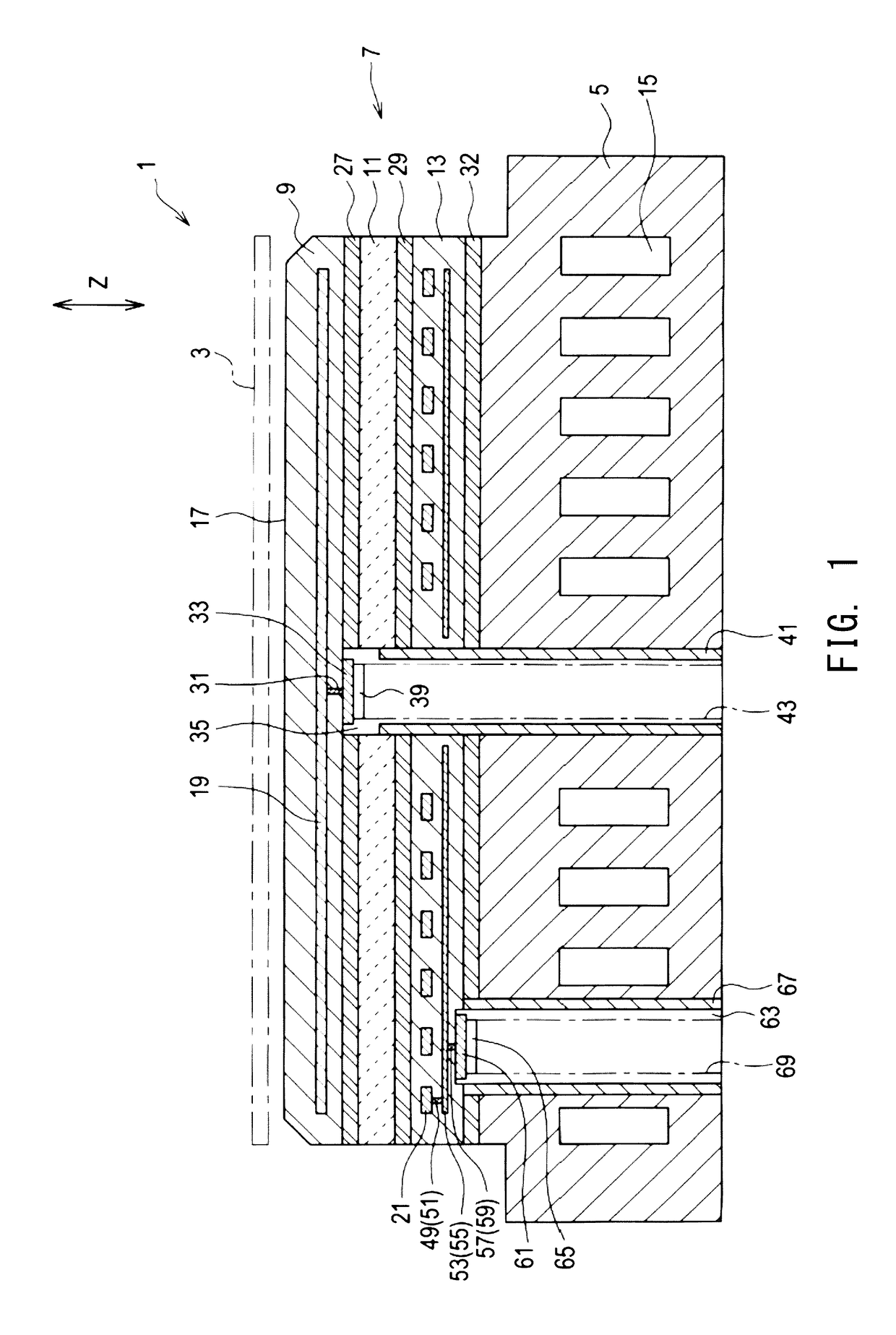

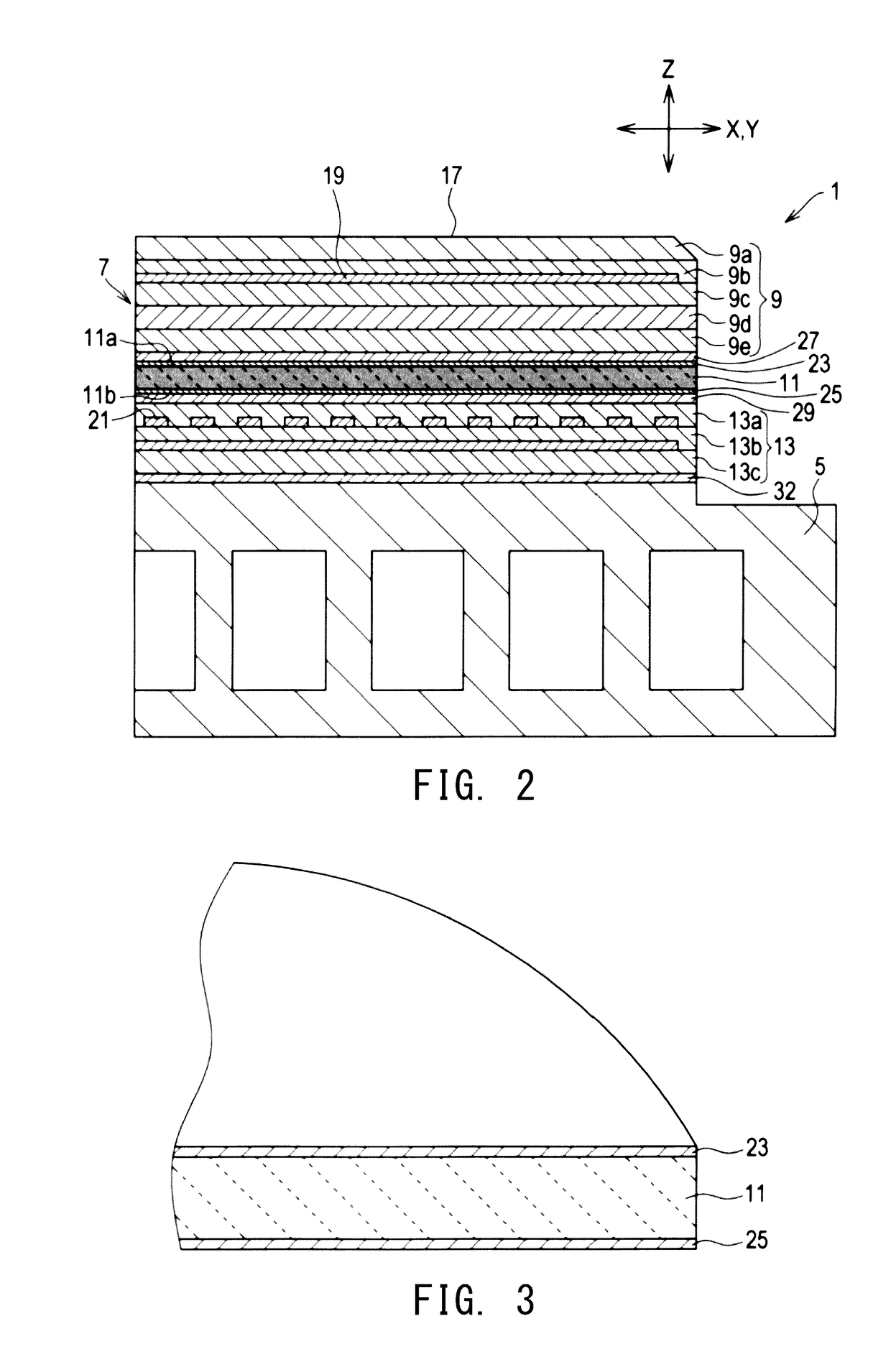

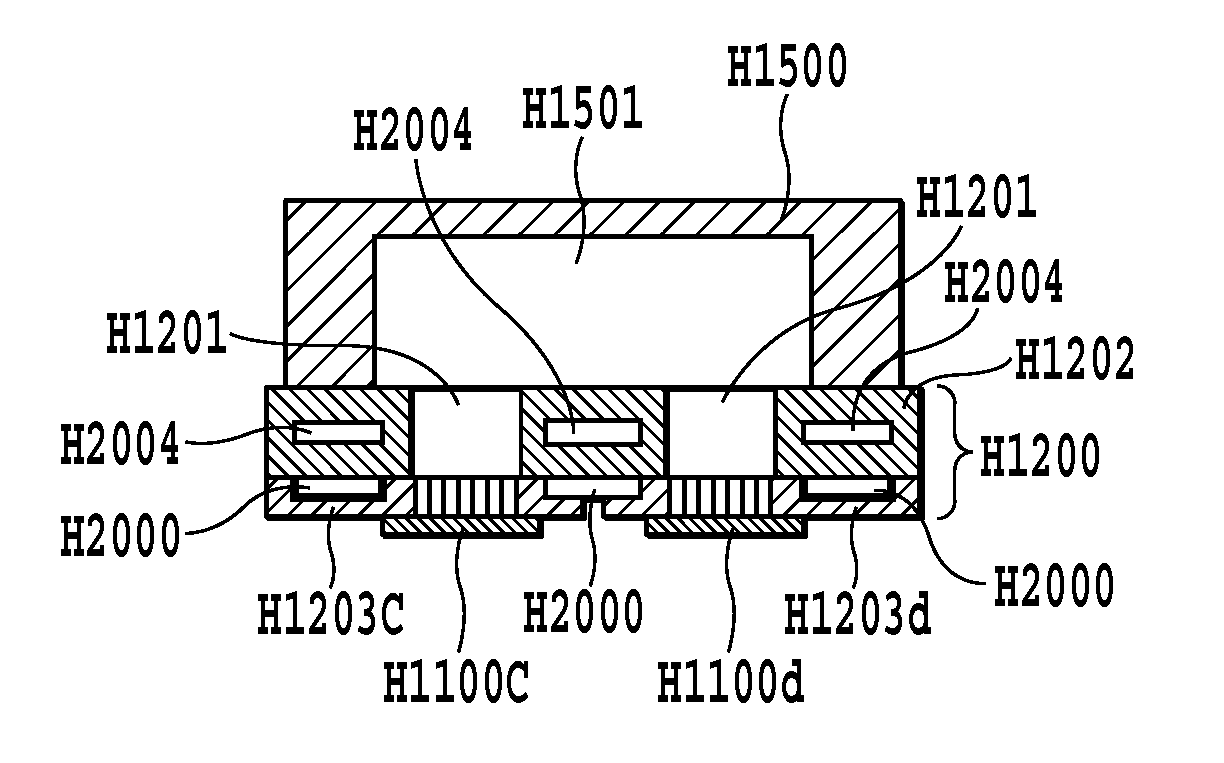

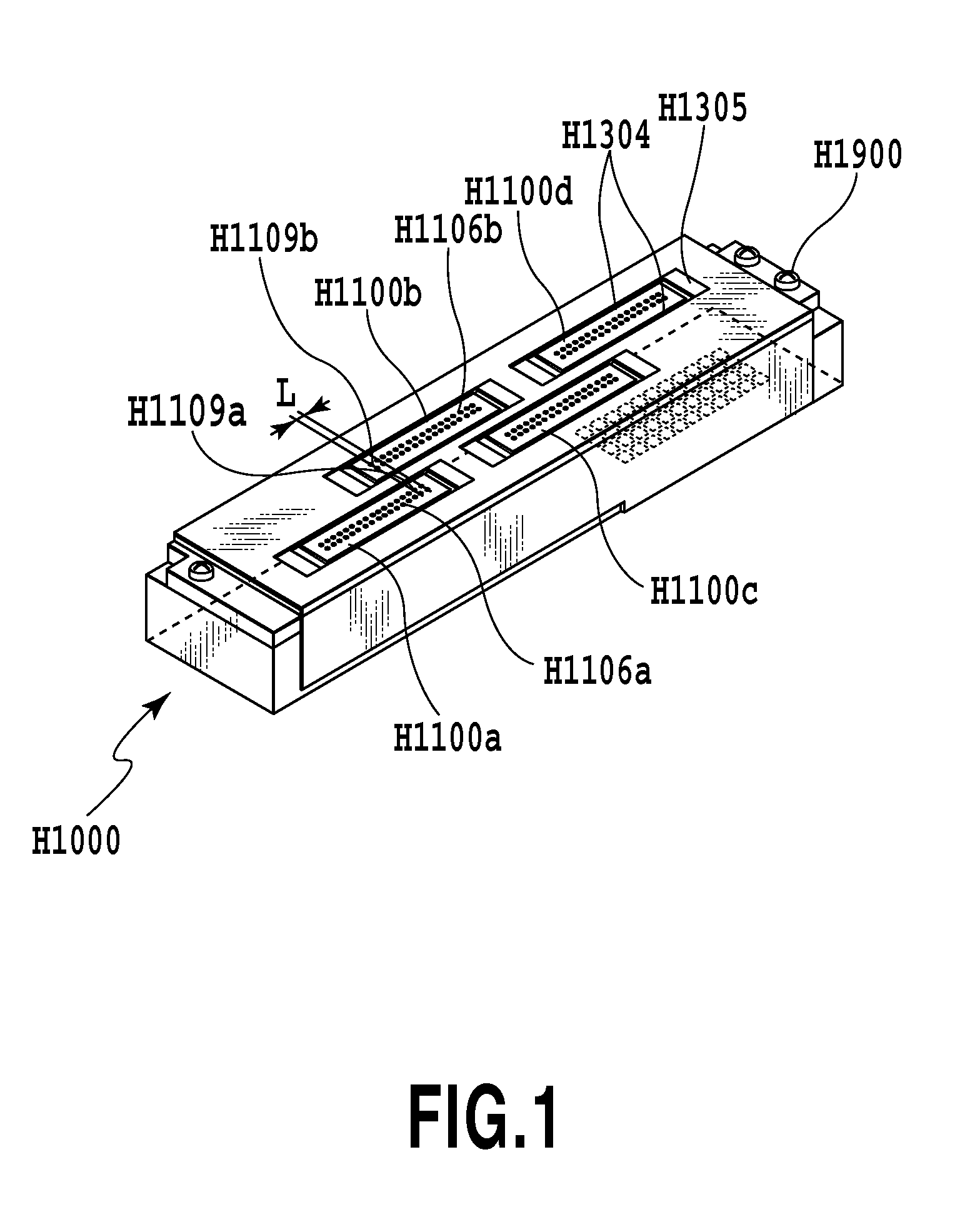

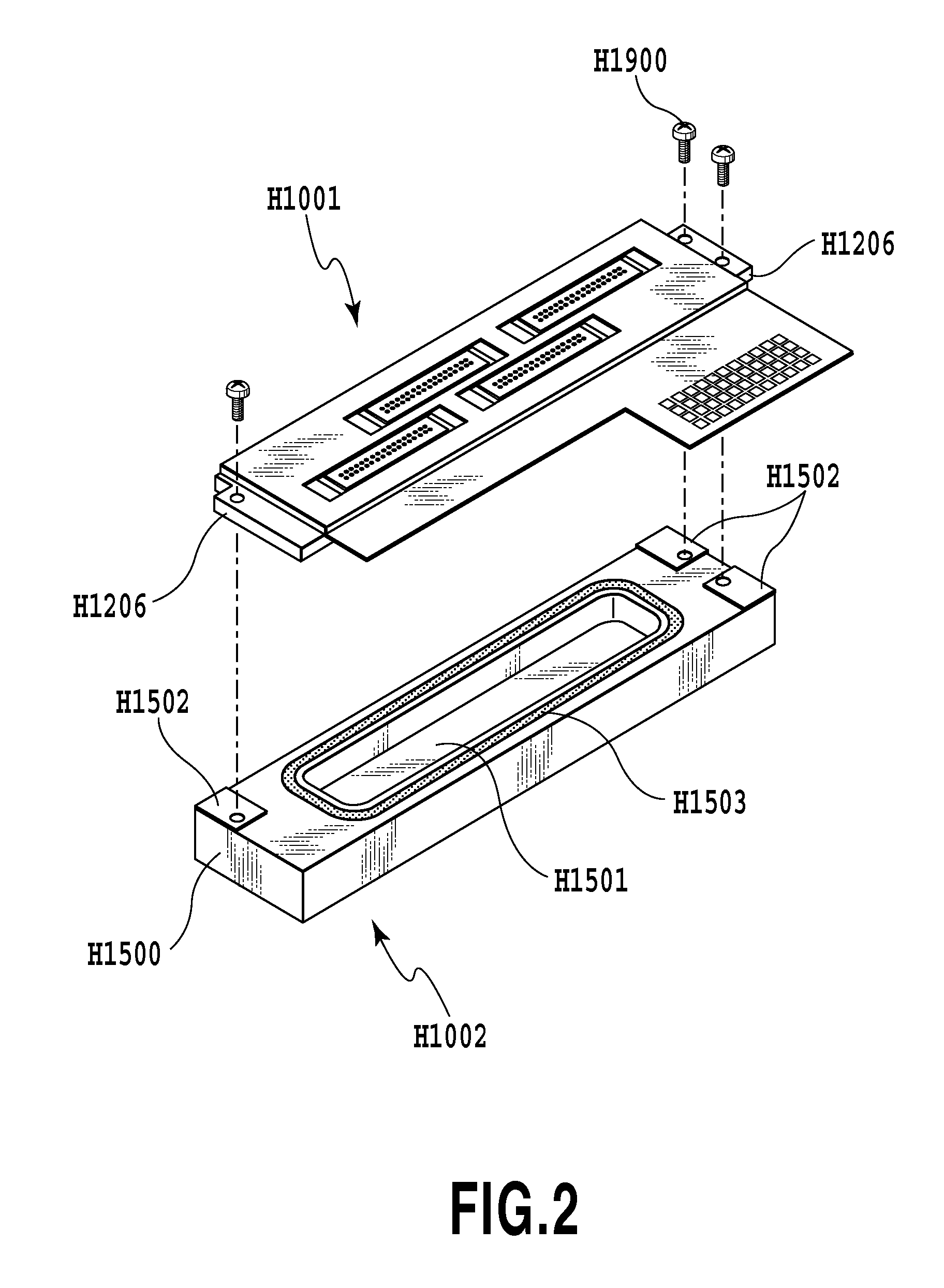

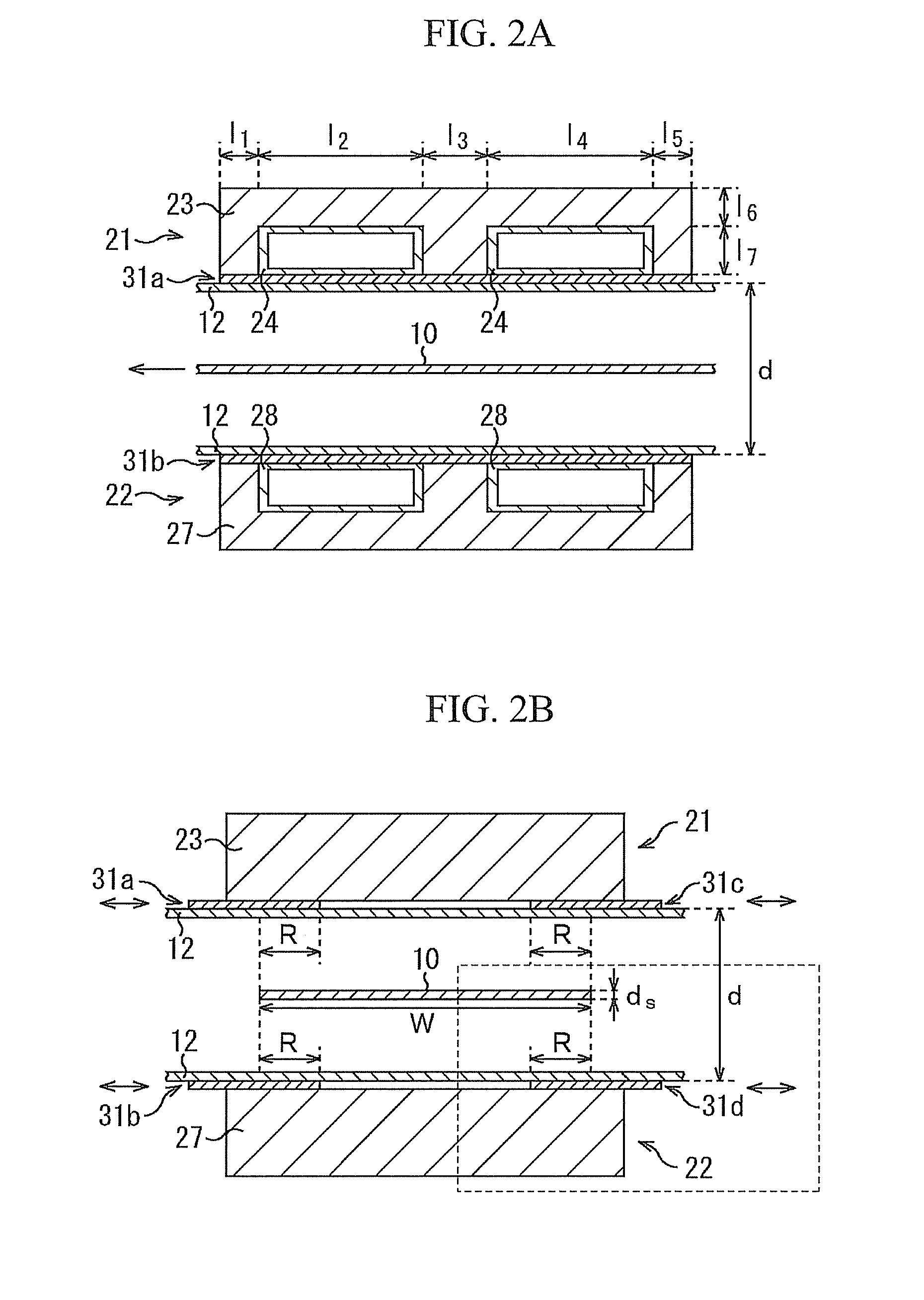

Inkjet print head and inkjet printing apparatus

InactiveUS20090141062A1High print reliabilitySuppress temperature unevennessInking apparatusOther printing apparatusEngineeringInkjet printing

A print head having high printing reliability, in which temperature unevenness is suppressed even when printing is performed using a print head having an increased length and density of an ejection opening array can be provided. Specifically, a temperature equalizing member such as a heat pipe and a cooling liquid passage is disposed between a first support substrate and each of second support substrates or is disposed inside the first support substrate. This makes it possible to equalize temperature among the plurality of second support substrates and further equalize temperature among the printing element substrates bonded to these support substrates. In addition, the temperature equalizing member is made close to the printing element substrate, thus making it possible to efficiently equalize temperature.

Owner:CANON KK

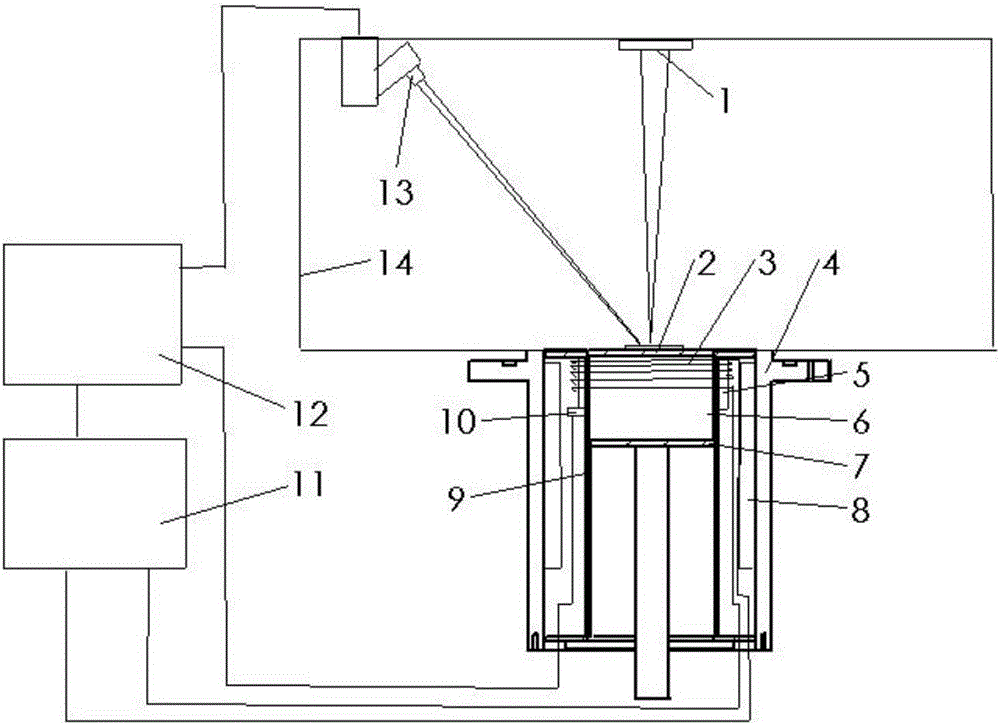

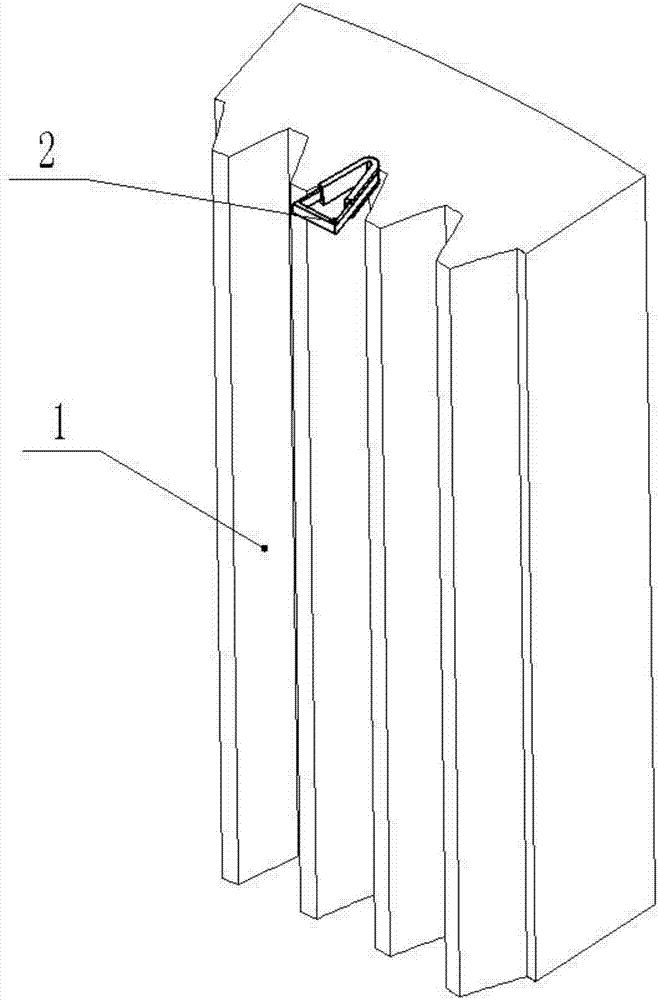

Electromagnetically-induced three-dimensional heating system for selective laser melting

ActiveCN105855544AReduce temperature unevennessReduce residual stressIncreasing energy efficiencySelective laser meltingLaser transmitter

The invention discloses an electromagnetically-induced three-dimensional heating system for selective laser melting. The electromagnetically-induced three-dimensional heating system comprises a forming chamber, wherein a laser transmitter is arranged at the top of the forming chamber, a forming working platform is arranged at the bottom of the forming chamber, the forming working platform is cooperated with an inner body of a forming cylinder, a coil is arranged between the inner body of the forming cylinder and an outer body of the forming cylinder, the forming working platform is arranged in the coil, the coil is connected with an electromagnetic induction heating control cabinet, and the electromagnetic induction heating control cabinet is connected with a central controller; a graphite block is arranged between the inner body of the forming cylinder and the coil, a temperature sensor used for monitoring a temperature of the graphite block in real time is installed on the graphite block, and the temperature sensor is connected with the central controller; and an infrared thermometer used for monitoring temperatures of the machined parts in real time is installed in the forming chamber, and the infrared thermometer is connected with the central controller. The electromagnetically-induced three-dimensional heating system disclosed by the invention is used for uniformly heating the machined parts and a machining planar area, thus reducing the interlayer temperature gradients of cooling solidification and machining of an SLM metal molten pool, and reducing residual stresses in the metal parts; and online annealing can be realized.

Owner:XI AN JIAOTONG UNIV

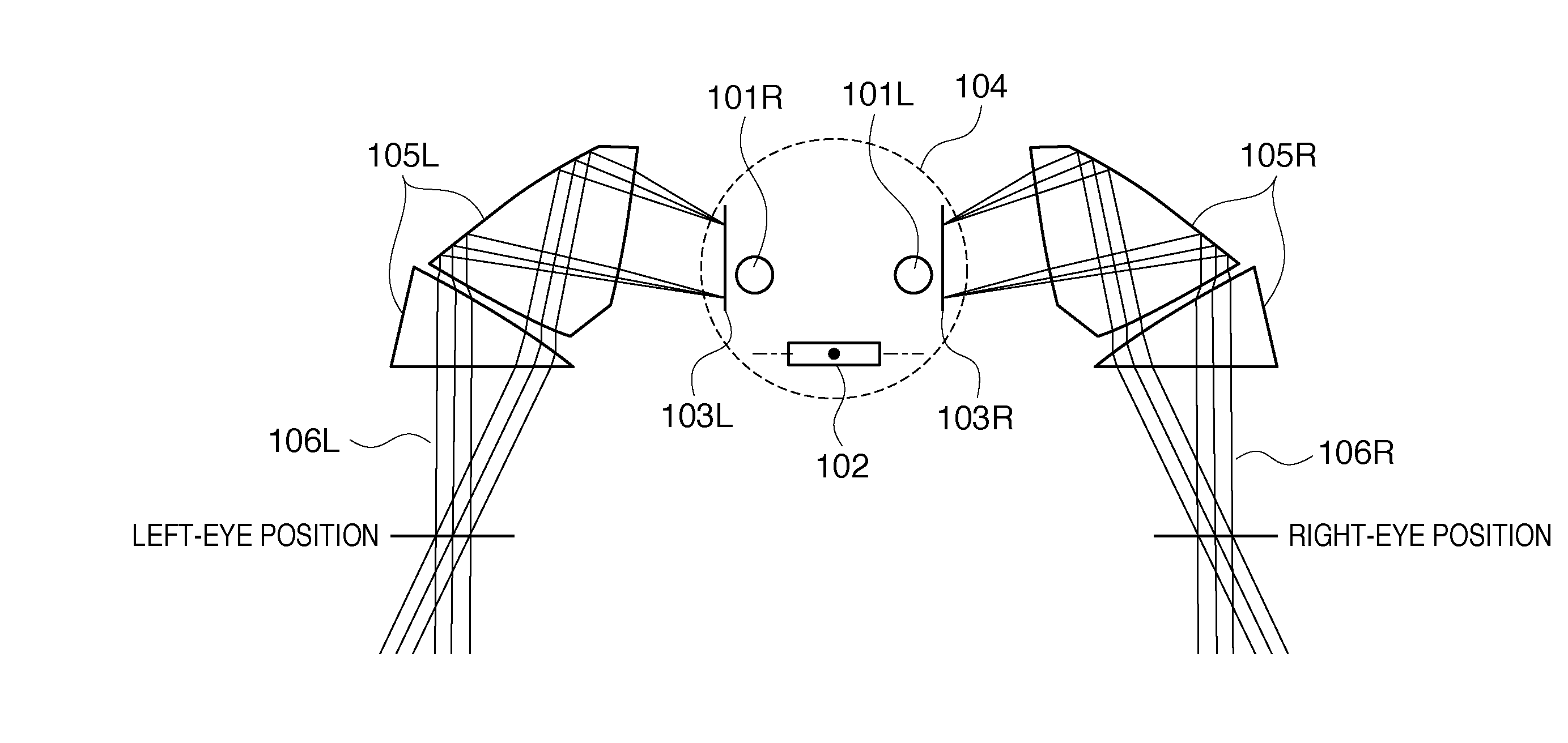

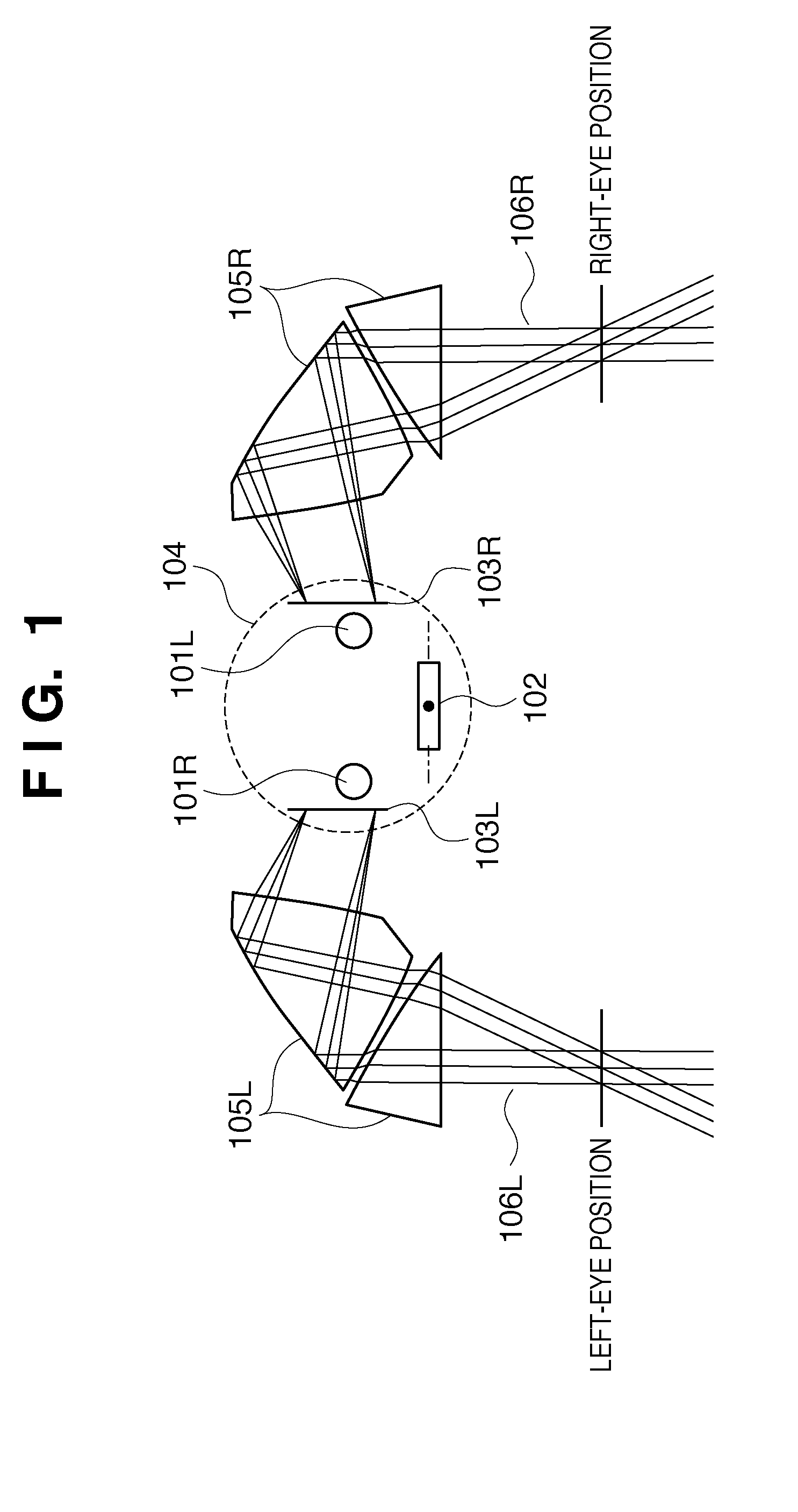

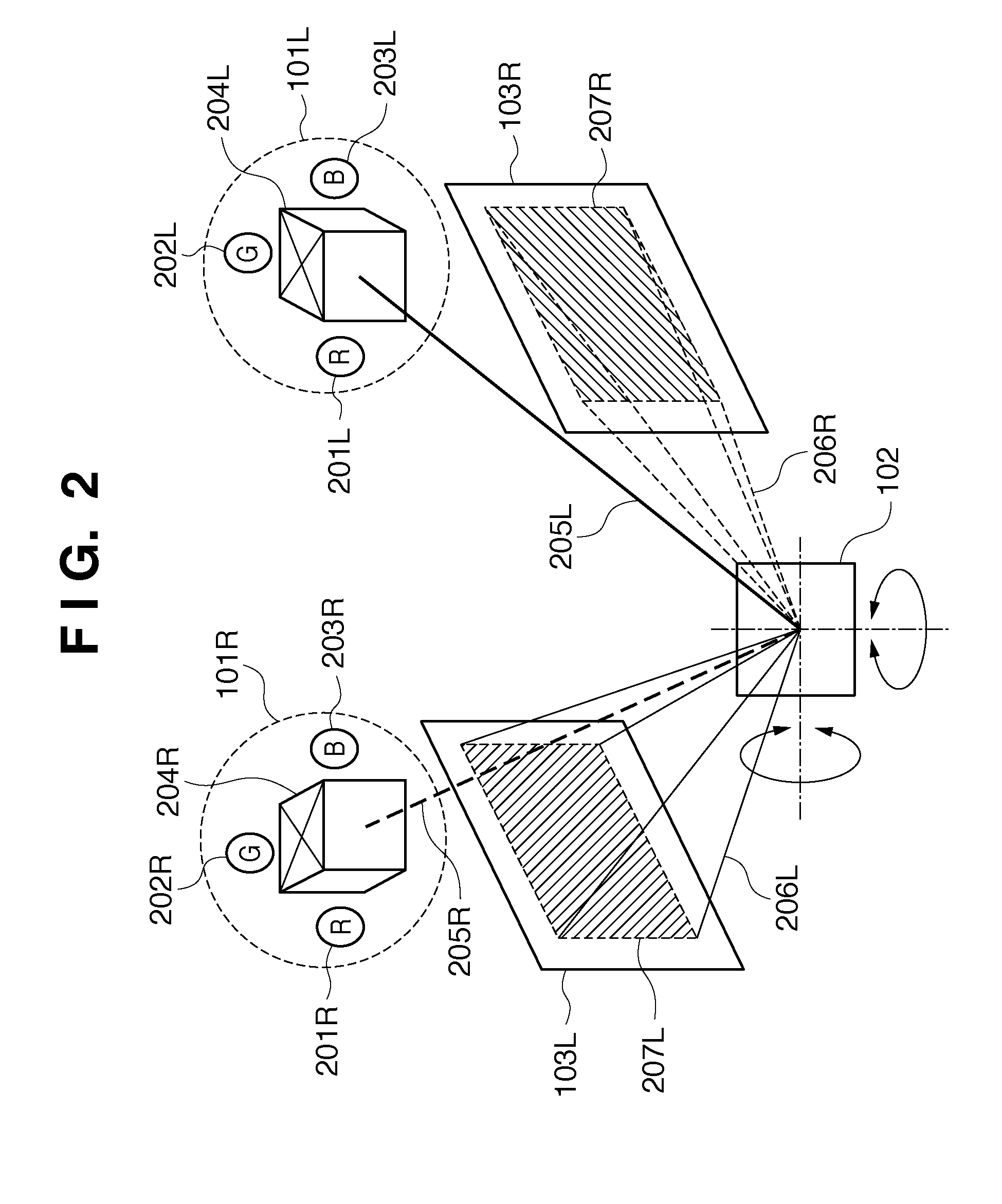

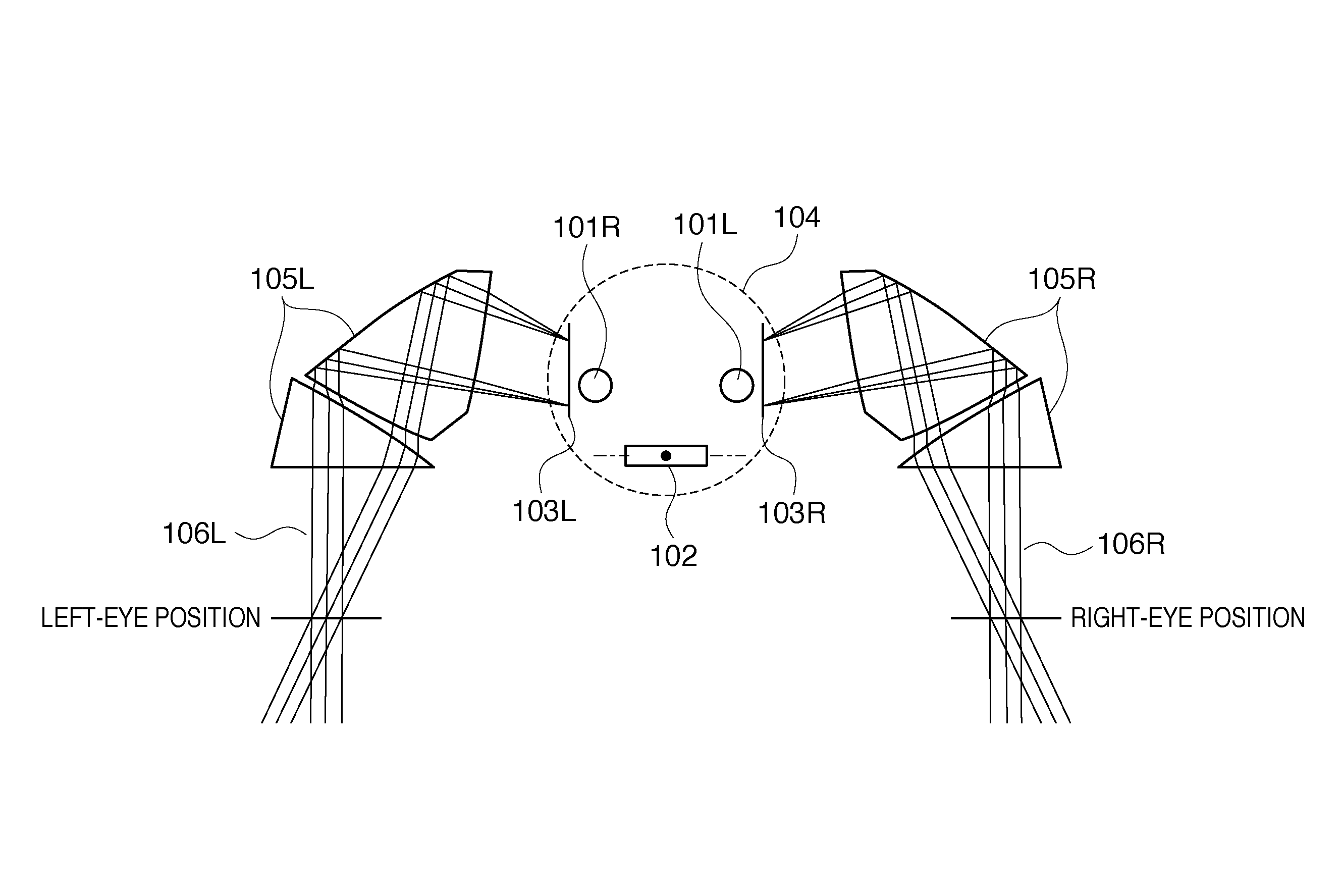

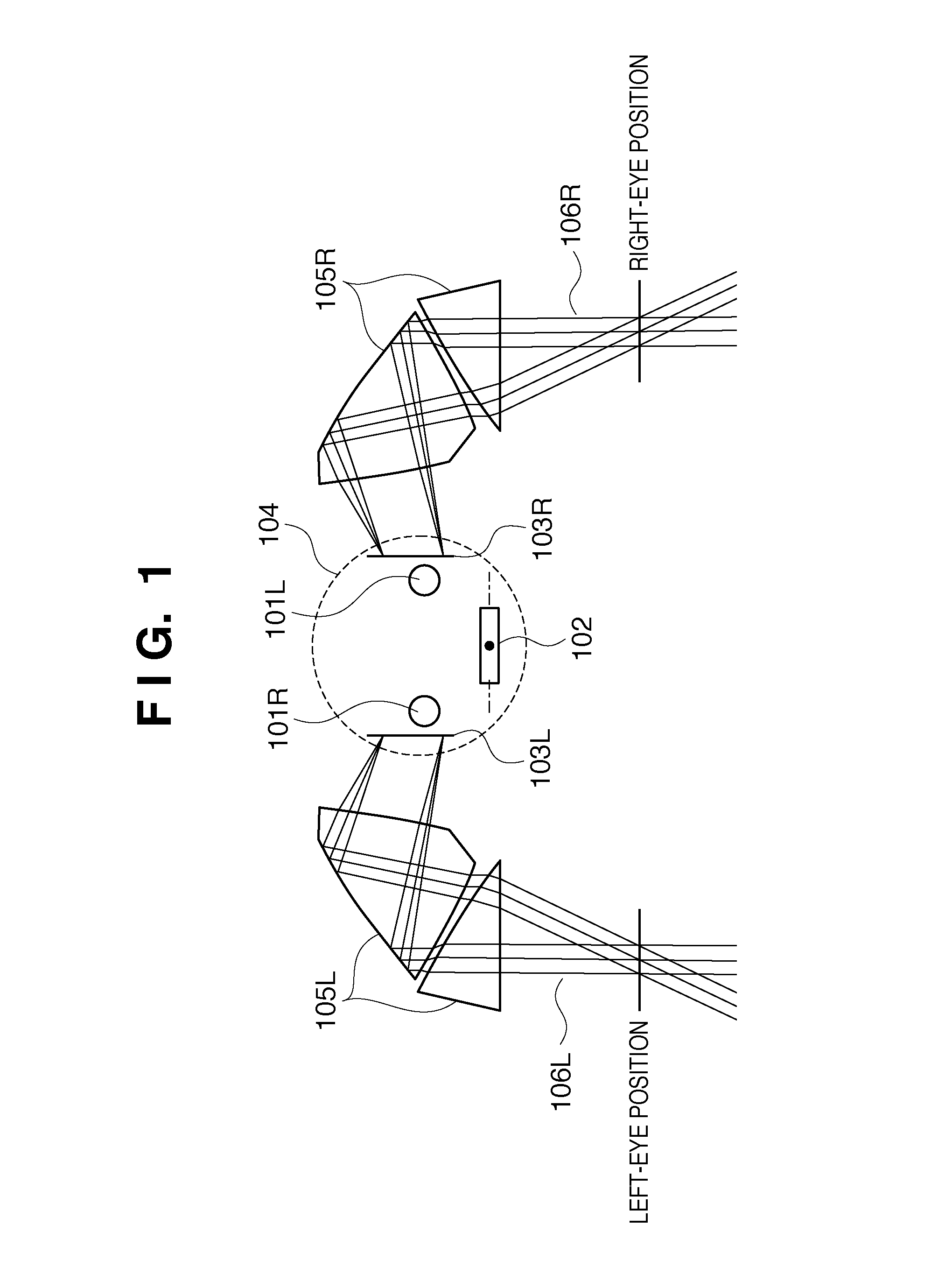

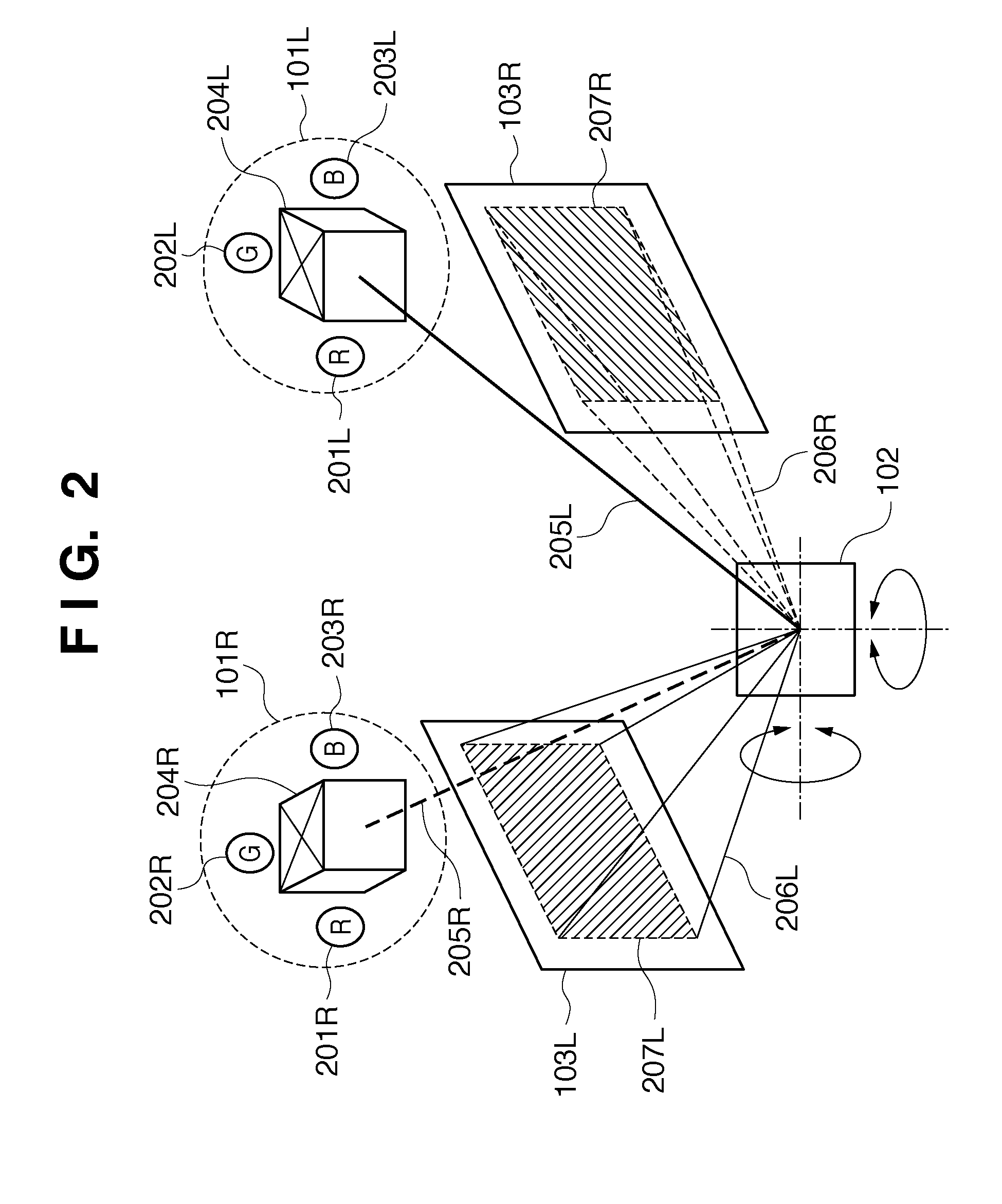

Image display apparatus and method of controlling the same

ActiveUS20100033791A1Reduce temperature unevennessCathode-ray tube indicatorsOptical elementsEngineeringImage signal

An image display apparatus generates a first light beam and a second light beam corresponding to image signals for the eyes of an observer, and makes the first light beam and the second light beam incident on a reflection surface which makes a reciprocating rotation about a first axis, thereby generating first and second scanning light beams to scan in a lateral direction. Images observable by the eyes of the observer are formed based on the first and second scanning light beams. Control is performed to reflect the first light beam and generate the first scanning light beam while the reflection surface rotates in the first direction of the reciprocating rotation and reflect the second light beam and generate the second scanning light beam while the reflection surface rotates in the second direction opposite to the first direction.

Owner:CANON KK

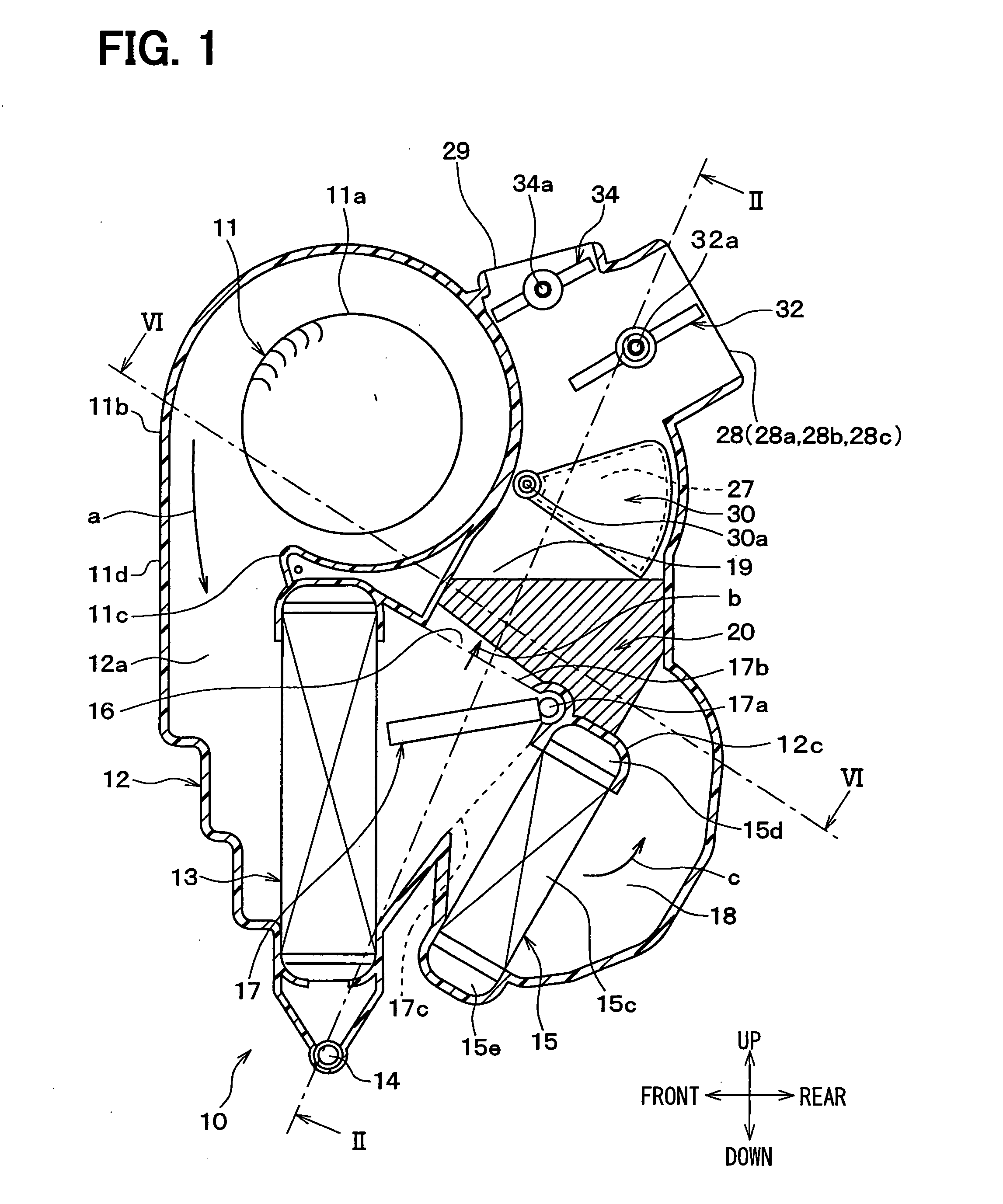

Air conditioning apparatus for vehicle

InactiveUS20080083241A1Uniform volumeReduce unevennessAir-treating devicesDomestic cooling apparatusEngineeringAir conditioning

An air conditioning apparatus for a vehicle has a unit case, a heat exchanger for generating a heated air, a bypass passage through which a bypass air flows while bypassing the heat exchanger, and a baffle member having first passages and second passages. The unit case has openings for introducing a conditioned air into a passenger compartment. The openings are aligned in an alignment direction across a width of the unit case. The first passages and second passages are alternately arranged in the alignment direction. One of the bypass air and the heated air has an uneven distribution of a flow speed in the alignment direction at a position upstream of the baffle member, and flows in the first passages. Widths of the first passages are varied according to the distribution of the flow speed.

Owner:DENSO CORP

Battery temperature unevenness suppressing power supply

ActiveUS8507121B2Avoid heat dissipationSuppress unevenness of battery temperatureElectric devicesCell temperature controlElectrical batteryElectrical and Electronics engineering

Owner:SANYO ELECTRIC CO LTD

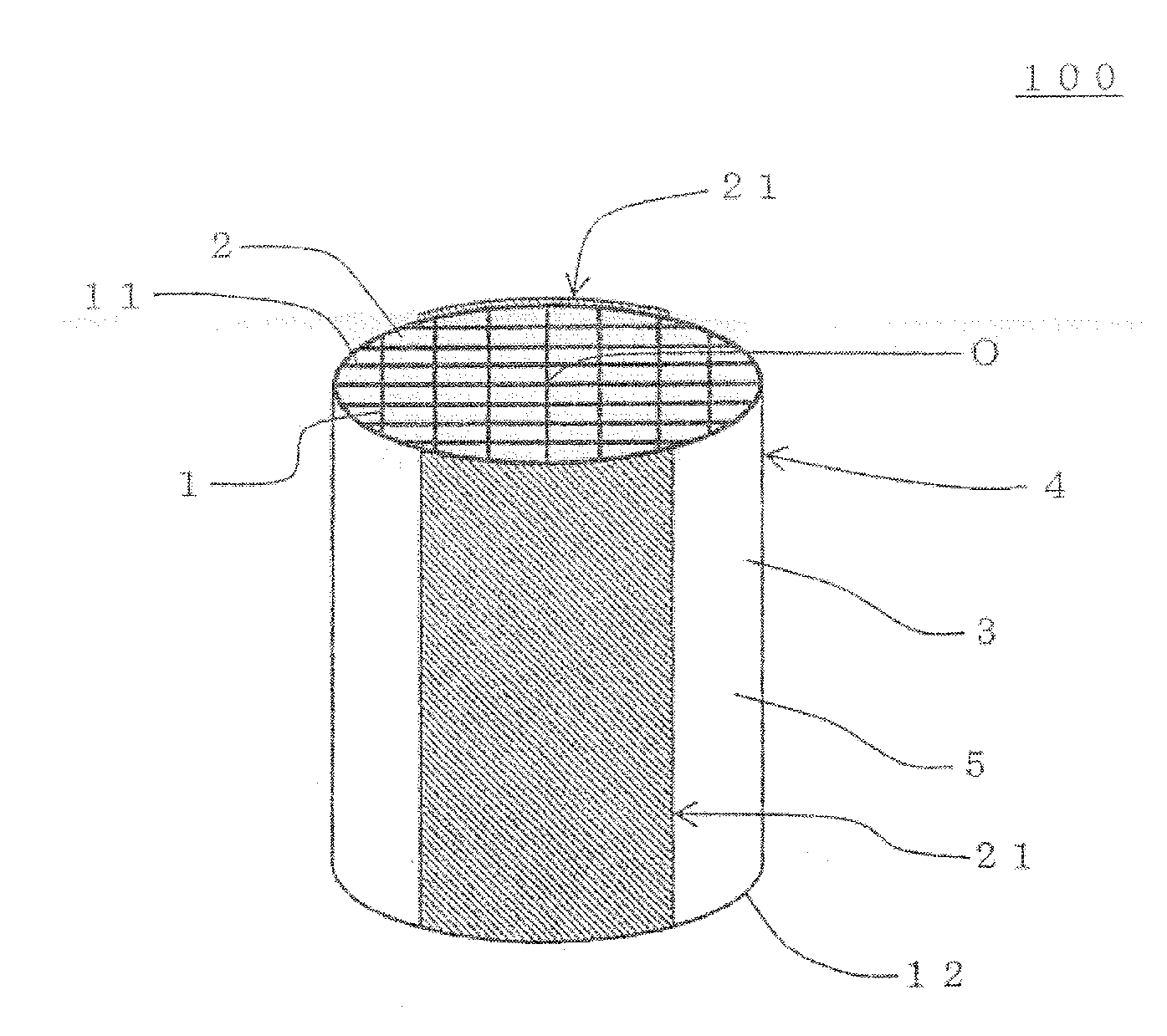

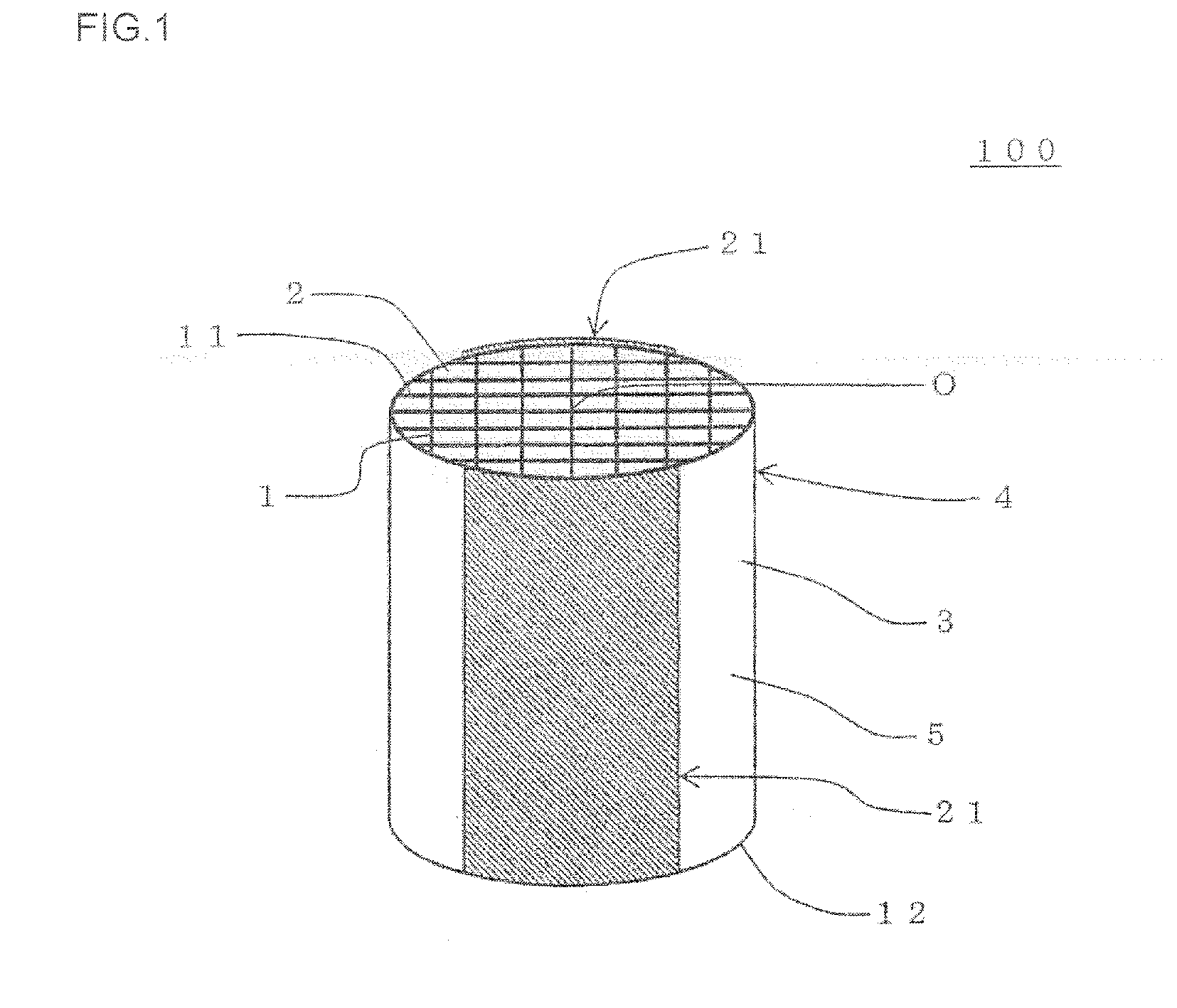

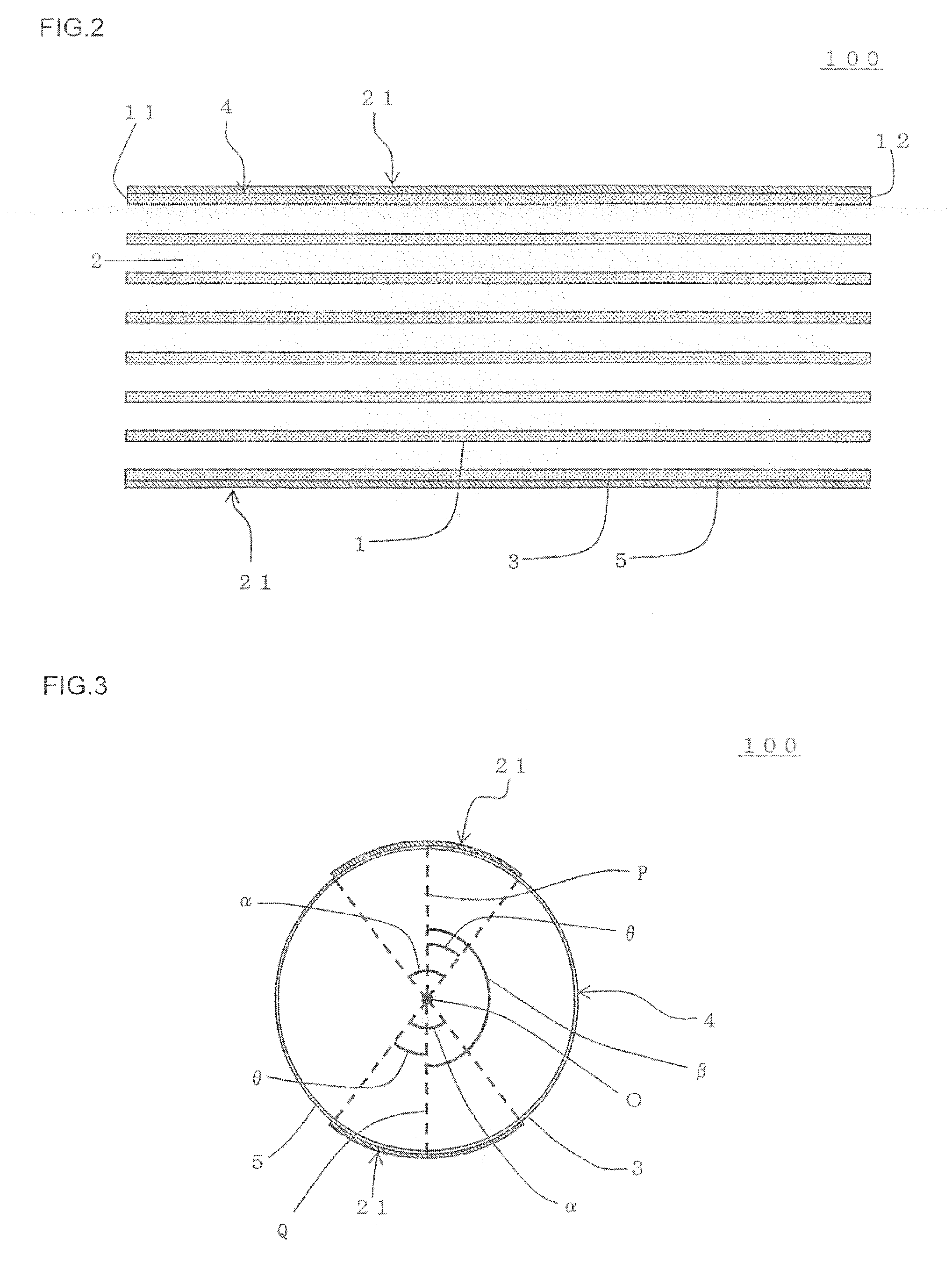

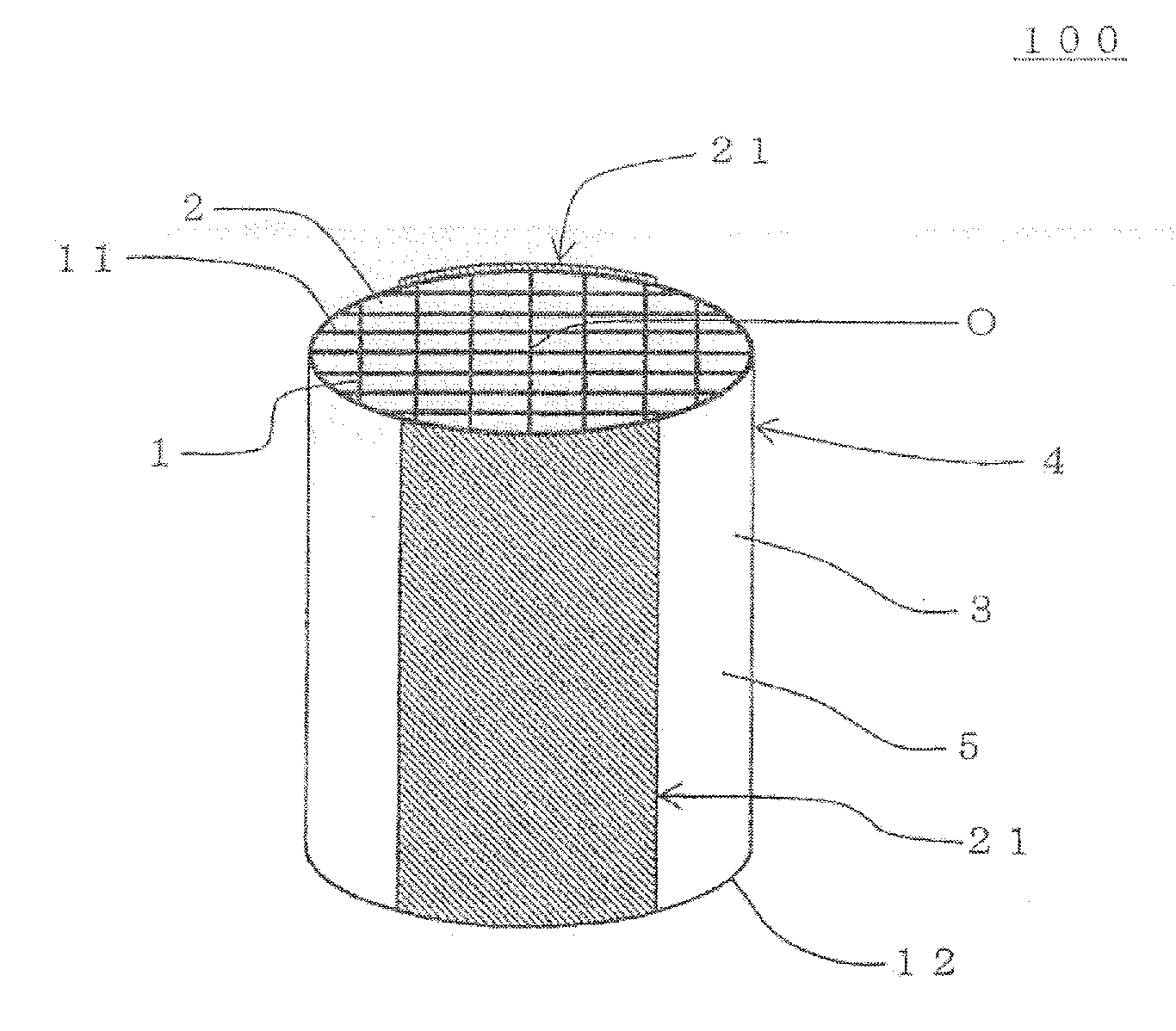

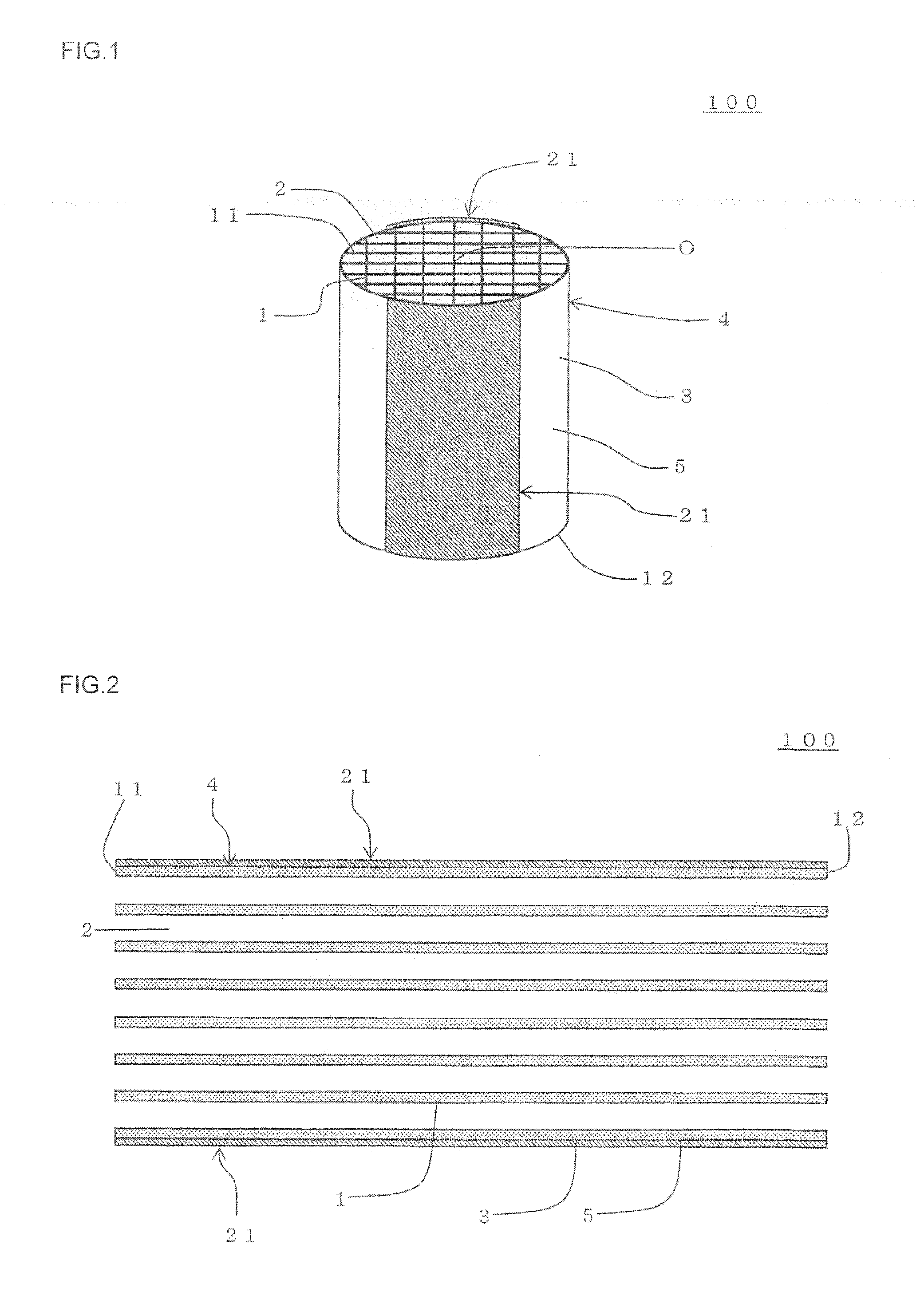

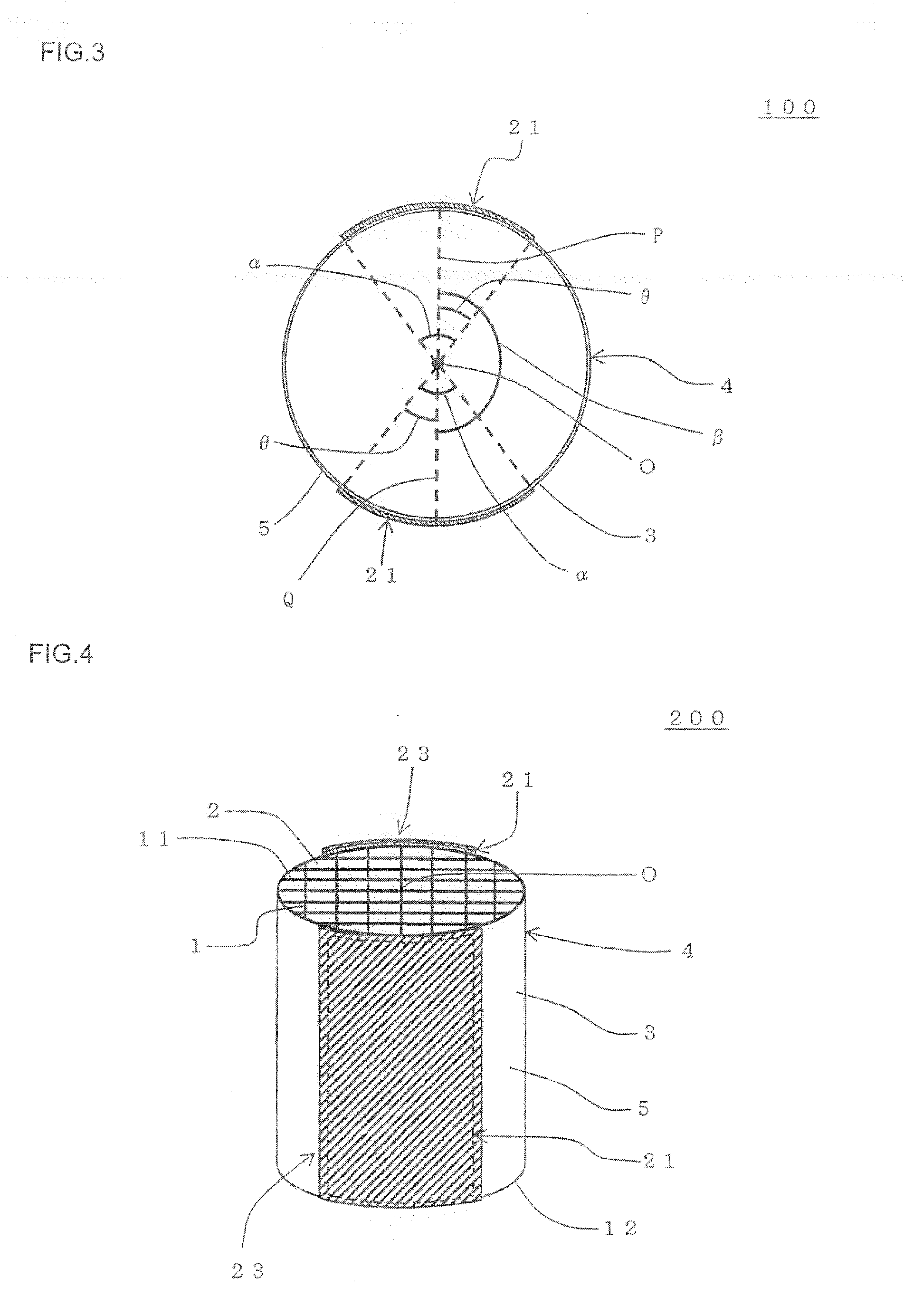

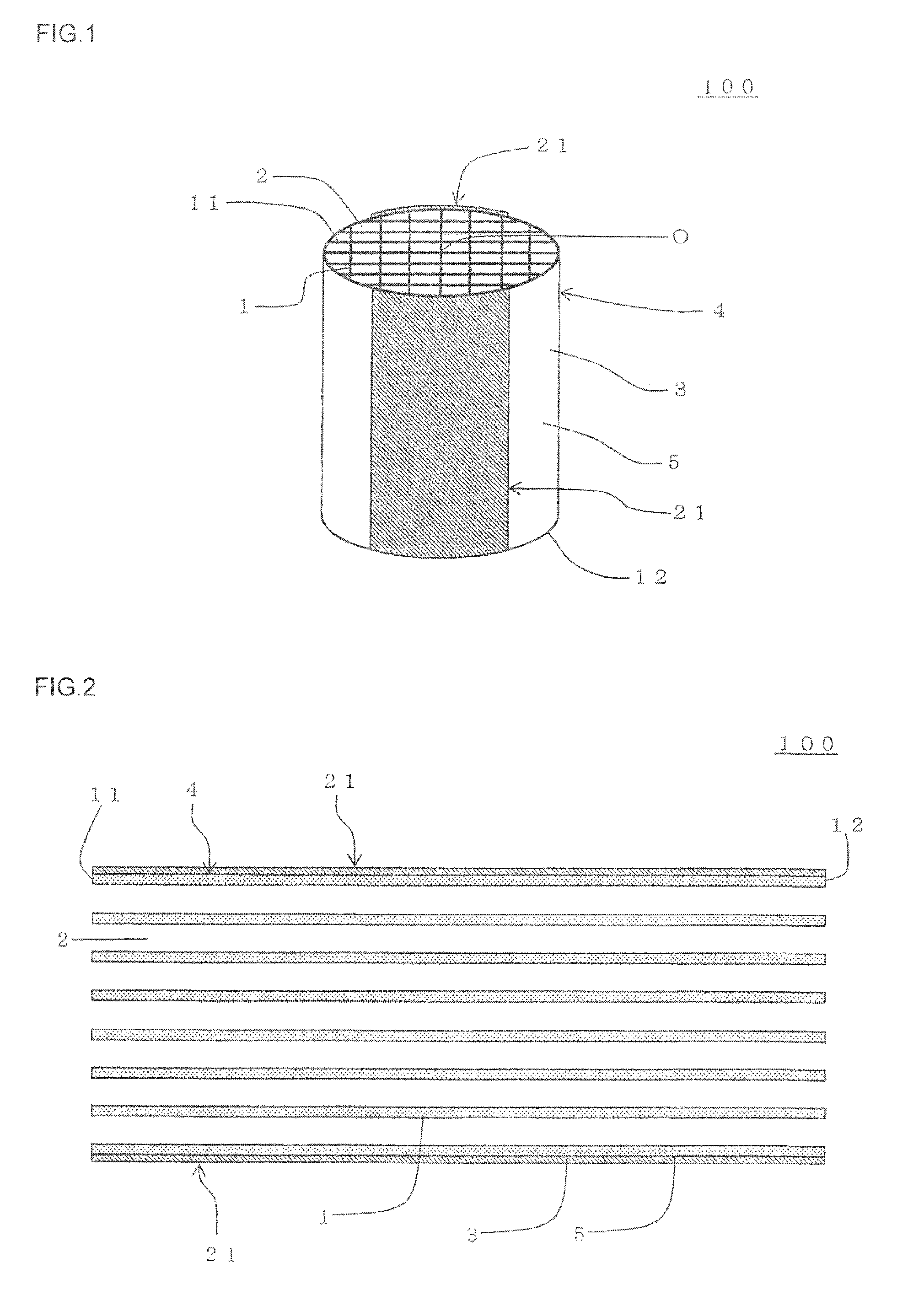

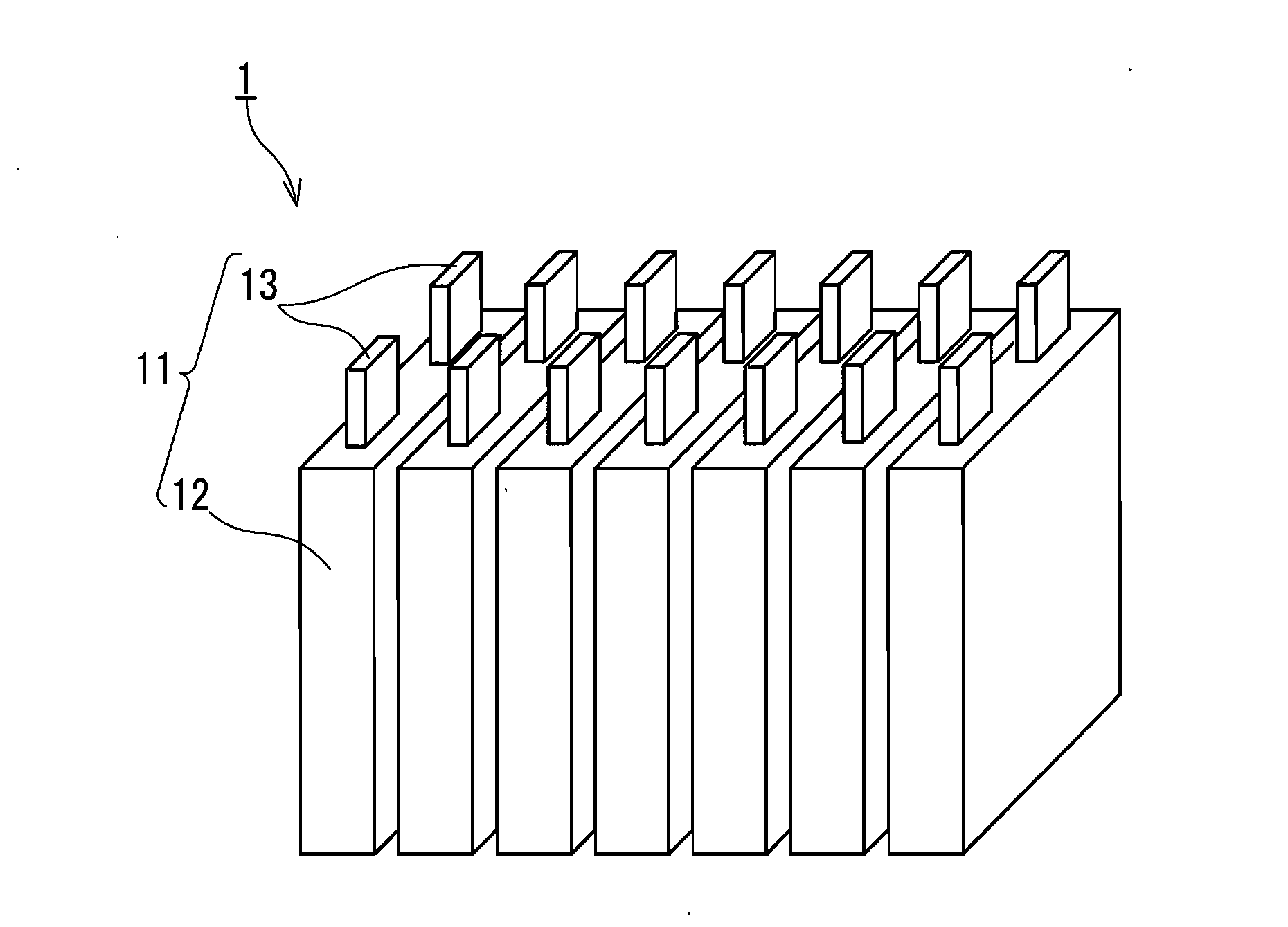

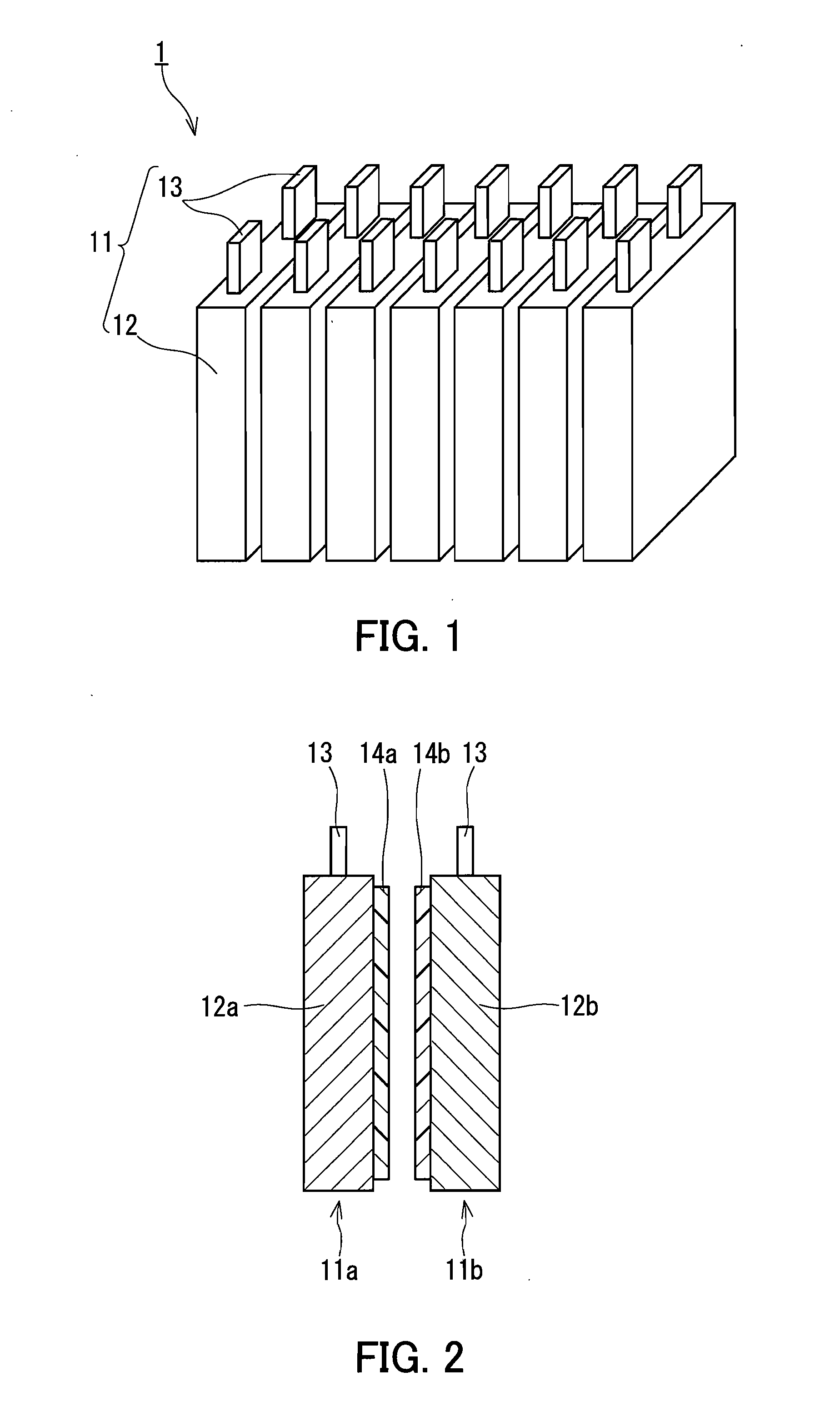

Honeycomb structure and manufacturing method of the same

ActiveUS20140294692A1Low resistivityLow heat generationCombination devicesDispersed particle filtrationBand shapeStacking fault

A honeycomb structure includes a tubular honeycomb structure body having porous partition walls to define and form a plurality of cells, and an outer peripheral wall; and a pair of electrode sections disposed on a side surface of the honeycomb structure body, an electrical resistivity of the honeycomb structure body is from 1 to 200 Ωcm, each of the pair of electrode sections is formed into a band shape extending in an extending direction of the cells, the electrode section is constituted of a porous body in which particles made of silicon carbide as an aggregate are bound by a binding material, silicon carbide as the aggregate constituting the electrode sections contains β-SiC having a stacking fault of 2% or less, and the binding material constituting the electrode sections contains silicon and a metal silicide.

Owner:NGK INSULATORS LTD

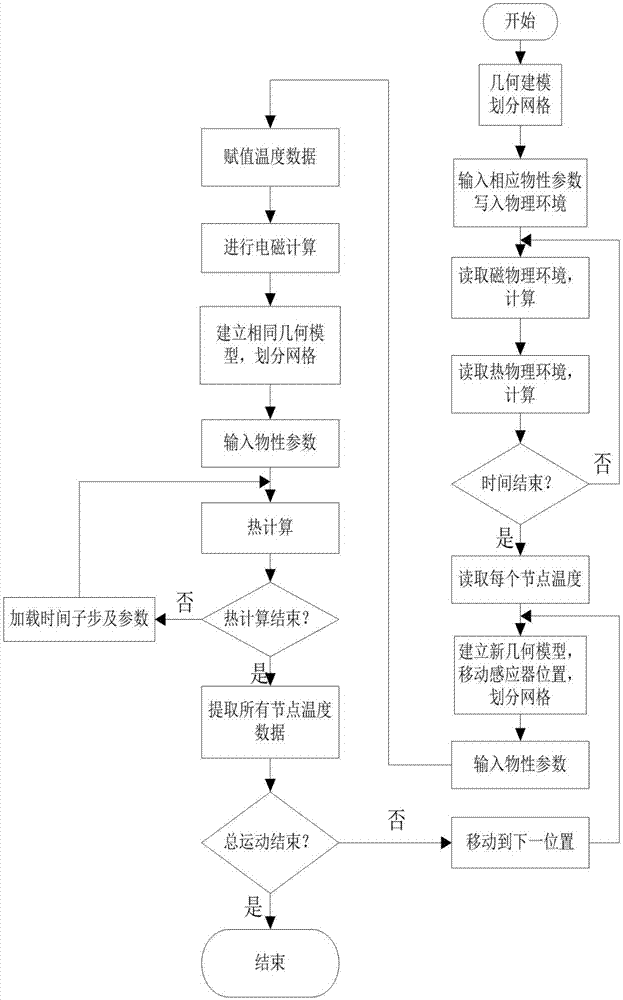

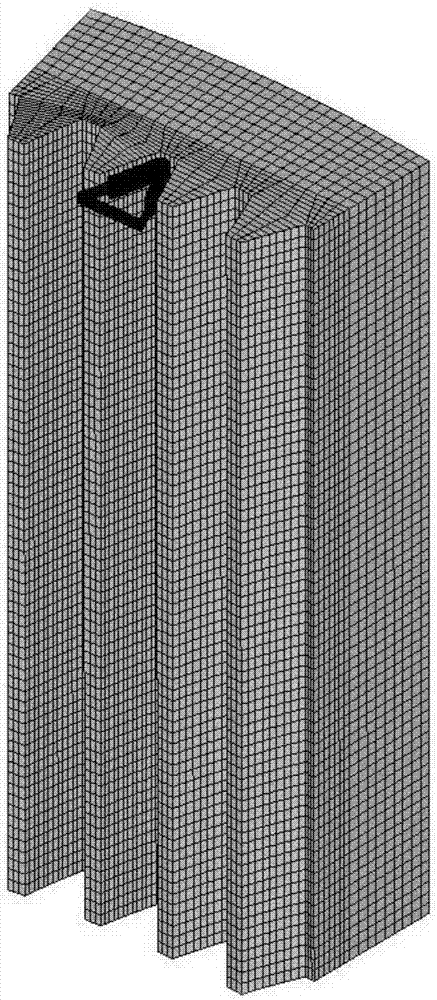

ANSYS simulation platform-based method for calculating movable induction heating of big gear rings

ActiveCN107169166AChange geometryChange the speed parameterDesign optimisation/simulationSpecial data processing applicationsCouplingEngineering

The invention discloses an ANSYS simulation platform-based method for calculating movable induction heating of big gear rings. The method comprises the following steps of: determining a modeling-required parameter according to main equipment and workpieces used in an induction heating process of big gear rings; determining a software-recognizable equivalent parameter according to an induction heating process parameter used in a production process; establishing an initial analysis geometric model according to the determining parameters, adding physical property parameters of used materials, and dividing grids; applying a boundary condition and a corresponding load, and carrying out initial electromagnetic heating coupling calculation; extracting all the node temperatures of the analyzed workpieces; moving an inductor, establishing a movement analysis geometric model according to the determined parameters, adding material attributes, dividing grids, endowing nodes in one-to-one correspondence with the workpieces with the node temperatures extracted in the electromagnetic calculation, applying a boundary condition and a load, and carrying out continuous electromagnetic heating coupling calculation; and controlling the movement speed of the inductor through realizing the distance of each movement of the inductor and a corresponding induction heating time until the whole calculation is completed.

Owner:YANSHAN UNIV

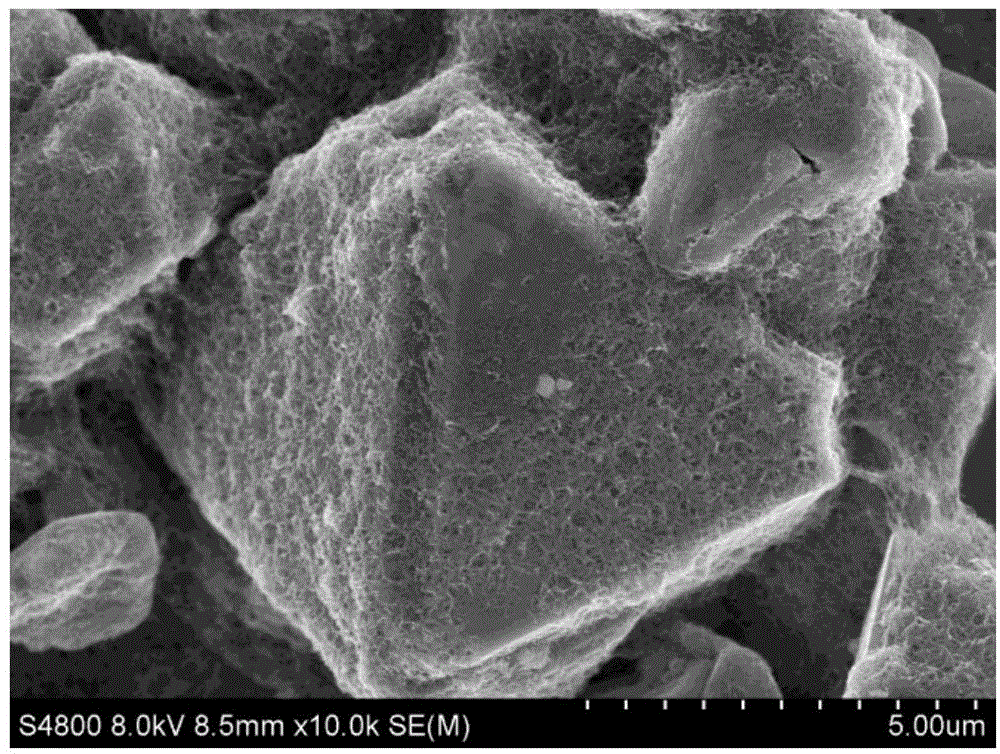

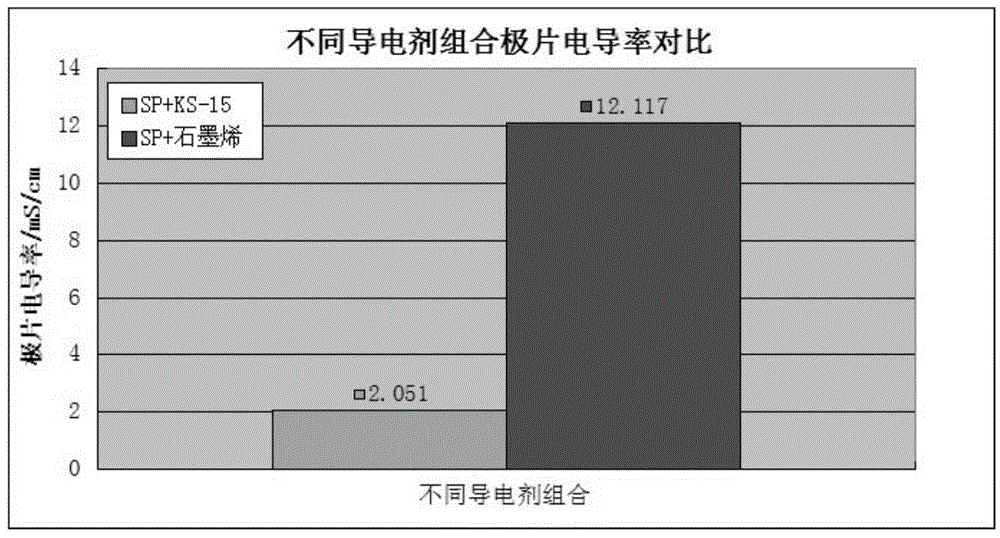

Method for increasing cycle life of lithium ion battery based on thermal conductivity

InactiveCN105826512AImprove conductivityImprove thermal conductivityElectrode manufacturing processesSecondary cells servicing/maintenanceFiberSolid carbon

The invention discloses a method for increasing cycle life of a lithium ion battery by increasing thermal conductivity of an electrode of the lithium ion battery. The method comprises the following steps: a heat conduction material having superhigh electric conduction and thermal conductivity is added in a positive pole piece of the lithium ion battery, and the flexibly packaged lithium ion battery is made. The heat conduction material is graphene or a carbon fiber material; the carbon fiber material comprises a hollow carbon nanotube and solid carbon nano fiber. The graphene and the carbon fiber material have excellent thermal conductivity, thereby, addition of graphene and the carbon fiber material can rapidly, uniformly and fully transmit heat generated during a charge and discharge process of the battery, uneven temperature in the batter due to accumulation of local heat is reduced, therefore, area degradation of the lithium ion battery is improved, the charge and discharge cycle efficiency of the battery is improved, and cycle life and security are increased.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

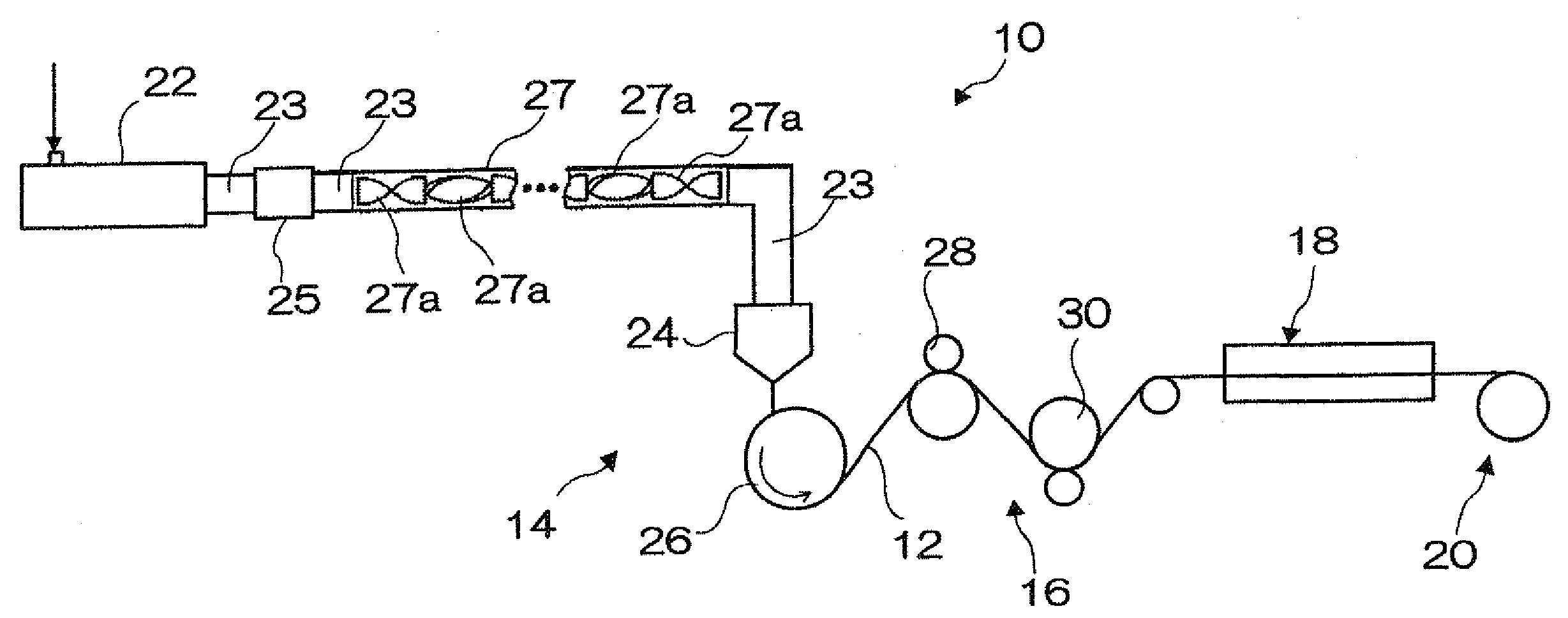

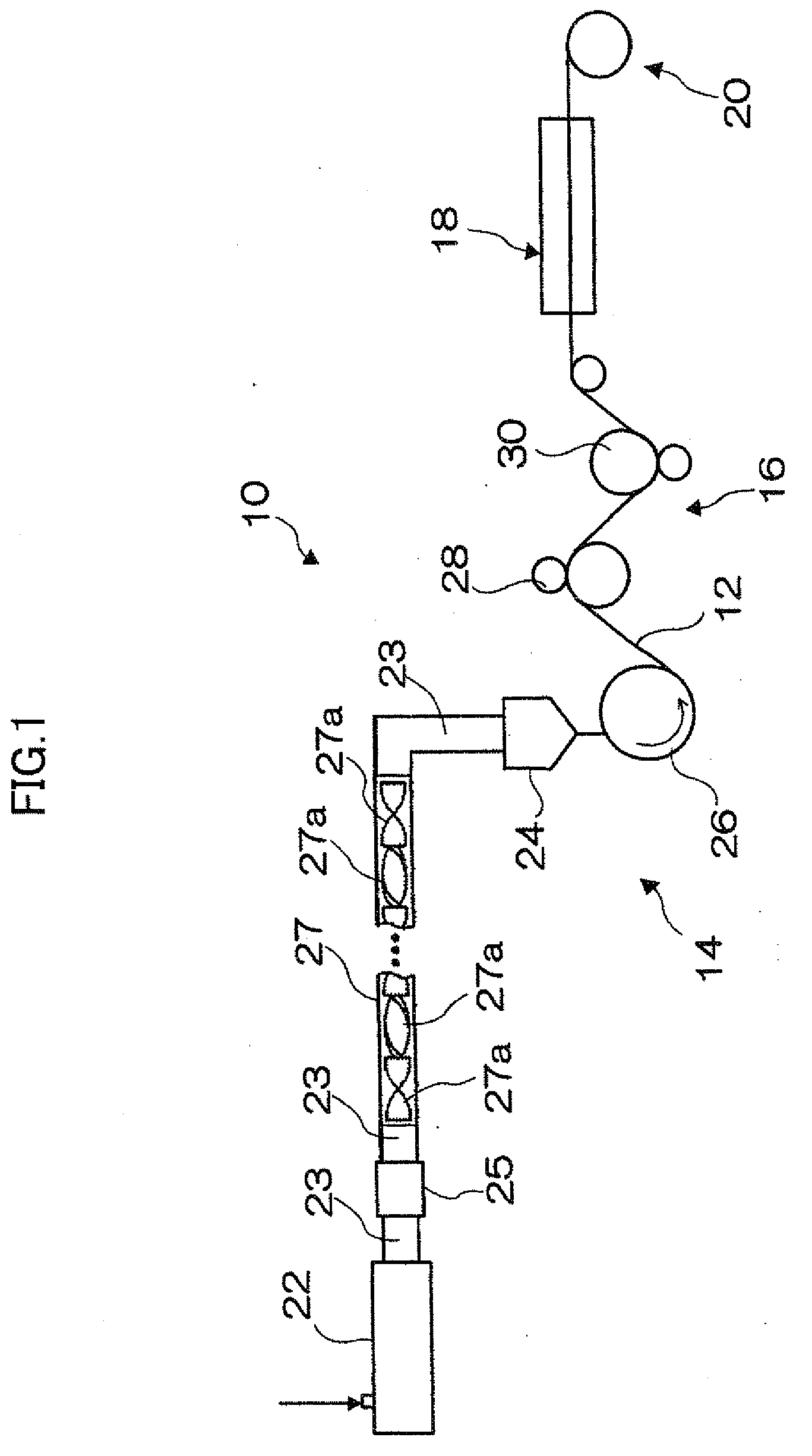

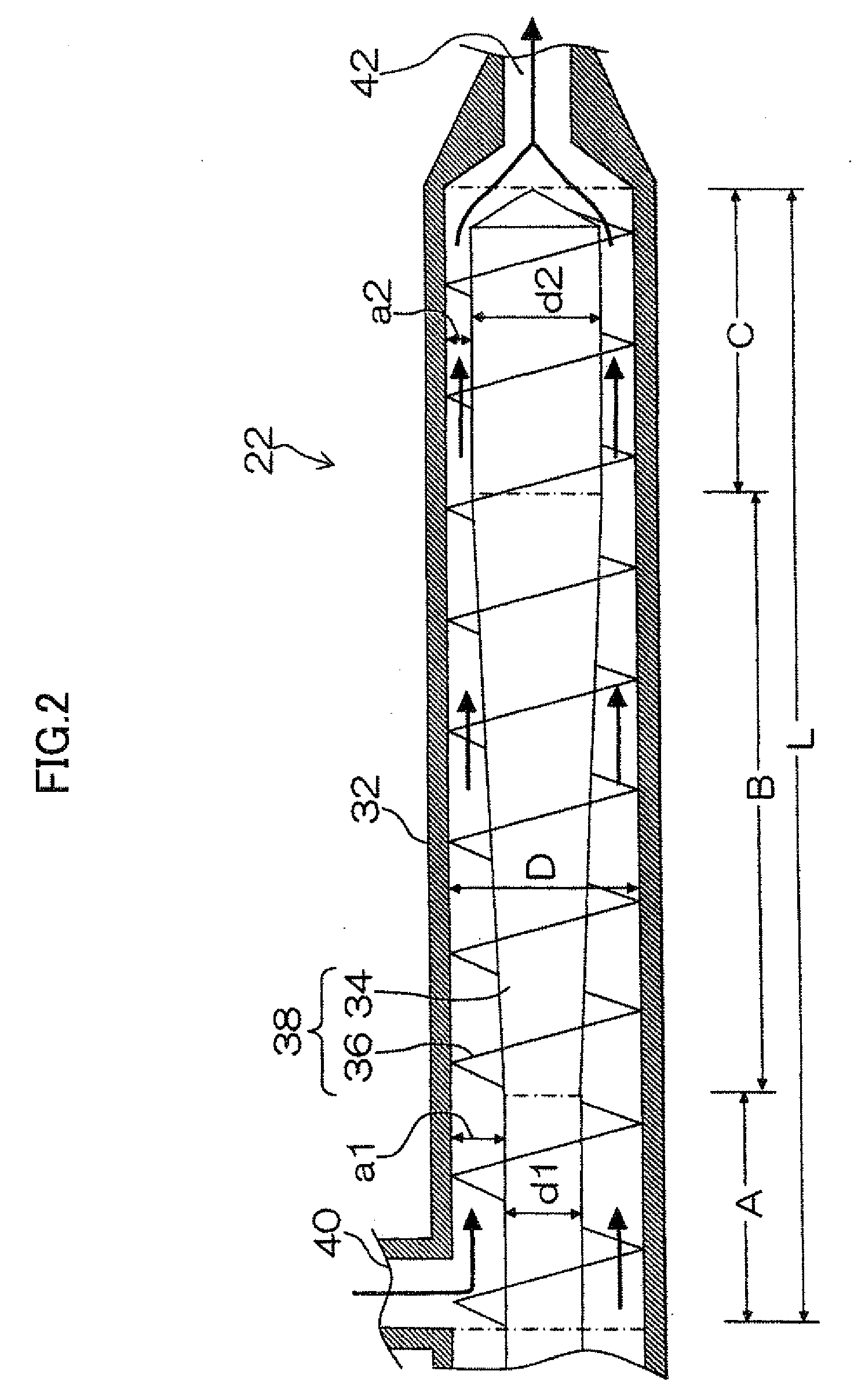

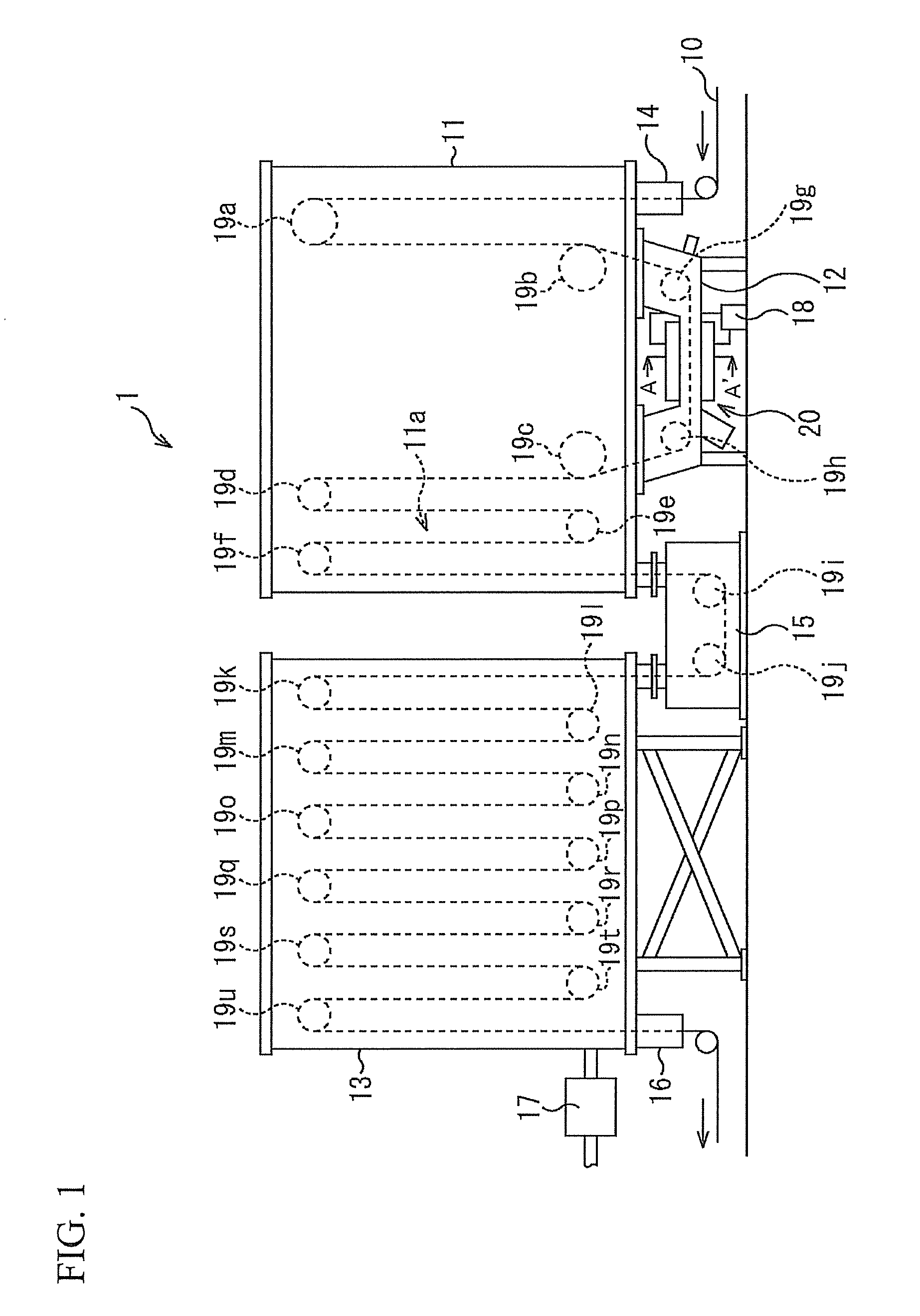

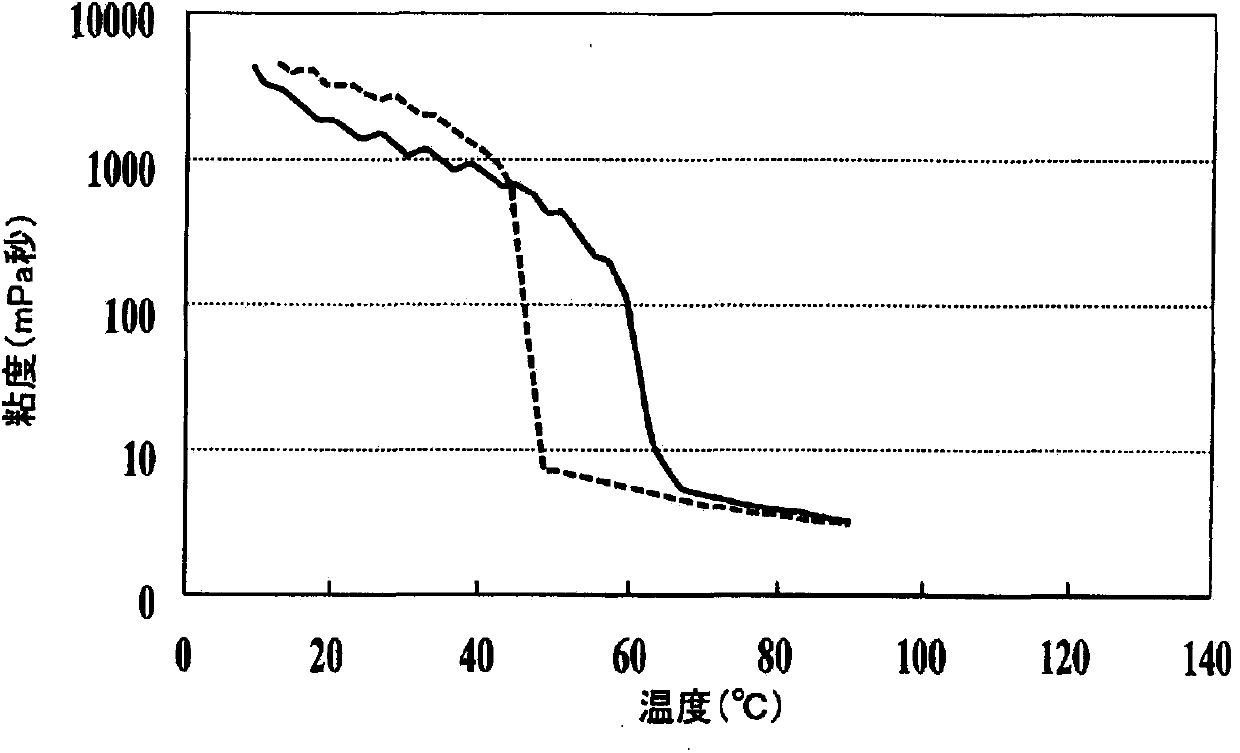

Apparatus and method of producing dope

InactiveUS20060118980A1Improve cooling efficiencyImproved in kneading functionDough homogenizationFrozen sweetsSolubilityOptical property

A stock solution is prepared by mixing and swelling TAC as a solute in a solvent, and is fed into an extrusion machine. The extrusion machine is cooled by a cooling medium, and is provided with twin-shaft screws. The screws are a compressing type where thread pitches of a helical flight decrease toward downstream. The screws are in mesh with each other and rotated in the same direction. Through the extrusion machine, the solute is dissolved in the solvent to form a dope. The dope is further cooled in a cooler to promote the solubility of the dope. Thereafter, the dope is heated by a heater to raise the fluidity. From the obtained dope, TAC film with excellent optical properties may be formed by a solution casting method.

Owner:FUJIFILM HLDG CORP +1

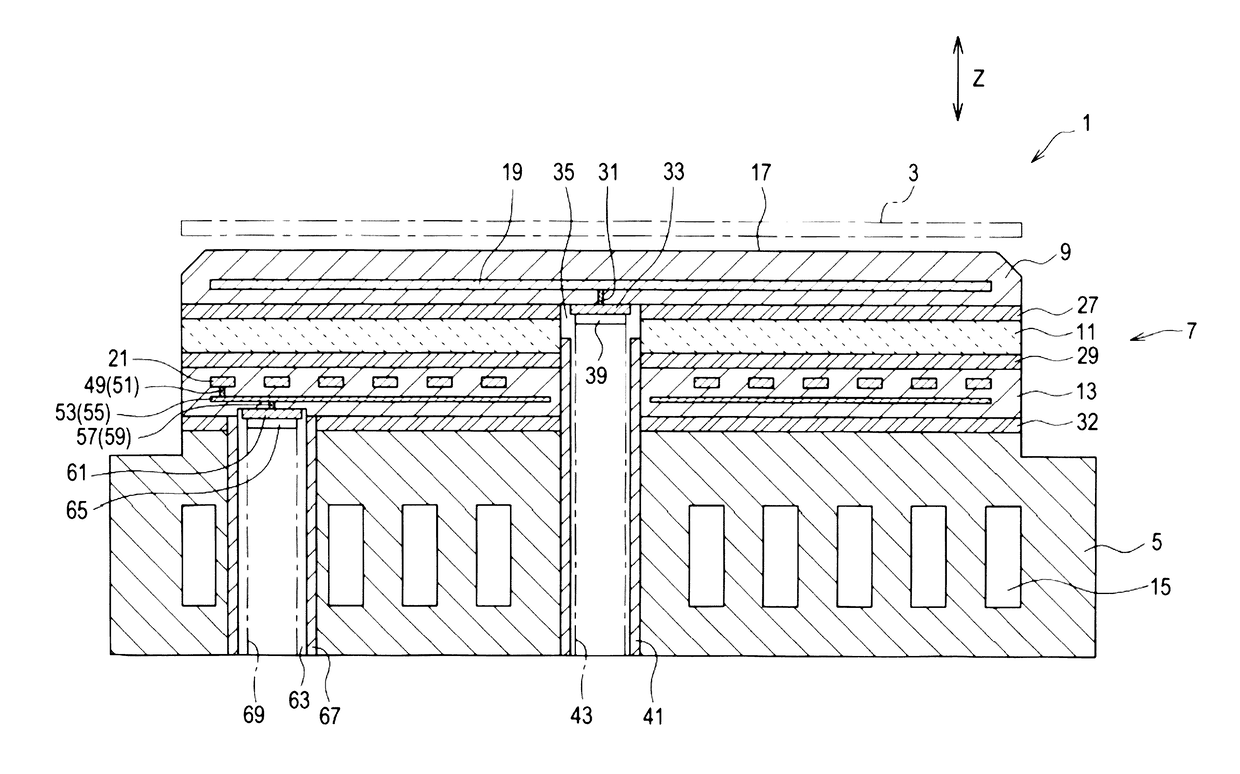

Electrostatic chuck

ActiveUS20170133258A1Reduce temperature unevennessEasy transferSemiconductor/solid-state device manufacturingPositioning apparatusElectrical conductorMolten metal

An electrostatic chuck includes an anisotropic heat conductor which is disposed between an attraction substrate and a first heater member, and has an upper surface and a lower surface, and a coefficient of thermal conductivity which varies depending on directions. The anisotropic heat conductor is disposed so that the coefficient of thermal conductivity in a plane direction is larger than the coefficient of thermal conductivity in a thickness direction. Further, the electrostatic chuck includes metal layers which are joined to the anisotropic heat conductor so as to cover the upper surface and the lower surface of the anisotropic heat conductor, and an adhesive layer which is provided on a surface of each metal layer, and joins the metal layer to the attraction substrate or the heater member. Moreover, at least one of the metal layers is a fused metal layer formed by solidifying a melted metal.

Owner:NGK SPARK PLUG CO LTD

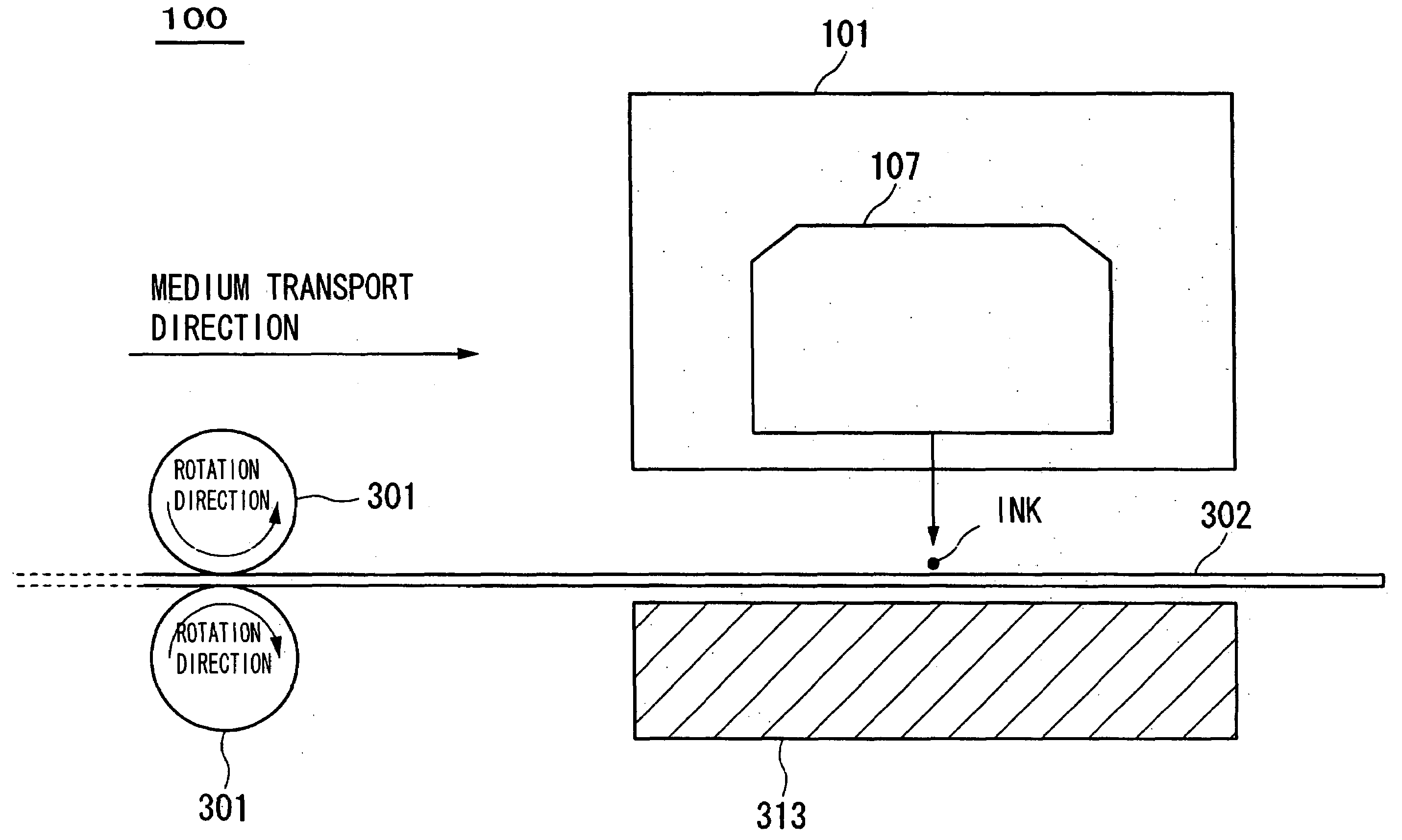

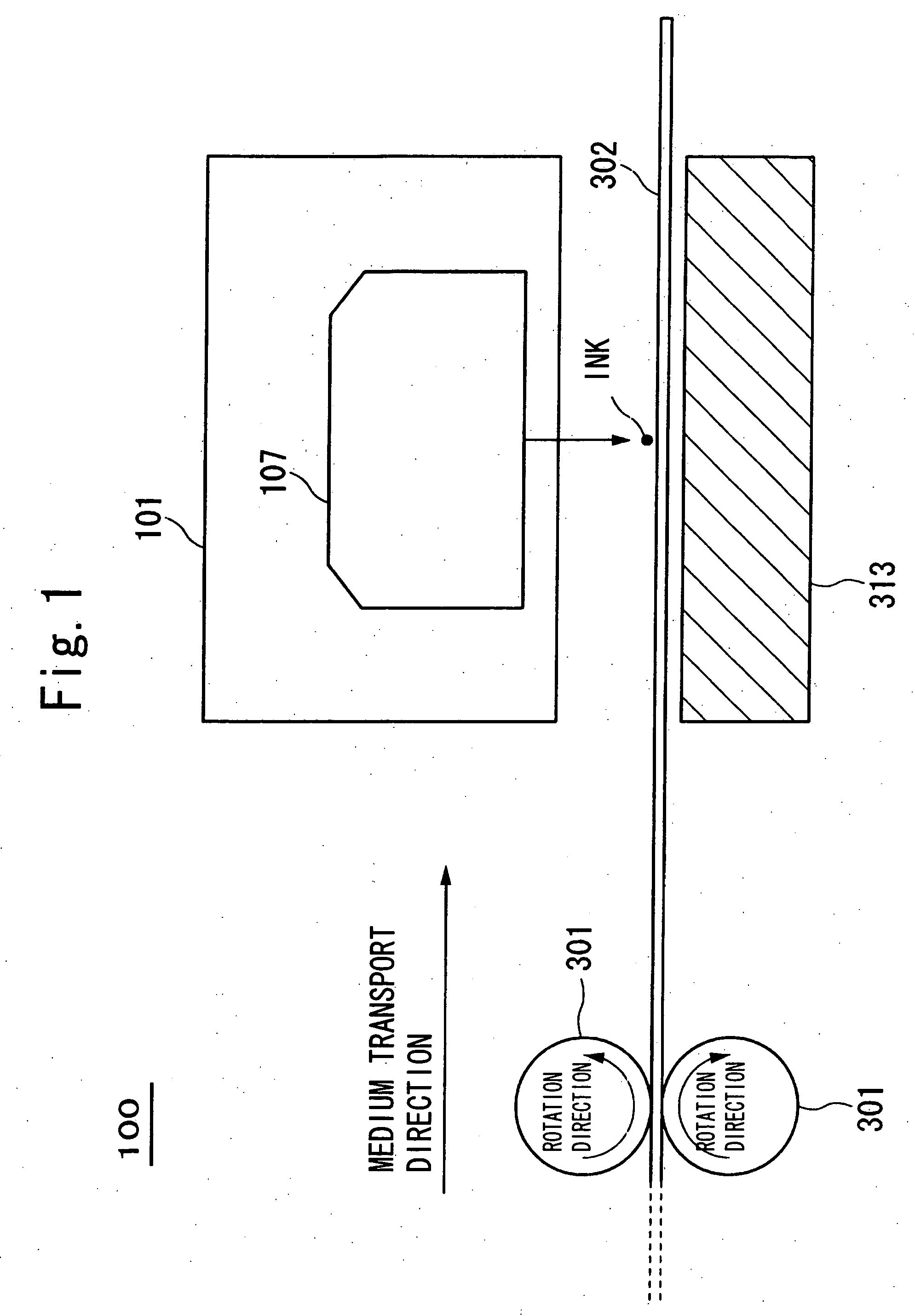

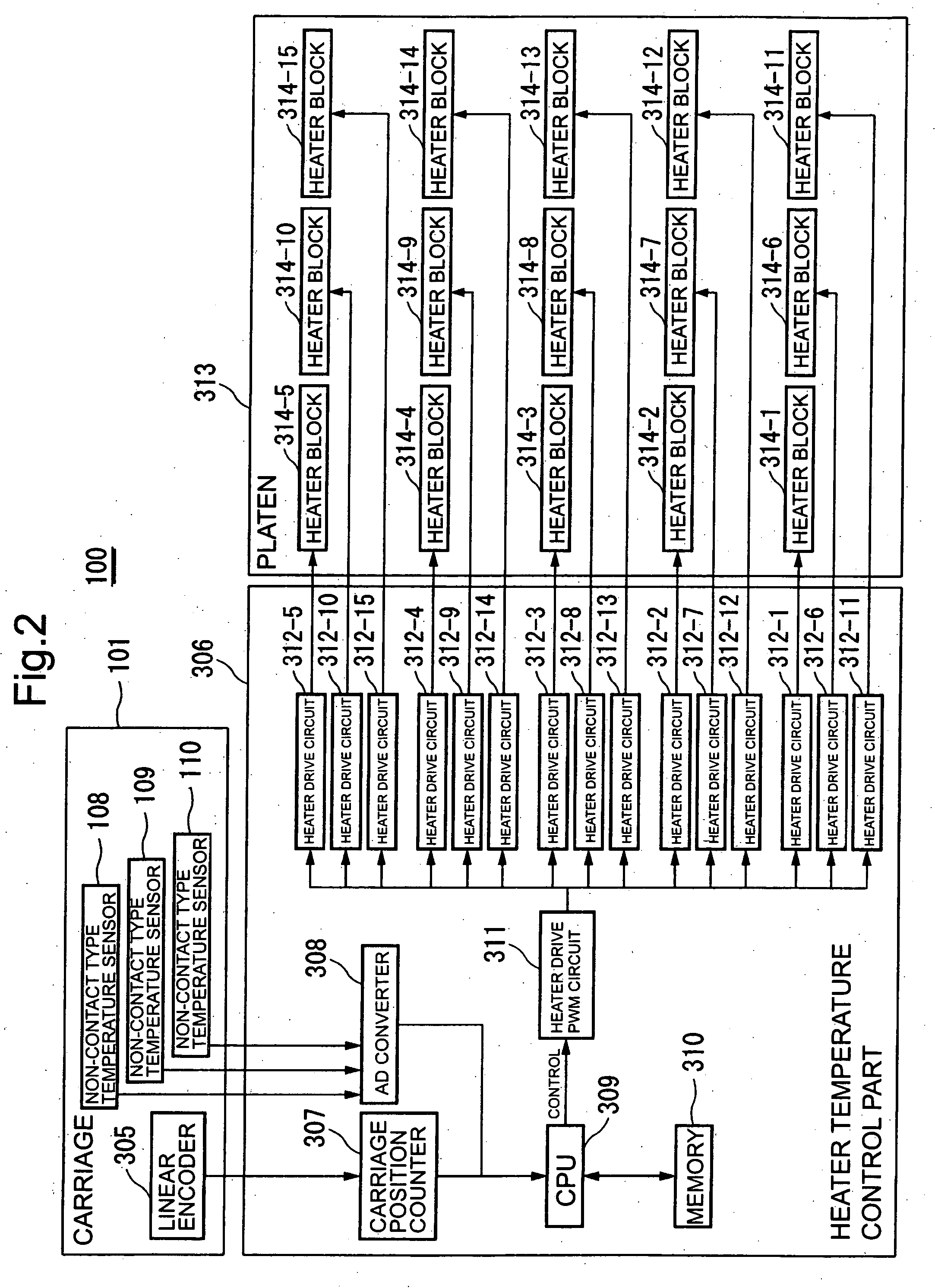

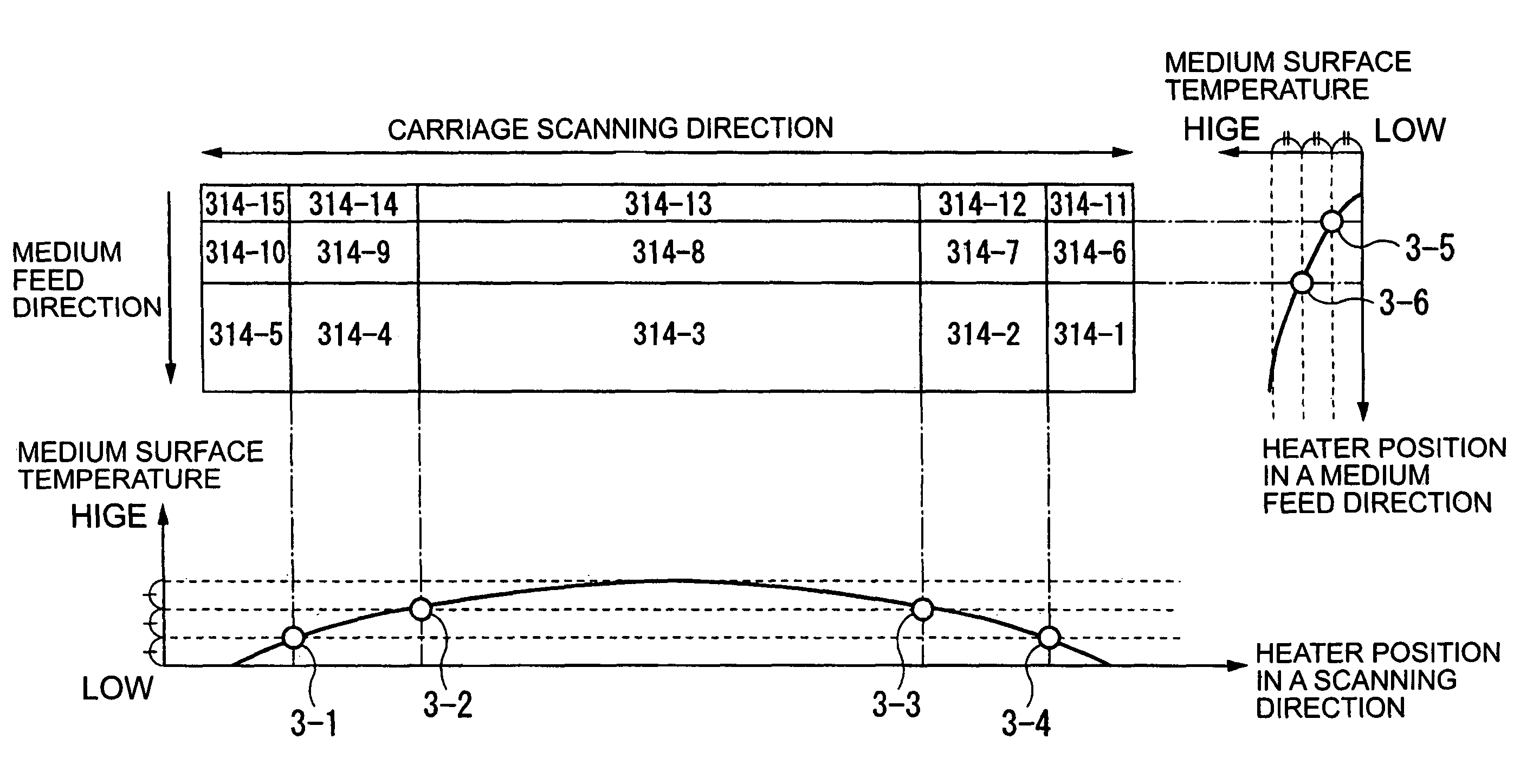

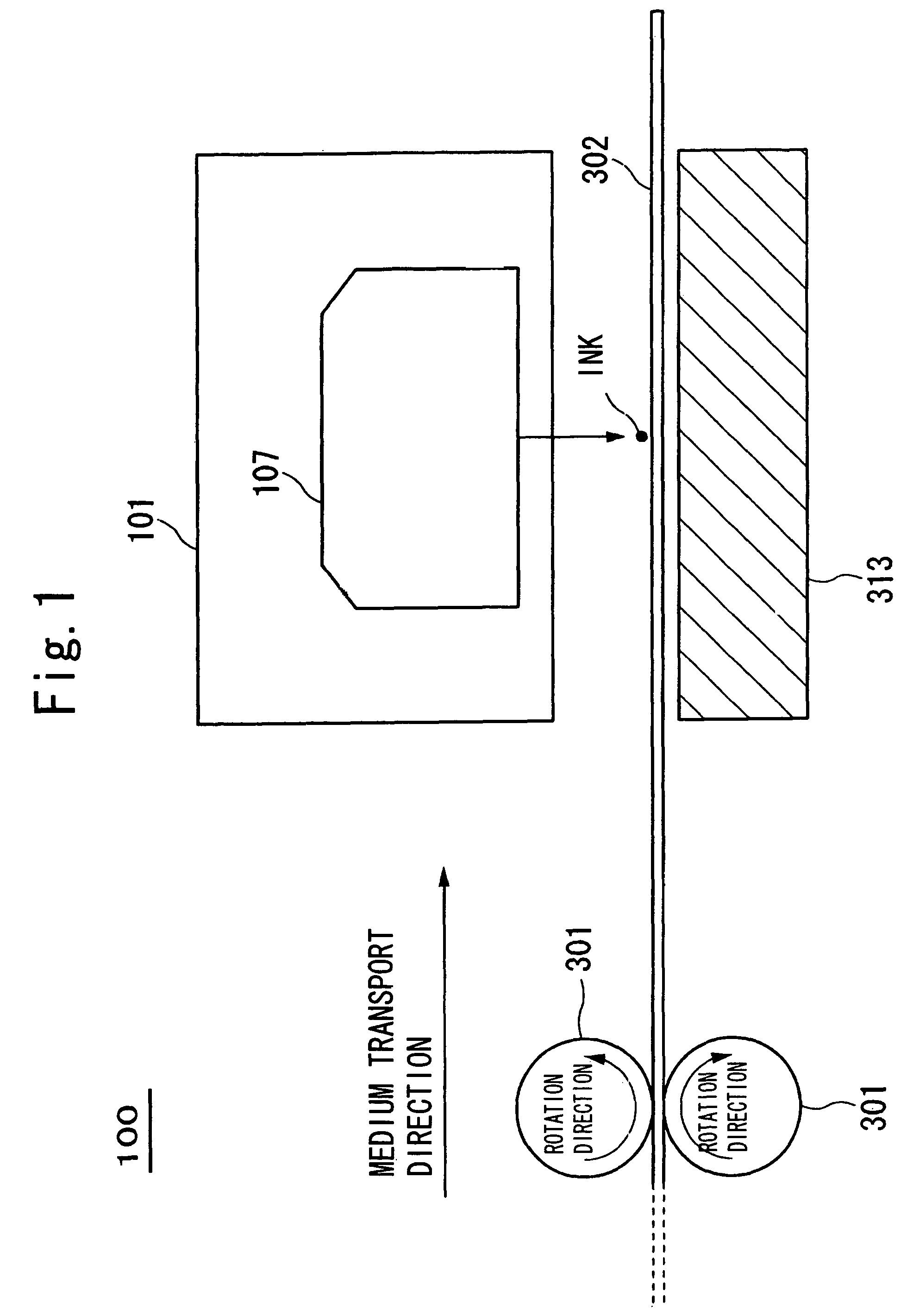

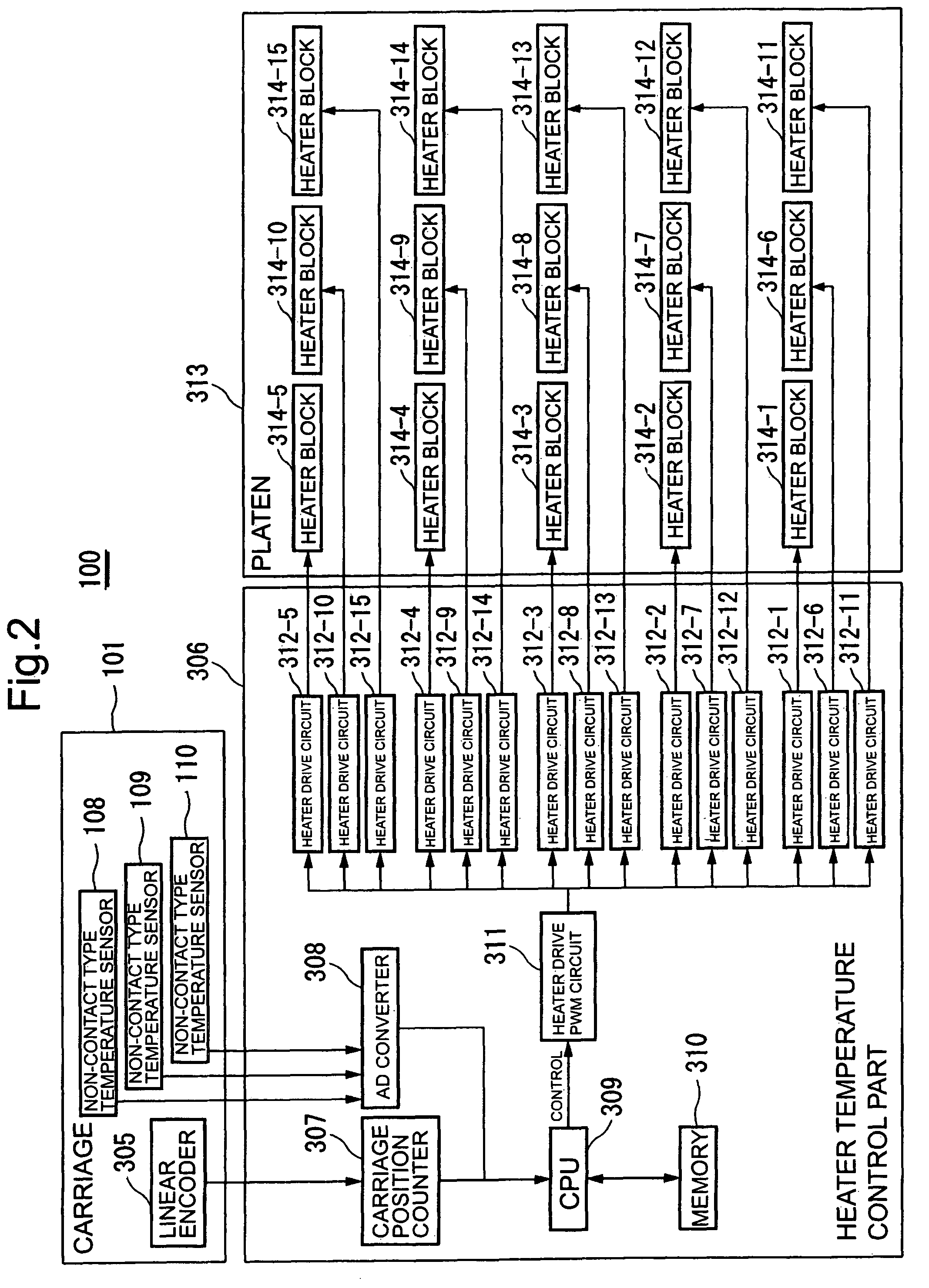

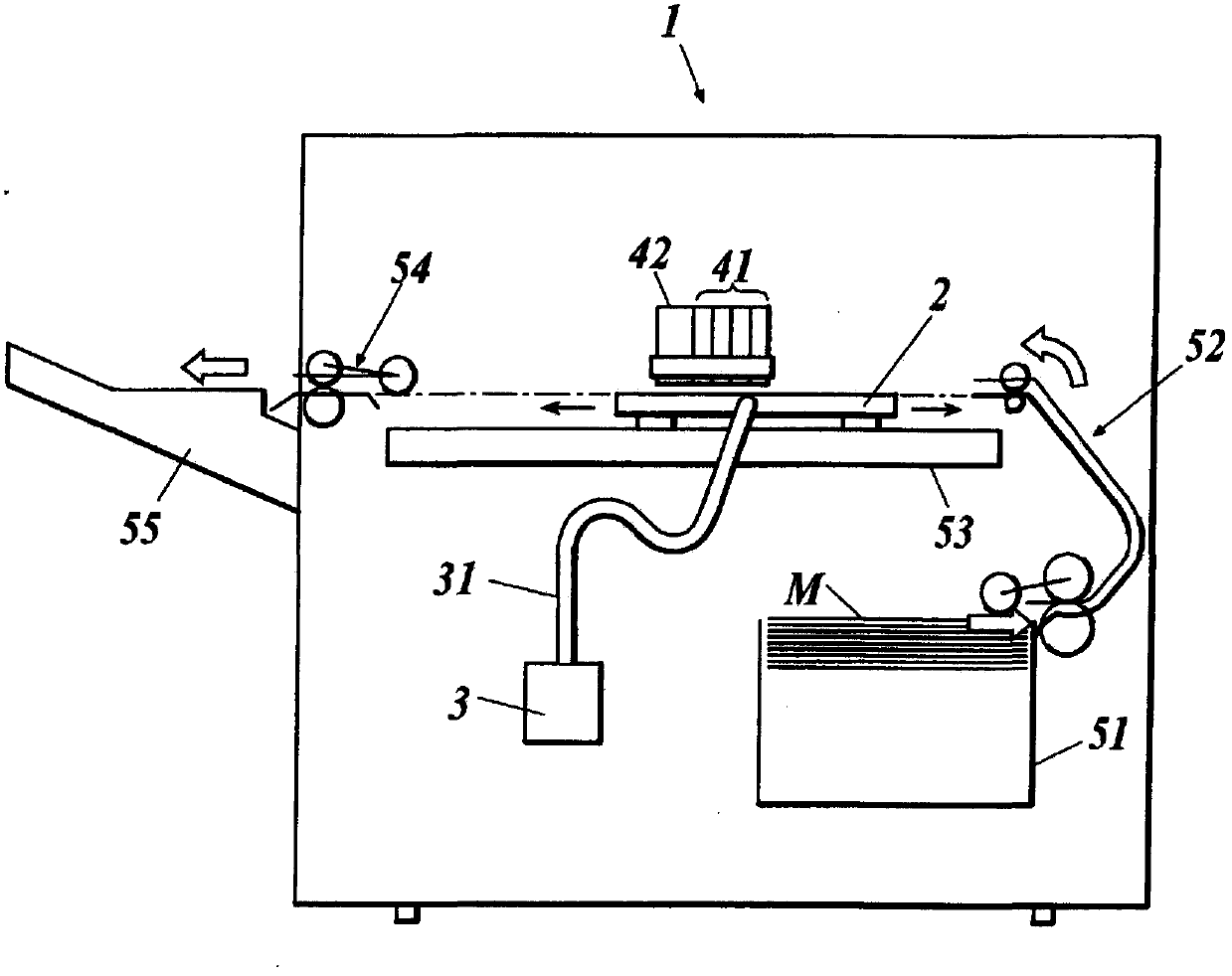

Ink-jet printer device and ink-jet printing method

InactiveUS20080204537A1Eliminate degradationReduce temperature unevennessOther printing apparatusContact typeElectrical and Electronics engineering

An ink-jet printer device equalizes a surface temperature of a print medium on the platen. In an ink-jet printer device which includes a platen having heater blocks, and a carriage having non-contact type temperature sensors each measure a surface temperature of each of a plurality of portions of the print medium on the platen. A CPU calculates an output value of each of the heater blocks for making the surface temperature of each of the plurality of portions of the print medium uniform based on the measured surface temperature, and a heater drive PWM circuit controls an output of each of the heater blocks based on the calculated output value.

Owner:OKI DATA CORP

Honeycomb structure and manufacturing method of the same

ActiveUS20140294691A1Low resistivityLow heat generationCombination devicesContact member manufacturingBand shapeHoneycomb structure

A honeycomb structure includes a tubular honeycomb structure body having porous partition walls to define and form a plurality of cells, and an outer peripheral wall; and a pair of electrode sections disposed on a side surface of the honeycomb structure body, an electrical resistivity of the honeycomb structure body is from 1 to 200 Ωcm, each of the pair of electrode sections is formed into a band shape extending in an extending direction of the cells, the electrode section contains silicon and an aggregate, and a ratio (the silicon / the aggregate) of a volume of the silicon to be contained in the electrode section to a volume of the aggregate to be contained in the electrode section is from 60 / 40 to 80 / 20.

Owner:NGK INSULATORS LTD

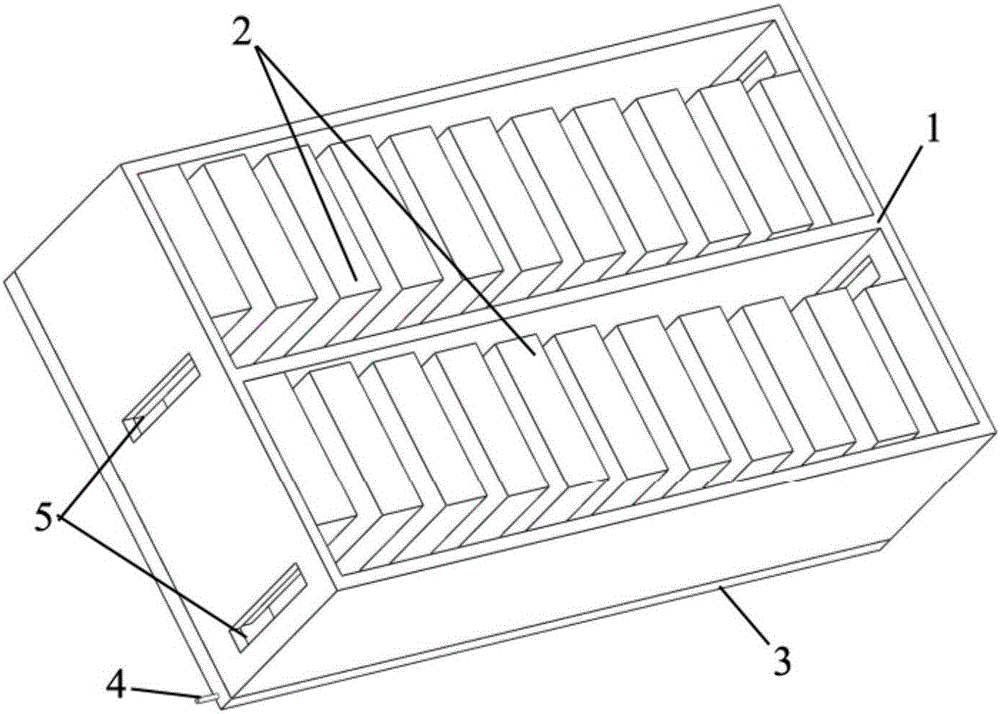

Hybrid cooling type power battery pack

ActiveCN106129529AReduce temperature unevennessTake away quicklySecondary cellsPower batteryHeat conducting

The invention discloses a hybrid cooling type power battery pack, which comprises a battery module arranged in a box body, wherein a water channel is arranged in the bottom part of the box body; a first heat-conducting silicone sheet is tiled between the battery module and the water channel; an air inlet and an air outlet are formed in two ends of the box body respectively; and a second heat-conducting silicone sheet is arranged between two adjacent single batteries in the battery module. Air convection is formed through the air inlet and the air outlet and the heat-conducting silicone sheets and circulating water are used for cooling, so that the cooling speed is improved; and the temperature uniformity of various parts in the battery pack is ensured.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Ink-jet printer device and ink-jet printing method

InactiveUS7959247B2Eliminate degradationReduce temperature unevennessOther printing apparatusTemperature controlInk printer

An ink-jet printer has a print head that performs printing on a print medium transported in a print medium transport direction by scanning in a scanning direction intersecting the print medium transport direction. A platen supports the print medium while the print medium is transported along the print medium transport direction. The platen has heater blocks that become smaller in width in the scanning direction toward both ends of the platen. A measurement section measures a surface temperature of each of portions of the print medium supported by the platen. A calculation section calculates an output value of each of the heater blocks for making the surface temperature of each of the portions of the print medium uniform based on the surface temperature measured by the measurement section. A heater temperature control section controls an output of each of the heater blocks based on the output value calculated by the calculation section.

Owner:OKI DATA CORP

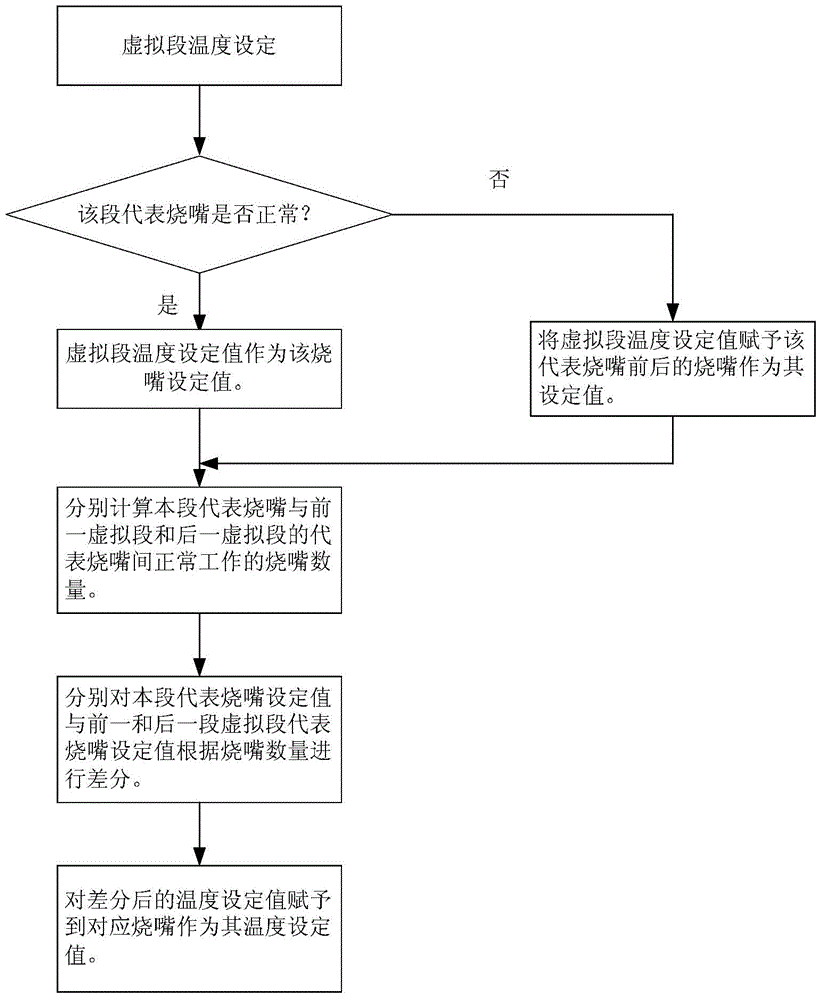

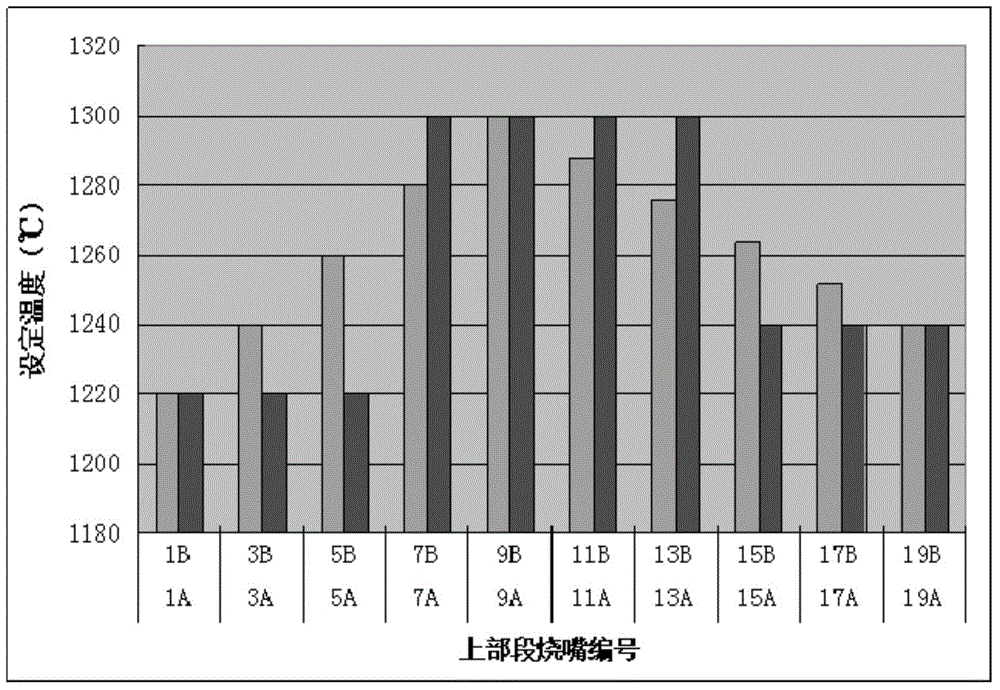

Temperature control method for pulse-type slab heating furnace

ActiveCN104805277AEasy temperature controlReduce temperature unevennessFurnace typesHeat treatment process controlTemperature controlEngineering

The invention relates to a temperature control method for a pulse-type slab heating furnace. A pulse-type slab heating furnace and a heating furnace burner groups thereof are included. The heating furnace burner groups are arranged in pairs on two sides; the burner group on each side is divided into an upper group and a lower group. The method is as below: selecting representative burners in a heat supply segment of the heating furnace burner group; setting the temperature of the representative burners; directly using the temperature set in the heat supply segment of the heating furnace as the set temperature of representative burners; then setting the temperature of other burners in the heat supply segment of the heating furnace burner group; and finally detecting the actual temperature of other burners in the heat supply segment of the heating furnace burner group. The temperature control method of the pulse-type slab heating furnace can improve the temperature control of the head and tail of the temperature control middle segment of the pulse-type slab heating furnace burner group to realize stability and controllability. The method can reduce uneven atmosphere temperature distribution in the furnace, rationally allocate the load of burners, greatly save the energy consumption and increase productivity.

Owner:BAOSHAN IRON & STEEL CO LTD

Inkjet print head and inkjet printing apparatus

InactiveUS8382231B2Improve reliabilitySuppress temperature unevennessInking apparatusOther printing apparatusHeat pipeCoolant channel

A print head having high printing reliability, in which temperature unevenness is suppressed even when printing is performed using a print head having an increased length and density of an ejection opening array, can be provided. Specifically, a temperature equalizing member such as a heat pipe and a cooling liquid passage is disposed between a first support substrate and each of second support substrates or is disposed inside the first support substrate. This makes it possible to equalize temperature among the plurality of second support substrates and further equalize temperature among the printing element substrates bonded to these support substrates. In addition, the temperature equalizing member is made close to the printing element substrate, thus making it possible to efficiently equalize temperature.

Owner:CANON KK

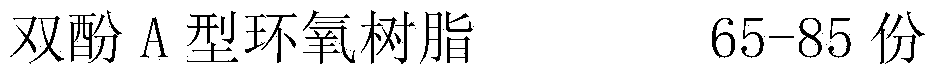

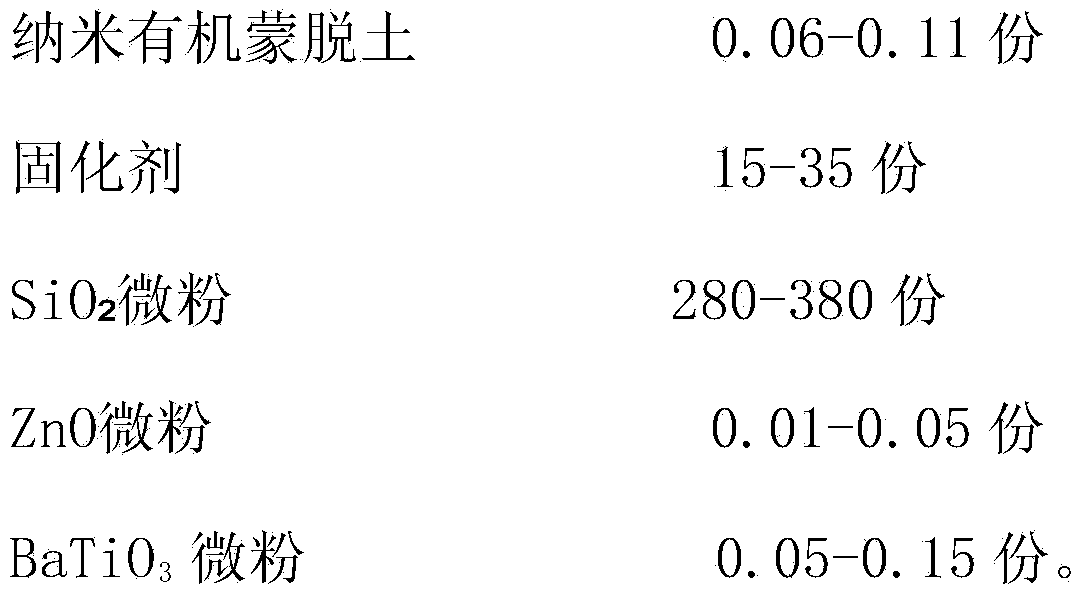

Insulating material for bus and preparation method thereof

ActiveCN103834141AImprove operational reliabilitySatisfy partial dischargeTransformerPower equipment

The invention relates to an insulating material for bus, which comprises the following components by weight: 65-85 parts of bisphenol A-type epoxy resin, 0.06-0.11 part of nanometer organic montmorillonite, 15-35 parts of a curing agent, 280-380 parts of SiO2 micro powder, 0.01-0.05 part of ZnO micro powder, and 0.05-0.15 part of BaTiO3 micro powder. The insulating material of the invention can operate under awful weather conditions, is widely applicable to power plants, power stations, transformer substations, photovoltaic power stations, wind power generation transformer substations, is an important accessory for power transmission equipment, is an important material for processing high voltage electric power matching insulating parts, and has good insulating properties and water resistance. The invention also provides a preparation method of the insulating material.

Owner:江苏华联天晴电力器材有限公司

Honeycomb structure and manufacturing method of the same

ActiveUS9273582B2Low resistivityReduce temperature unevennessCombination devicesInternal combustion piston enginesBand shapeHoneycomb structure

A honeycomb structure includes a tubular honeycomb structure body having porous partition walls to define and form a plurality of cells, and an outer peripheral wall; and a pair of electrode sections disposed on a side surface of the honeycomb structure body, an electrical resistivity of the honeycomb structure body is from 1 to 200 Ωcm, each of the pair of electrode sections is formed into a band shape extending in an extending direction of the cells, the electrode section contains silicon and an aggregate, and a ratio (the silicon / the aggregate) of a volume of the silicon to be contained in the electrode section to a volume of the aggregate to be contained in the electrode section is from 60 / 40 to 80 / 20.

Owner:NGK INSULATORS LTD

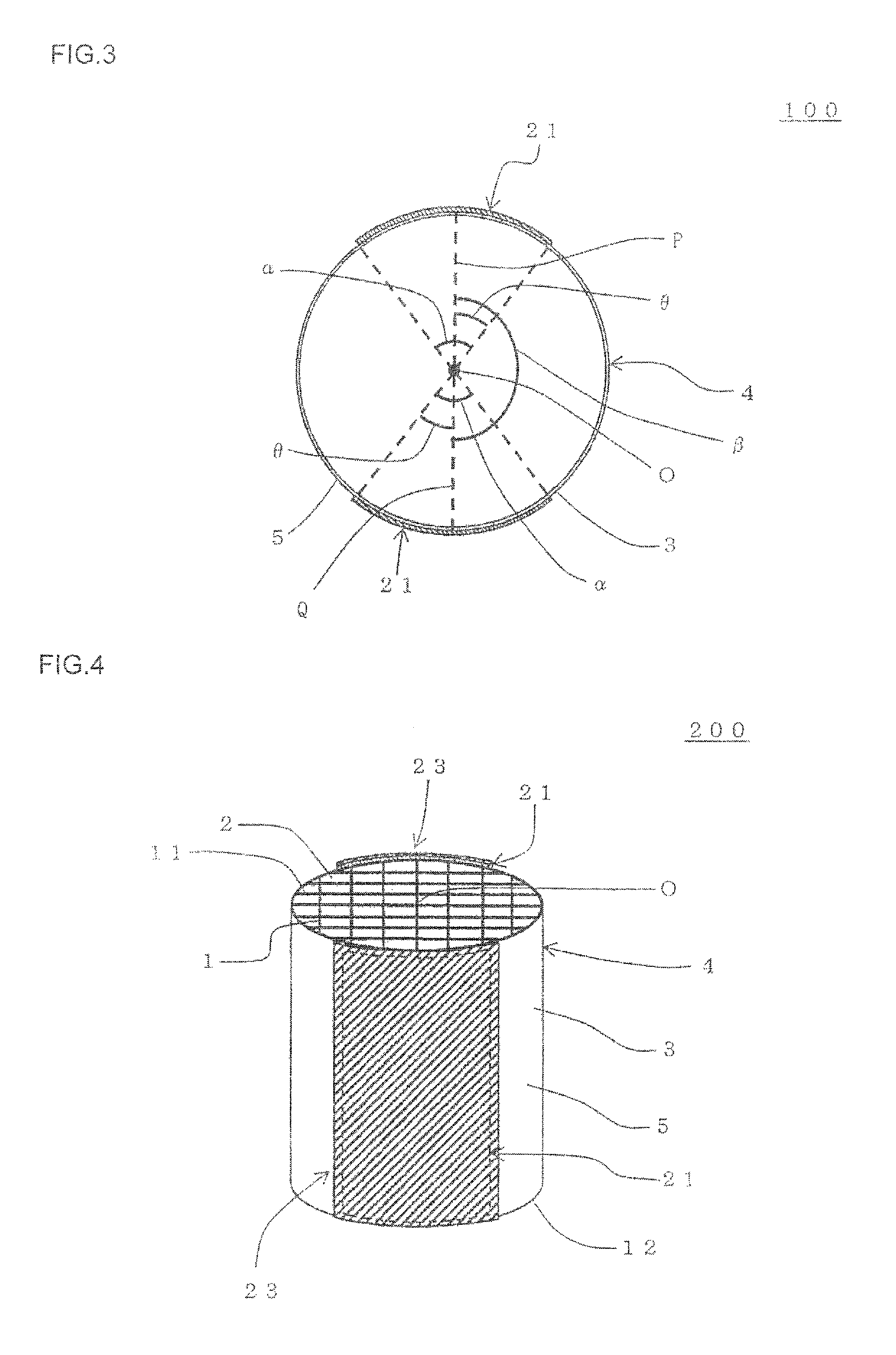

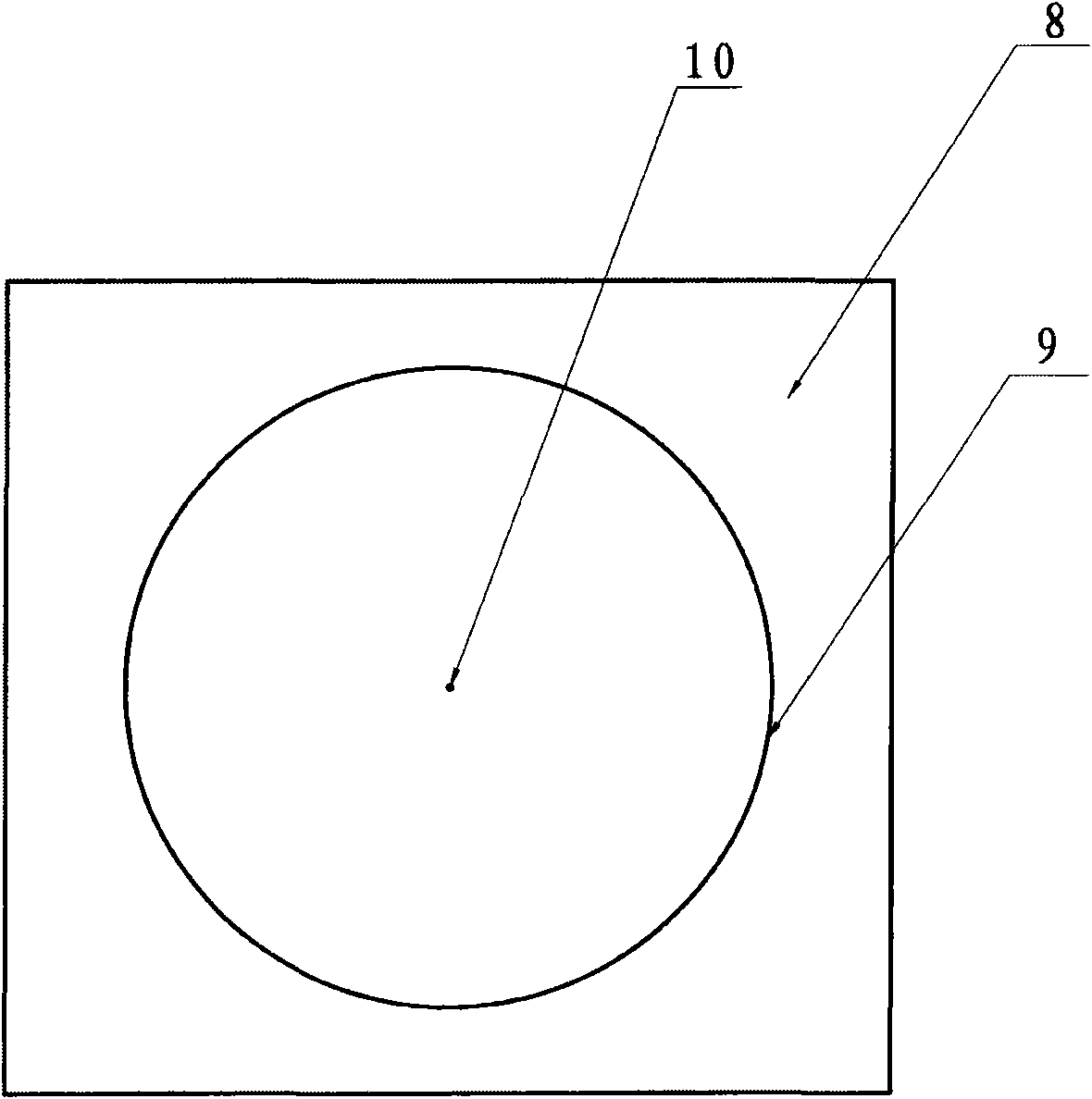

Accessory system for fast stacking of annealed steel coil and operation method thereof

InactiveCN101948081AImprove stacking efficiencyImprove stacking qualityLoad-engaging elementsSight lineElectricity

The invention discloses an accessory system for fast stacking of annealed steel coil and an operation method thereof. The system comprises an embedding sleeve, an image pickup system, an illuminating system, a viewer-sight indicating system, a display, and a position indicating mark, wherein the embedding sleeve is arranged at the center of the lower end face of a guide cone of a steel coil lifting appliance; the image pickup system is arranged at the center of the lower surface of the embedding sleeve in a sunk manner; the illuminating system is arranged at the lower surface of the embedding sleeve and adjacent to the image pickup system; the viewer-sight indicating system is arranged in the embedding sleeve in a sunk manner and adjacent to the image pickup system and the illuminating system; the display is electrically connected with the image pickup system and used for displaying images shot by the image pickup system and the viewing field mark central point; and the position indicating mark is arranged at the center of the upper surface of a starting fan on a steel coil stacking platform; and the center line of the embedding sleeve coincides with the center lien of the guide cone, the viewer-sight indicating system sends out two mutually vertical light rays from the viewing field, so that mutually vertical viewer-sight lines are displayed on the display, the point of the intersection of the viewer-sight lines coincides with the central point of the viewing field. The system and the method of the invention can improve stacking efficiency and quality.

Owner:SHANDONG IRON & STEEL CO LTD

Cellulose acylate film, saturated norbornene resin film, and process for producing these

InactiveUS20090192280A1Suppress of streakingHigh-quality filmPolarising elementsFlat articlesCelluloseNorbornene

A high-quality cellulose acylate film and saturated norbornene resin film which are produced by a melt film formation method and can be inhibited from having steak failures. Also provided is a process for producing the cellulose acylate film or the saturated norbornene resin film. The process, which is for producing a cellulose acylate film (12) or a saturated norbornene resin film, comprises melting a cellulose acylate resin or saturated norbornene resin with an extruder (22), feeding the molten resin to a die (24) through a piping (23), and ejecting the melt in a sheet form from the die (24) onto a cooled support (26) which is running or rotating to thereby cool and solidify the sheet. Thus, a cellulose acylate film (12) or saturated norbornene resin film is formed. In the process, a static mixer (27) is disposed in the piping (23) and the molten resin flowing in the piping (23) is statically stirred.

Owner:FUJIFILM CORP

Electrode material for lithium-ion rechargeable battery, method for manufacturing electrode material for lithium-ion rechargeable battery, electrode for lithium-ion rechargeable battery, and lithium-ion rechargeable battery

InactiveUS20170092937A1Improve output characteristicsIncreased durabilityElectrode thermal treatmentPositive electrodesBattery chargeLithium metal

Provided are an electrode material for a lithium-ion rechargeable battery including core particles of an active material and a carbonaceous film, in which a powder resistance is 150 Ω·cm or less, and a lithium-ion rechargeable battery produced using the electrode material and a lithium metal exhibits a difference between a sum of a charge capacity with an upper limit voltage of 4.2 V and the lithium-ion rechargeable battery charged at a constant current and a charge capacity with the lithium-ion rechargeable battery charged at a constant voltage for seven days at 4.2 V after the constant current charging and a discharge capacity with the lithium-ion rechargeable battery discharged at a constant current to 2 V after the constant voltage charging reaches 25 mAh / g or less, a method for manufacturing the electrode material, an electrode including the electrode material, and a lithium-ion rechargeable battery including the electrode as a cathode.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Electrode material for lithium-ion secondary battery, method for manufacturing same, electrode for lithium-ion secondary battery, and lithium-ion secondary battery

InactiveUS20170237064A1Improve output characteristicsIncreased durabilityElectrode thermal treatmentElectrode carriers/collectorsElectrical resistance and conductanceLithium metal

An electrode material for a lithium-ion secondary battery includes an electrode active material and a carbonaceous film with which a surface of the electrode active material is coated, in which a powder resistance under compression at a pressure of 45 MPa is 130 Ω·cm or lower and a lithium-ion secondary battery including a cathode including the electrode material for a lithium-ion secondary battery and an anode made of lithium metal exhibits battery characteristics that a difference between a sum of a charge capacity thereof obtained when constant current charged with an upper limit voltage with respect to the anode set to 4.20 V and a charge capacity thereof obtained when constant voltage charged at 4.20 V for ten days after the constant current charge and a discharge capacity thereof obtained when constant current discharged to 2 V after the constant voltage charge is set to 20 mAh / g or lower.

Owner:SUMITOMO OSAKA CEMENT CO LTD

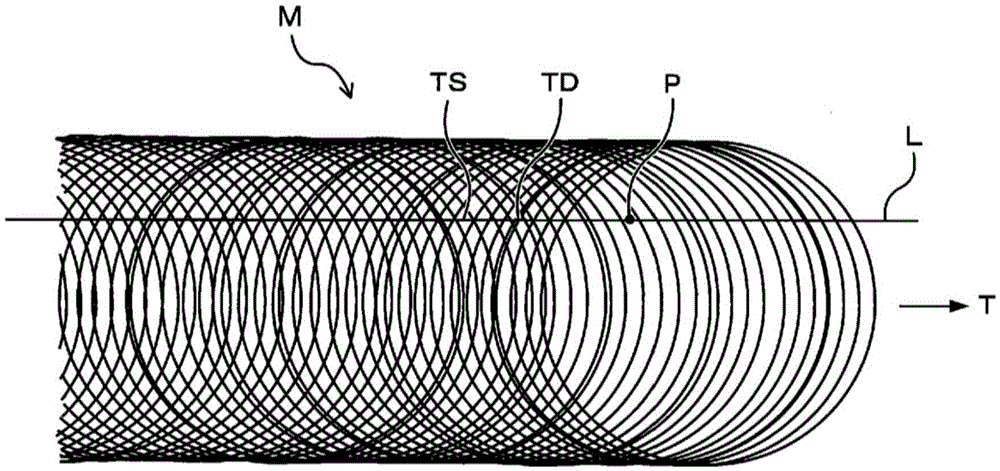

Wire rod cooling device and wire rod cooling method

InactiveCN105658348AUniform temperatureUniform cooling on both sides of the temperatureTemperature control deviceMeasuring devicesWire rodEngineering

Owner:NIPPON STEEL CORP

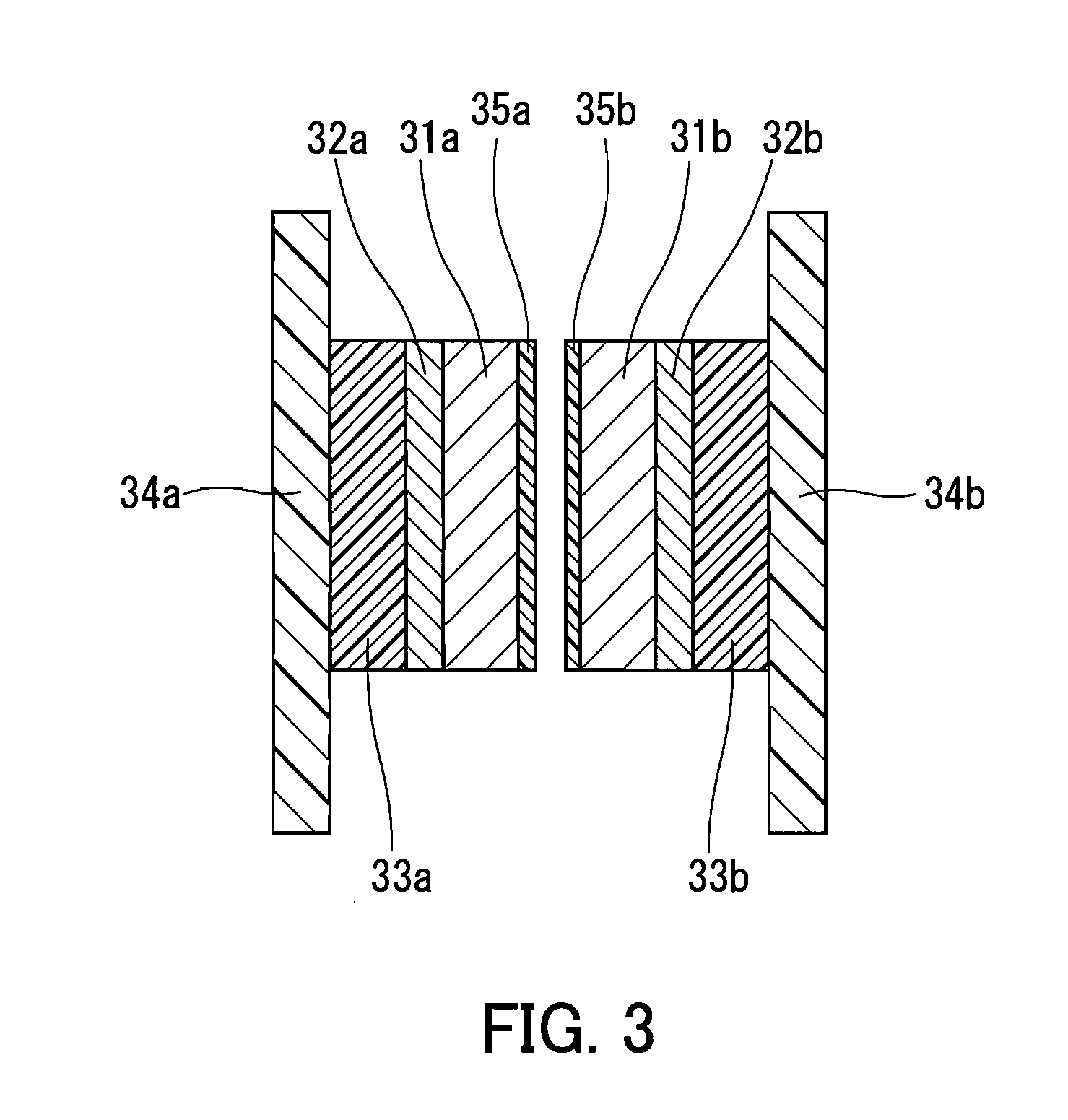

Transverse flux induction heating device

ActiveUS9578693B2Reliably flowReduce temperature unevennessCoil arrangementsIncreasing energy efficiencyTransverse fluxElectrical conductor

The transverse flux induction heating device allows an alternating magnetic field to intersect the sheet face of a conductive sheet which is conveyed in one direction, thereby inductively heating the conductive sheet. The transverse flux induction heating device includes a heating coil disposed such that a coil face faces the sheet face of the conductive sheet; a core around which the heating coil is coiled; and a shielding plate formed of a conductor and disposed between the core and a side end portion in a direction perpendicular to the conveyance direction of the conductive sheet, wherein the shielding plate has a protruded portion, and the side surface of the protruded portion represents a closed loop when viewed from a direction perpendicular to the coil face.

Owner:NIPPON STEEL CORP

Image display apparatus and method of controlling the same

ActiveUS8416501B2Reduce temperature unevennessCathode-ray tube indicatorsOptical elementsLight beamImage signal

An image display apparatus generates a first light beam and a second light beam corresponding to image signals for the eyes of an observer, and makes the first light beam and the second light beam incident on a reflection surface which makes a reciprocating rotation about a first axis, thereby generating first and second scanning light beams to scan in a lateral direction. Images observable by the eyes of the observer are formed based on the first and second scanning light beams. Control is performed to reflect the first light beam and generate the first scanning light beam while the reflection surface rotates in the first direction of the reciprocating rotation and reflect the second light beam and generate the second scanning light beam while the reflection surface rotates in the second direction opposite to the first direction.

Owner:CANON KK

Hot blade type electronic garbage pyrolysis device

PendingCN106433707AUniform temperatureReduce temperature unevennessDirect heating destructive distillationSpecial form destructive distillationElectric heatingEngineering

The invention relates to the technical field of garbage treatment, in particular to a hot blade type electronic garbage pyrolysis device. The hot blade type electronic garbage pyrolysis device comprises an electronic garbage pyrolysis reactor and an electric heating system, wherein the electronic garbage pyrolysis reactor comprises a material pyrolysis assembly and a reactor shell; the material pyrolysis assembly comprises a spiral casing pipe and a propelling helix; the electric heating system comprises an electric heating wire and a power supply rotating joint; and the two ends of the electric heating wire stretch out along a spiral shaft of the propelling helix to be connected with the power supply rotating joint. The device adopts a spiral blade to heat, the electric heating wire is arranged in the propelling spiral shaft blade, materials perform heat transfer from inside to outside while being propelled by the helix, and the materials are directly heated by the high-temperature blade in the propelling process, so the thickness of a heat-preserving layer is reduced, the utilization rate of heat is increased and the production and manufacturing cost is reduced; meanwhile, the heating spiral blade rotates along with the spiral shaft, so the temperature is more uniform.

Owner:SHENWU TECH GRP CO LTD

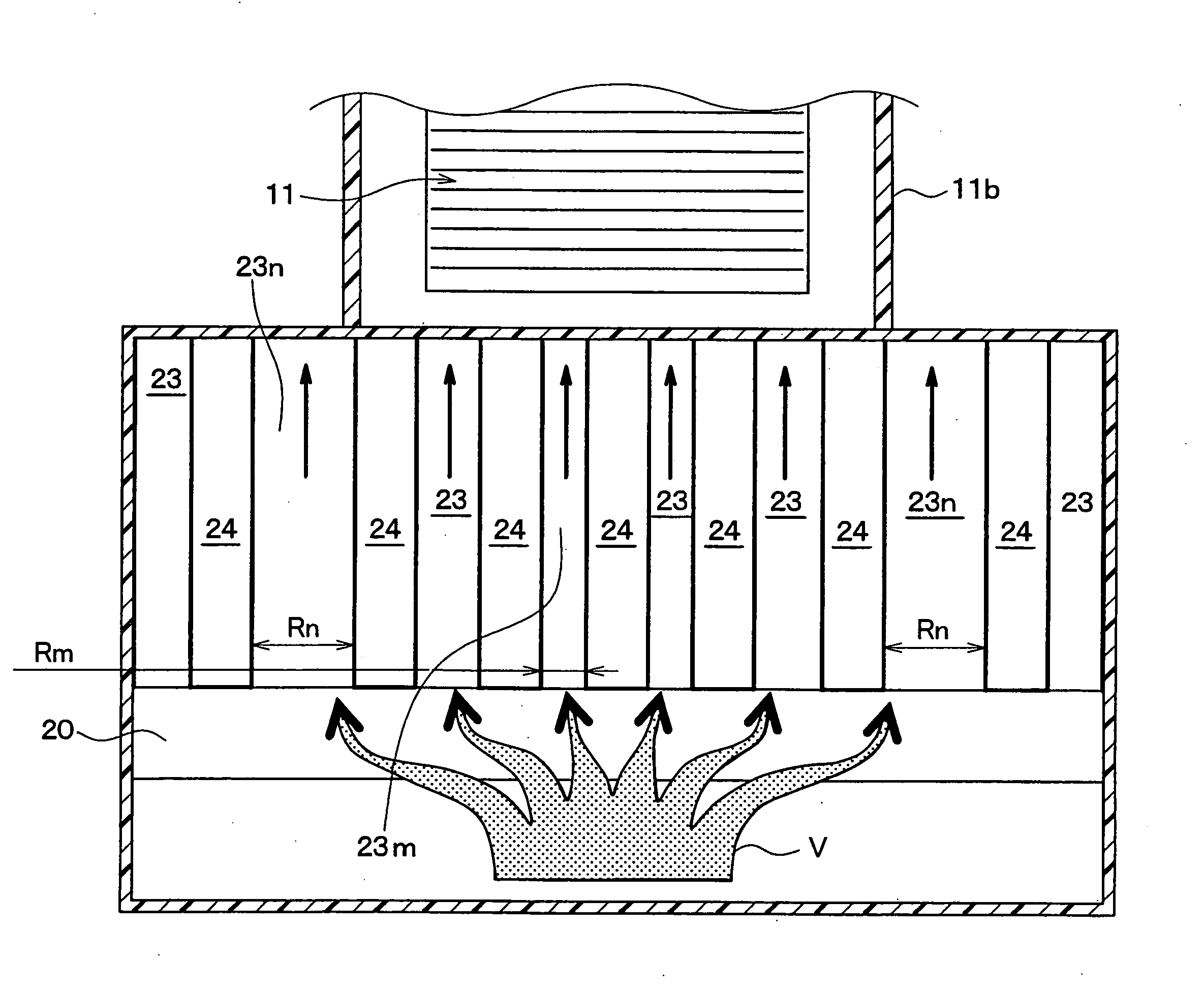

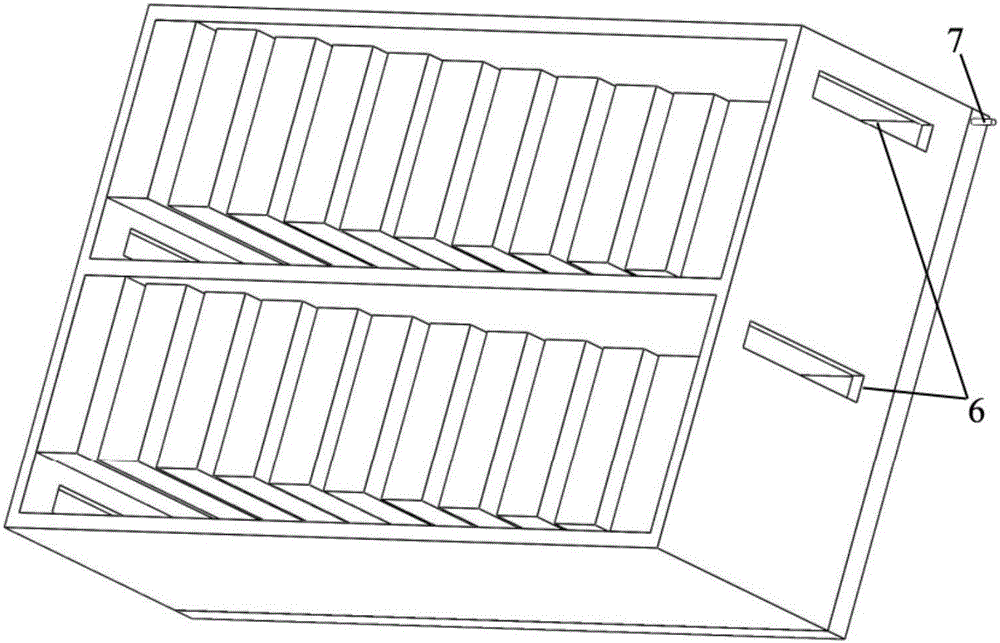

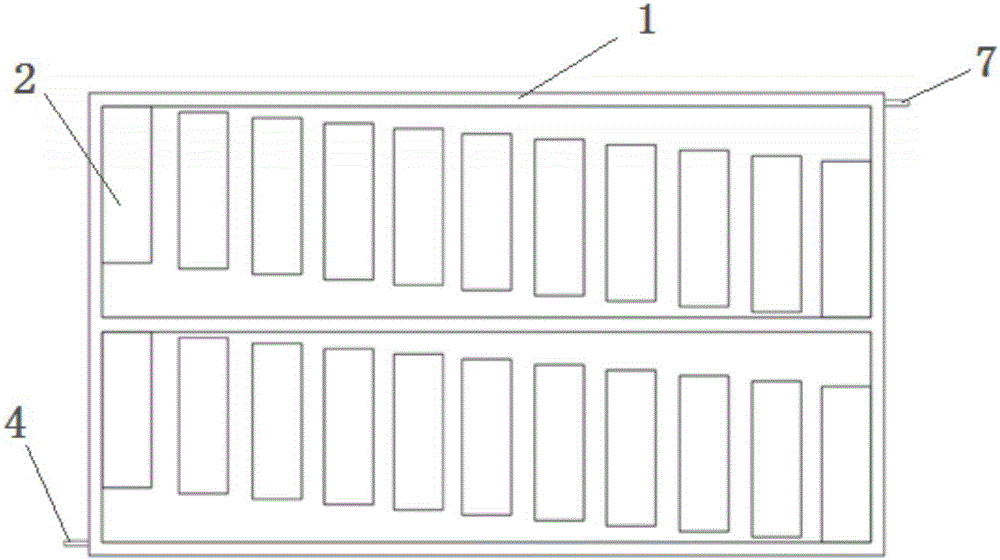

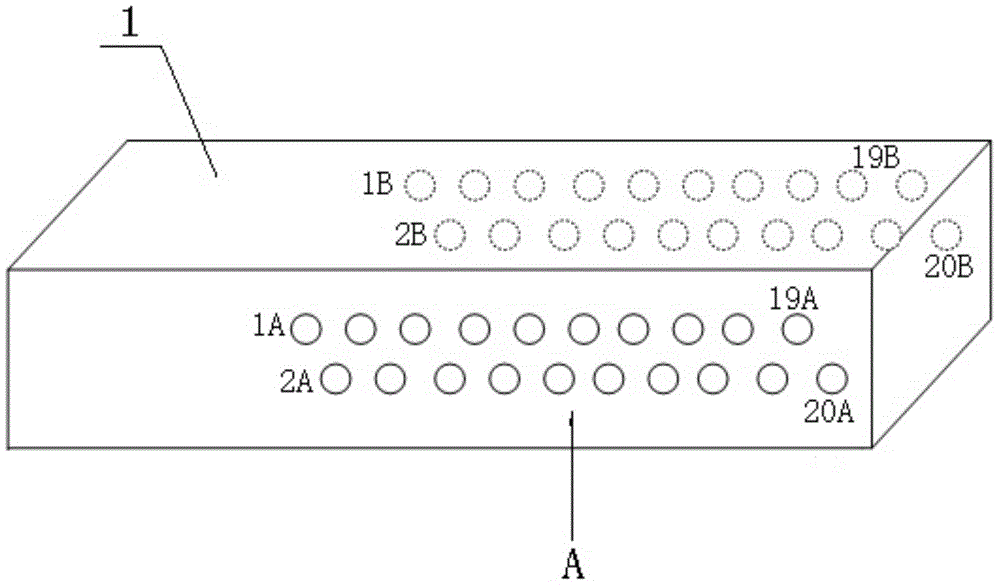

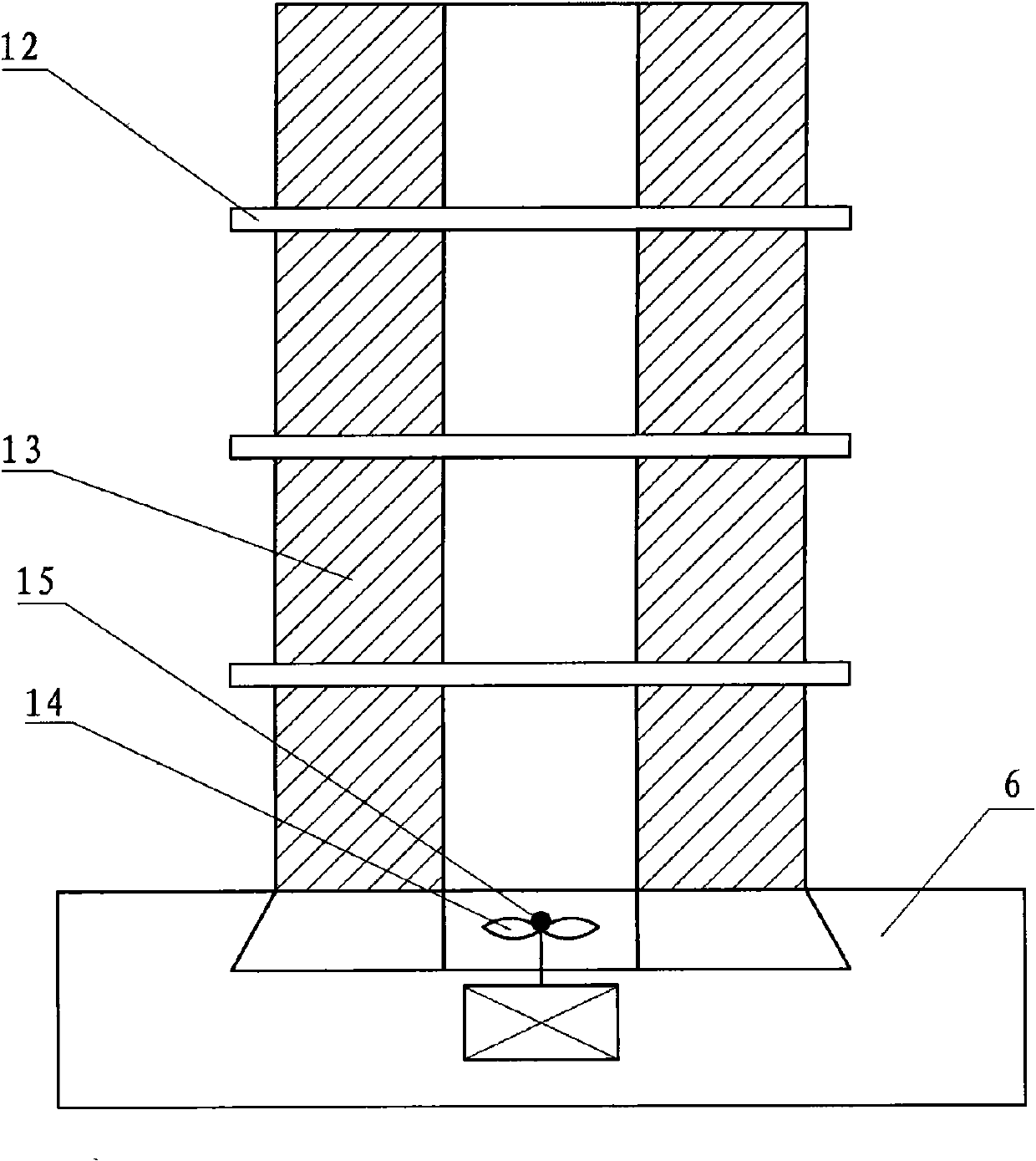

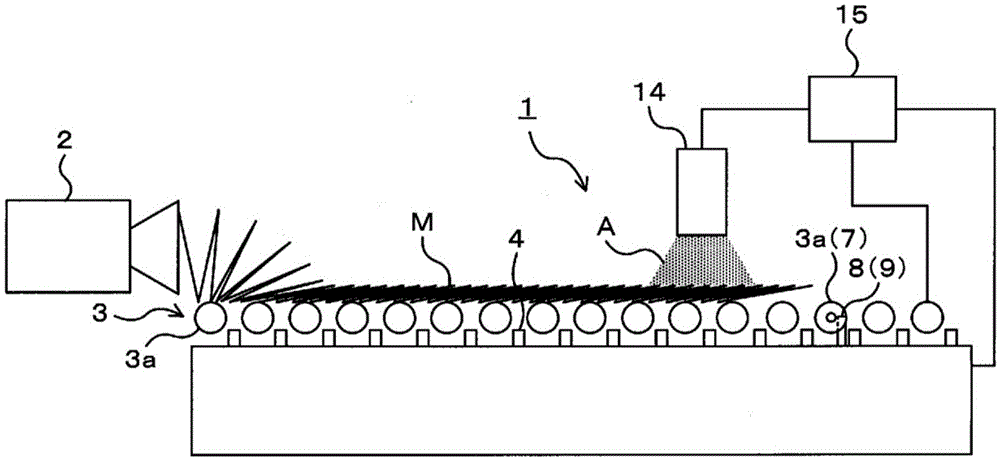

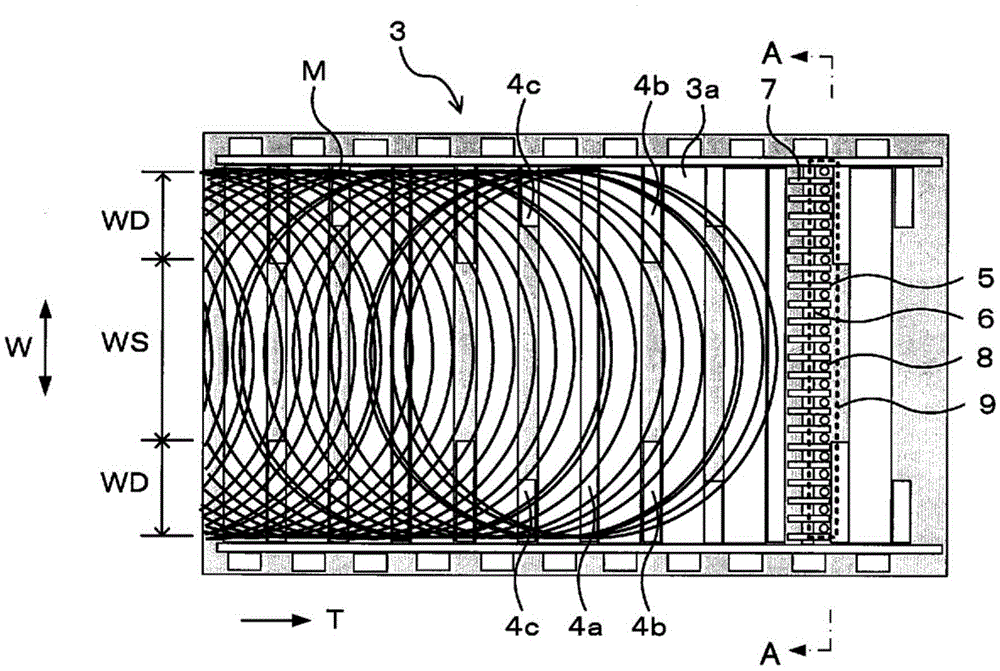

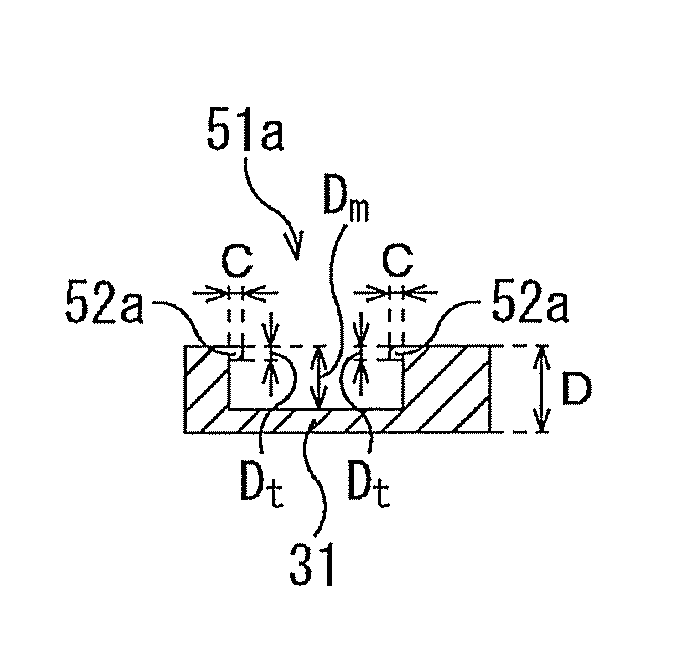

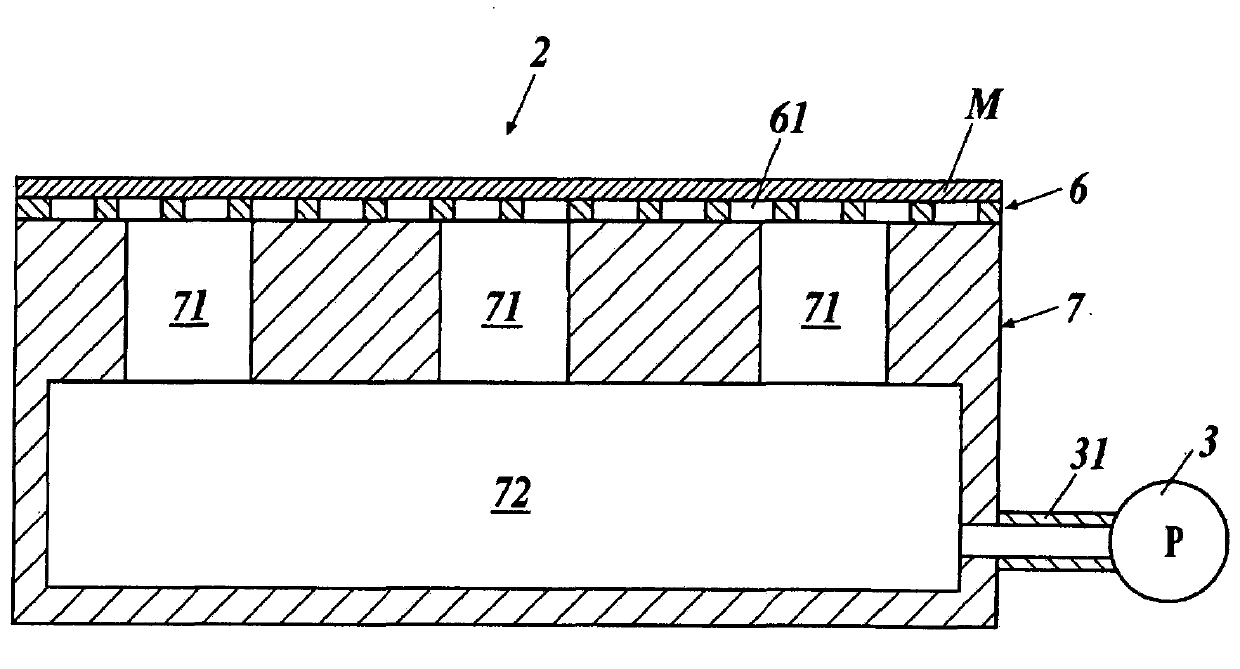

Inkjet recording device

ActiveCN103502015AReduce temperature unevennessPrevent floatingOther printing apparatusLiquid stateEngineering

In an inkjet recording device using ink, the phase of which changes between a gel state or a solid state and a liquid state depending on temperature, when a recording medium fixing means is applied in which a recording medium is sucked and fixed by air suction via adsorbing holes contacting the recording medium, it is prevented that the pattern of the adsorbing holes appears on an image. The recording medium fixing means (2) for sucking and fixing a recording medium (M) by air suction via adsorbing holes (61) contacting the recording medium has: a recording medium holding layer (6) in which adsorbing holes are formed and a temperature by which ink becomes a gel state or a solid state is maintained; and a supporting layer (7) configured with at least one layer for supporting the recording medium holding layer and having suction holes (71) formed so as to communicate with the adsorbing holes. The opening area at the opening end of the adsorbing holes, which contacts the recording medium, is made smaller than the opening area at the opening end of the suction holes, which contacts the recording medium holding layer. This reduces the difference between the temperature above the adsorbing holes and the temperature above the member around the adsorbing holes and prevents the pattern of the adsorbing holes from appearing on an image.

Owner:KONICA MINOLTA INC

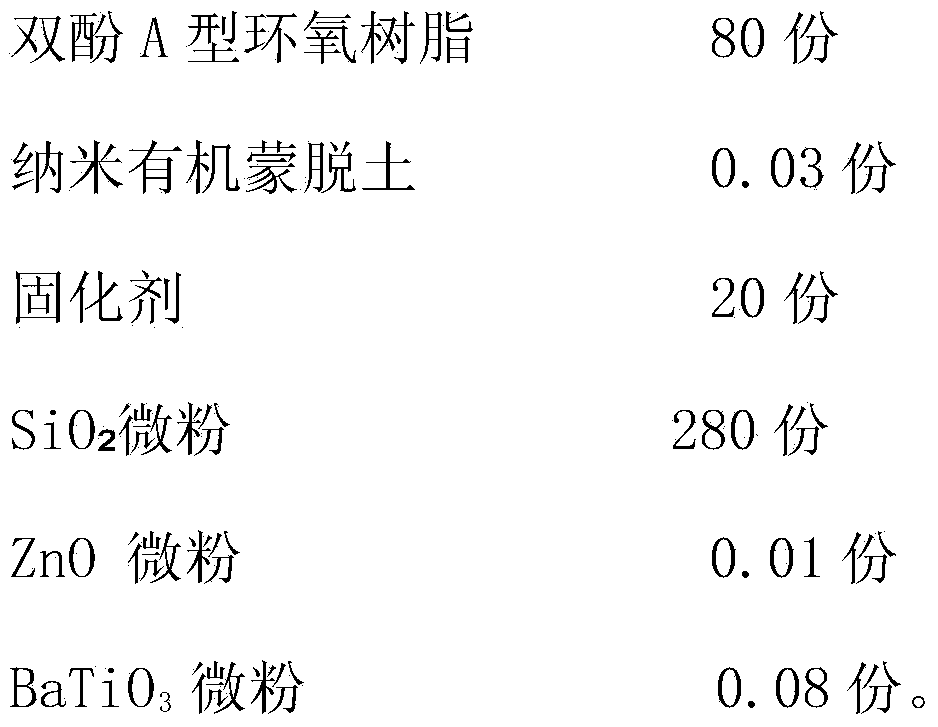

Assembled battery device

InactiveUS20130323575A1Improve the level ofEfficient transferPrimary cell to battery groupingCell temperature controlEngineeringMechanical engineering

An assembled battery device (1) of the present invention includes: a plurality of single cells (11) electrically connected to each other and arranged in a row; and a thermal emission tape disposed between a single cell (A) and a single cell (B) that are adjacent to each other among the plurality of single cells (11). The plurality of single cells (11) each include battery elements and a metallic container (12) housing the battery elements. The thermal emission tape is attached to at least a portion of a surface of an outer wall of the container of the single cell (A), and / or to at least a portion of a surface of an outer wall of the container of the single cell (B), the surface of the outer wall of the container of the single cell (A) facing the single cell (B), the surface of the outer wall of the container of the single cell (B) facing the single cell (A). The thermal emission tape has a total emissivity of 0.7 or more at a wavelength of 2 μm to 14 μm.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com