Accessory system for fast stacking of annealed steel coil and operation method thereof

An auxiliary system, annealed steel technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem of not being able to meet the precise positioning of stacking, so as to reduce the phenomenon of sticking steel, reduce the uneven temperature in the furnace, and improve stacking efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

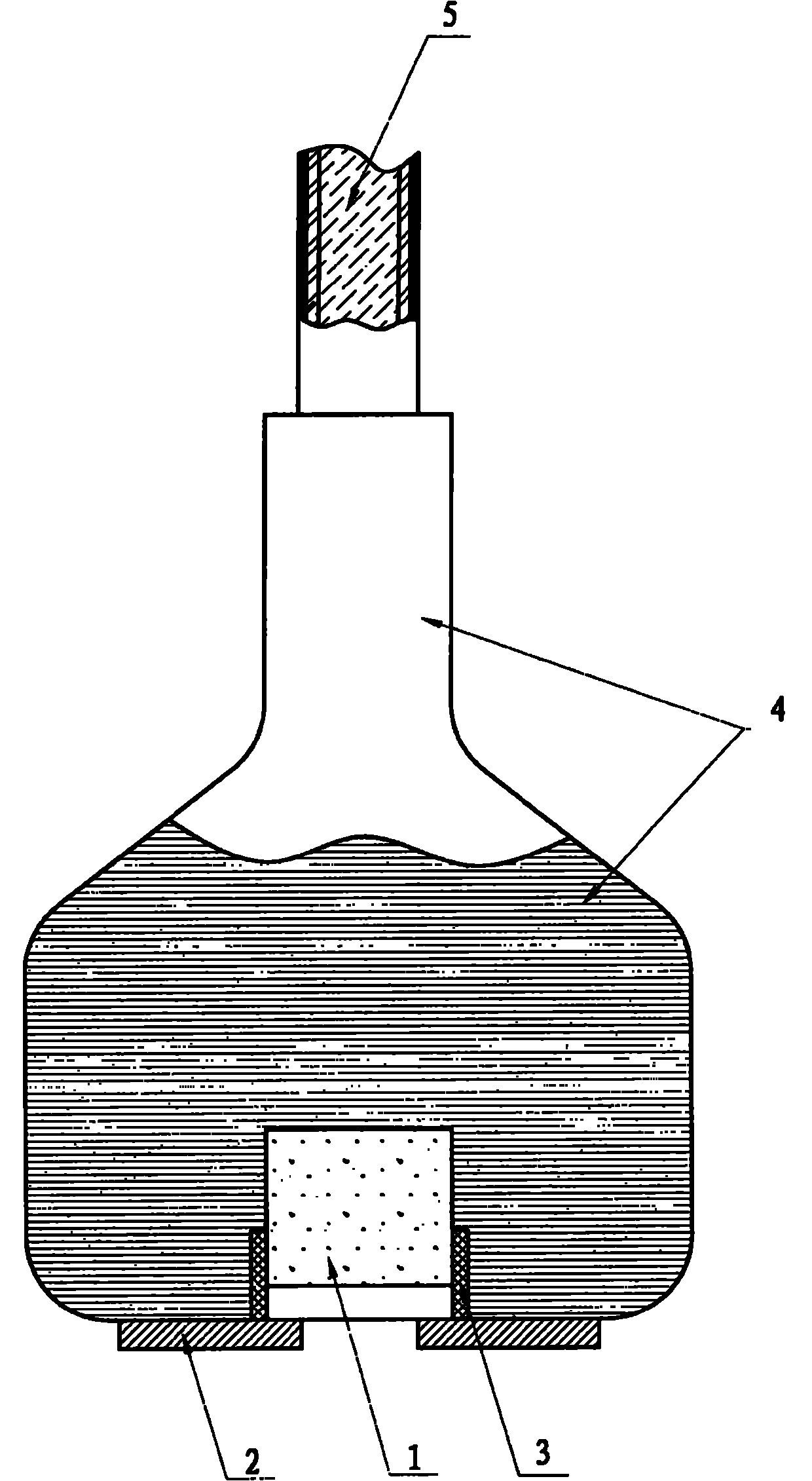

[0051] In iron and steel production enterprises, in order to accurately hoist steel coils, a guide cone 17 needs to be assembled on the steel coil spreader 16, such as figure 1 shown. Under the guidance of the guide cone 17, the steel coil hanger 16 can hoist the steel coil. In order to quickly and accurately lift steel coils, the present invention proposes an annealed steel coil rapid stacking auxiliary system.

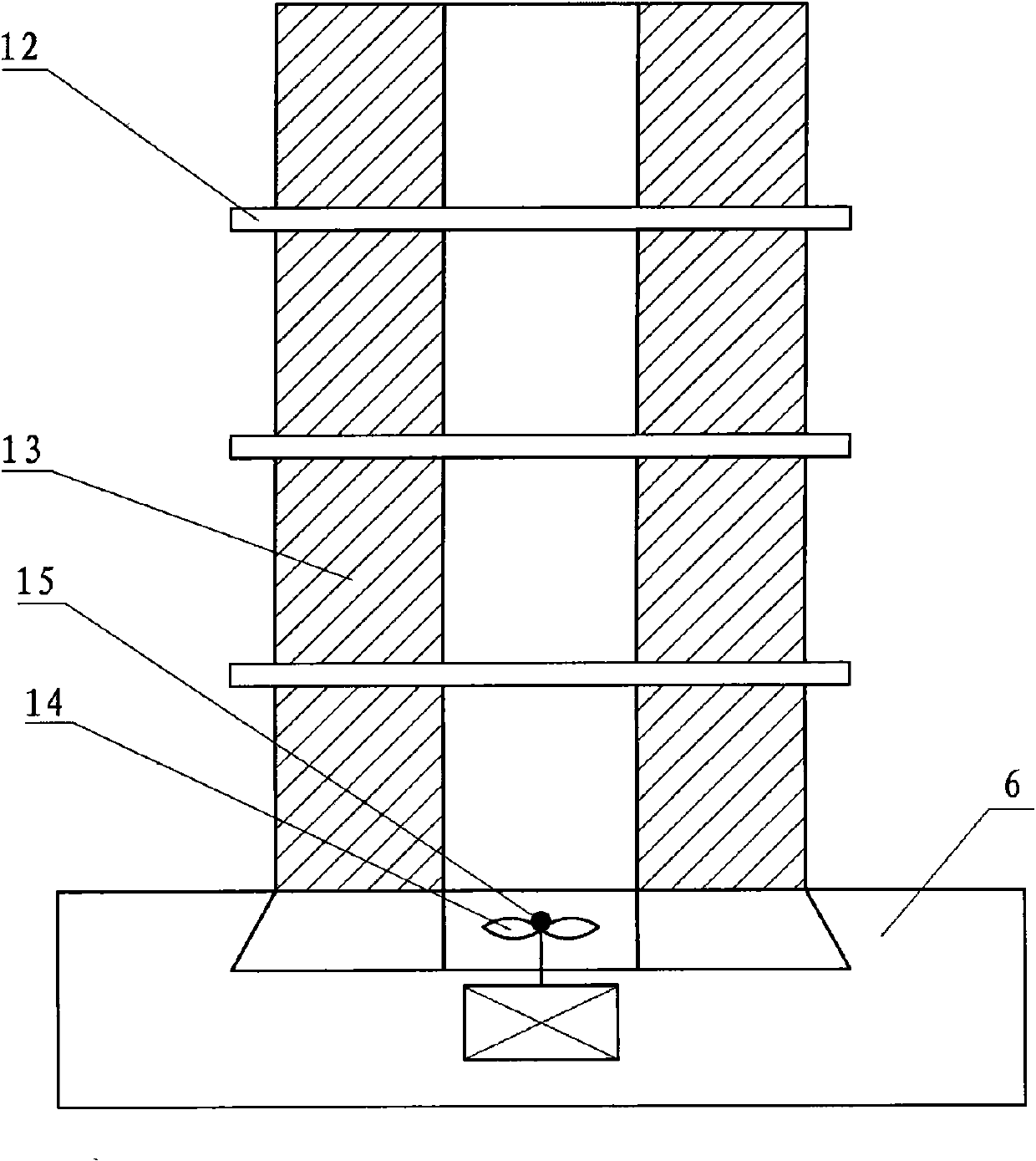

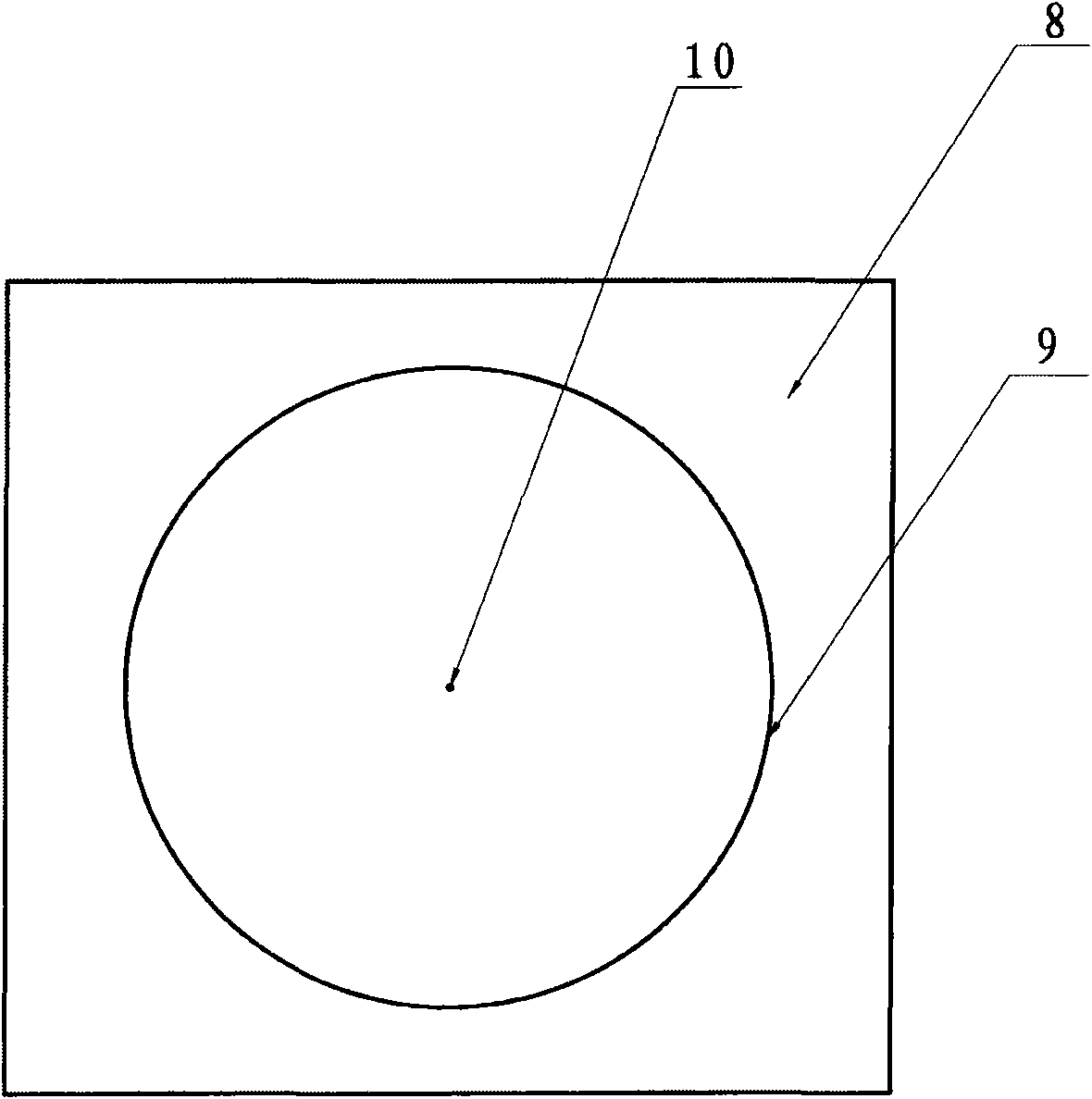

[0052] Such as Figure 2 to Figure 6 As shown, the auxiliary system for rapid stacking of annealed steel coils according to an exemplary embodiment of the present invention includes: a mosaic sleeve 4 fixedly installed in the center of the lower end surface of the guide cone 17 of the steel coil hanger 16; the camera system 1 , is recessedly installed in the center of the lower surface of the mosaic sleeve 4, and is used to shoot the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com