Paraxial wire feeding device and additive manufacturing system

A technology of wire feeding device and guide wire, which is applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of affecting the effect and efficiency of additive manufacturing, failing to reach the direction and angle of wire feeding, and low degree of automation. Achieve the effect of high degree of automation, good versatility and good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

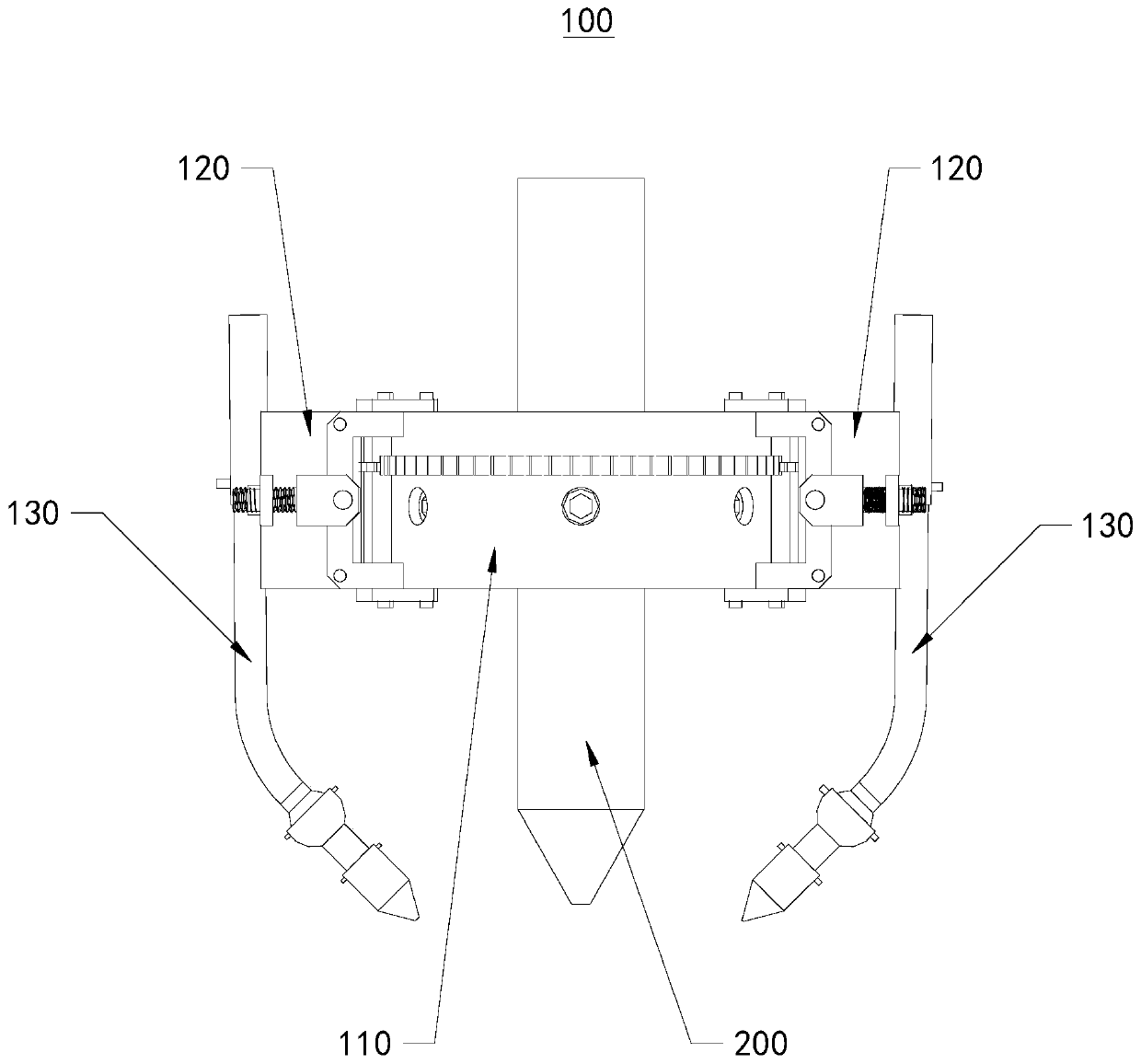

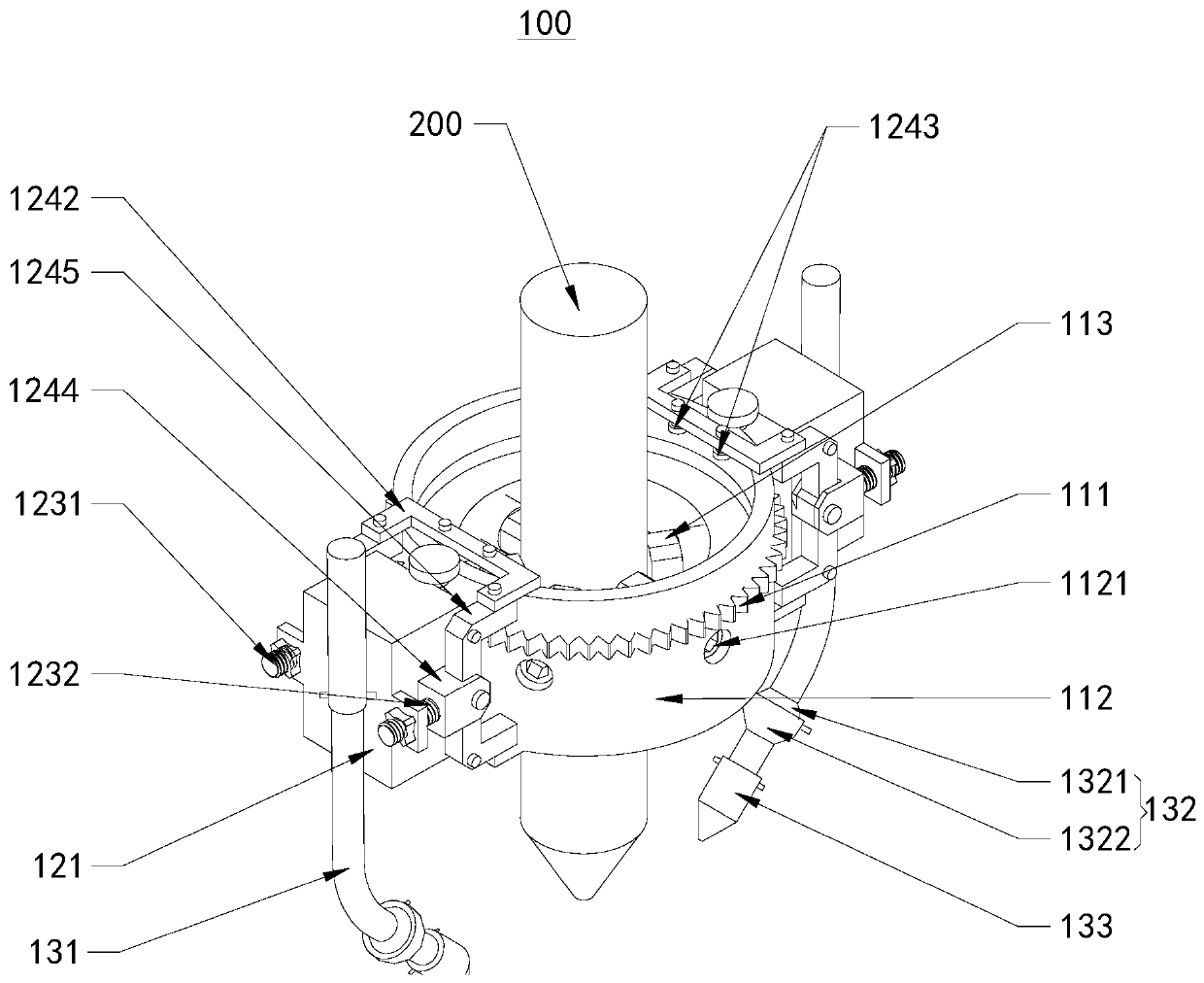

[0038] Please refer to figure 1 and figure 2 , the present embodiment provides a side-axis wire feeding device 100 , which includes a mounting mechanism 110 , a traveling mechanism 120 and a wire guiding mechanism 130 .

[0039] The installation mechanism 110 is used to install the welding torch 200, and its specific structure please refer to figure 2 and image 3 :

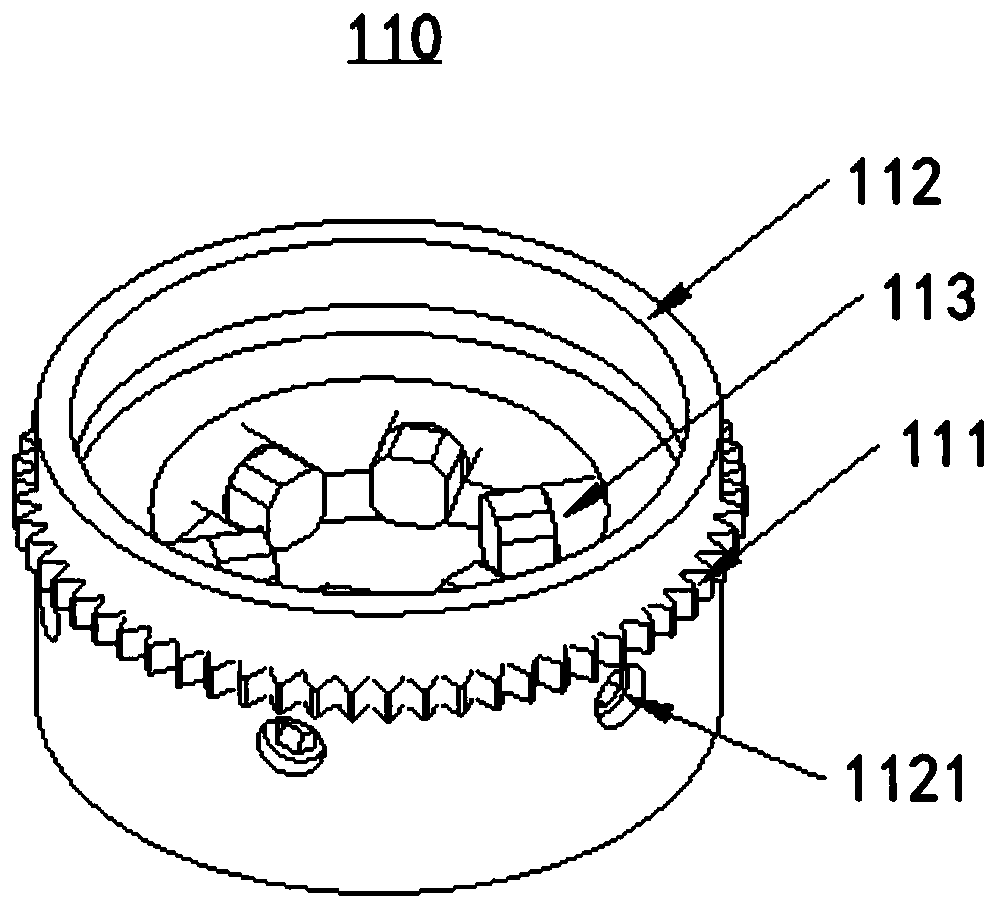

[0040] The installation mechanism 110 includes an annular rack 111 , an annular cylinder 112 and an installation portion 113 .

[0041]In the present application, the ring rack 111 is disposed on the outer wall of the ring cylinder 112 and is fixedly connected with the ring cylinder 112 . Specifically, in this application, screws are used to connect the ring rack 111 to the ring barrel 112 . It should be understood that, in other implementation manners, the fixed connection may also be achieved by means of welding or clipping. The ring rack 111 in this application is a kind of ring track, which is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com