Tungsten-wire electric-arc additive manufacturing device and method under action of auxiliary wire

A technology of additive manufacturing and electric arc, which is applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of low accumulation efficiency and excessive damage of accumulation layers, and achieve the effect of improving accumulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for additive manufacturing of a tungsten-wire arc additive manufacturing device under the action of auxiliary wires, comprising the following steps:

[0034] Step 1: Plan the stacking path and process parameters according to the geometric structure of the metal component to be processed, and select the wire material required for the test. The process parameters include stacking current I, welding speed v, shielding gas flow L, and feeding of the first wire 5a. wire speed v 1 , The wire feeding speed v of the second wire 5b 2 ; The accumulation current I is 100-250A, and the protective gas flow L is 10-30L / min.

[0035] Step 2: Mechanically clean the surface of the substrate 10, wipe it clean with acetone, and fix the substrate 10 on the workbench through a clamp; connect the welding torch 2 to the negative pole of the arc additive manufacturing power supply 1 through a cable; the second guide wire One end of the nozzle 6b is connected to the positive pole of ...

Embodiment 2

[0041] A method for additive manufacturing using a tungsten-wire arc additive manufacturing device under the action of auxiliary wires, comprising the following steps:

[0042] Step 1: Plan the stacking path and process parameters according to the geometric structure of the metal component to be processed, and select the wire material required for the test. The process parameters include stacking current I, welding speed v, shielding gas flow L, and feeding of the first wire 5a. wire speed v 1 , The wire feeding speed v of the second wire 5b 2 ; The accumulation current I is 100-250A, and the protective gas flow L is 10-30L / min.

[0043] The stainless steel member described in this embodiment is a multi-layer single-channel thin-walled part, with a member width of 6 mm, a total height of 25 mm, and a forming path length of 160 mm. In this test, the Fronius welding machine provides the arc additive manufacturing power supply, the motion execution device is an ABB robot, and t...

Embodiment 3

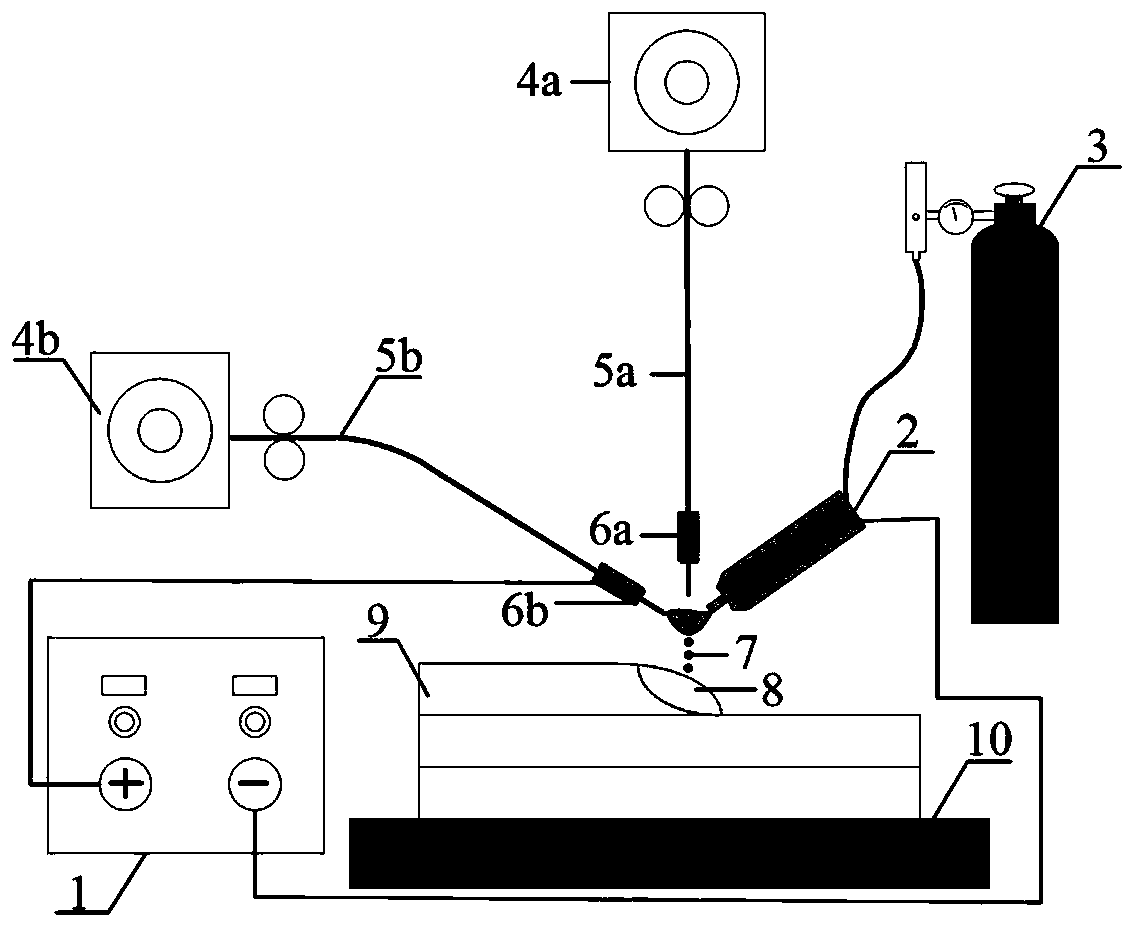

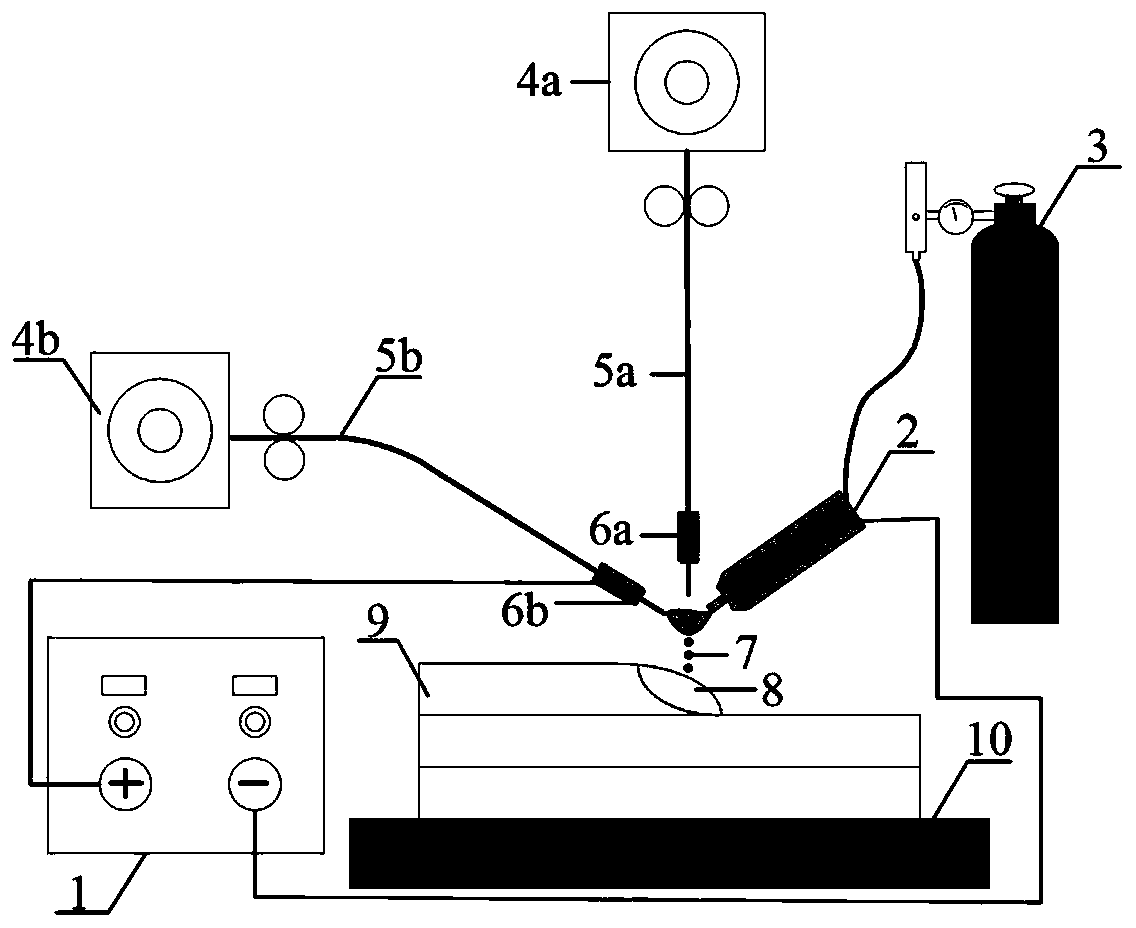

[0051] The present invention also provides a tungsten-wire arc additive manufacturing device under the action of auxiliary wire, including an arc additive manufacturing power supply 1, a welding torch 2, a shielding gas cylinder 3, a first wire feeder 4a, a second wire feeder 4b, a second A metal wire 5a, a second metal wire 5b, a first wire guide 6a, and a second wire guide 6b;

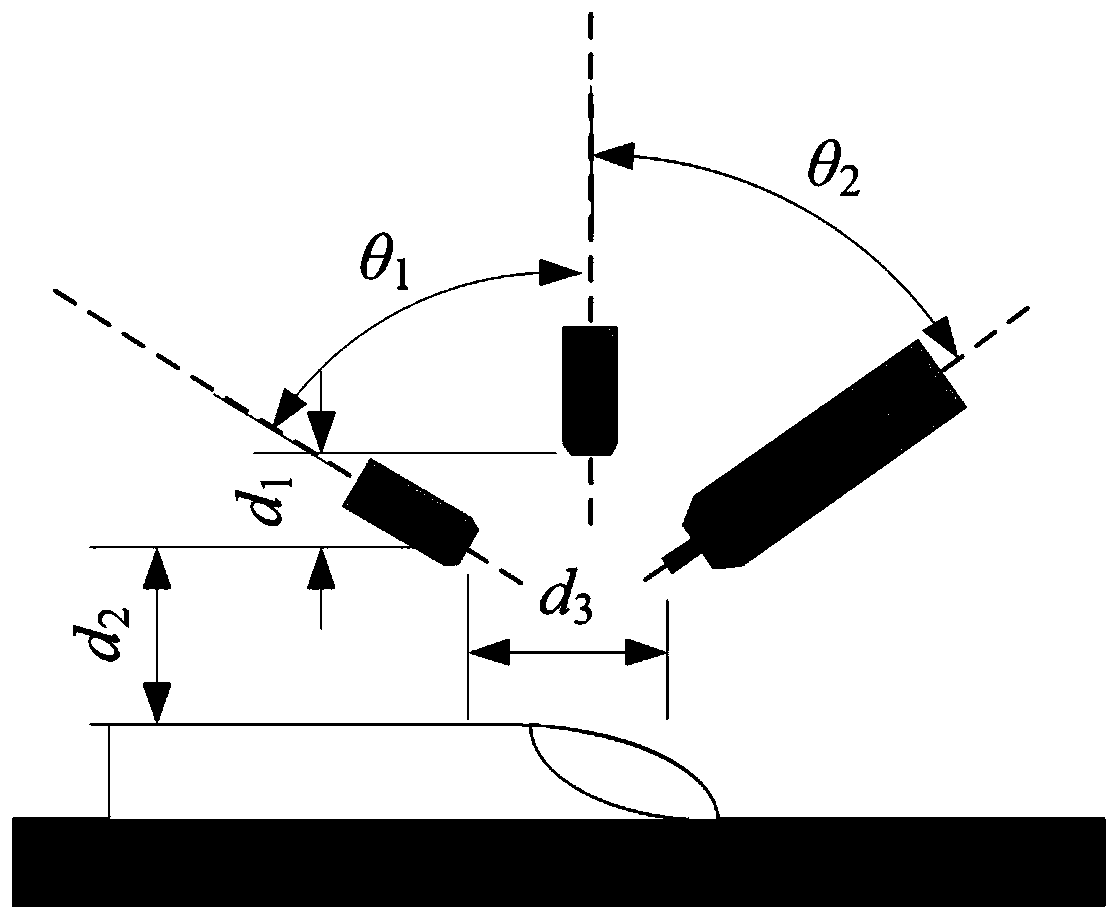

[0052]The torch 2 is connected to the negative pole of the arc additive manufacturing power supply 1 through a cable; one end of the second wire guide 6b is connected to the positive pole of the arc additive manufacturing power supply 1 through a cable; one end of the first metal wire 5a is passed through Through the first wire guide nozzle 6a, one end of the second metal wire 5b passes through the second wire guide nozzle 6b; the shielding gas bottle 3 is connected with the welding torch 2 through a gas supply hose for providing shielding gas; The wire machine 4a and the second wire feeder 4b are us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com