Box filler double-channel stacking system

A dual-channel, cartoning machine technology, applied in packaging, object stacking, transportation and packaging, etc., can solve the problems of restricting the speed of the front production line, the height of the bottom block of the stack, and prolonging the single stacking time. , to achieve the effect of short changeover time, reasonable structure and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

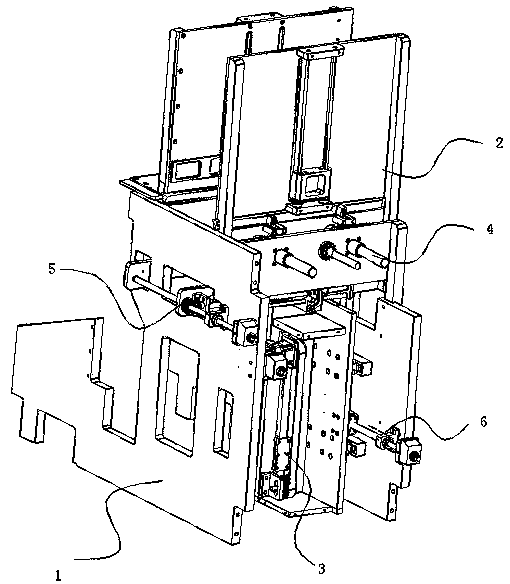

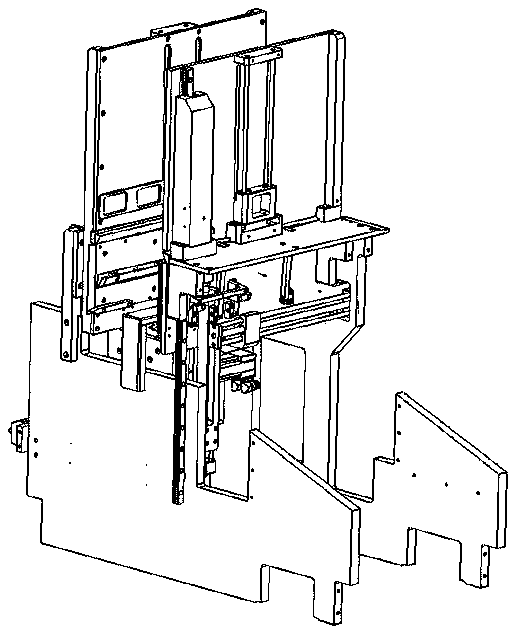

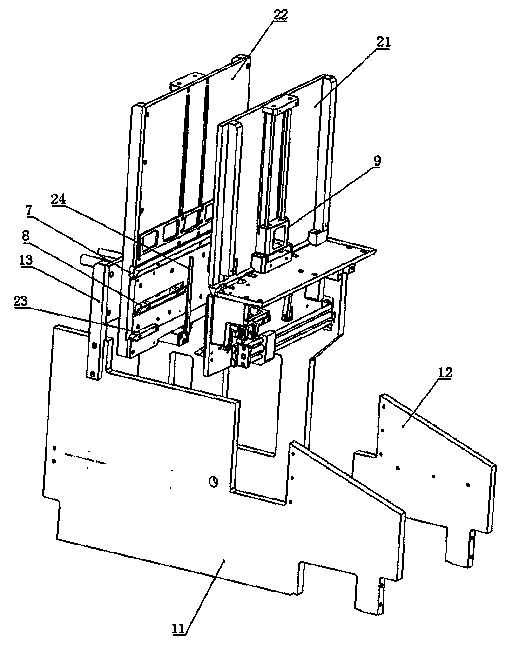

[0034] see figure 1 , the present invention discloses a double-channel stacking system structure of a case packer, including a frame 1, a stacking mechanism 2, a jacking mechanism 3, a baffle width adjusting mechanism 4, a feed limit adjusting mechanism 5, a jacking position Regulator 6.

[0035] The stacking mechanism 2 is installed on the upper end of the frame 1, and the jacking mechanism 3 that lifts the items to be stacked upwards into the stacking mechanism 2 is arranged in the frame 1; the baffle width adjustment mechanism 4 is installed on the top of the frame 1 for Adjust the width of the stacked items of the stacking mechanism 2. The feed limit adjustment mechanism 5 is installed in the frame 1 to adjust the horizontal initial position of the stacked items after entering the stacking mechanism 2; the jacking position adjustment mechanism 6 is installed between the frame 1 and the jacking mechanism 3, and is To change the jacking position in the horizontal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com