Conveyor of continuous food heating cooling conveying device and cover lifting device

A technology of cooling conveying and conveyor, applied in the direction of lifting device, etc., can solve the problems of cumbersome cleaning method, inconvenience, inconvenient installation of related equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

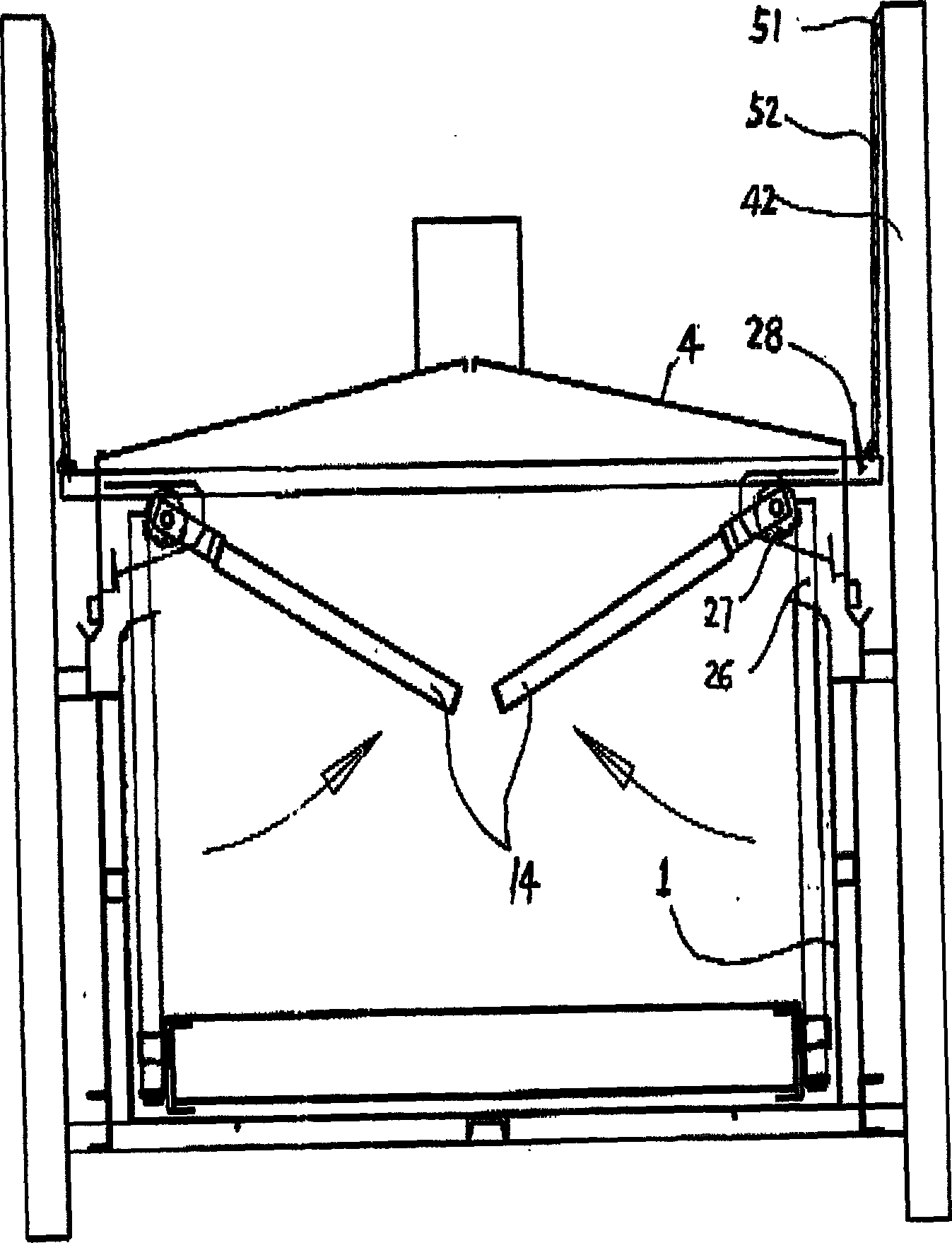

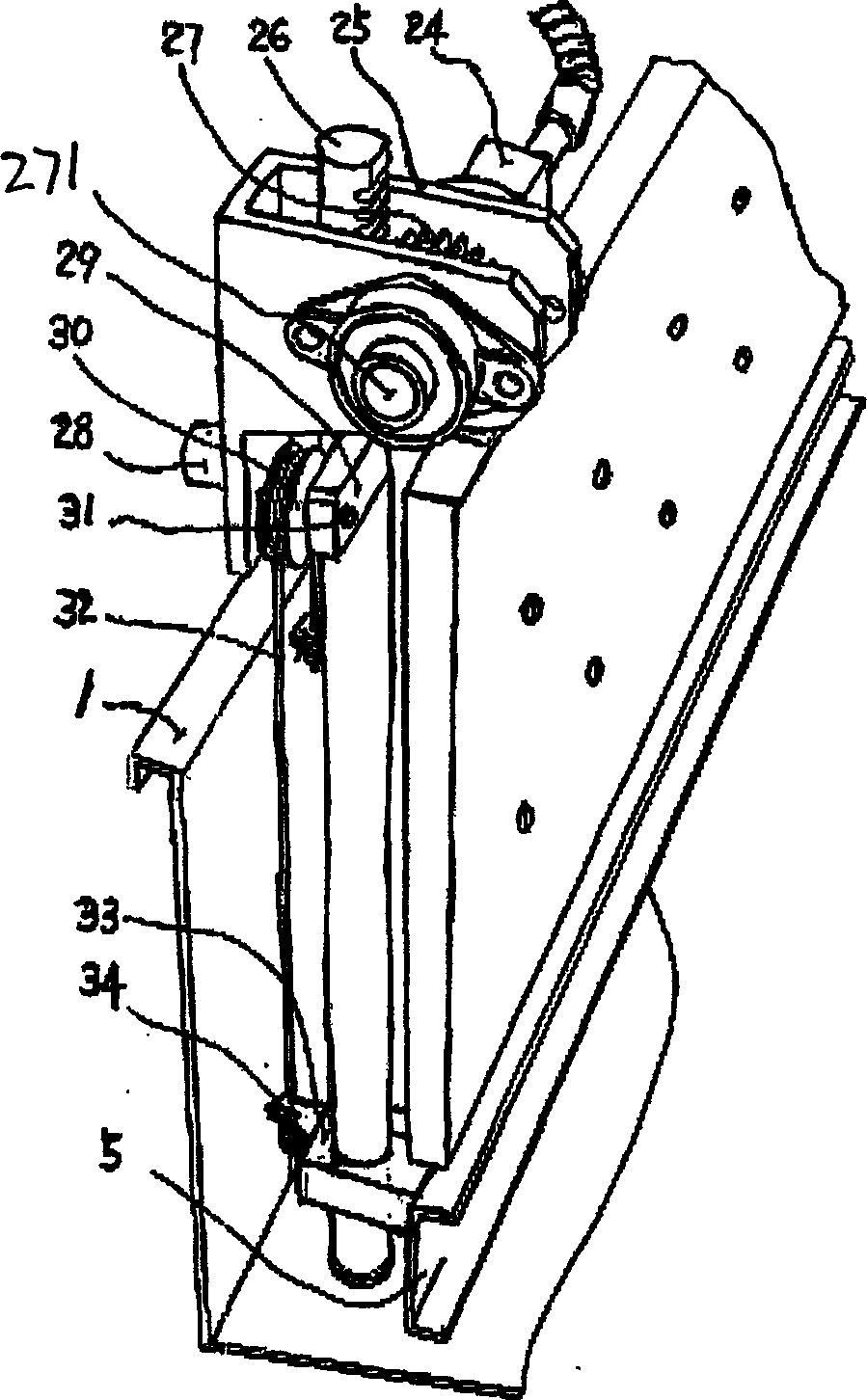

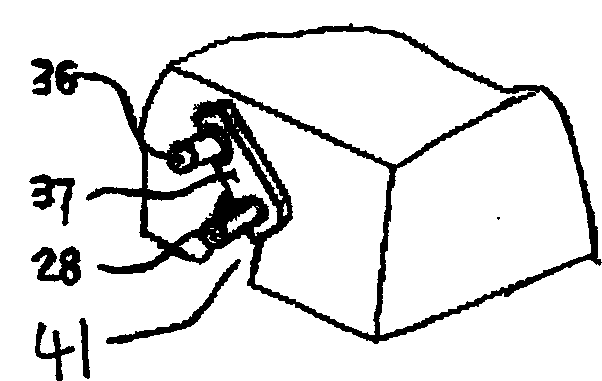

[0015] Embodiment: a conveyor and a cover lifting device of a continuous food heating and cooling conveying device, the upper end of the column 42 of the fixed frame is provided with an integral lifting wheel 51, and the lifting wheel 51 is threaded downwards on the integral lifting wire rope 52, and the overall lifting steel wire rope 52 One end is connected to the rising fixed shaft 36, and the other end of the overall rising steel wire rope 52 is connected to the driving device. It can be hung on the rising connecting shaft 28, and is provided with a rising connecting bracket 25. The rising connecting bracket 25 is on the side above the opening of the water tank 1. The rising connecting shaft 28 is fixed on the left side of the rising connecting bracket 25 facing away from the water tank 1. The rising gear 27 is fixedly sleeved on the rising gear fixed shaft 271, and the two ends of the rising gear fixed shaft 271 are rotatably fixedly connected to the opposite front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com