Patents

Literature

34results about How to "Short changeover times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

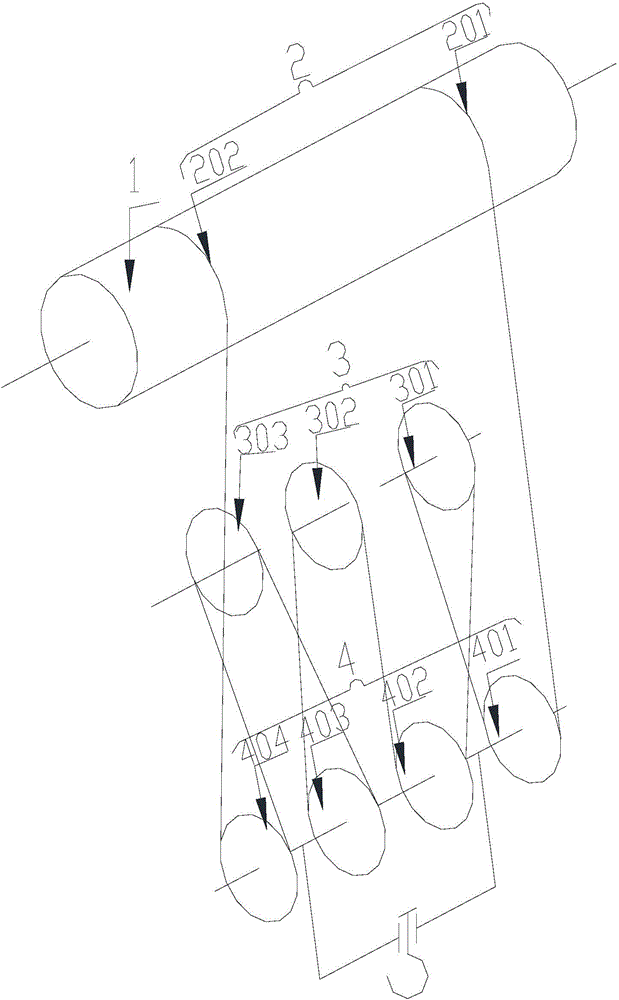

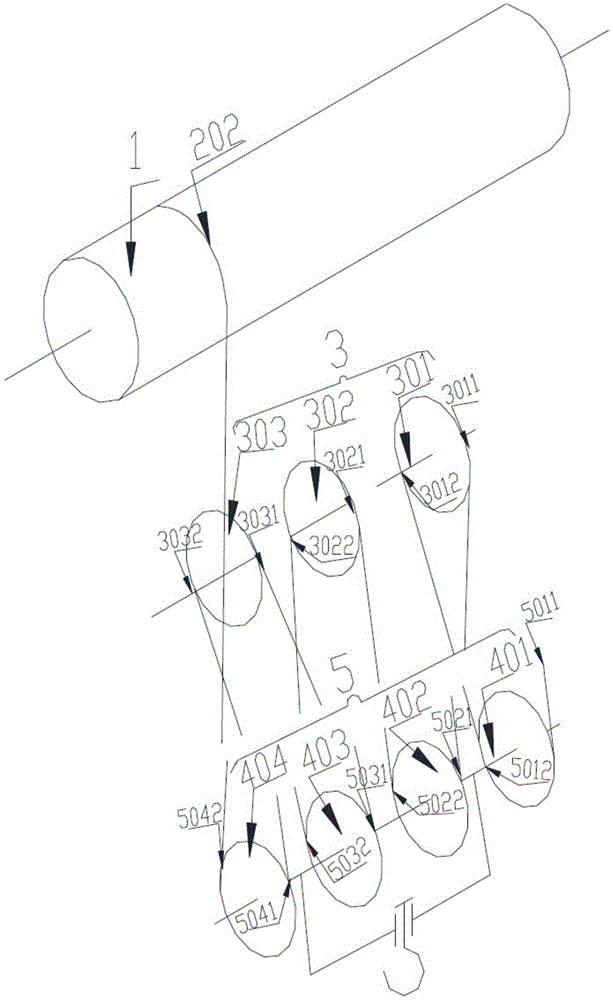

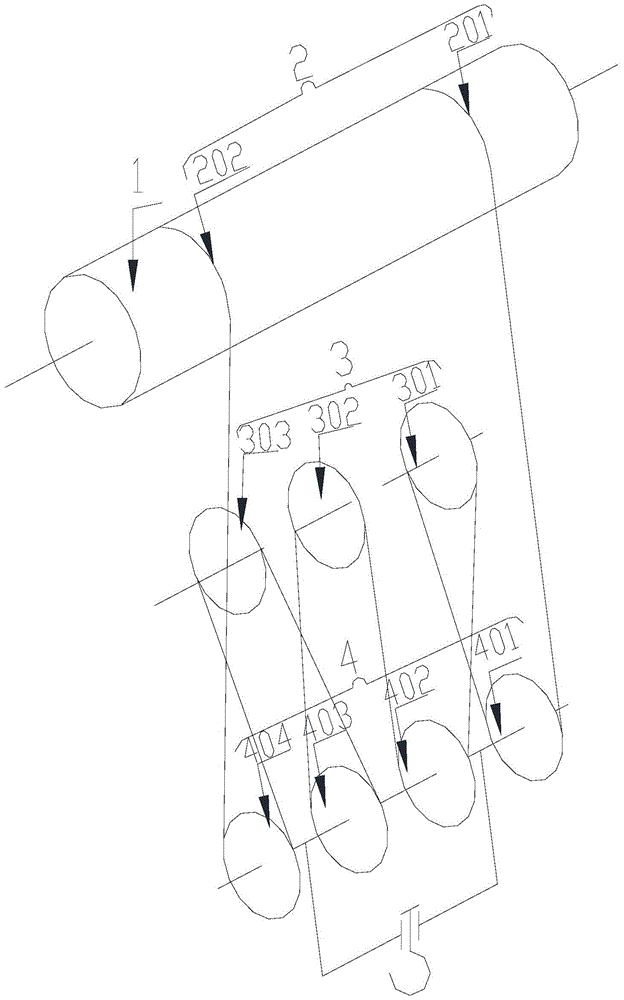

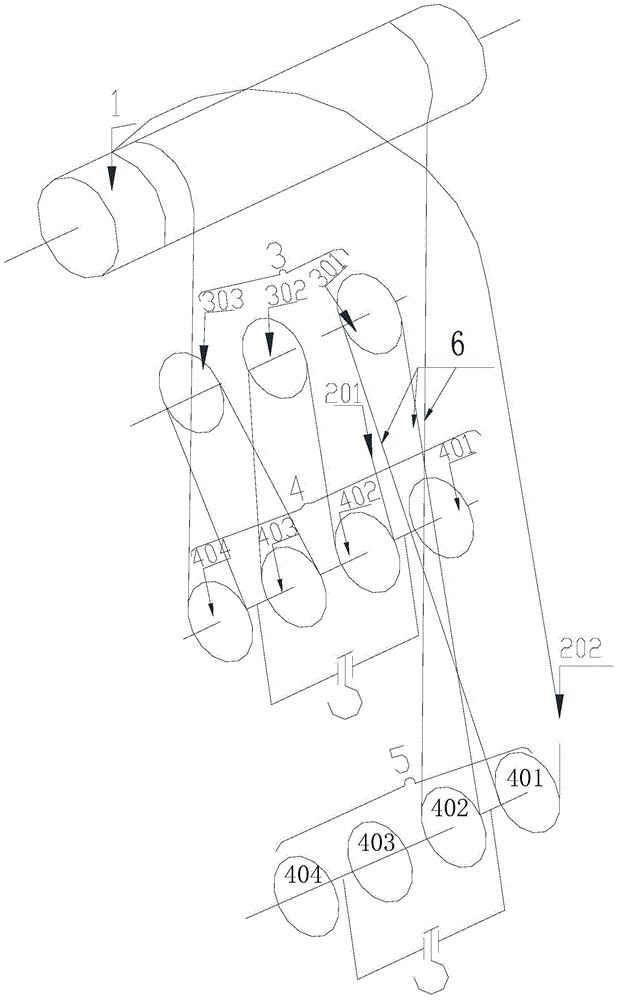

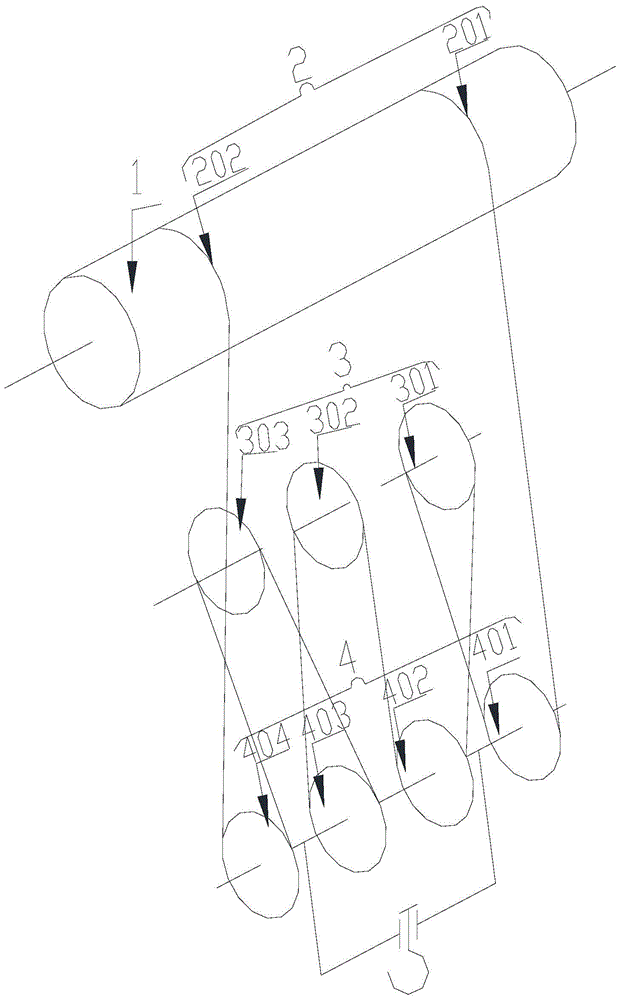

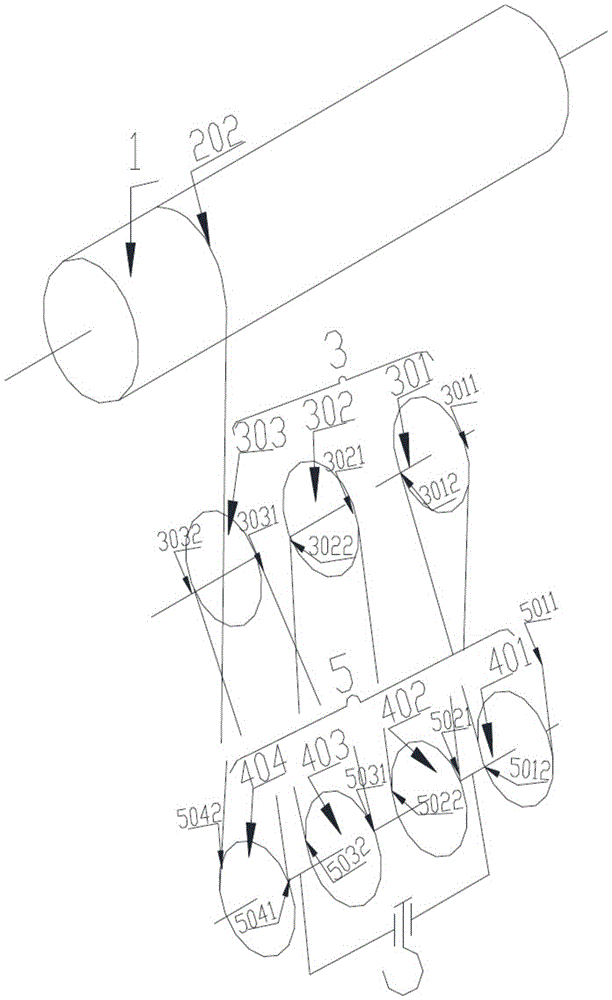

Movable pulley set and wire rope replacing method used for bridge type crane

ActiveCN104828696AReduce workloadShort changeover timesPortable liftingTrolleysBridge typeBlock and tackle

The present invention provides a movable pulley set and wire rope replacing method used for a bridge type crane, according to the method, a plurality of nylon cords are used, one nylon cord is connected between each fixed pulley and each movable pulley, under traction of the nylon cords, a new wire rope is intertwined with a new movable pulley set for completion of movable pulley set and wire rope simultaneous replacing operation of the bridge crane, compared with the movable pulley set and wire rope replacing method used for the bridge type crane in the prior art, the replacing operation time is short, the work intensity is greatly reduced, the workload of workers is reduced, and the working efficiency is improved.

Owner:SHANDONG IRON & STEEL CO LTD

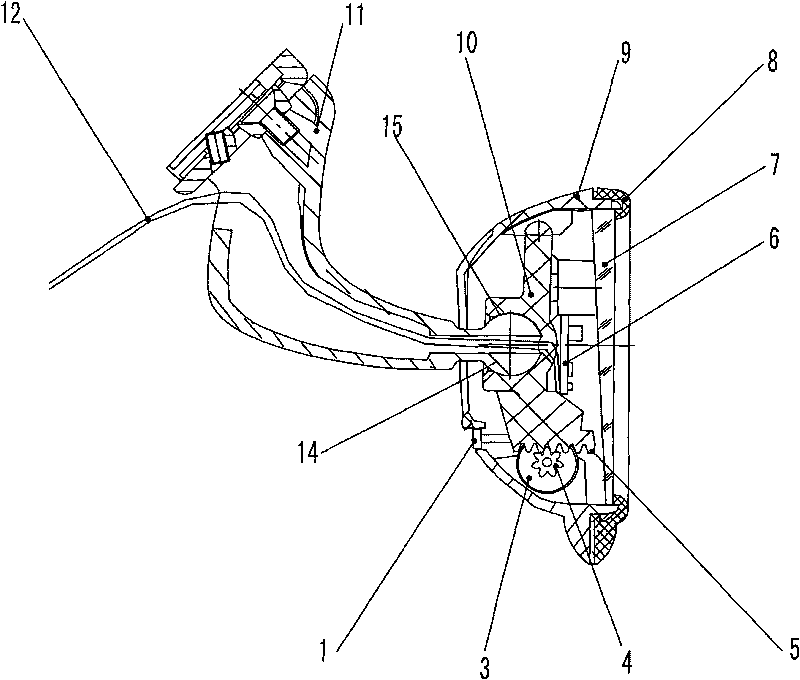

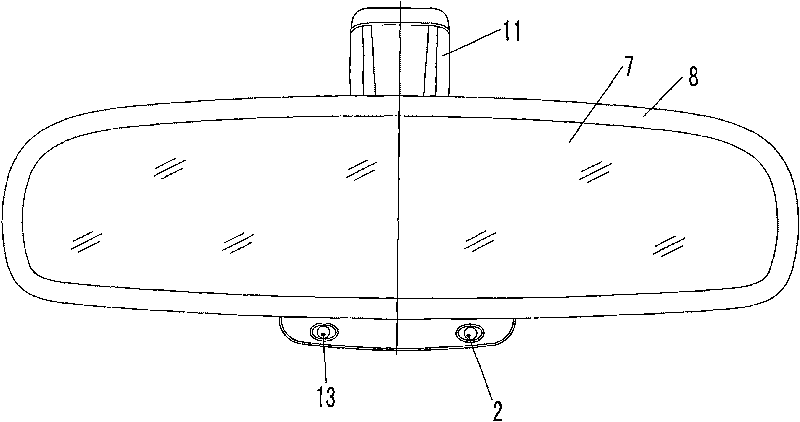

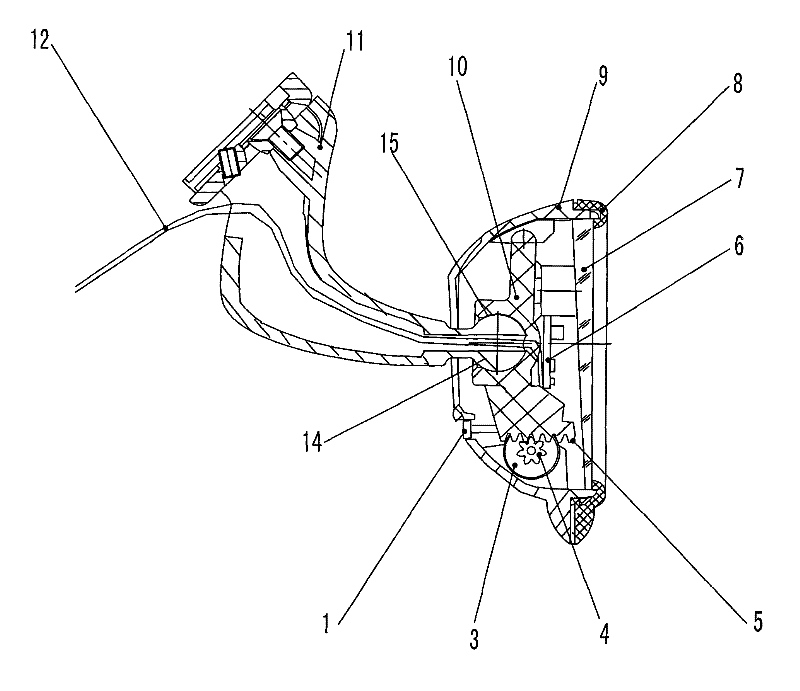

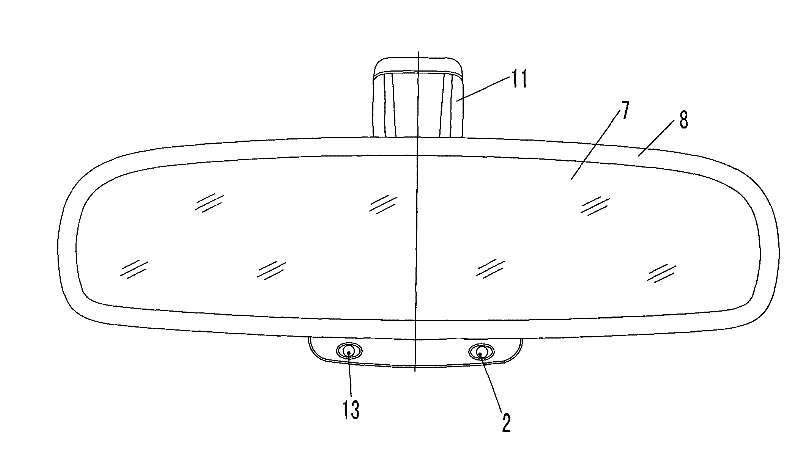

Automatic anti-glare inner rear-view mirror

InactiveCN101716913ANight driving safetyAchieve automatic anti-glare functionMountingsOptical viewingDrive motorEngineering

The invention relates to an automatic anti-glare inner rear-view mirror, comprising a support, a mirror shell, a mirror ring, a lens and a rotating plate mounted on a ball head of the support. The mirror shell is rotarably connected with the rotating plate and is provided with a driving motor and a control circuit module inside. The driving motor drives the mirror shell to overturn the mirror with a certain angle relative to the rotating plate through a transmission plate and further drives the lens to overturn through the mirror ring; the lens is an anti-glare lens and has a second surface with the luminous reflectivity of greater than or equal to 80% and a first surface with the luminous reflectivity of smaller than or equal to 70%. The first surface and the second surface form a bevel of 3.67 degrees; a first photosensor and a second photosensor are respectively arranged on the mirror ring and the mirror shell. When the light from the back of the vehicle irradiates the first photosensor, the control circuit module controls the driving motor so that the mirror on the mirror shell on the second surface as a reflective surface automatically turns to the first glass surface as the reflective surface through the transmission mechanism, therefore, the reflectivity is overturned from the one greater than or equal to 80% to the one smaller than or equal to 70%, thereby realizing the automatic anti-glare function.

Owner:上海久真汽车配件有限公司

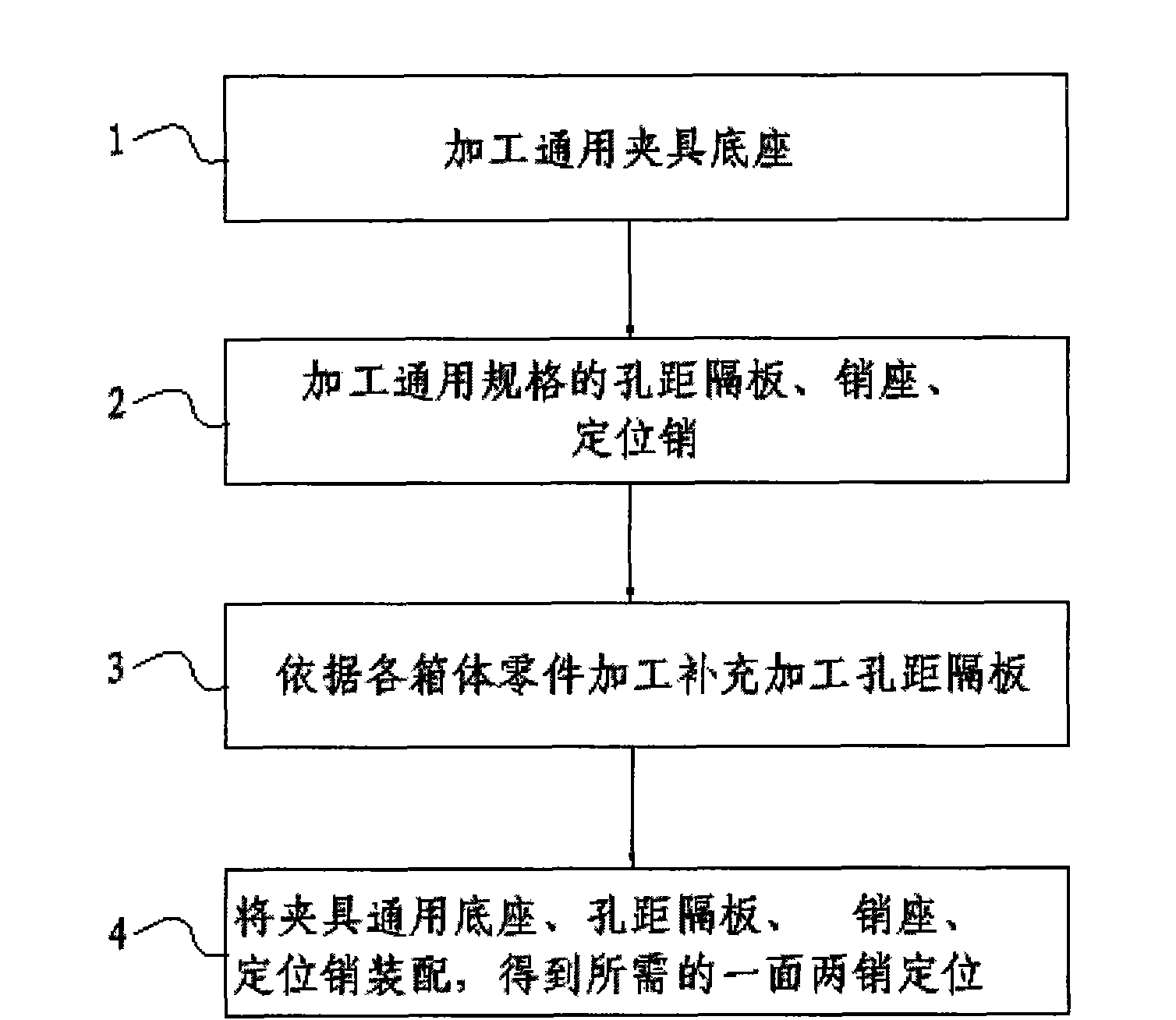

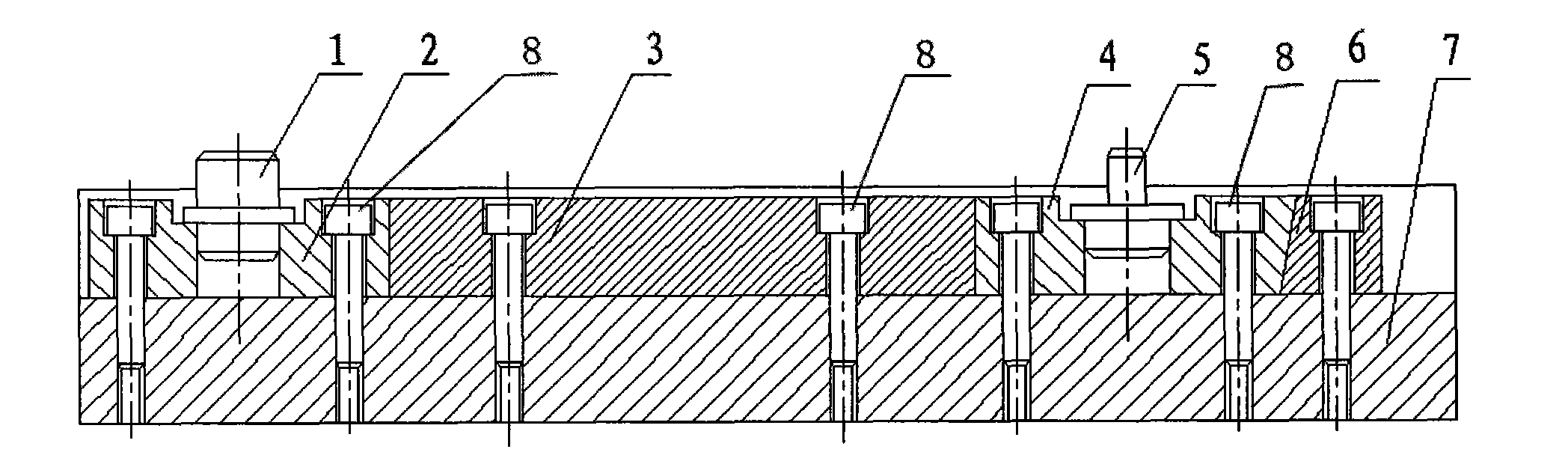

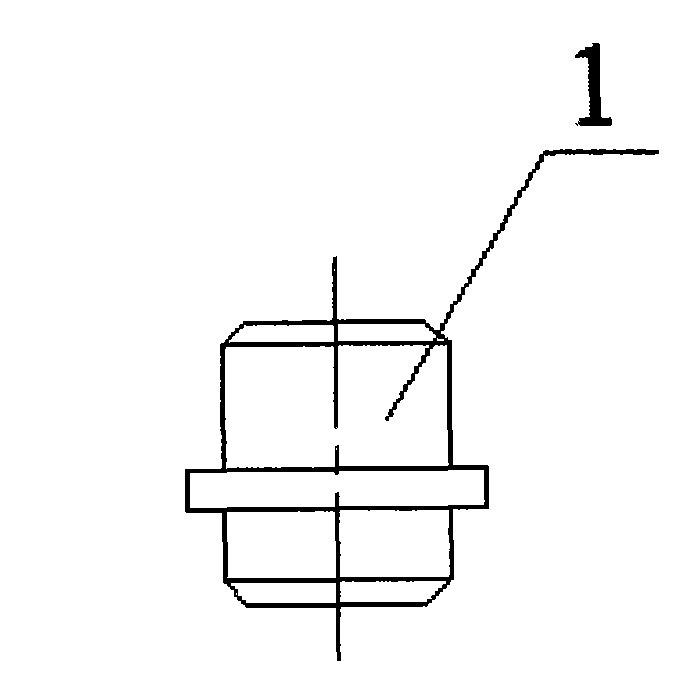

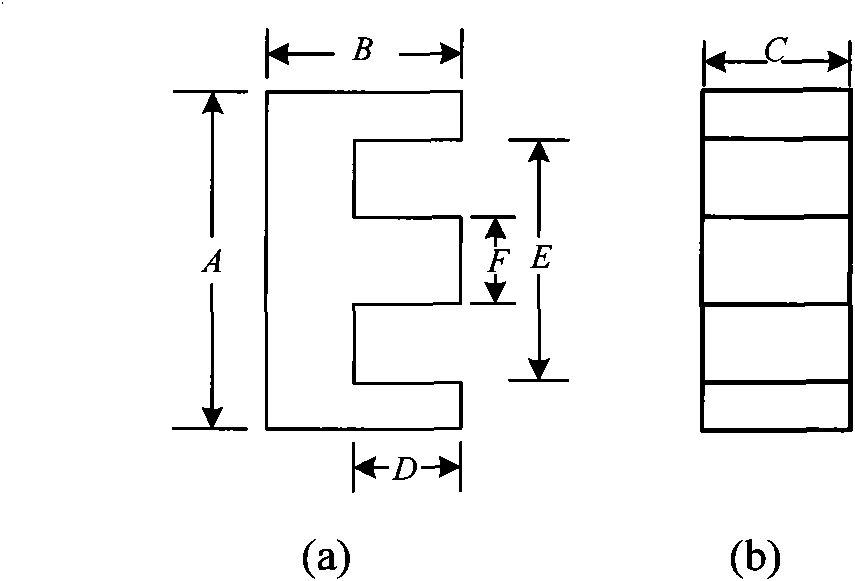

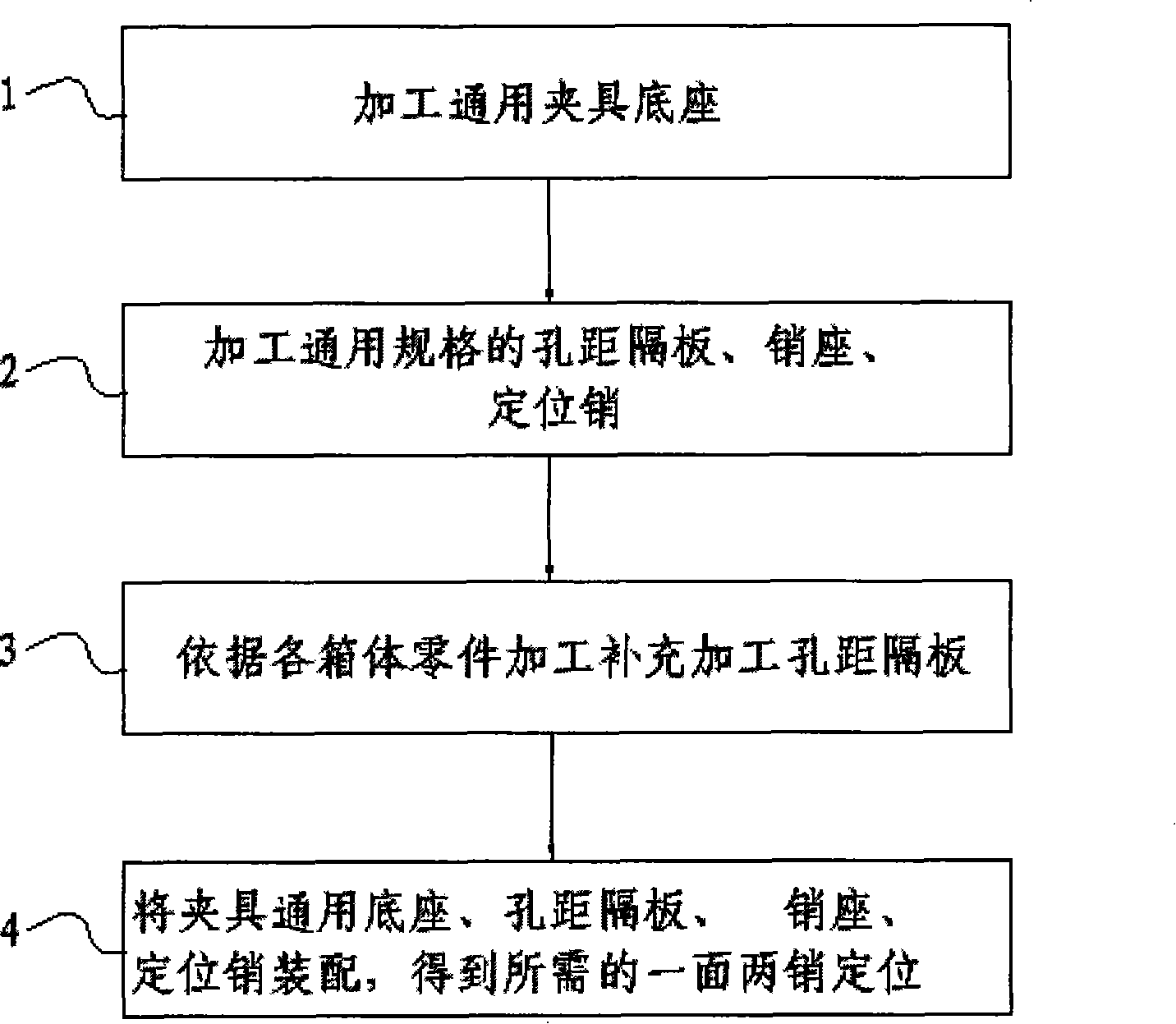

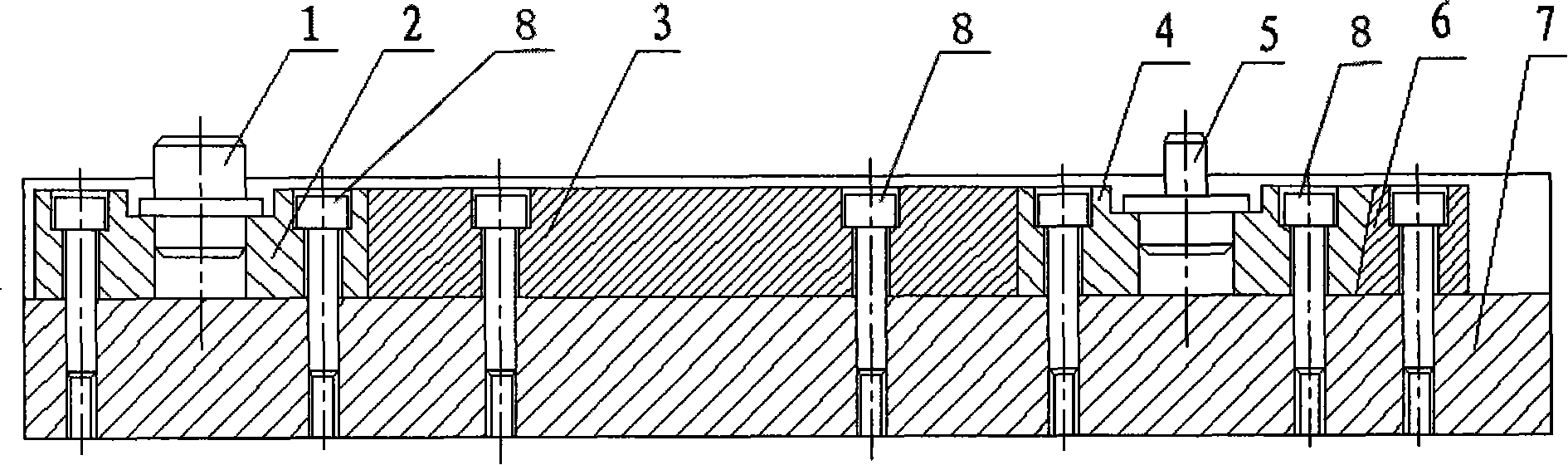

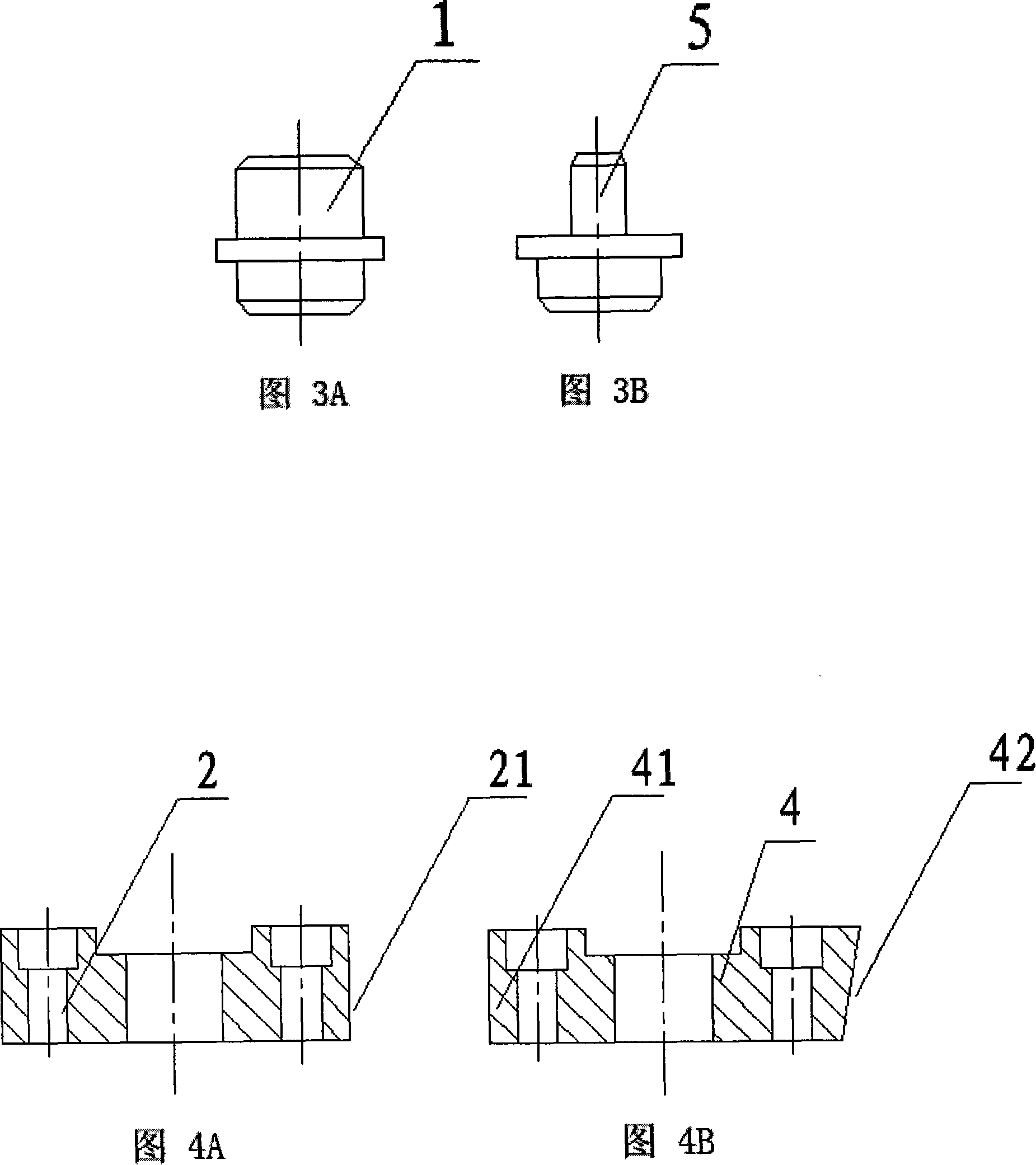

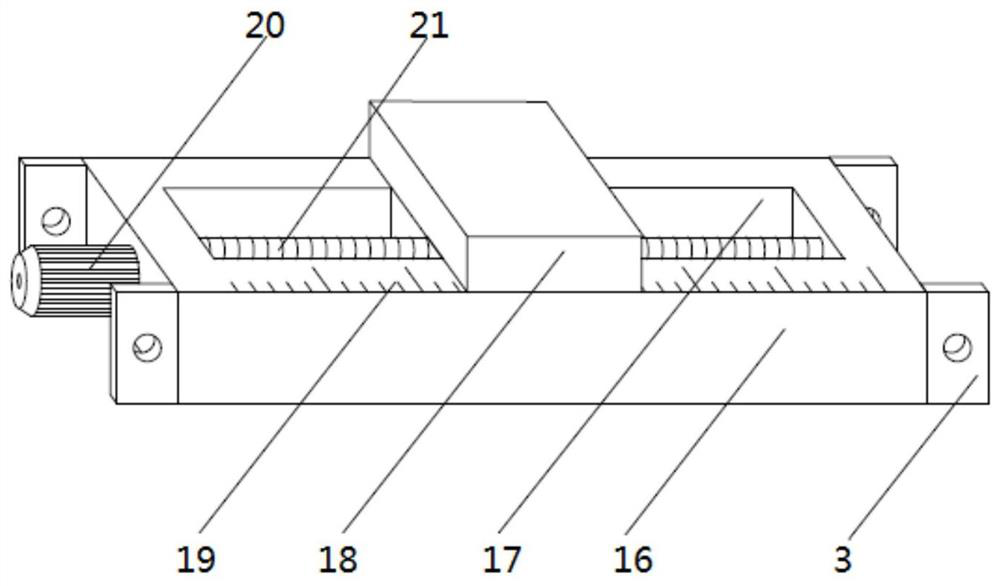

Clamp with one surface and two pins and manufacture method thereof

ActiveCN101602168ASmall changeover investmentShort changeover timesPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a clamp with one surface and two pins and a manufacture method thereof. The method comprises the following steps: processing a clamp base; processing a pitch clapboard, a first pin hole seat, a second pin hole seat and a locating pin; additionally processing grid spacers according to the sizes of parts of each box body; and assembling the clamp base, the pitch clapboard, the pin hole seats and the locating pin to obtain the clamp with one surface and two pins. The method rapidly obtains a needed locating datum by the additional processing of the pitch clapboard. Compared with the traditional method in which one base is manufactured by using variety of box-type parts, the invention has the characteristics of little investment, simple and effective technology, flexible type change, and the like, on the condition of meeting the requirement of the product, thereby being suitable for production of box-type parts of various specifications.

Owner:GUANGXI YUCHAI MASCH CO LTD

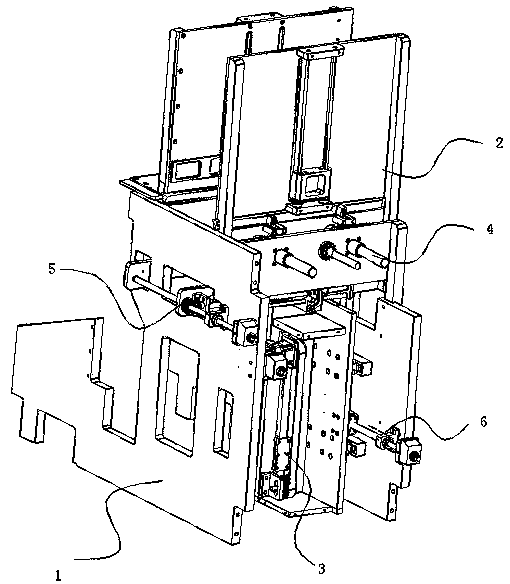

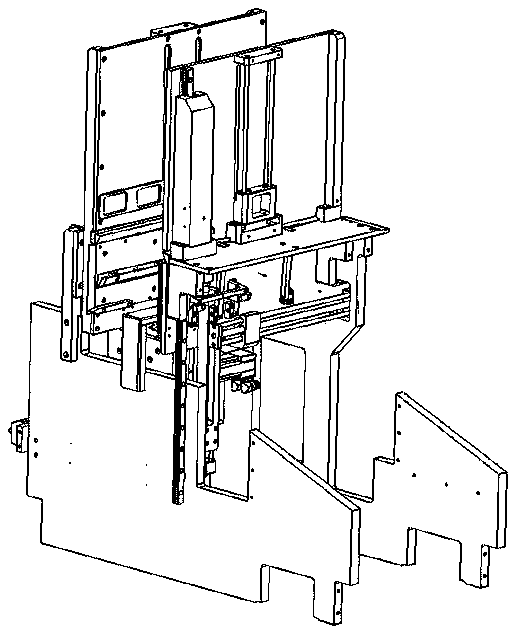

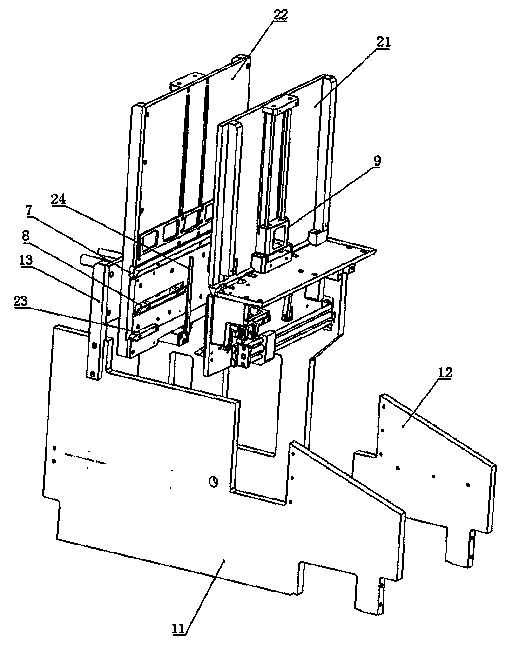

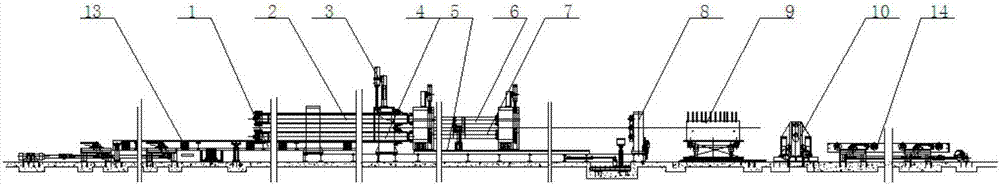

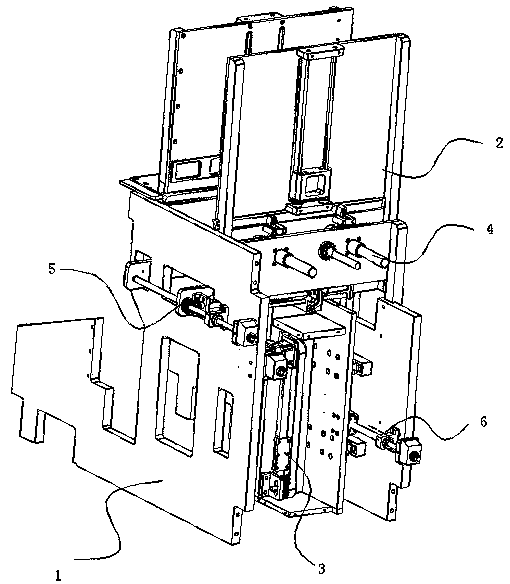

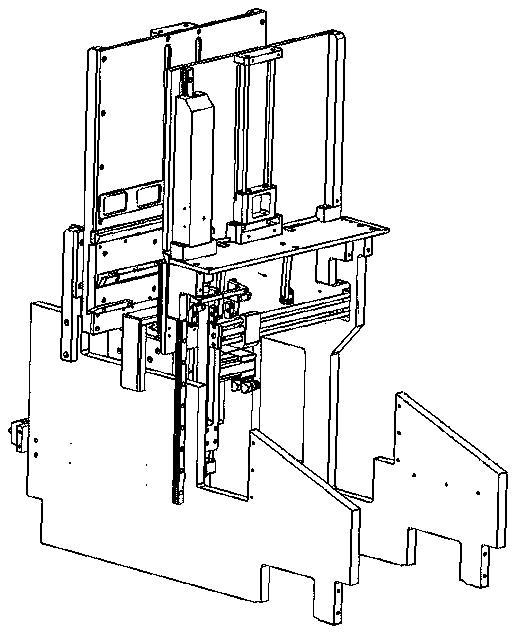

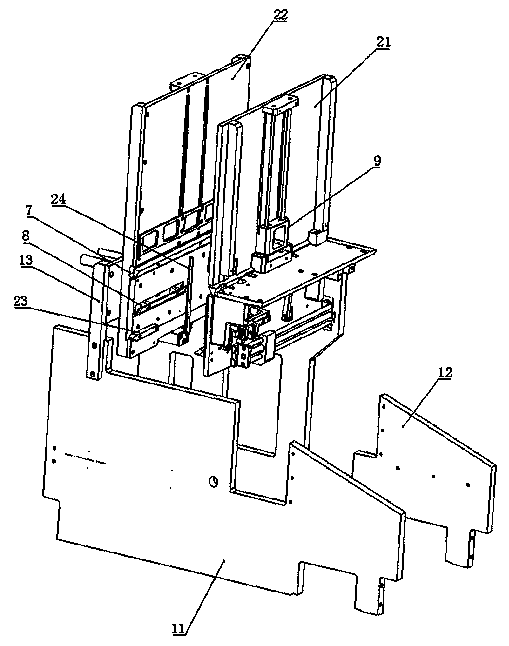

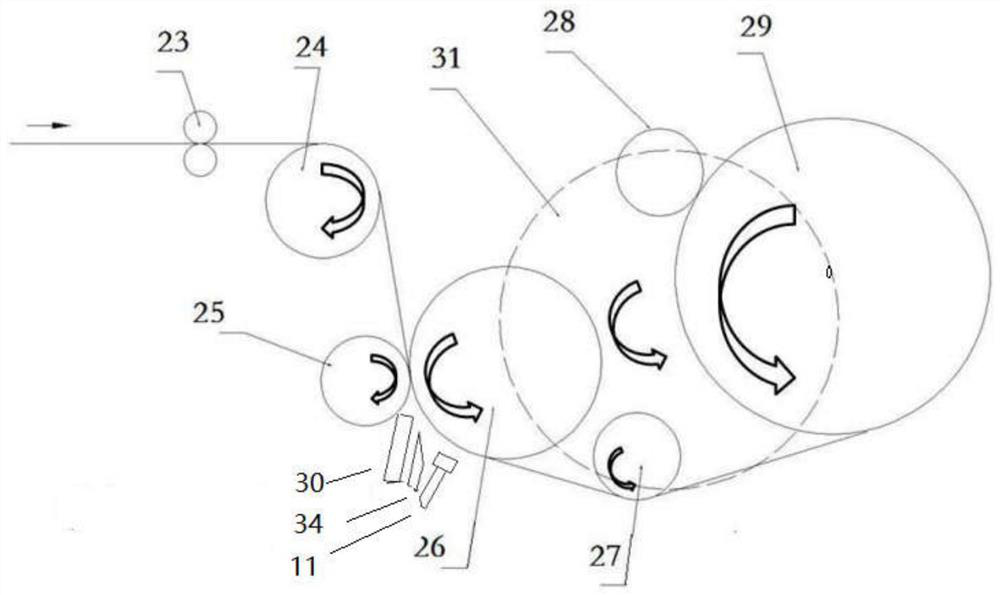

Box filler double-channel stacking system

ActiveCN103523272AReduce ascent heightDoes not affect speedPackagingStacking articlesClassical mechanicsStructural engineering

The invention relates to a box filler double-channel stacking system which is characterized in that a machine frame is included, a stacking mechanism is arranged at the upper end of the machine frame, a jacking mechanism is arranged in the machine frame, the stacking mechanism is arranged at the upper end of the machine frame and comprises a pair of first blocking plate and second blocking plate, the first blocking plate and the second blocking plate are parallel to each other and are vertically arranged, a stacking zone is formed between the first blocking plate and the second blocking plate, a single-direction bearing component is arranged in the middle of the stacking zone, at least one middle buffering mechanism placed below the single-direction bearing component is arranged in the middle of the stacking zone, and starting of the middle buffering mechanism can be controlled by an action air cylinder. The middle-transition middle buffering mechanism is added and is started or closed correspondingly according to the size of a product, then the lifting height of a jacking pushing plate is lowered, stacking efficiency is improved, and accordingly the system can meet the requirements for box filling of products of different sizes, and the speed of a whole line cannot be affected.

Owner:NANTONG UNIVERSAL MACHINERY

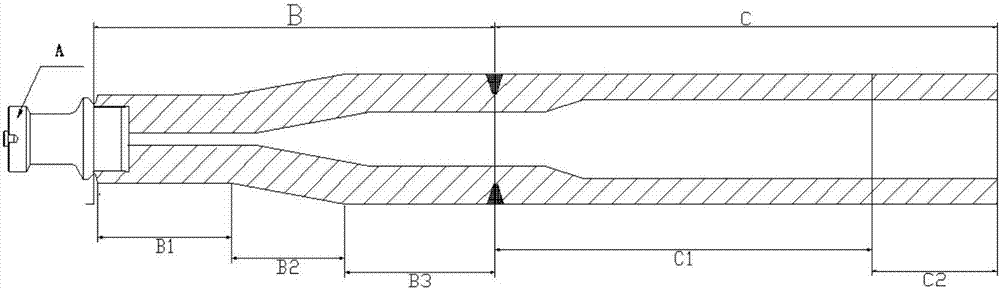

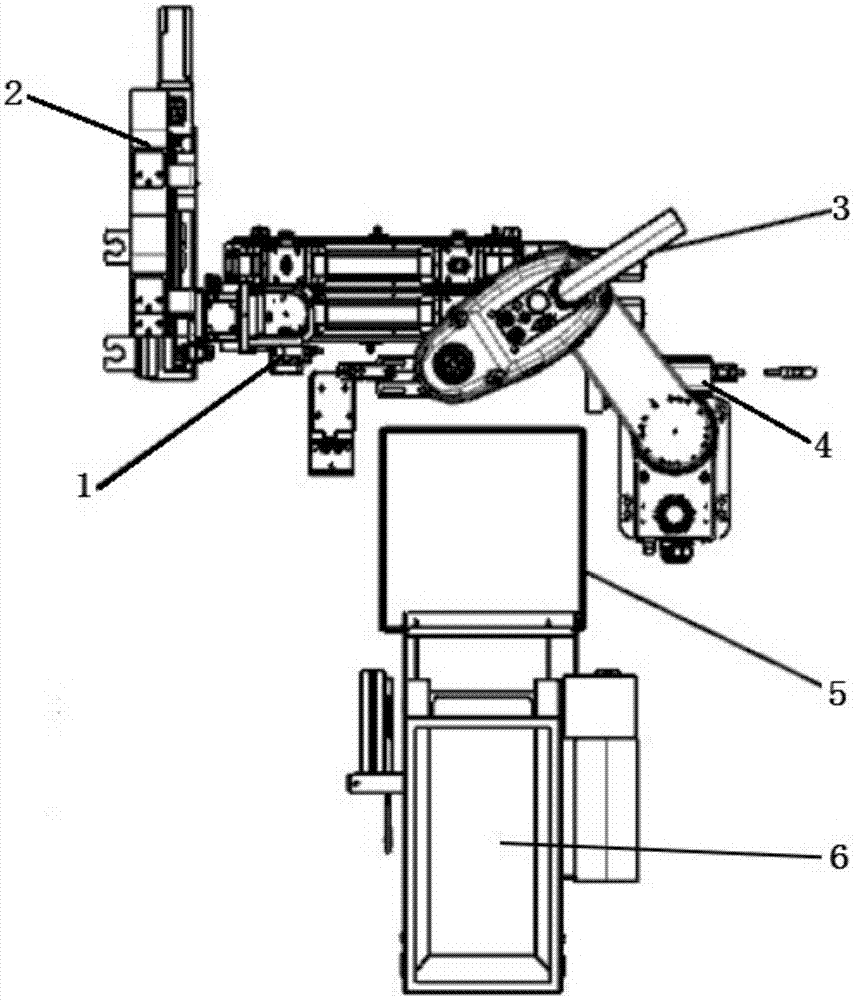

Two-step push type external expander of large-caliber seamless steel pipe and thermal expanding process for two-step push type external expander

InactiveCN106914554AFast and even controllable heatingUniform and controllable heatingShaping toolsMetal-working feeding devicesHydraulic cylinderMedium frequency

The invention discloses a two-step push type external expander of a large-caliber seamless steel pipe. The two-step push type external expander comprises a base and a drawbar, wherein a to-be-pushed steel tube sleeves outside one end of the drawbar; the other end of the drawbar is equipped with a pushing core rod; a feeding roller path for conveying the steel tube is arranged on the base; a hydraulic lifting gate plate capable of vertically lifting is arranged on the feeding roller path; and the hydraulic lifting gate plate can descend, jack and push the steel tube to horizontally convey to a medium-frequency induction heating coil. According to the two-step push type external expander disclosed by the invention, length of a hydraulic cylinder can be reduced nearly a half through two-step push, so that equipment manufacturing cost is reduced, length limitation of oil cylinder processing is solved from the process, raw materials are be quickly and uniformly heated in a controllable mode by the medium-frequency heating equipment, the raw materials can be pushed and deformed at constant speed, and performance uniformity of the tube body can be guaranteed. According to the thermal expander and the process thereof, the investment is less, the equipment is simple, the construction period is short, the product quality is good, the geometric accuracy is high, the yield is high, the energy consumption is low, and pollution is avoided.

Owner:浙江卓业能源装备有限公司

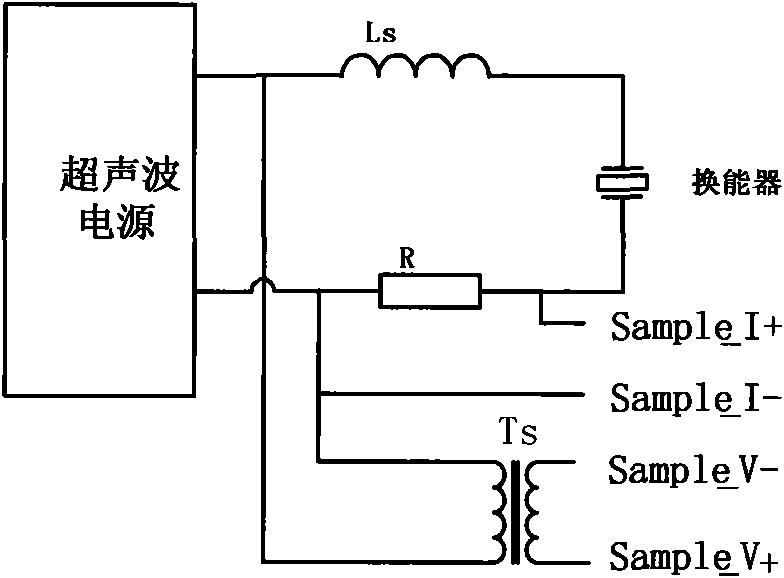

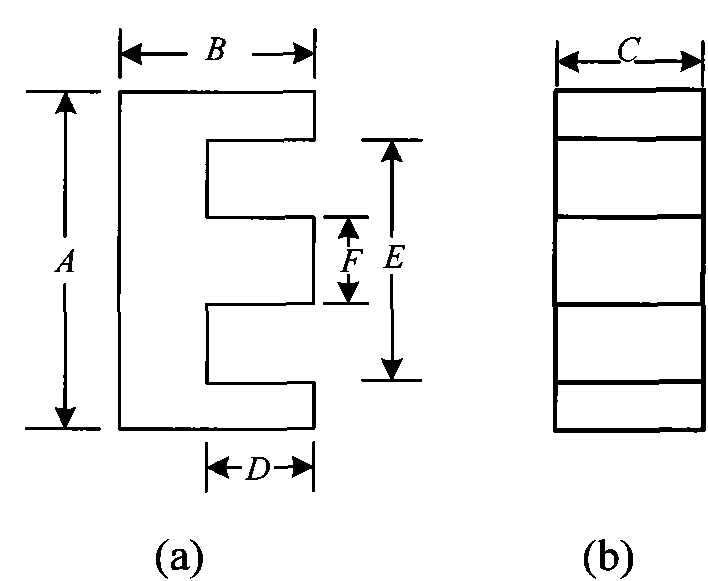

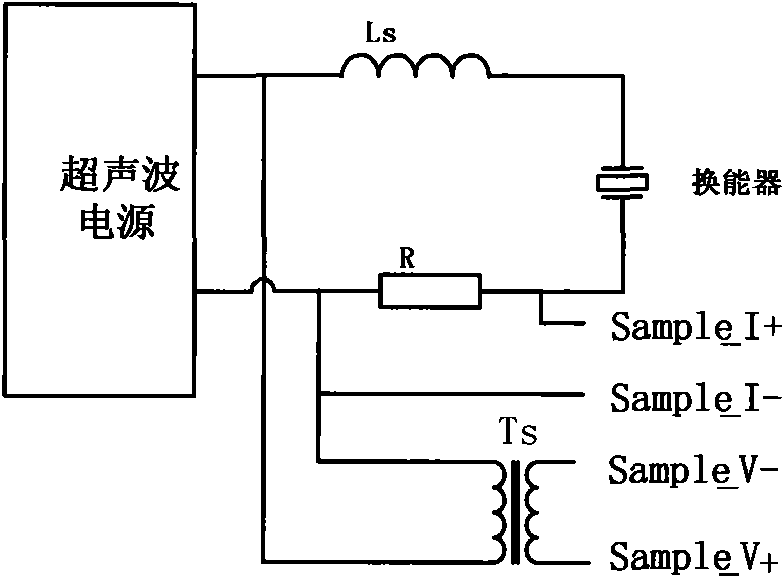

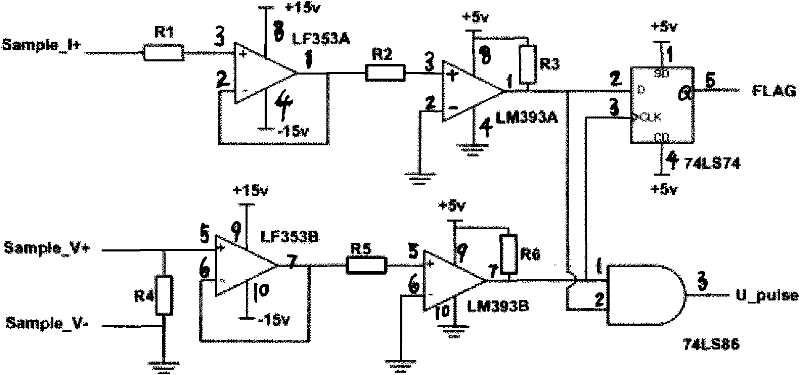

Ultrasonic power system based on high frequency transformer feedback

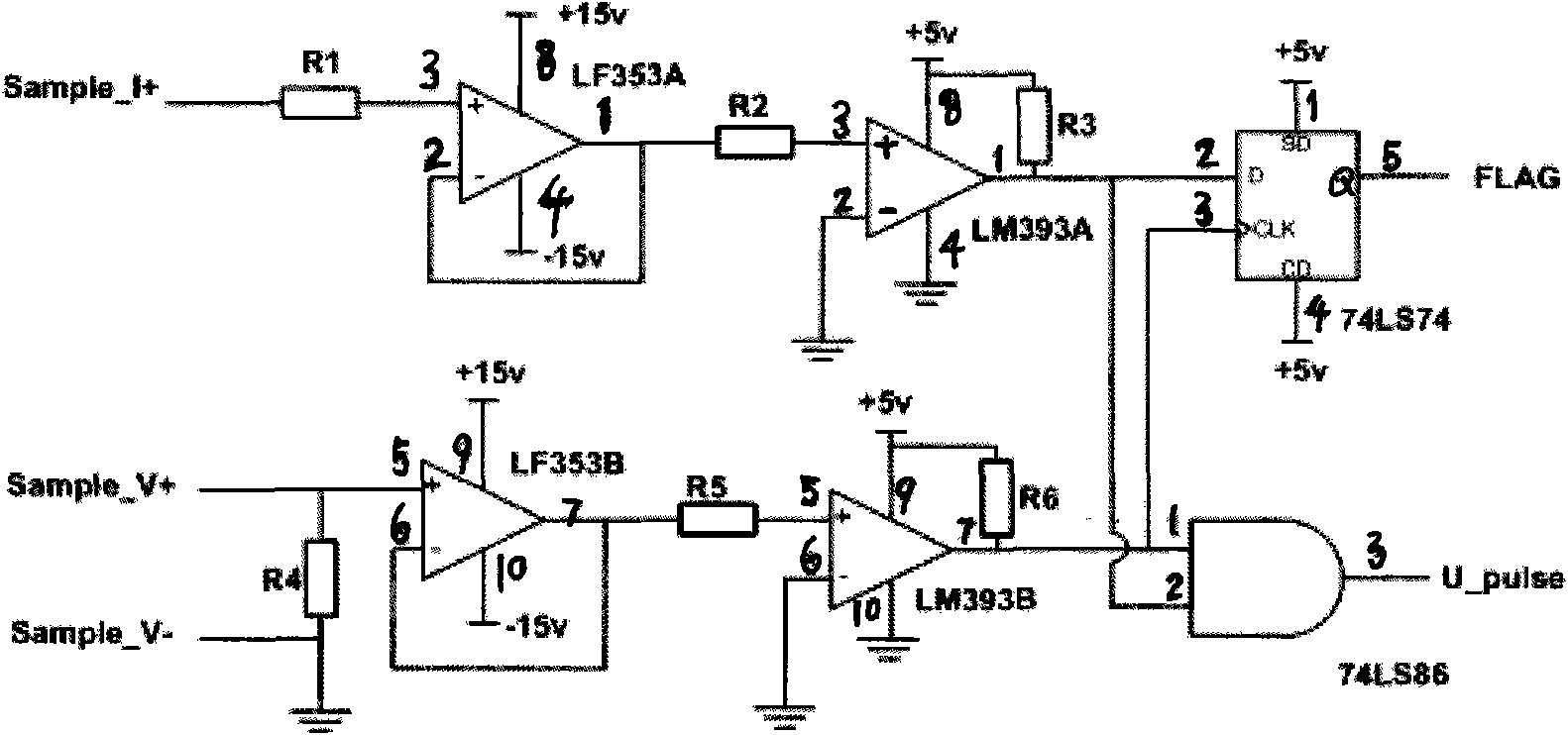

InactiveCN101640487AShort changeover timesEliminate delaysConversion without intermediate conversion to dcTransformers/inductances magnetic coresDiscriminatorUltrasonic sensor

The invention discloses an ultrasonic power system based on high frequency transformer feedback, comprising an ultrasonic power, a matching inductor, an ultrasonic transducer, a non-inductive resistance, a high frequency pulse transformer, a phase discriminator and a DSP, wherein one output end of the ultrasonic power is connected with the matching inductor and the transducer in series in order and then is connected with one end of the non-inductive resistance and an end of a phase discrimination circuit resistance R1 respectively; the other end of the non-inductive resistance is connected with the other output end of the ultrasonic power; the output signal of the phase discrimination circuit is connected with the DSP; a primary terminal of the high frequency pulse transformer is connectedwith the output end of the ultrasonic power, one end of a secondary terminal of the high frequency pulse transformer is connected with one end of a phase discrimination circuit resistance R4 and theground, and the other end of the secondary terminal of the high frequency pulse transformer is connected with the other end of the phase discrimination circuit resistance R4 and a 5th pin of an operation amplifier. The ultrasonic power system solves the problem of response delay in voltage phase measurement and reduces system error; and compared with a sensor, the high frequency transformer in thesystem has the advantages of small volume, light weight and low price.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

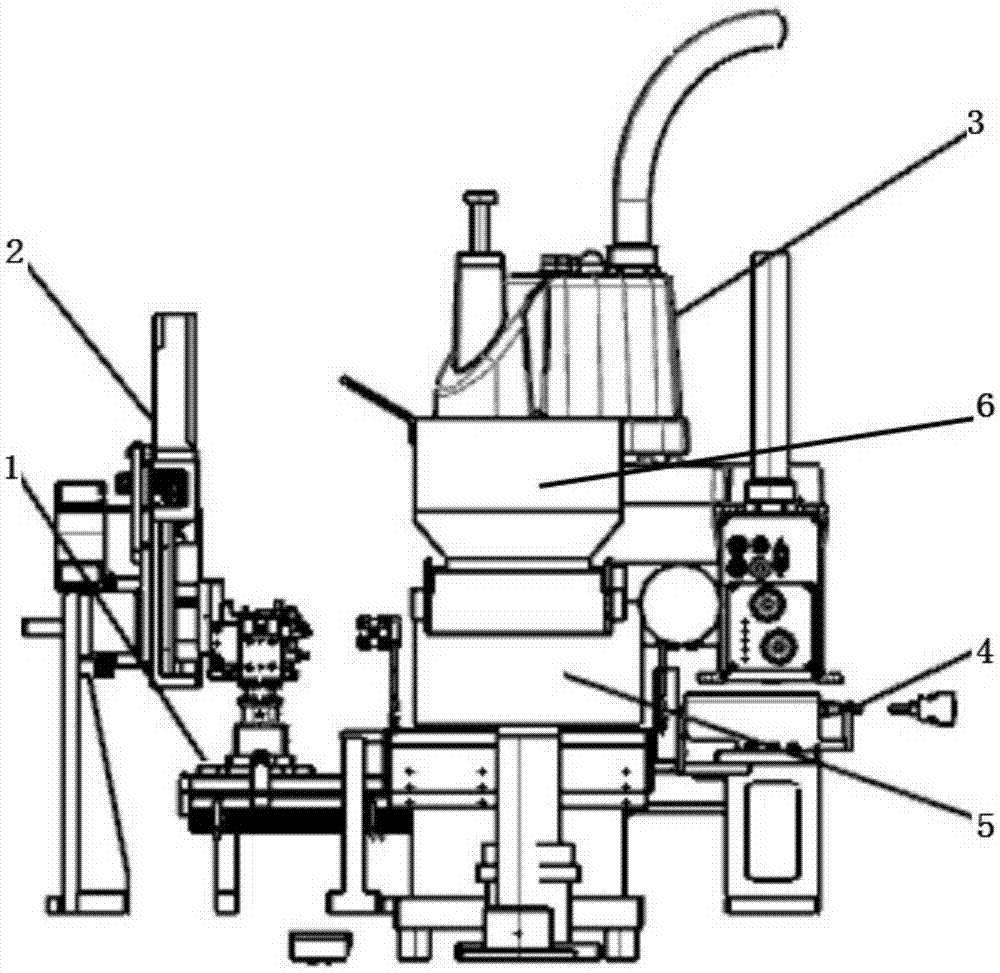

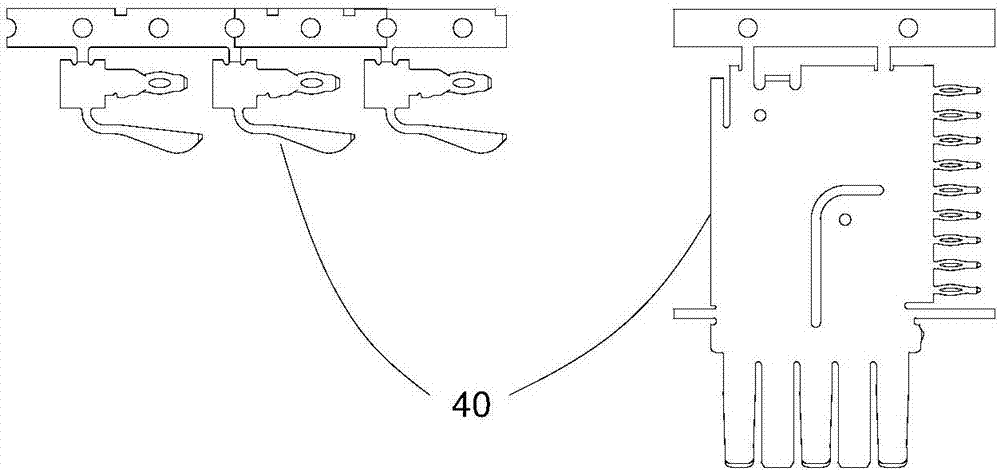

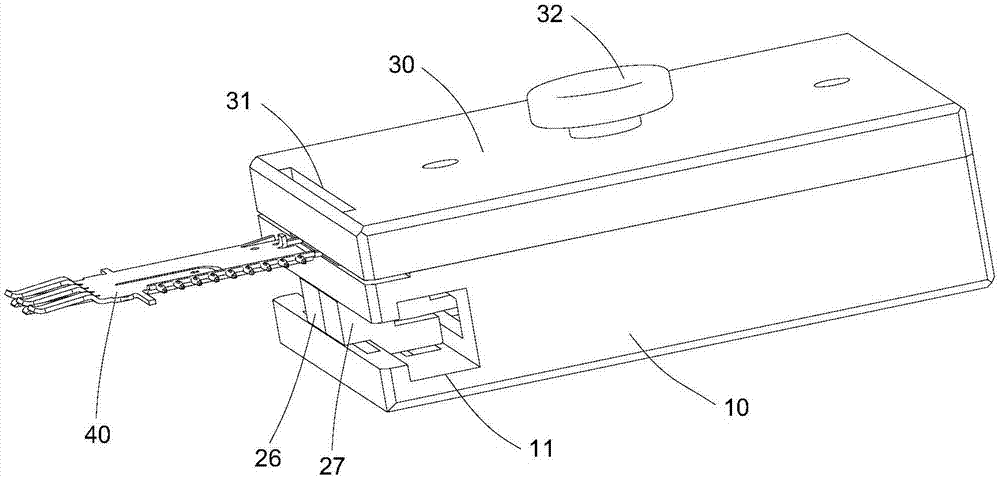

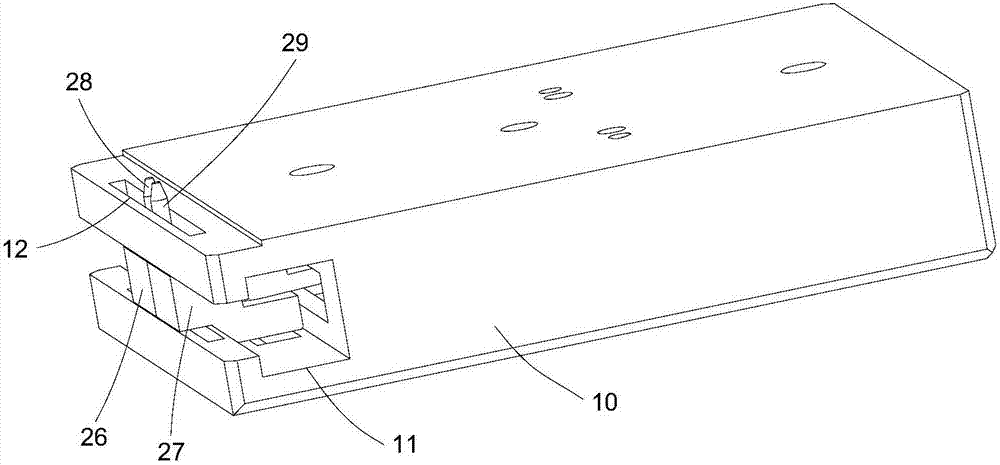

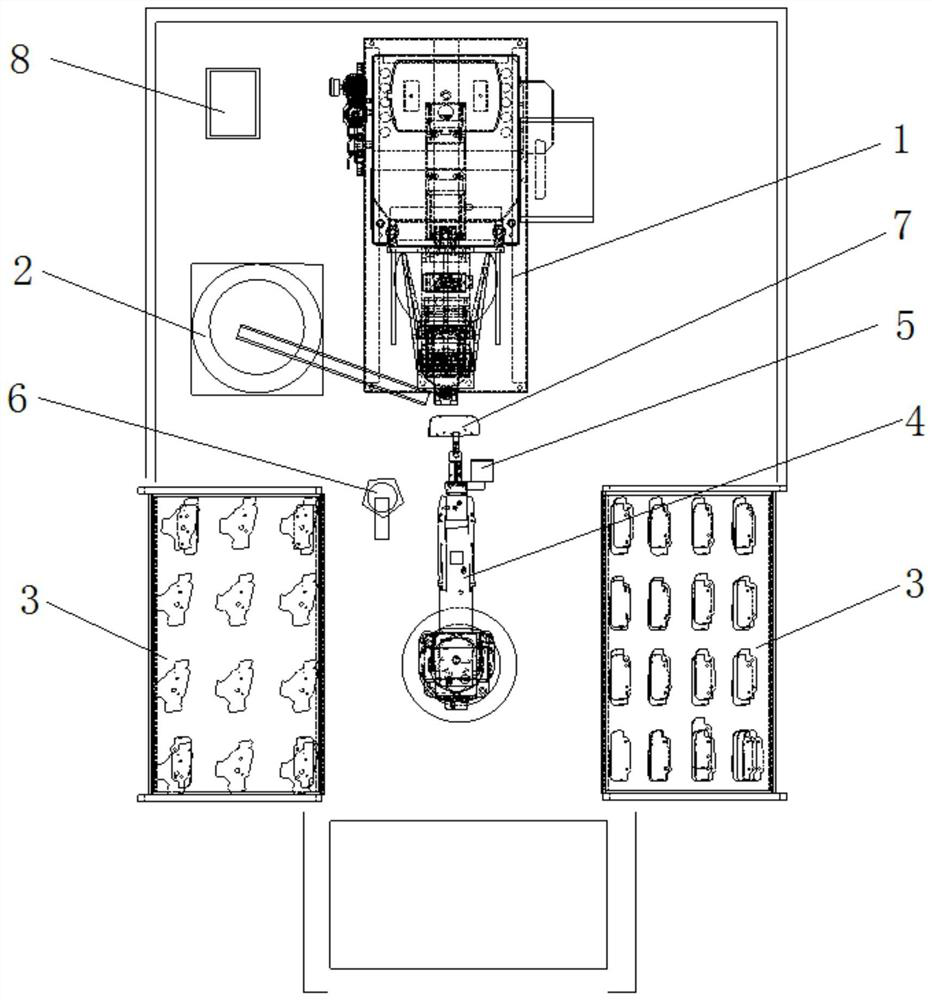

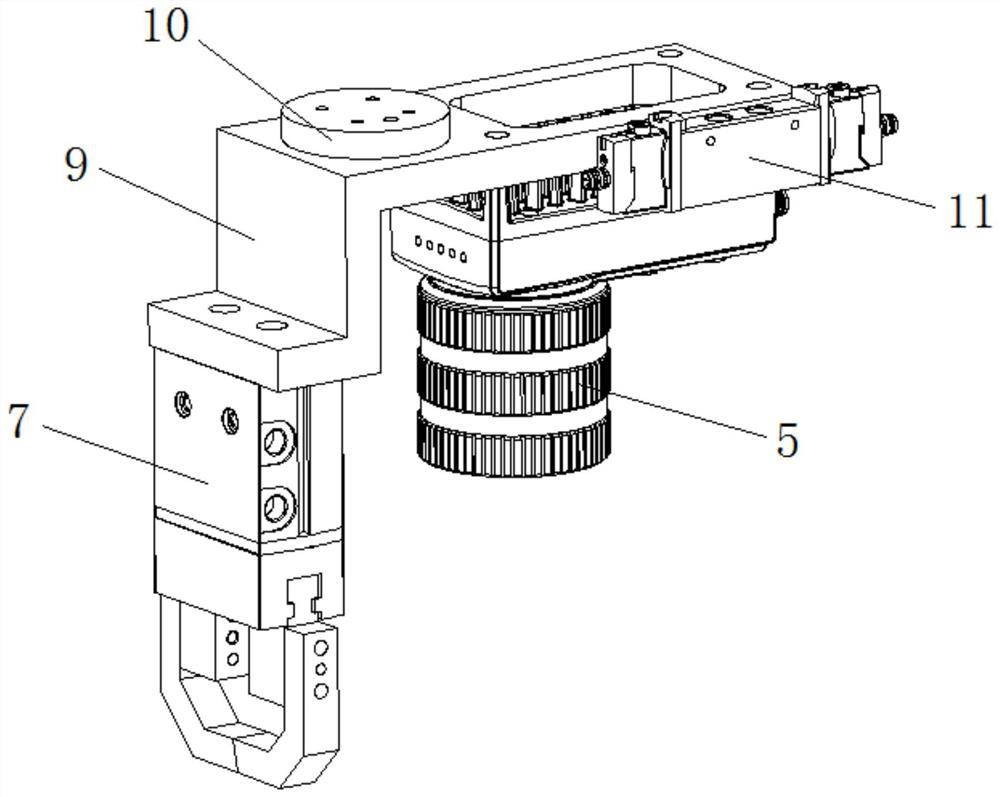

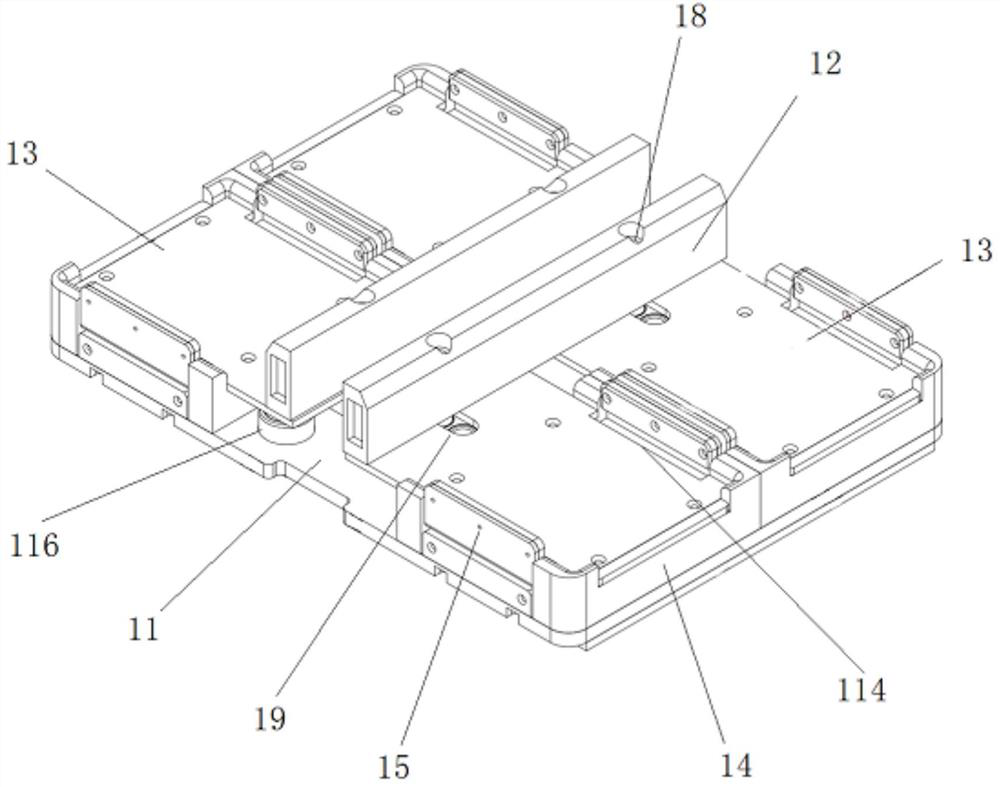

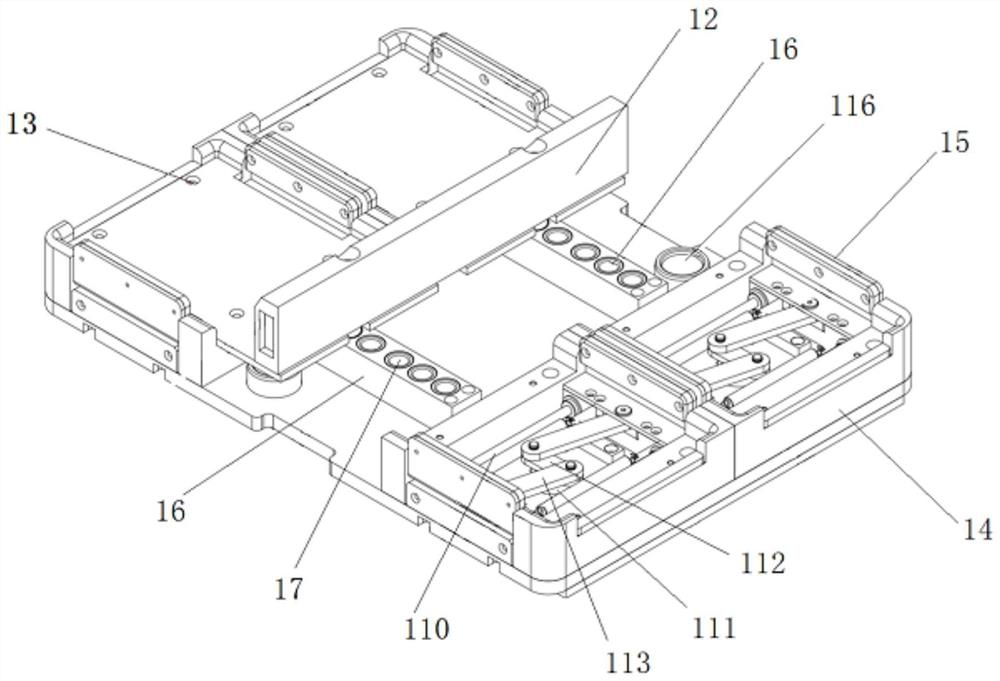

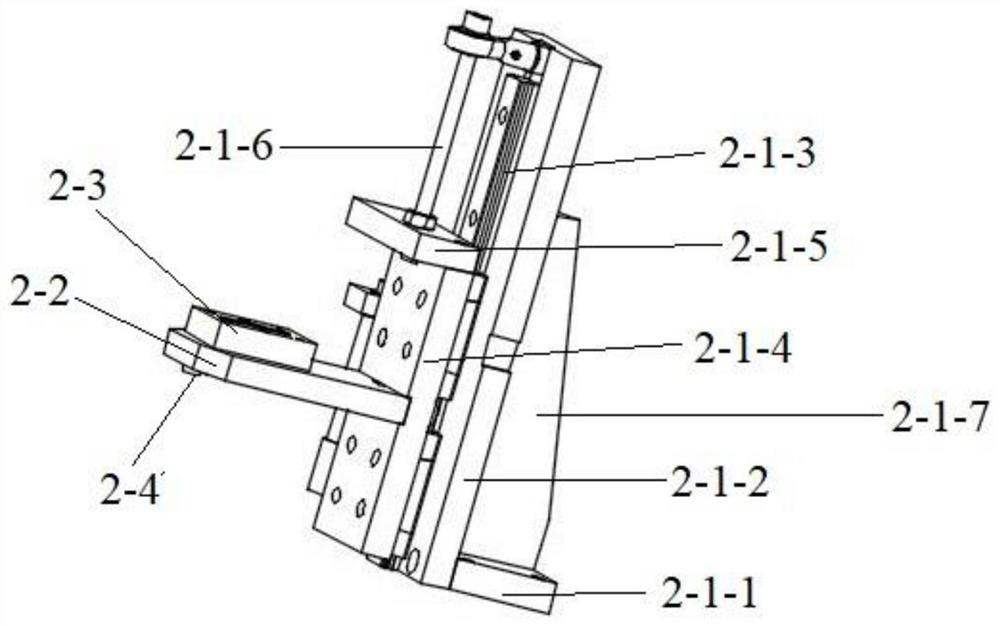

Flexible feeding system for assembling connector

PendingCN106925964AGuaranteed stabilityGuaranteed continuityMetal working apparatusElectrical controlEngineering

The invention relates to a flexible feeding system for assembling a connector. The system comprises a feeding elevator, a feeding vibration unit arranged on one side of the feeding elevator, a grabbing mechanical arm, a vision image unit, a feeding transfer unit, an assembling robot and an electric control cabinet, wherein the grabbing mechanical arm and the vision image unit are used in cooperation with the feeding vibration unit, the feeding transfer unit is arranged below the grabbing mechanical arm, the assembling robot is used in cooperation with the feeding transfer unit, and the electric control cabinet is electrically connected with the feeding elevator, the feeding vibration unit, the vision image unit, the grabbing mechanical arm, the feeding transfer unit and the assembling robot. Compared with the prior art, the flexible feeding system is simple and compact in structure, convenient and fast to operate, economical, practical, high in automation degree and flexible and convenient to produce and use; and wire replacing is convenient and fast, and the conveying efficiency of materials for assembling the connector can be effectively improved.

Owner:DELPHI ELECTRICAL CENTS SHANGHAI CO LTD

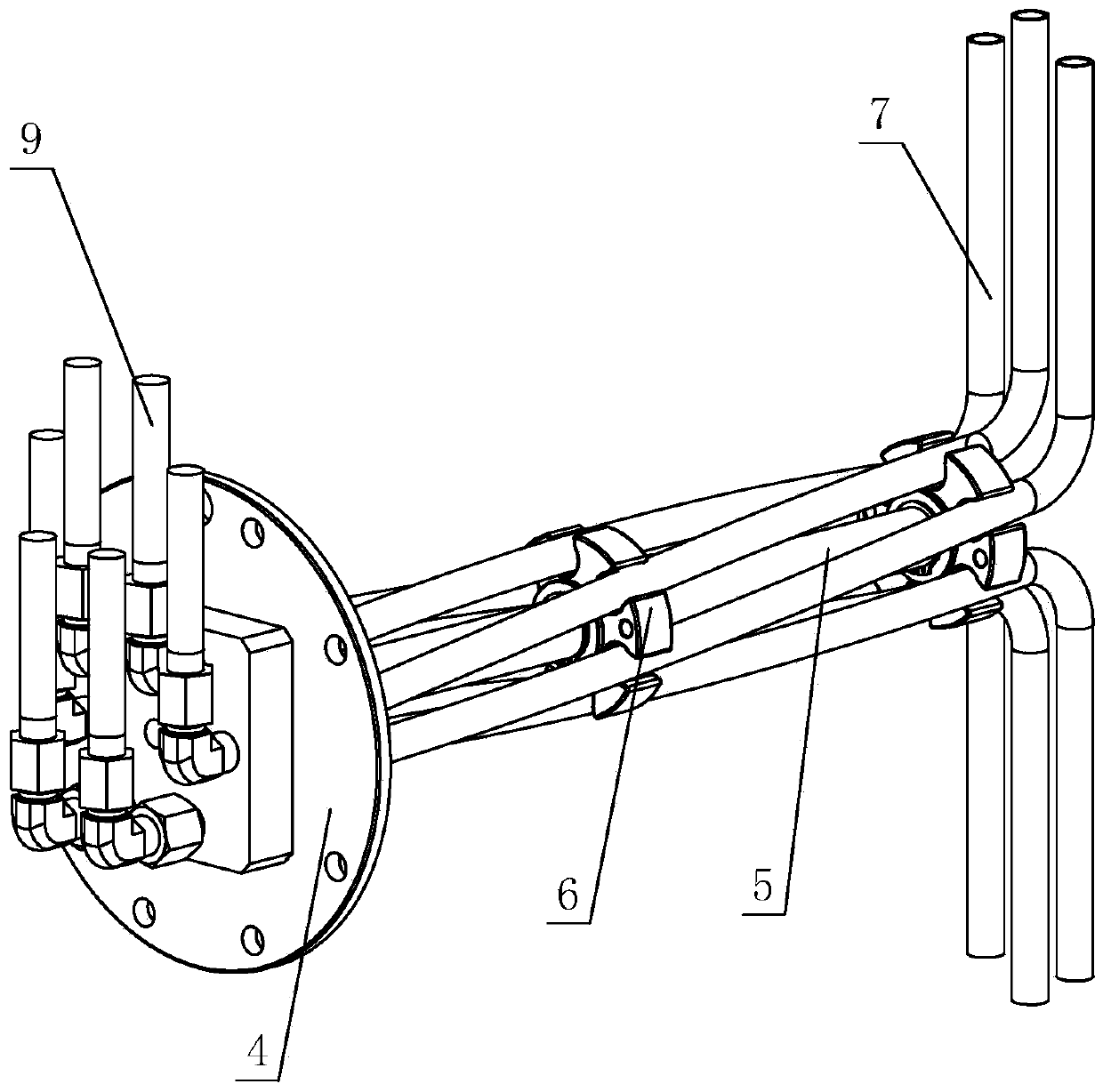

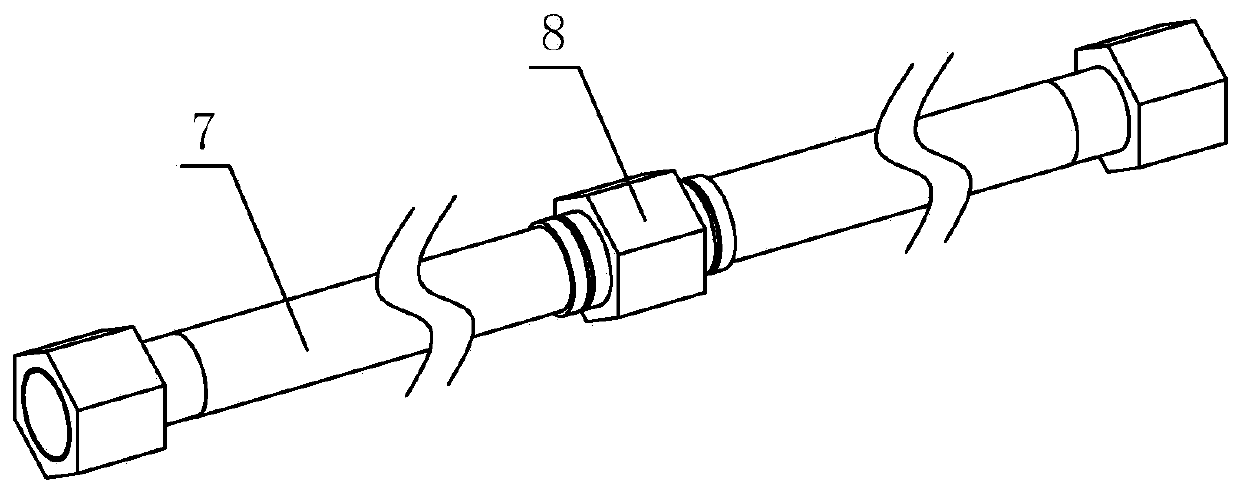

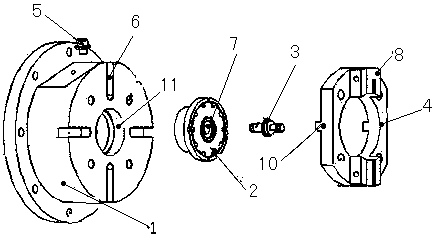

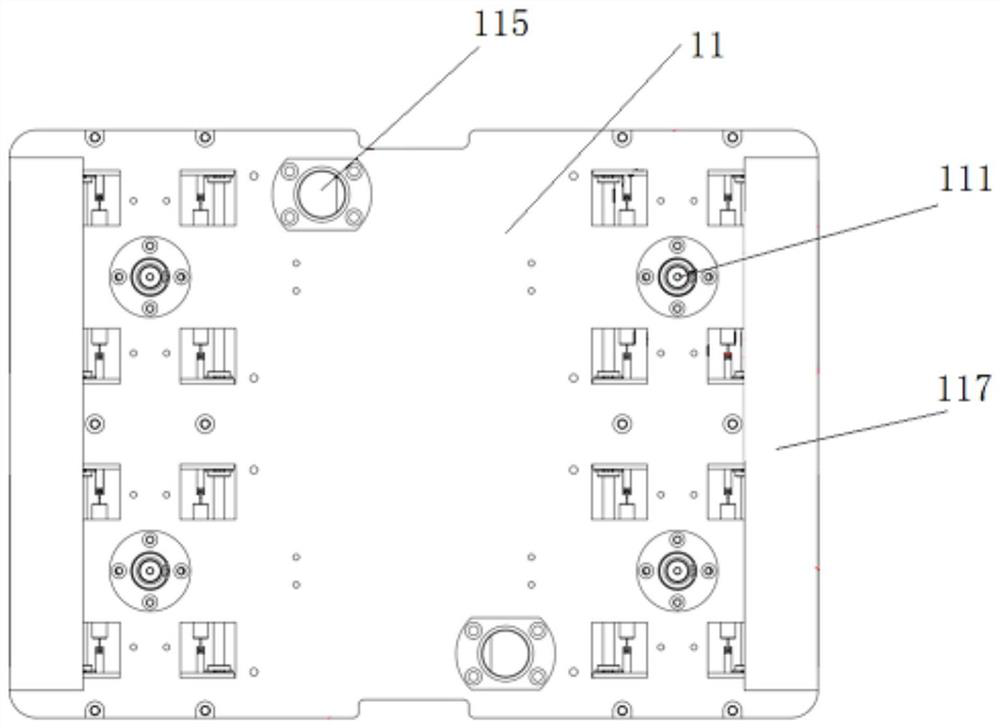

Turntable pipe damage prevention structure for multi-component injection molding machine

The invention discloses a turntable pipe damage prevention structure for a multi-component injection molding machine. The turntable pipe damage prevention structure for the multi-component injection molding machine comprises a movable mold plate and a turntable device rotationally arranged on the movable mold plate, wherein a rotating device is arranged between the movable mold plate and the turntable device and comprises a fixed plate, a rotating shaft, a pipe divider and a turntable pipe; the fixed plate is arranged on a core shaft of the turntable device; the rotating shaft is arranged on the fixed plate; the pipe divider is arranged on the rotating shaft; one end of the turntable pipe is in matched connection with the fixed plate, the middle of the turntable pipe is arranged on the pipe divider, and the other end of the turntable pipe is arranged on the turntable device; and a rotating joint is further arranged on the rotating table pipe, and the turntable pipe can freely rotate through the rotating joint. Through the improvement of the structure, the turntable pipe damage prevention structure for the multi-component injection molding machine has the characteristics of simple and reasonable structure, excellent performance, quick disassembly and assembly, convenient use, short pipe replacement time, simple daily maintenance, low manufacturing cost, long service life, safety, reliability, simple and attractive appearance and high practicability.

Owner:广东伊之密精密注压科技有限公司 +1

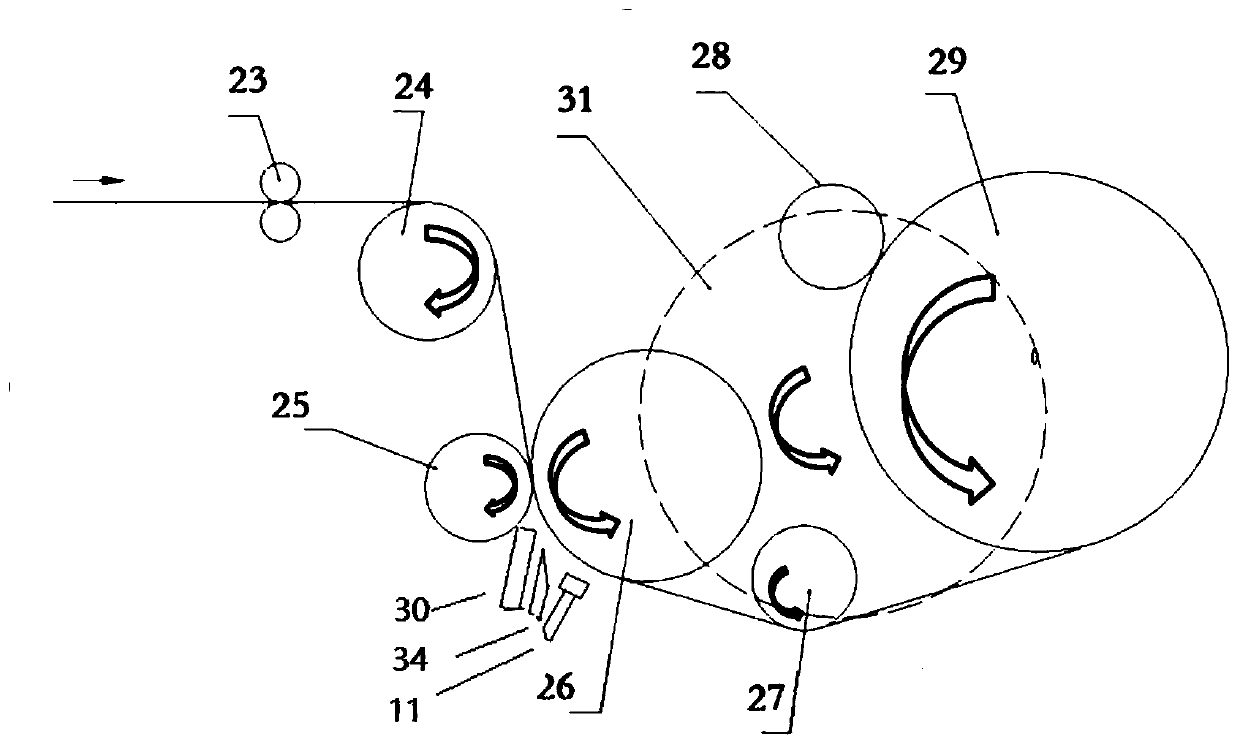

Anti-static film rolling method and device

ActiveCN110861955AGuarantee attachedGuaranteed success rateElectrostatic chargesWebs handlingThin membraneTower

The invention relates to an anti-static film rolling method and device. The film rolling device is used in the method. A rolling rotating tower is arranged in the film rolling device, two rolling steel shafts are fixed to the rolling rotating tower in a spaced manner, and a static adsorption bar and a cutter are sequentially arranged at the positions close to the rolling steel shafts. After the improvement is conducted, an air blowing mechanism is additionally arranged in the rolling device. By means of the anti-static film rolling method and device, the structure in ingenious, all the processes are connected tightly, it is ensured that at the moment that the transverse cutter cuts a piece head open, the piece head is immediately blown to the empty rolling shaft, the phenomenon that adsorption of the piece head is poor due to the self electric conduction characteristic of the product is avoided, the automatic roll changing success rate is effectively ensured, and the production efficiency is also improved.

Owner:HEFEI LUCKY SCI & TECH IND

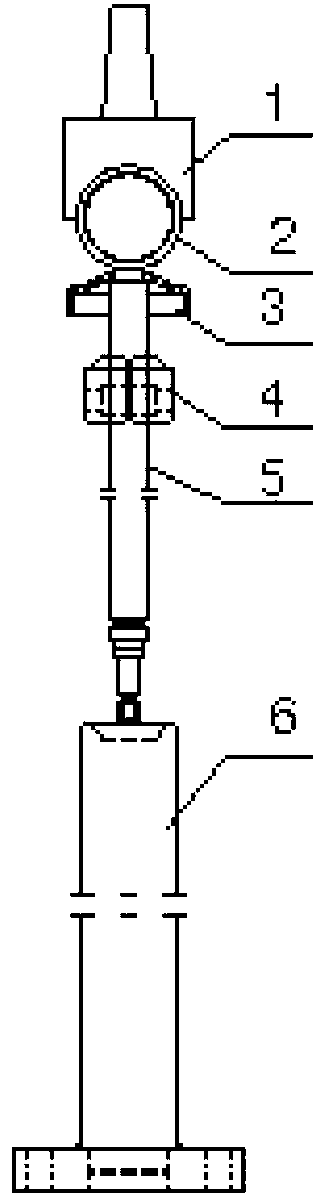

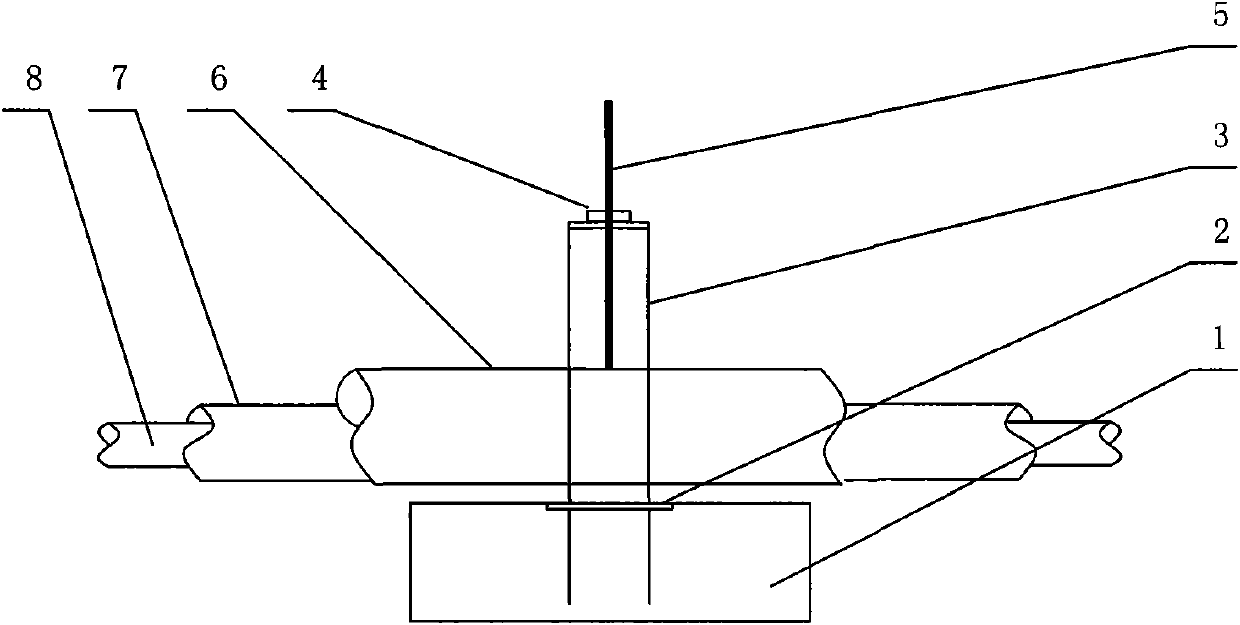

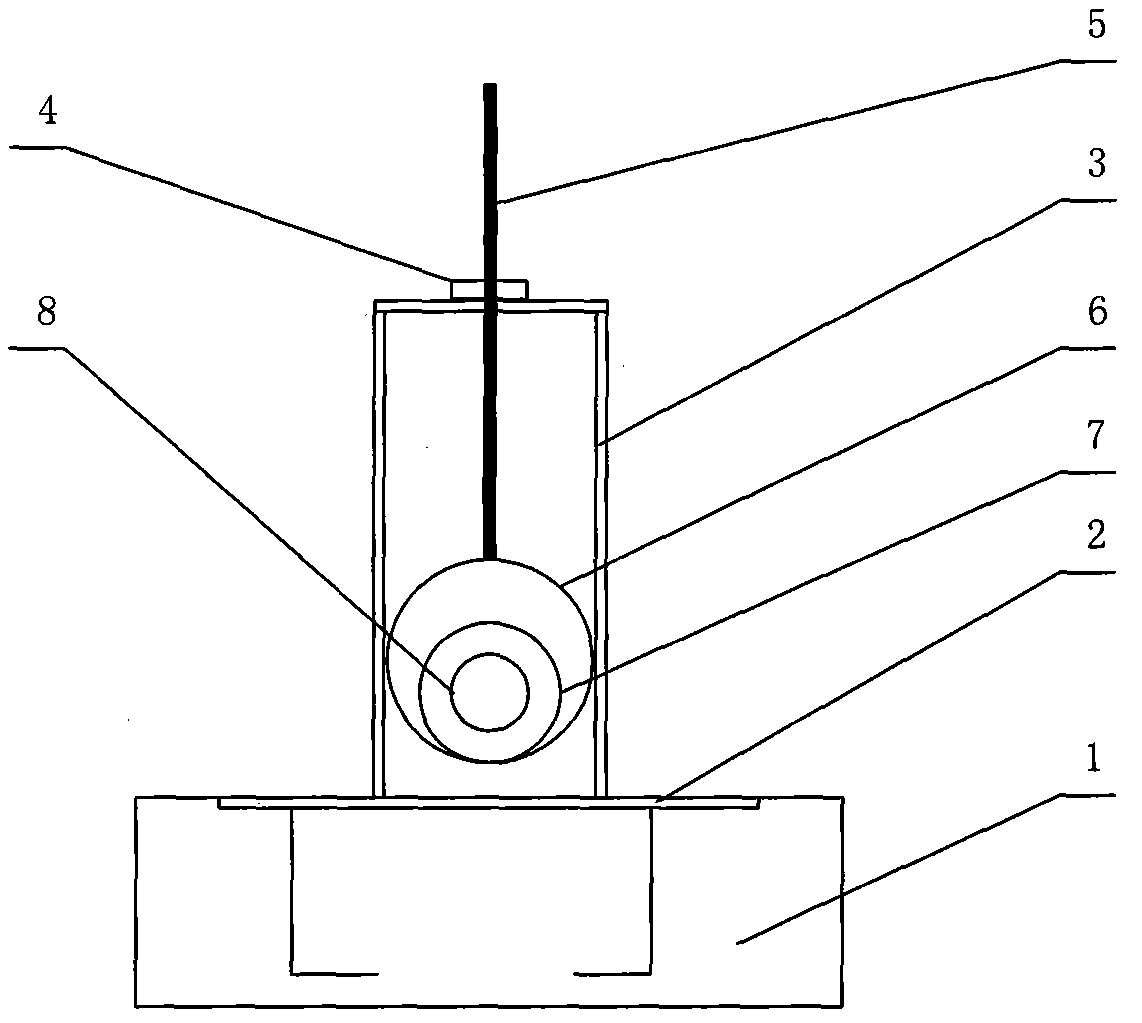

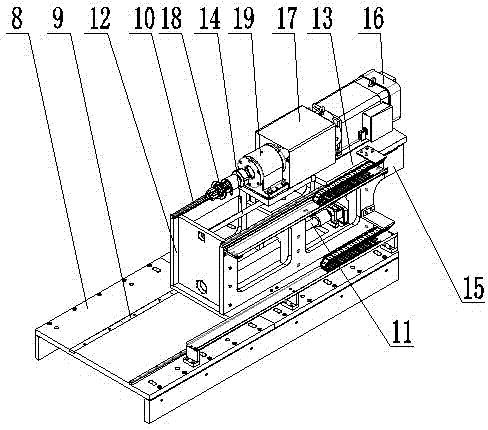

Welding device of piston rod sub-assembly of telescopic shock absorber

InactiveCN103273246ANo burnsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesWaste productPiston rod

A welding device of a piston rod sub-assembly of a telescopic shock absorber is used for welding the piston rod sub-assembly of an automotive telescopic shock absorber. The welding device comprises a piston rod, wherein the upper end of the piston rod is sequentially provided with a dustproof cover and an upper hanging ring; the bottom of the piston rod is provided with a lower positioning seat which is used for supporting the piston rod; and the top of the upper hanging ring is provided with an upper electrode. The welding device is characterized in that a clamping block which is used for fixing the piston rod is arranged between the lower positioning seat and the upper electrode. The welding device of the piston rod sub-assembly of the telescopic shock absorber has the advantages of being simple in structure, enabling the clamping block to be replaced according to the diameter of the piston rod, being short in exchange production time, causing no burn to the surface of the piston rod after welding, improving the product quality and reducing waste products.

Owner:TIANJIN TIANDE SUSPENSION SYST

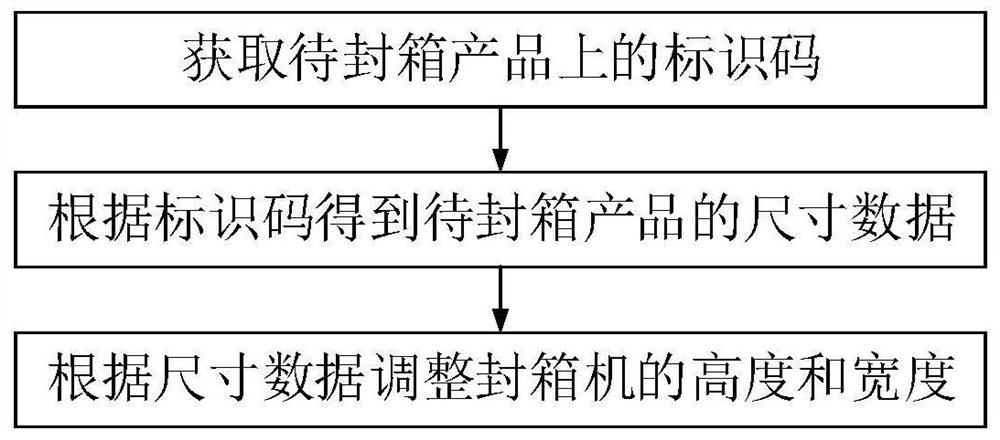

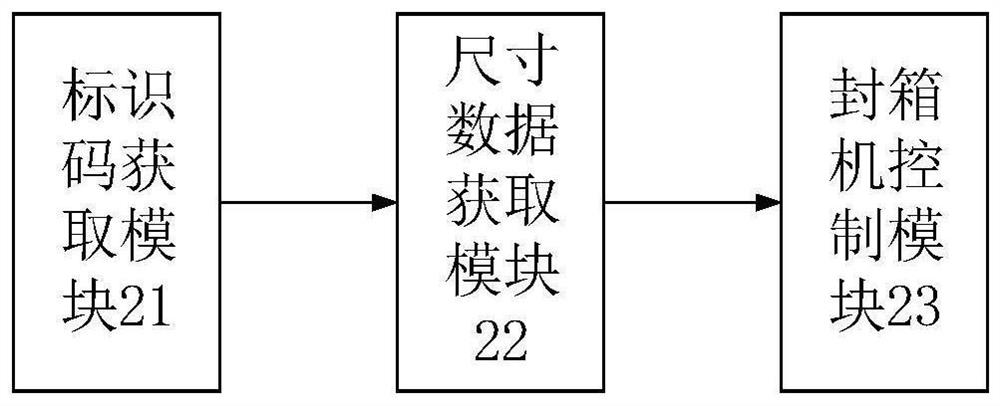

Box sealing method, device and system

InactiveCN112429335AAuto height adjustmentUto-fit widthWrapper twisting/gatheringPackaging automatic controlProcess engineeringMachine

The invention discloses a box sealing method, device and system, and belongs to the field of product box sealing. The method comprises the steps of acquiring an identification code on a product to besealed; and obtaining size data of the product to be sealed according to the identification code, and adjusting the height and width of a box sealing machine according to the size data. According to the scheme, the problem that the width and height of the box sealing machine need to be manually adjusted is solved, manual operation is not needed, the height and width of the box sealing machine canbe automatically adjusted, the time consumed during model changing is short, errors caused by manual operation are avoided, automatic production is achieved, and the production efficiency is greatly improved.

Owner:GREE ELECTRIC APPLIANCES INC

Clamp with one surface and two pins and manufacture method thereof

ActiveCN101602168BSmall changeover investmentShort changeover timesPositioning apparatusMetal-working holdersEngineering

The invention discloses a clamp with one surface and two pins and a manufacture method thereof. The method comprises the following steps: processing a clamp base; processing a pitch clapboard, a first pin hole seat, a second pin hole seat and a locating pin; additionally processing grid spacers according to the sizes of parts of each box body; and assembling the clamp base, the pitch clapboard, the pin hole seats and the locating pin to obtain the clamp with one surface and two pins. The method rapidly obtains a needed locating datum by the additional processing of the pitch clapboard. Compared with the traditional method in which one base is manufactured by using variety of box-type parts, the invention has the characteristics of little investment, simple and effective technology, flexible type change, and the like, on the condition of meeting the requirement of the product, thereby being suitable for production of box-type parts of various specifications.

Owner:GUANGXI YUCHAI MASCH CO LTD

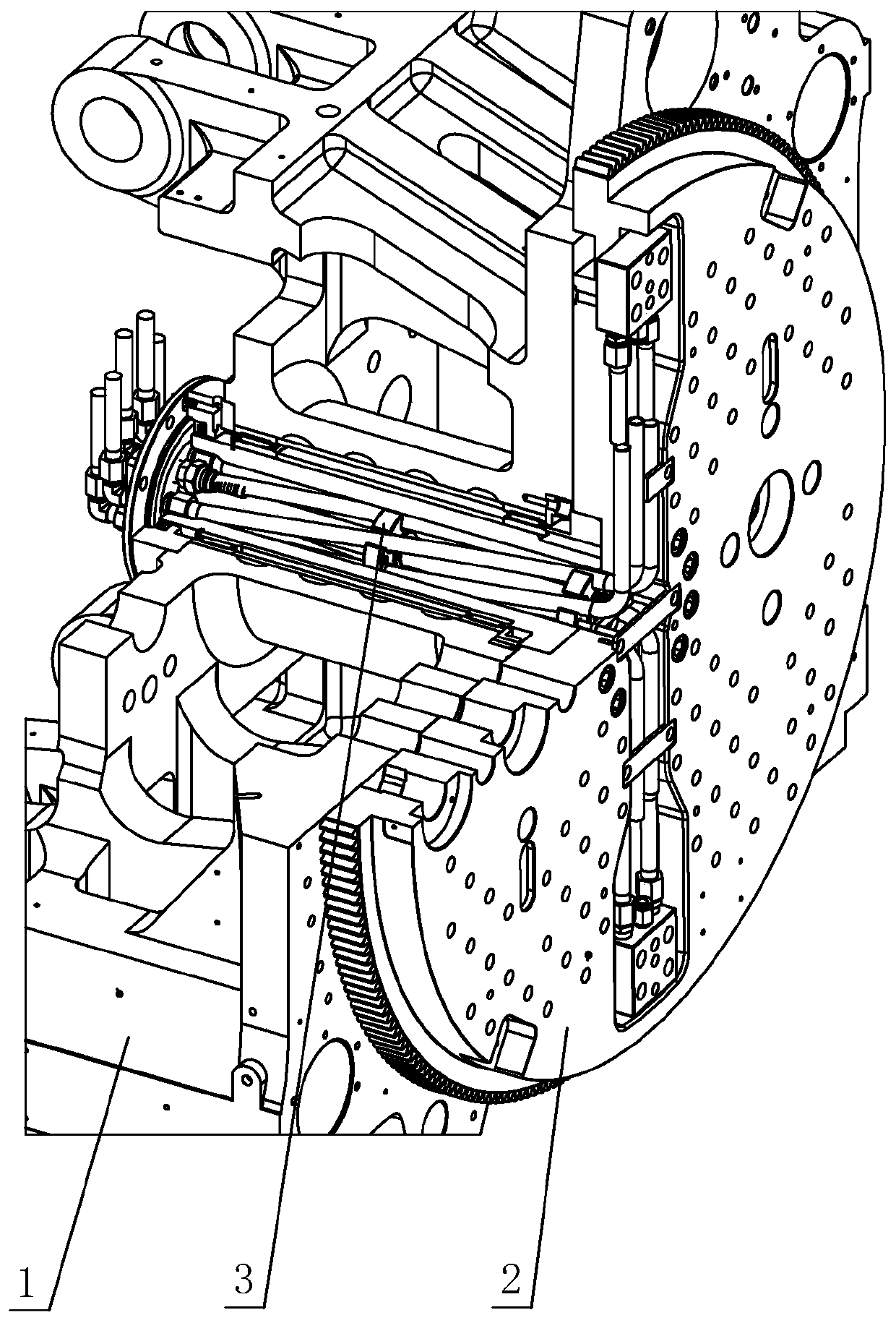

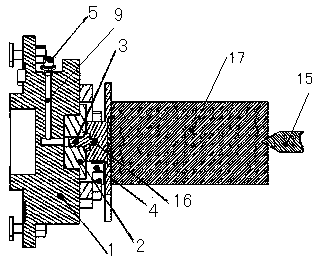

A rotary machine tool fixture and a method for clamping workpieces

ActiveCN106975956BStart fastQuick closePositioning apparatusMetal-working holdersHydraulic pumpEngineering

The invention relates to a rotating machine tool clamp. The rotating machine tool clamp is characterized in that a positioning ring, a hydraulic channel, a hydraulic joint and a plurality of keyways are arranged on and formed in a main shaft connector, wherein a zero-point positioning die is mounted in the positioning ring; a central hole is formed in the zero-point positioning die; one end of the hydraulic channel is connected with the hydraulic joint, and the other end of the hydraulic channel communicates with the central hole; the hydraulic joint is connected with a hydraulic pump; a pulling nail is mounted on the central hole; the main shaft connector is connected with a rotating preventing positioning block through a bolt; positioning keys fitting the keyways are arranged on the rotating preventing positioning block; the rotating preventing positioning block is fixedly connected to one end surface of a blank; a preset hole which is fixedly connected with the pulling nail is formed in one end surface of the blank. According to the rotating machine tool clamp, the blank can be accurately positioned and tensioned through the hydraulic pump and the pulling nail, so that the blank can be prevented from axial moving during being processed; the end surface of the blank is fixed through the rotating preventing positioning block, so that the blank can be prevented from axial displacing during being processed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

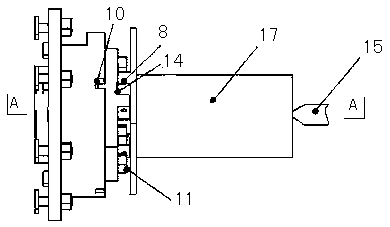

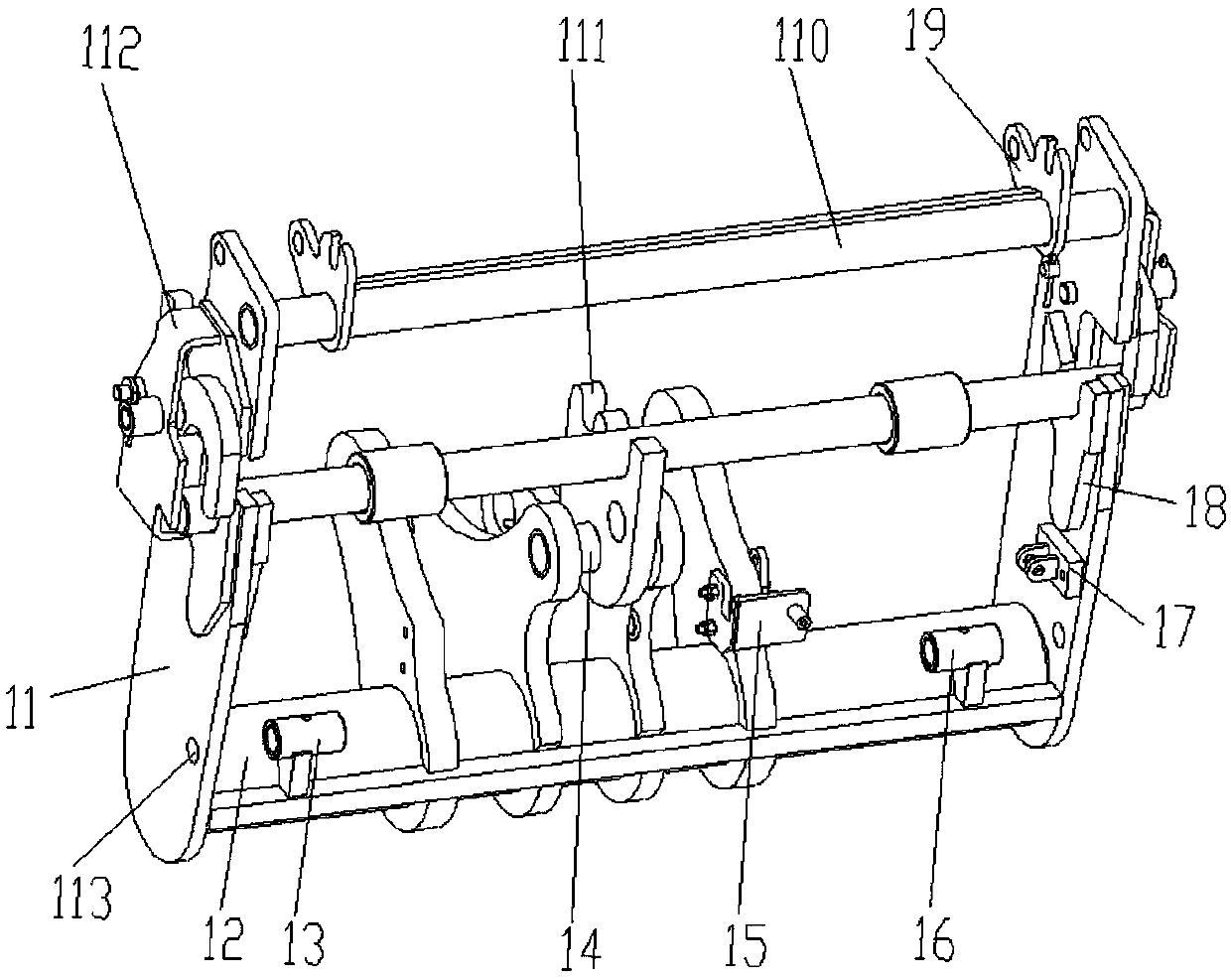

Hydraulic quick-change mechanism for accessory

PendingCN109577405ASimple structureSolution to short lifeMechanical machines/dredgersEngineeringLocking mechanism

The invention discloses a hydraulic quick-change mechanism for an accessory. The hydraulic quick-change mechanism comprises an accessory connecting frame, a quick-change oil cylinder, a quick-change connection rod mechanism and a long shaft locking mechanism; the accessory connecting frame comprises side plates, a lower supporting shaft, a first guide shaft sleeve, installation supports, a secondguide shaft sleeve and an upper supporting shaft; the two ends of the upper supporting shaft and the two ends of the lower supporting shaft are connected through the side plates correspondingly, and each side plate is provided with a groove; locking mechanisms are arranged on the outer sides of the side plates; the lower supporting shaft is provided with installation supports distributed in a triangular shape, the first guide shaft sleeve and the second guide shaft sleeve; the quick-change connection rod mechanism is limited and installed on the accessory connecting frame through the installation supports, the first guide shaft sleeve and the second guide shaft sleeve; the quick-change connection rod mechanism rotates by a small angle, thus, large-stroke sliding can be obtained, the mechanism change action time is shorter, and the whole machine operating efficiency is improved; and the axis of a quick-change oil cylinder and the quick-change connection rod mechanism are located on thesame plane, additional torque is not generated during change action, and the quick-change mechanism is long in service life and high in reliability.

Owner:XUZHOU XUGONG SPECIAL CONSTR MASCH CO LTD

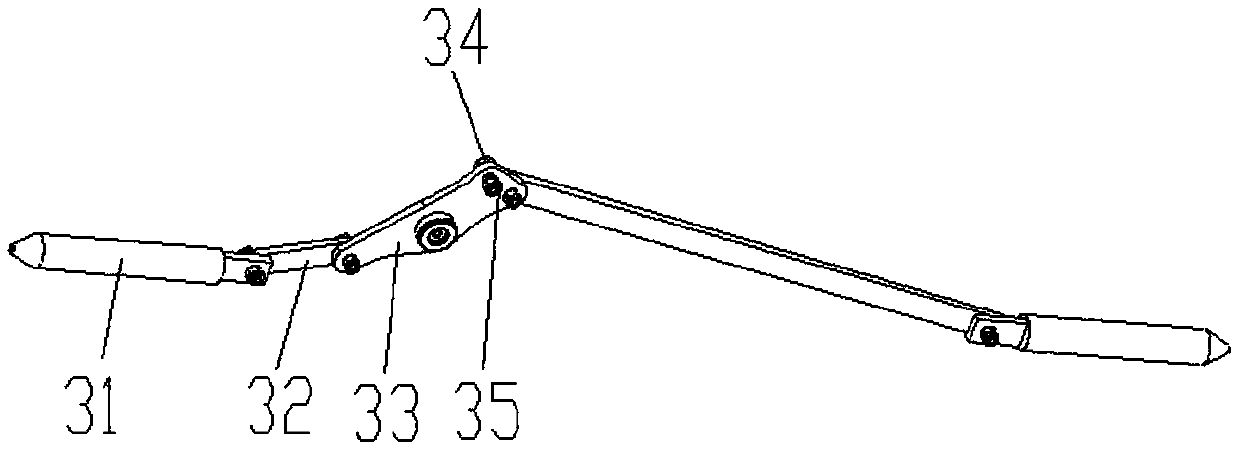

Universal forming terminal fixture for measurement

PendingCN107350987AReduce investmentReduce manufacturing costWork holdersControl engineeringStructural engineering

The invention provides a universal forming terminal fixture for measurement. The universal forming terminal fixture comprises a clamping seat, an empty chamber is formed in the clamping seat, and a clamping mechanism is arranged in the empty chamber. The clamping mechanism comprises a guide seat, and a connecting block is connected in the guide seat in a sliding mode. One end of the connecting block is fixedly connected with a driving part, and the other end of the connecting block is respectively hinged with one end of a first connecting rod and one end of a second connecting rod. The other end of the first connecting rod is hinged with a first mobile block, and the other end of the second connecting rod is hinged with a second mobile block. A first positioning column is fixedly arranged on the first mobile block, and a second positioning column is fixedly arranged on the second mobile block. A guide rail groove is formed in one end of the clamping seat and is vertical to the connecting block, and the first mobile block and the second mobile block are connected in the guide rail groove in a sliding mode. The universal forming terminal fixture can fix different specifications and sizes of terminal material belts and reduces the production cost, and the changeover time is short. The space between the two positioning columns can be slightly adjusted without fine operation, and the whole structure is simple.

Owner:FCI CONNECTORS DONGGUAN

Automatic anti-glare inner rear-view mirror

InactiveCN101716913BNight driving safetyAchieve automatic anti-glare functionMountingsOptical viewingComputer moduleDrive motor

The invention relates to an automatic anti-glare inner rear-view mirror, comprising a support, a mirror shell, a mirror ring, a lens and a rotating plate mounted on a ball head of the support. The mirror shell is rotarably connected with the rotating plate and is provided with a driving motor and a control circuit module inside. The driving motor drives the mirror shell to overturn the mirror with a certain angle relative to the rotating plate through a transmission plate and further drives the lens to overturn through the mirror ring; the lens is an anti-glare lens and has a second surface with the luminous reflectivity of greater than or equal to 80% and a first surface with the luminous reflectivity of smaller than or equal to 70%. The first surface and the second surface form a bevel of 3.67 degrees; a first photosensor and a second photosensor are respectively arranged on the mirror ring and the mirror shell. When the light from the back of the vehicle irradiates the first photosensor, the control circuit module controls the driving motor so that the mirror on the mirror shell on the second surface as a reflective surface automatically turns to the first glass surface as the reflective surface through the transmission mechanism, therefore, the reflectivity is overturned from the one greater than or equal to 80% to the one smaller than or equal to 70%, thereby realizing the automatic anti-glare function.

Owner:上海久真汽车配件有限公司

Automobile body projection welding workstation based on 2D visual guidance

PendingCN112570871AImprove flexibilityImprove intelligenceResistance welding apparatusMachineVisually guided

The invention relates to an automobile body projection welding workstation based on 2D visual guidance. The workstation comprises a projection welding machine, a nut conveyor, feeding tables and a robot. The projection welding machine and the robot are oppositely arranged, the nut conveyor is arranged on one side of the projection welding machine, and the feeding tables are arranged on the side face of the robot. The robot is provided with a gripper used for gripping automobile body parts on the feeding tables and a first 2D visual guider used for guiding the gripper to grip the automobile body parts, a second 2D visual guider used for guiding the gripper to convey the automobile body parts to the projection welding machine is arranged on one side of the robot, and the gripper, the first 2D visual guider and the second 2D visual guider are all connected to an automatic controller. Compared with the prior art, the welding workstation is good in flexibility, suitable for various types ofautomobile body parts and high in intelligent degree.

Owner:SHANGHAI ANDELAI AUTO PARTS

Detection tool and detection system for electric meter detection

ActiveCN113945882AImprove versatilityImprove interchangeabilityElectrical measurementsStructural engineeringMechanical engineering

The invention discloses a detection tool and a detection system for electric meter detection. A meter table support, a test flow channel disposed in the meter table support, a detection assembly disposed in the test flow channel, two belt lines penetrating through the test flow channel, and the detection tool disposed on the belt lines are included. The detection tool comprises a mounting bottom plate, a stop block A arranged on the mounting bottom plate, a plurality of electric meter placing plates arranged on the mounting bottom plate and located on one side of the stop block A, and a plurality of stop blocks B arranged on the mounting bottom plate, the stop block A and the stop block B are located on the two opposite sides of the electric meter placing plates respectively, and the other two sides of the electric meter placing plates are provided with sliding baffle plates which are in sliding connection with the mounting bottom plate. The beneficial effects of the invention are that the detection tool can achieve the online and simultaneous detection of a plurality of electric meters, does not need to repeatedly transfer the electric meters, saves the time for transferring, improves the number of electric meters which can be detected in unit time, and facilitates the improvement of the detection efficiency.

Owner:SHENZHEN KAIFA TECH (CHENGDU) CO LTD

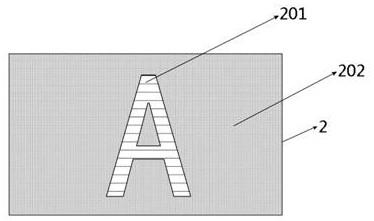

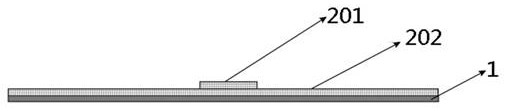

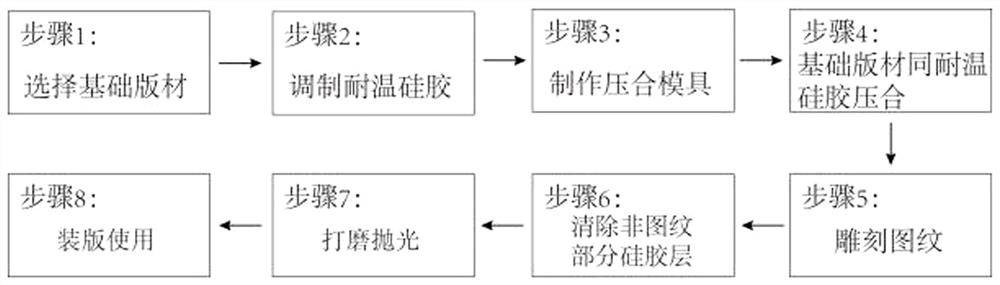

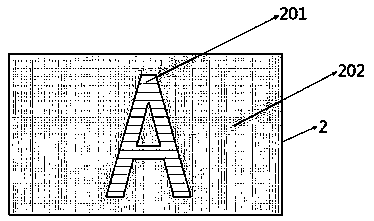

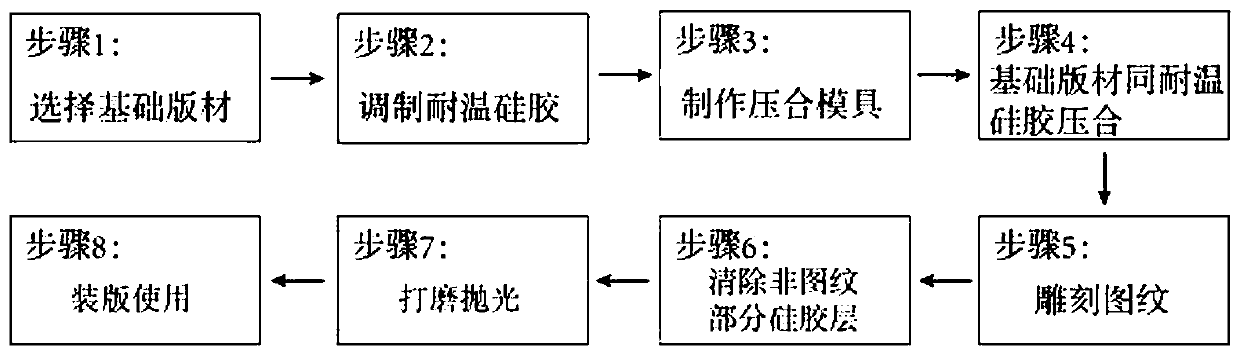

A method of making a hot emboss transfer hot stamping plate that can be quickly assembled and disassembled

ActiveCN110948998BPlate lightShort changeover timesPlate printingFoil printingHot stampingSilica gel

The invention relates to a method for making a thermal emboss transfer hot stamping plate that can be quickly assembled and disassembled, comprising the following steps: 1) selecting the basic plate material; 2) preparing temperature-resistant silica gel; Convex transfer hot stamping plate; 5) Engraving patterns; 6) Clearing non-pattern parts; 7) Grinding and polishing; 8) Mounting and using. The hot emboss transfer hot stamping plate made by this method has a lighter plate, and the weight of each plate is 2kg; the plate change time is shorter, and it only takes 20 minutes for each plate change; the manufacturing cost is relatively low, and each plate The manufacturing cost is 1,000 yuan; the cost can be greatly reduced, while the production efficiency is improved, and the design is simple and convenient.

Owner:YUNNAN QIAOTONG PACKAGE PRINTING

Adjustable protection device for gas pipe

InactiveCN101907203AShort changeover timeProduction and life impactPipe laying and repairLine tubingEngineering

The invention relates to an adjustable protection device for a gas pipe. The device comprises the gas pipe, wherein a base is arranged under the gas pipe; a steel plate is pre-embedded on the top of the base and provided with a door-shaped frame; the upper end of the door-shaped frame is provided with a fixing nut and connected with a lead screw; the lower end of the lead screw is connected with a steel protection pipe; and the gas pipe passes through the steel protection pipe. Thus, the safety of the pipeline of the gas pipe can also be ensured during serious ground surface subsidence. The device has the characteristics of ensuring the safety of the pipeline during underground engineering construction and reducing safety risk, along with higher convenience, higher safety and short pipeline reconnection time. The device can be widely used as the adjustable protection device for pipelines during the underground engineering construction needing to pass through the gas pipe, such as tunnels, underground passages, underground stores and the like.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

Method for manufacturing hot protruding transfer hot stamping plate capable of being quickly assembled and disassembled

The invention relates to a method for manufacturing a hot protruding transfer hot stamping plate capable of being quickly assembled and disassembled. The method includes the following steps that (1) abasic plate material is selected; (2) temperature-resistant silicone is prepared; (3) a press-fit mold is manufactured; (4) the hot protruding transfer hot stamping plate is manufactured; (5) a pattern is engraved; (6) a non-patterned part is removed; (7) polishing and buffering are conducted; (8) and lock up using is performed. The hot protruding transfer hot stamping plate manufactured by adopting the method has a lighter plate material, and the weight of each plate is 2kg; plate changing time is shorter, and each plate changing needs only 20 minutes; the manufacturing cost is low, and themanufacturing cost of each plate material is 1000 yuan; and the cost can be greatly lowered, the production efficiency can be improved at the same time, and the design is simple and convenient.

Owner:YUNNAN QIAOTONG PACKAGE PRINTING

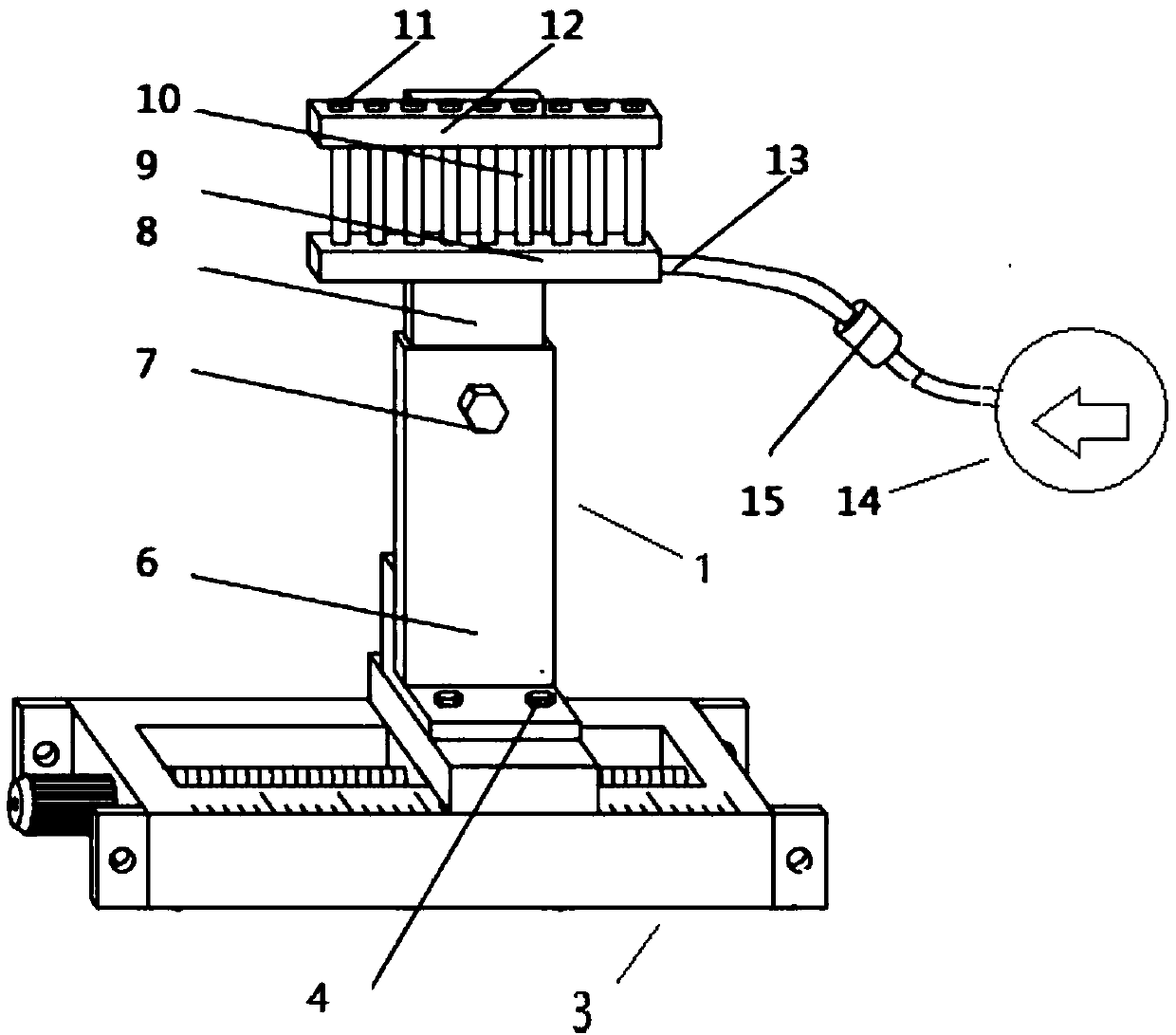

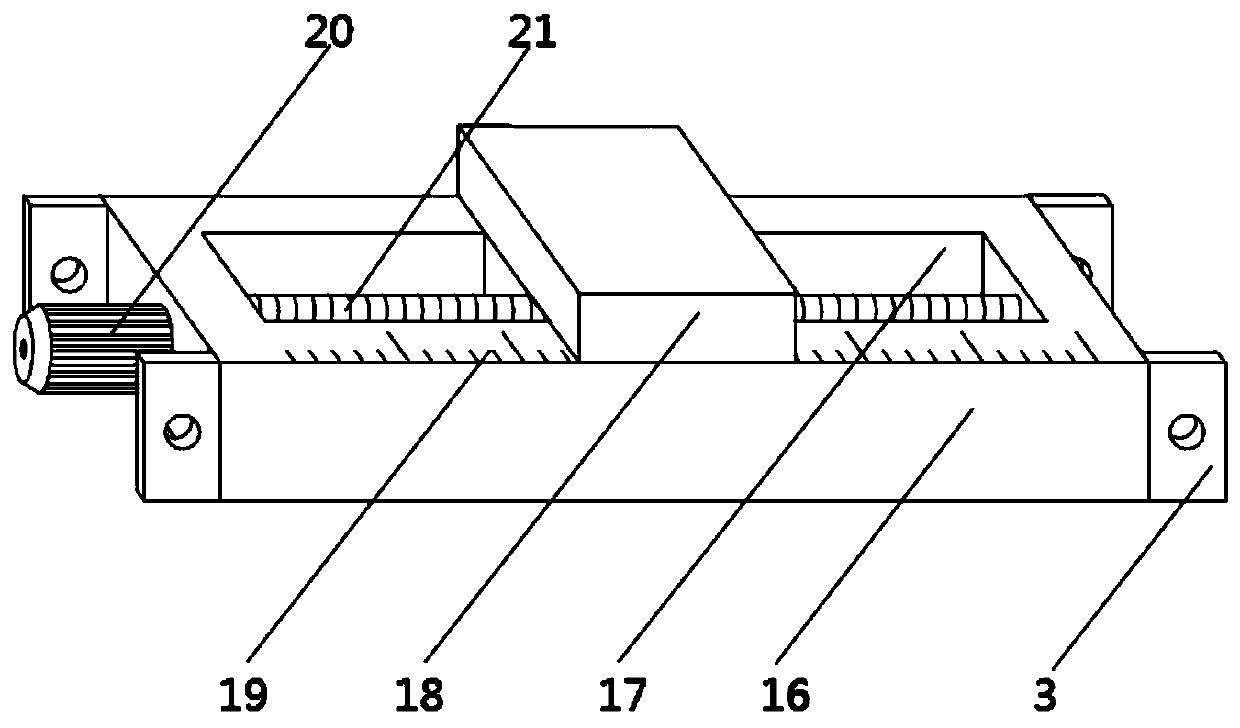

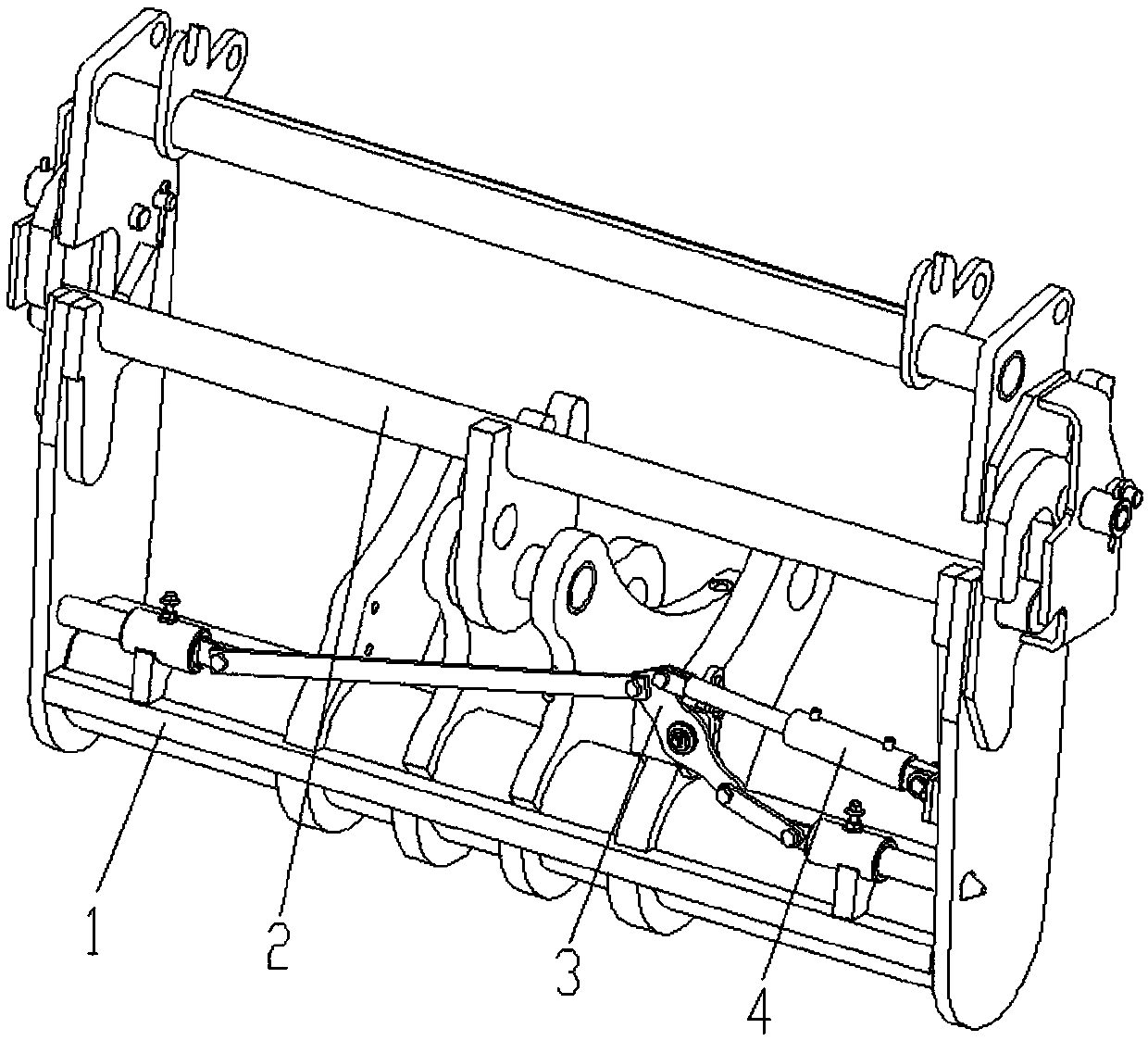

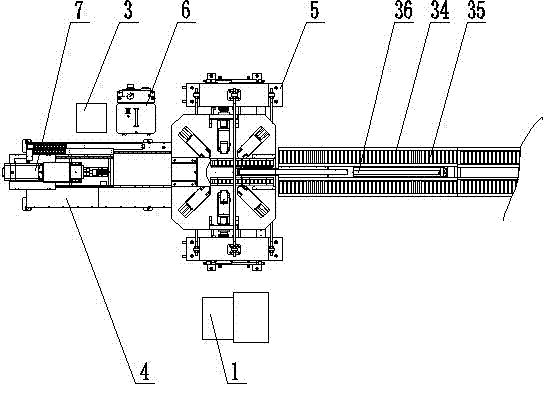

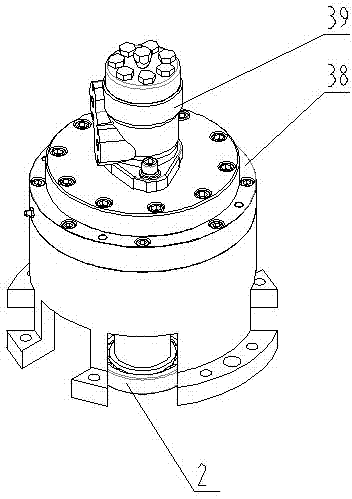

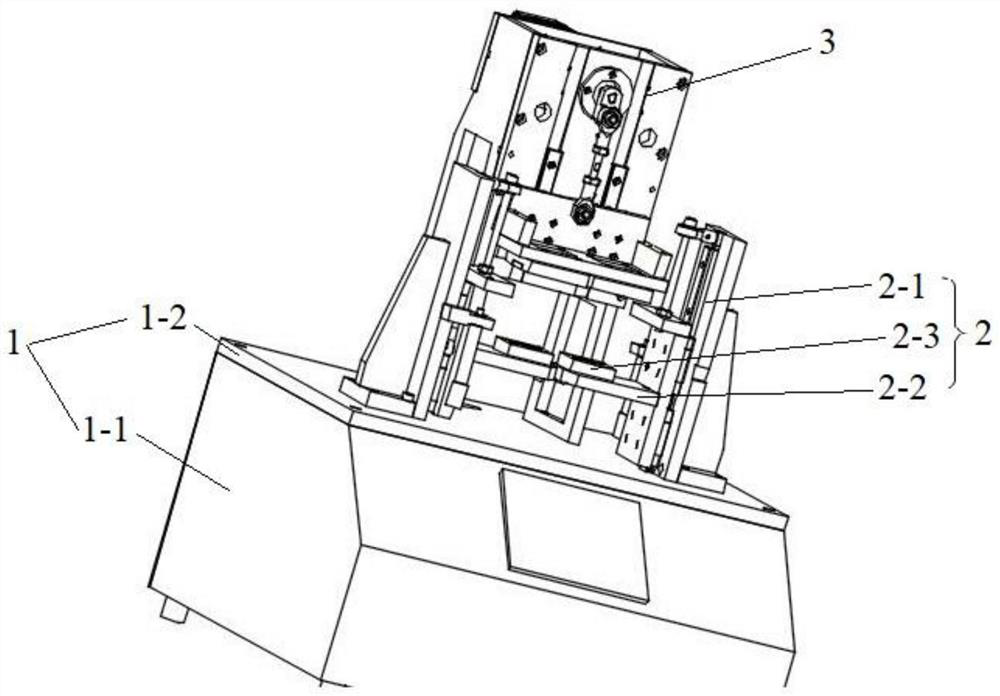

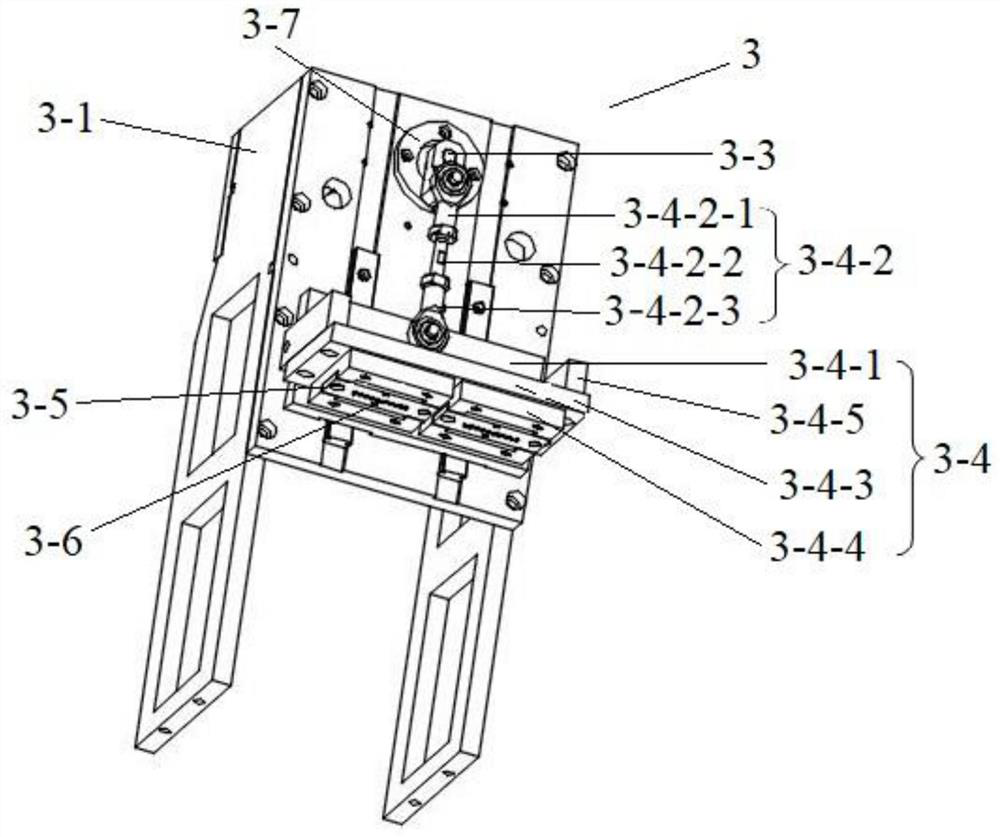

Heavy load automotive rear axle wheel side comprehensive experiment table

The invention relates to an experiment table, in particular to a heavy load automotive rear axle wheel side comprehensive experiment table. The heavy load automotive rear axle wheel side comprehensive experiment table is composed of a foundation support, a program control cabinet, a conveying device, a workpiece turnover device, an oil mist lubricating device and a torque testing device. The conveying device is mounted at one end of the workpiece turnover device, and the torque testing device is mounted at the other end of the workpiece turnover device. The program control cabinet is arranged on one side of the workpiece turnover device. The workpiece turnover device, the torque testing device, the conveying device and the oil mist lubricating device are respectively connected with the program control cabinet through wires. The heavy load automotive rear axle wheel side comprehensive experiment table is novel and ingenious in design, experimental measuring of the rotating speed condition and the torque performance can be achieved at one time through the workpiece turnover device and the torque testing device, and the problems that due to a traditional testing method, the labor intensity of workers is large, working efficiency is low, and the requirements for lean production and ergonomics can not be met are solved. Meanwhile, the heavy load automotive rear axle wheel side comprehensive experiment table has the advantages of being capable of achieving heavy loading, convenient to maintain, short in remodeling time, low in manufacturing cost, convenient in field operation and the like.

Owner:HUBEI JINGCHUAN INTELLIGENT EQUIP

A method for replacing movable pulley blocks in bridge cranes

ActiveCN104803285BReduce workloadShort changeover timesPortable liftingTravelling cranesBlock and tackleOverhead crane

Owner:SHANDONG IRON & STEEL CO LTD

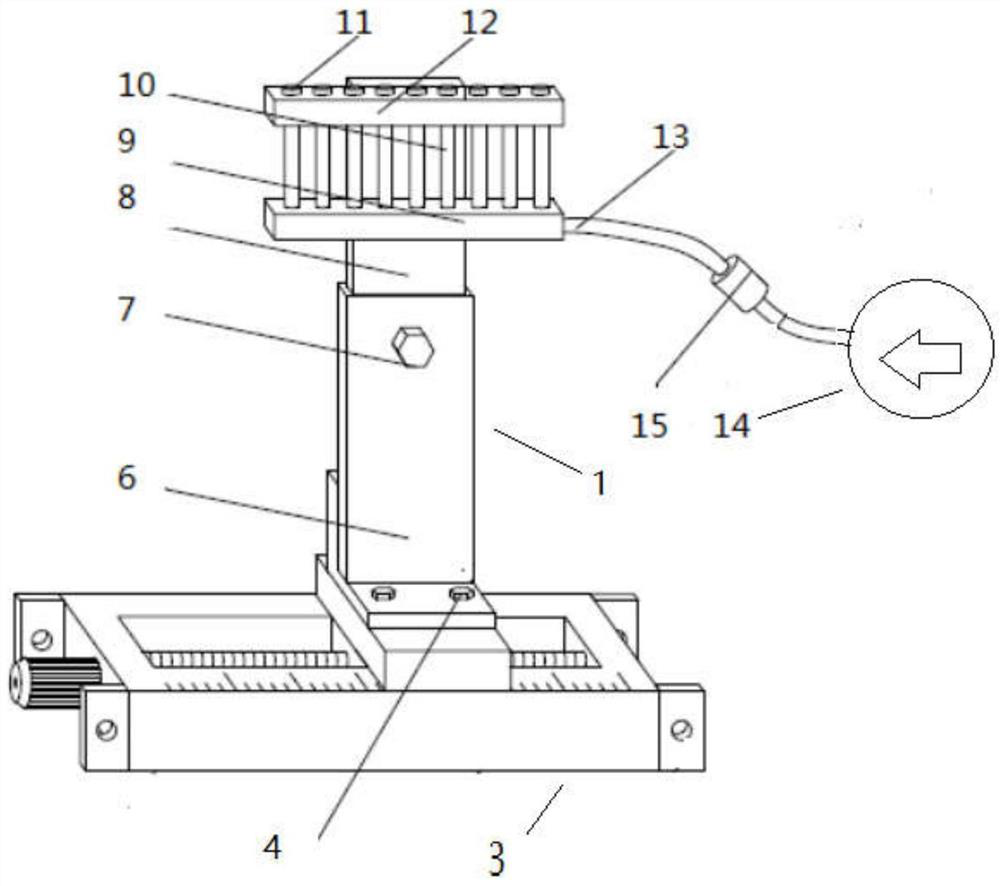

A Probe Fatigue Impedance Tester

ActiveCN111596136BShorten the timeLow costResistance/reactance/impedenceMaterial strength using repeated/pulsating forcesStructural engineeringMachine

Owner:渭南木王智能科技股份有限公司

Ultrasonic power system based on high frequency transformer feedback

InactiveCN101640487BShort changeover timesEliminate delaysConversion without intermediate conversion to dcTransformers/inductances magnetic coresDiscriminatorUltrasonic sensor

The present invention discloses an ultrasonic power system based on high frequency transformer feedback, comprising an ultrasonic power, a matching inductor, an ultrasonic transducer, a non-inductive resistance, a high frequency pulse transformer, a phase discriminator and a DSP, wherein one output end of the ultrasonic power is connected with the matching inductor and the transducer in series in order and then is connected with one end of the non-inductive resistance and an end of a phase discrimination circuit resistance R1 respectively; the other end of the non-inductive resistance is connected with the other output end of the ultrasonic power; the output signal of the phase discrimination circuit is connected with the DSP; a primary terminal of the high frequency pulse transformer is connected with the output end of the ultrasonic power, one end of a secondary terminal of the high frequency pulse transformer is connected with one end of a phase discrimination circuit resistance R4 and the ground, and the other end of the secondary terminal of the high frequency pulse transformer is connected with the other end of the phase discrimination circuit resistance R4 and a 5th pin of an operation amplifier. The ultrasonic power system solves the problem of response delay in voltage phase measurement and reduces system error; and compared with a sensor, the high frequency transformer in the system has the advantages of small volume, light weight and low price.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Box filler double-channel stacking system

ActiveCN103523272BReduce ascent heightDoes not affect speedPackagingStacking articlesClassical mechanicsStructural engineering

The invention relates to a box filler double-channel stacking system which is characterized in that a machine frame is included, a stacking mechanism is arranged at the upper end of the machine frame, a jacking mechanism is arranged in the machine frame, the stacking mechanism is arranged at the upper end of the machine frame and comprises a pair of first blocking plate and second blocking plate, the first blocking plate and the second blocking plate are parallel to each other and are vertically arranged, a stacking zone is formed between the first blocking plate and the second blocking plate, a single-direction bearing component is arranged in the middle of the stacking zone, at least one middle buffering mechanism placed below the single-direction bearing component is arranged in the middle of the stacking zone, and starting of the middle buffering mechanism can be controlled by an action air cylinder. The middle-transition middle buffering mechanism is added and is started or closed correspondingly according to the size of a product, then the lifting height of a jacking pushing plate is lowered, stacking efficiency is improved, and accordingly the system can meet the requirements for box filling of products of different sizes, and the speed of a whole line cannot be affected.

Owner:NANTONG UNIVERSAL MACHINERY

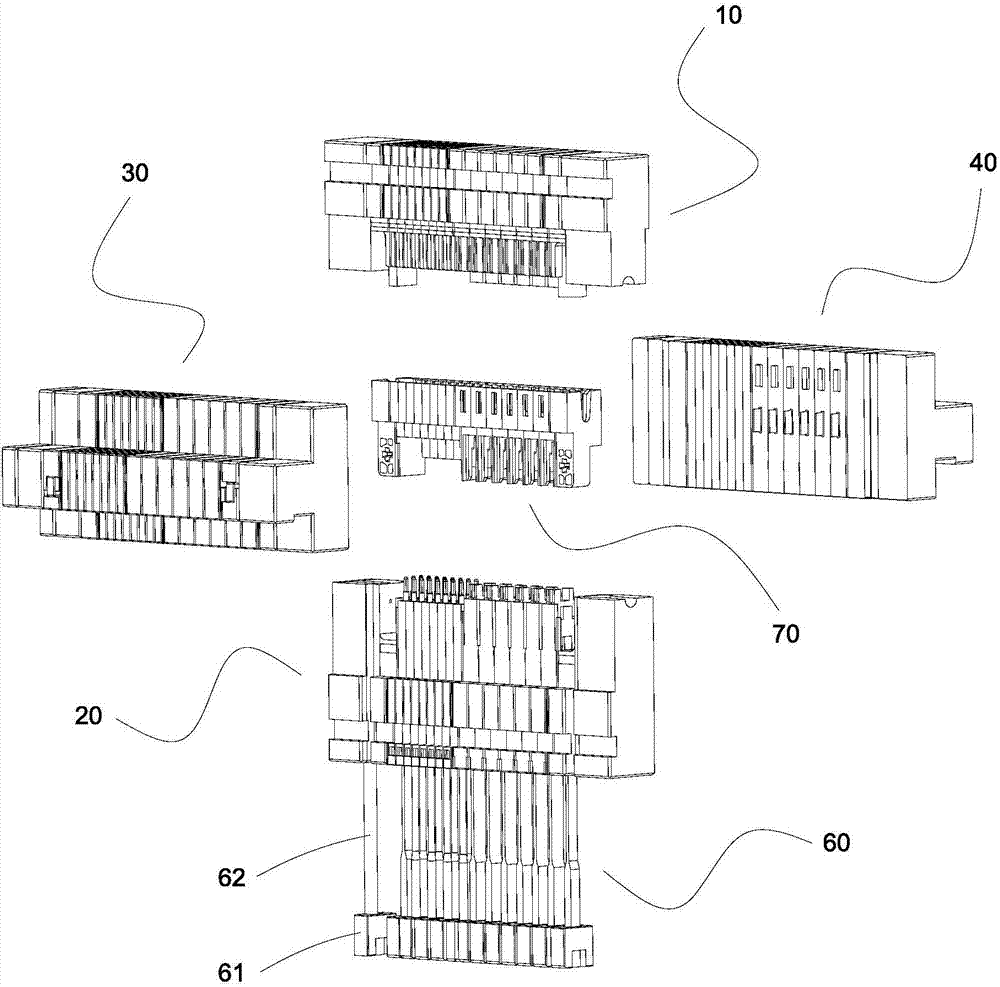

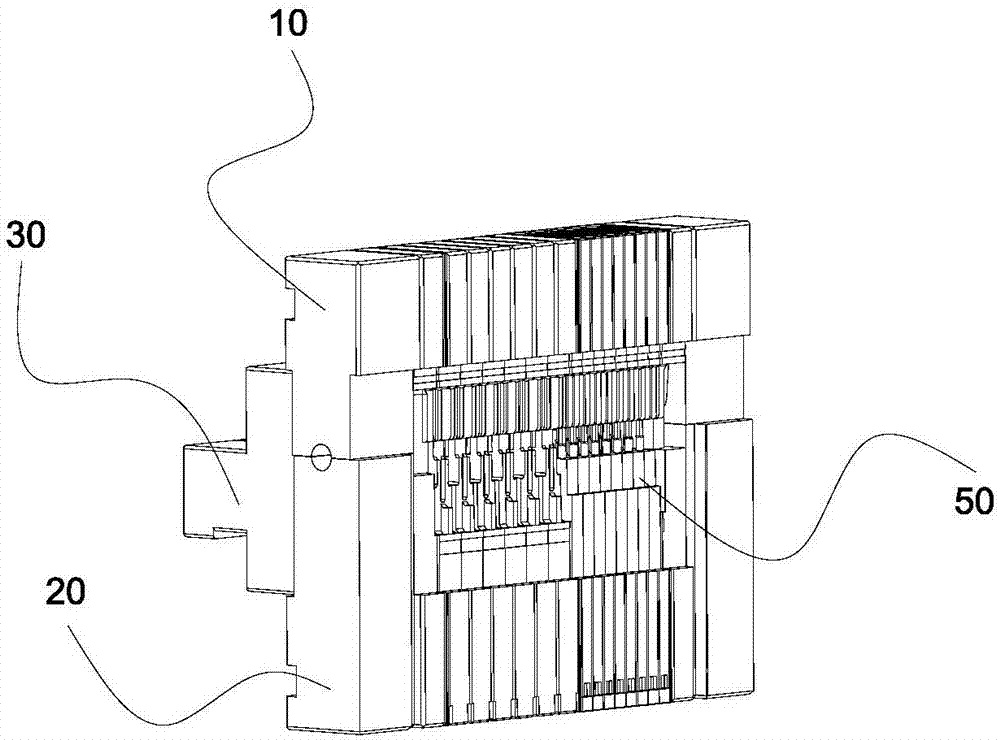

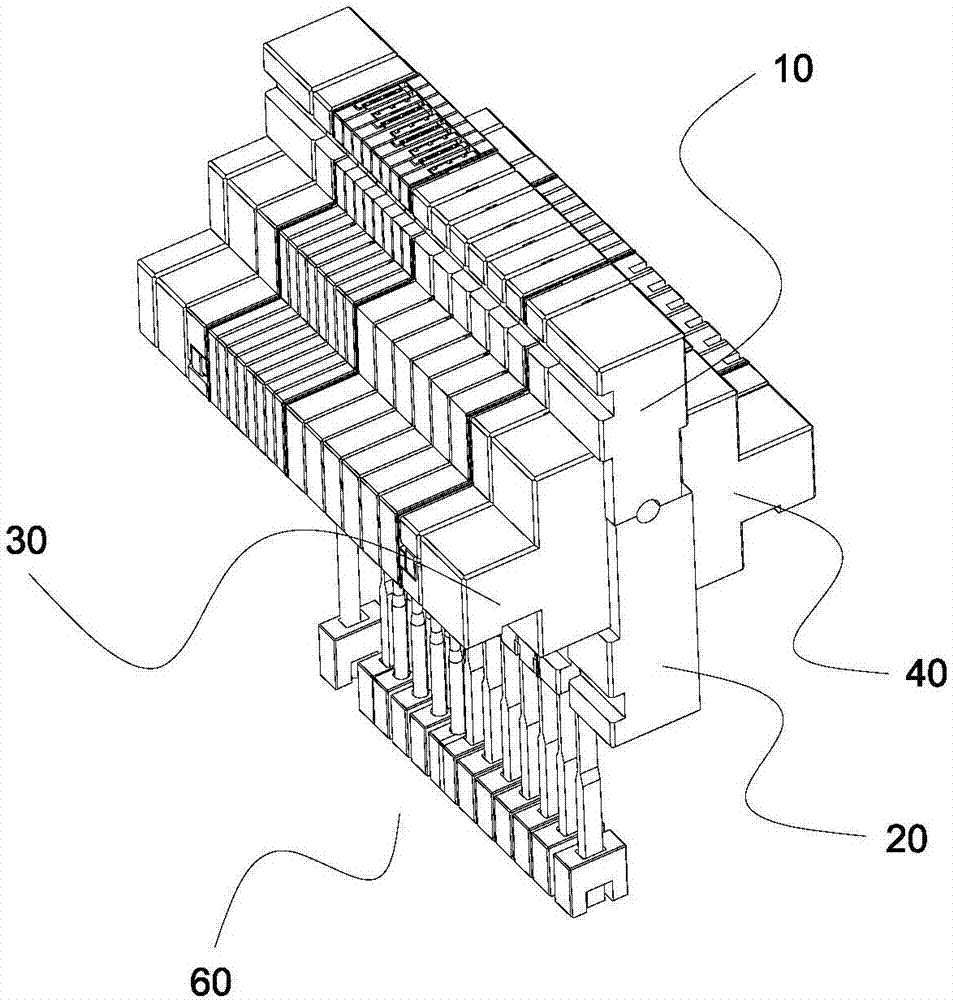

Modular plastic mold structure and design method thereof

The invention provides a modular plastic mold structure and a design method thereof. An upper mold comprises n second upper mold modules, and upper mold forming portions are fixed to the lower portions of the second upper mold modules. A lower mold comprises n second lower mold modules, and lower mold forming portions are fixed to the upper portions of the second lower mold modules. A front mold comprises n second lower mold modules, and front mold forming portions are fixed to the rear portions of the second lower mold modules. A rear mold comprises n second rear mold modules, and rear mold forming portions are fixed to the front portions of the second rear mold modules. A mold cavity is defined by the upper mold forming portions, the lower mold forming portions, the front mold forming portions and the rear mold forming portions together. The upper mold, the lower mold, the front mold and the rear mold are combined through a mold assembly system of an injection molding machine, and the injection molding machine is used for performing injection molding on the mold cavity. According to the modular plastic mold structure and the design method thereof, modular design is conducted on a traditional plastic mold, different molds are formed by combining the different modules, the modules of certain structures can be applied to different plastic parts, the mold input cost is low, the time of path change is short, and the production efficiency is high.

Owner:FCI CONNECTORS DONGGUAN

A method and device for winding an antistatic film

ActiveCN110861955BGuarantee attachedGuaranteed success rateElectrostatic chargesWebs handlingThin membraneEngineering

Owner:HEFEI LUCKY SCI & TECH IND

A method for replacing movable pulley blocks and wire ropes in bridge cranes

ActiveCN104828696BReduce workloadShort changeover timesPortable liftingTrolleysBridge typeBlock and tackle

The present invention provides a movable pulley set and wire rope replacing method used for a bridge type crane, according to the method, a plurality of nylon cords are used, one nylon cord is connected between each fixed pulley and each movable pulley, under traction of the nylon cords, a new wire rope is intertwined with a new movable pulley set for completion of movable pulley set and wire rope simultaneous replacing operation of the bridge crane, compared with the movable pulley set and wire rope replacing method used for the bridge type crane in the prior art, the replacing operation time is short, the work intensity is greatly reduced, the workload of workers is reduced, and the working efficiency is improved.

Owner:SHANDONG IRON & STEEL CO LTD

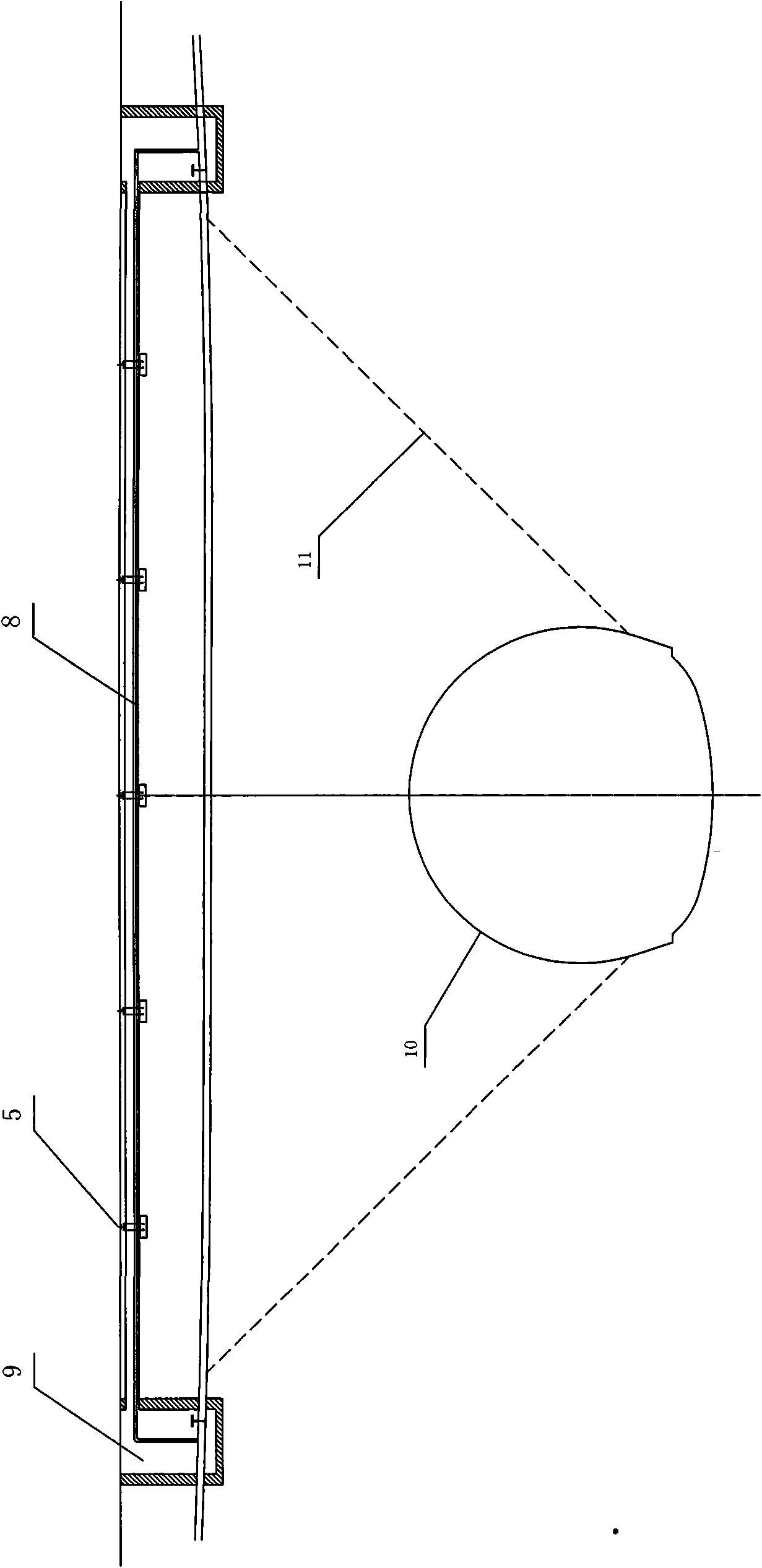

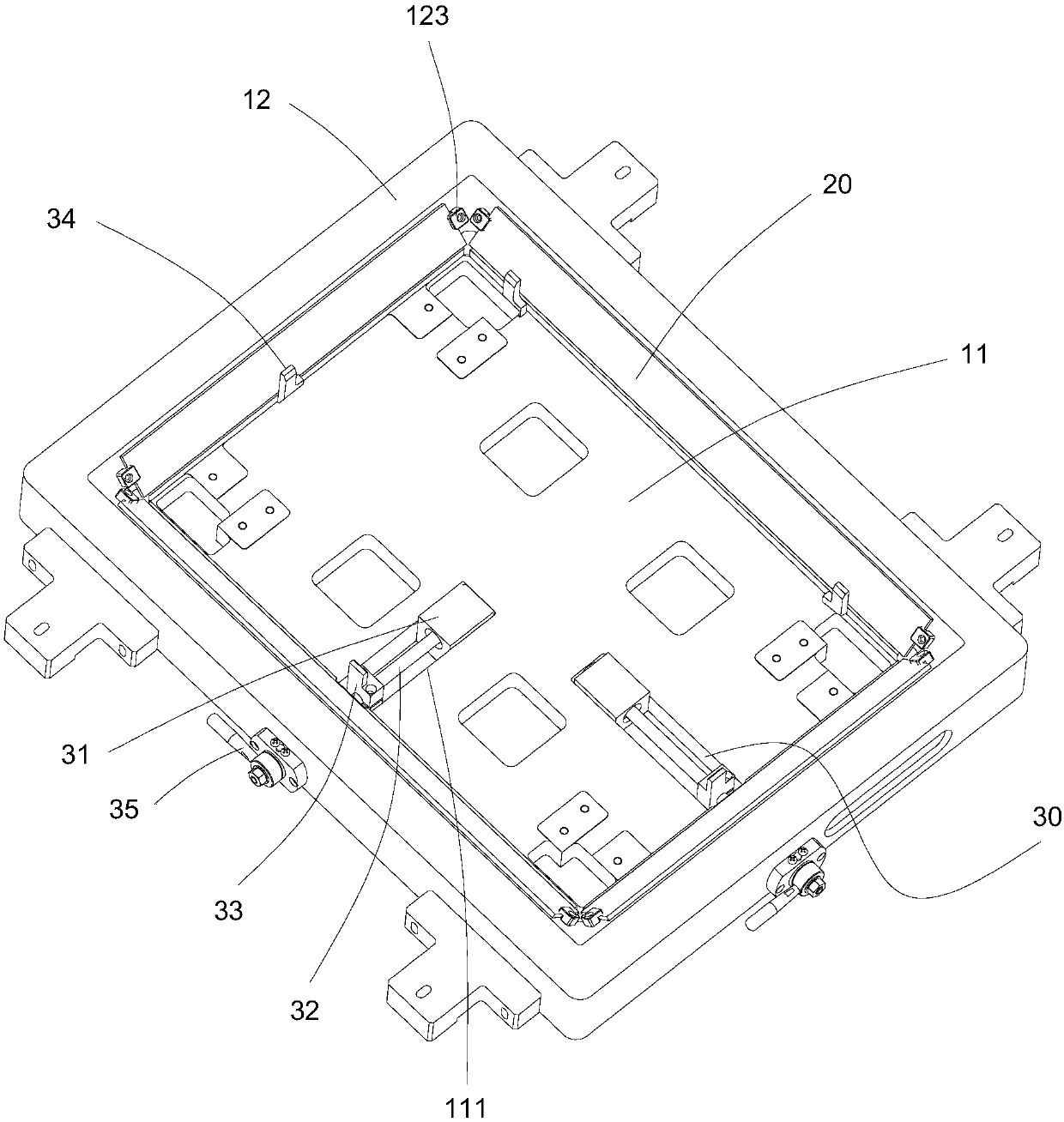

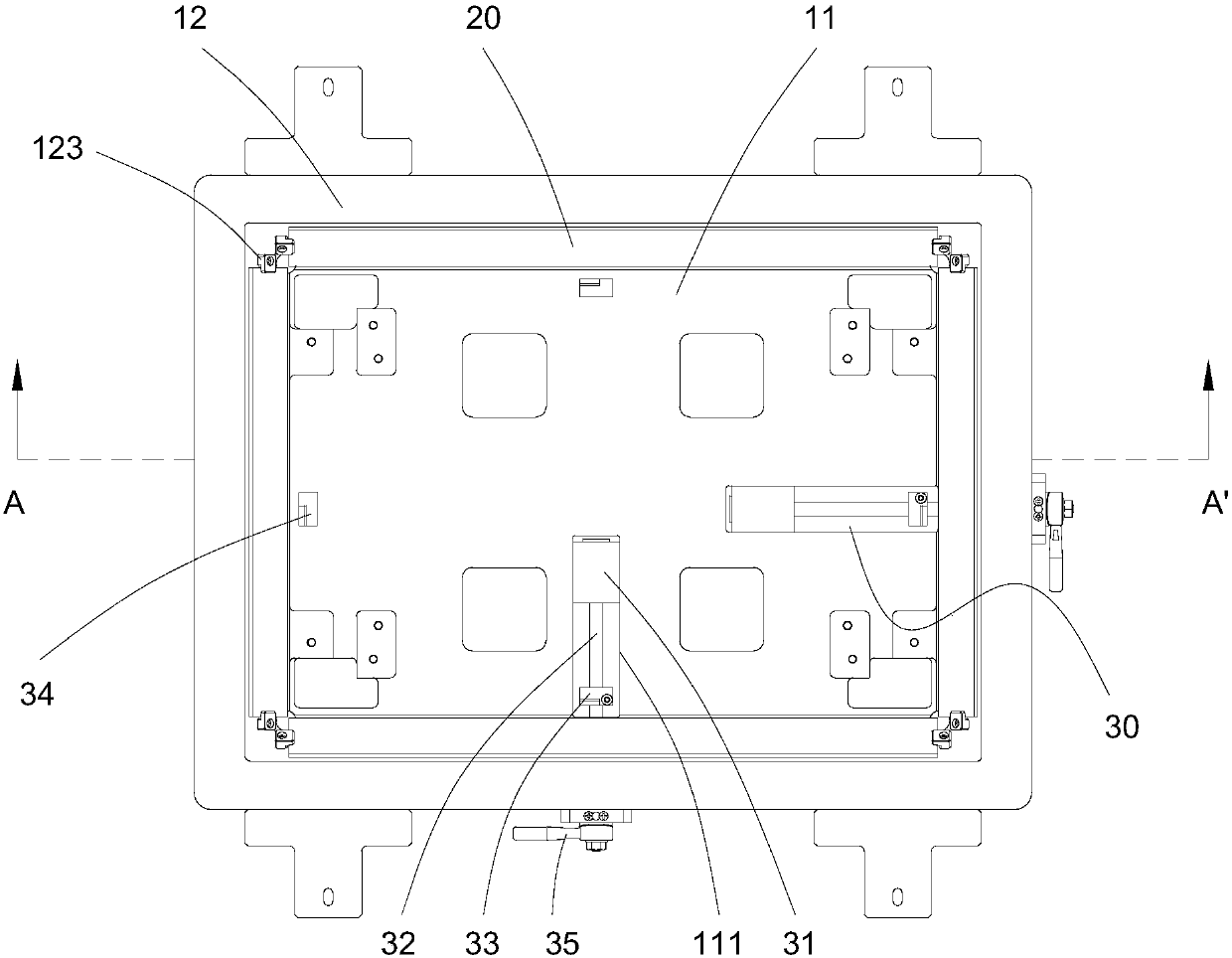

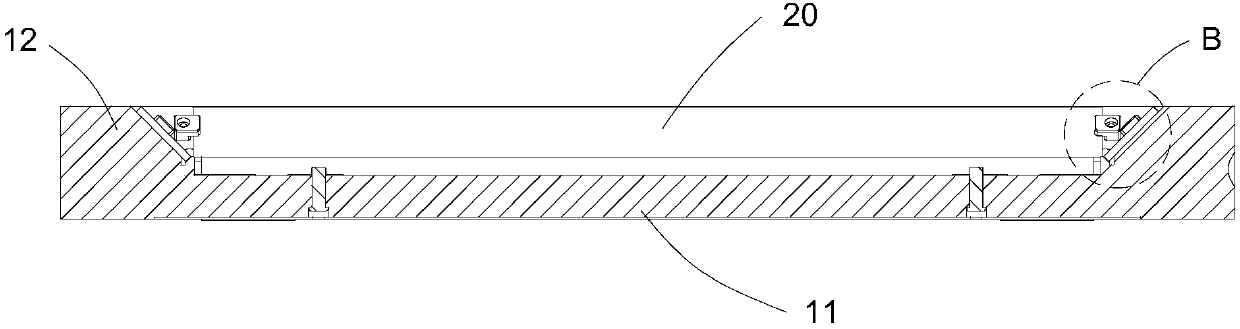

Universal pneumatic fixture for visual inspection devices

PendingCN107806894AReduce manufacturing costShort changeover timeMeasurement apparatus componentsGeneral purposeVisual inspection

The invention provides a universal pneumatic fixture for visual inspection devices. The universal pneumatic fixture includes a bottom plate. A frame is fixed around the bottom plate. The thickness ofthe frame is greater than that of the bottom plate. A reflector is arranged around the inner side of the frame. The reflecting surface of the reflector tilts towards the upper center of the bottom plate. The reflecting surface of the reflector and the horizontal plane form an included angle Alpha. At least one adjustable clamping mechanism is arranged on the bottom plate. The image light information on the four sides of a product can be converted into information in the same direction and propagated. Through the cooperation of the general pneumatic fixture and a simple visual inspection devicefor single-direction detection, product image information in five directions at most can be obtained simultaneously. During line replacement, there is neither need for the visual inspection device tomake avoiding adjustment nor need to focus the lens. The time for line replacement is very short. The efficiency of visual inspection can be improved. Moreover, the production cost of the fixture islow, there is no need for a multi-direction multi-lens visual inspection device, and the cost of visual inspection can be reduced. The fixture can clamp most of the products, and is of high universality.

Owner:东莞市兆丰精密仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com