Ultrasonic power system based on high frequency transformer feedback

A high-frequency transformer, power system technology, applied in the direction of transformer/inductor core, conversion equipment that can be converted to DC without intermediate conversion, etc., can solve the response delay, the inaccurate measurement of the phase difference of the output voltage and current, etc. problems, to achieve the effects of reducing system errors, light weight, and overcoming response delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

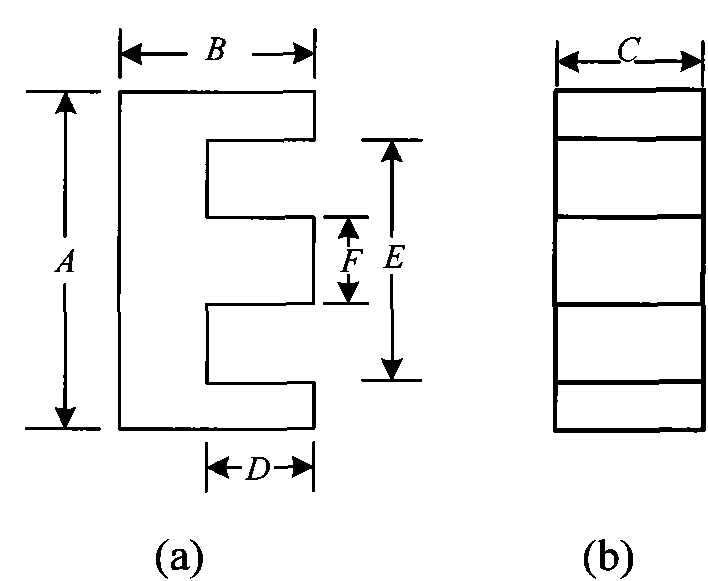

[0014] Such as figure 1 As shown, the high-frequency pulse transformer designed by the present invention according to the technical index requirements adopts the EE10 type ferrite core structure, the primary side adopts a copper wire with a diameter of 0.54mm, the primary side is wound with 18 turns, and the secondary side adopts a diameter of 0.72mm Copper wire, 1 turn around the secondary side. A=10mm, B=5.4mm, C=4.65mm, D=4.2mm, E=7mm, F=2.4mm, the window area of the EE core can be calculated as Aw=(E-F)D=19.32mm2. In this way, the amplitude of the output voltage of the main circuit of the ultrasonic power supply can be reduced to the voltage required by the control circuit, and the power circuit can be isolated from the control circuit.

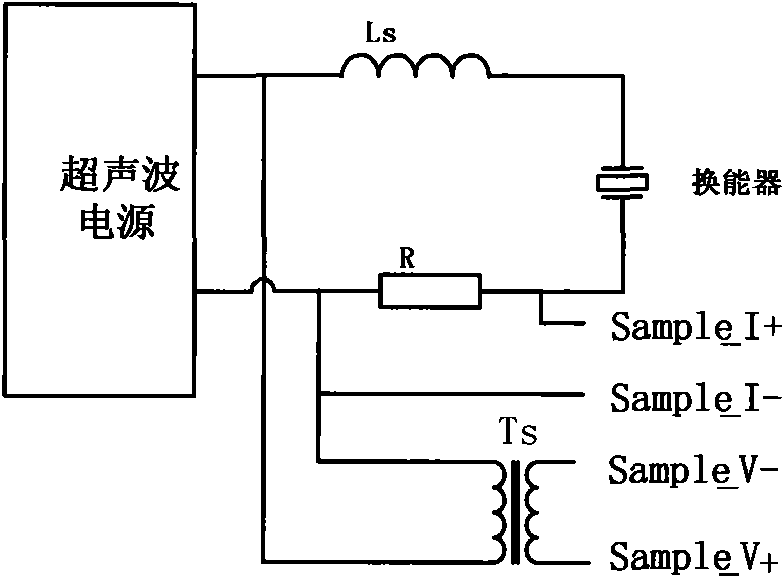

[0015] Such as figure 2 As shown, Ls is the matching inductance, the high-frequency pulse voltage output b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com