A method and device for winding an antistatic film

A winding device, anti-static technology, applied in the direction of static electricity, thin material processing, electrical components, etc., can solve the problems of poor film adhesion to the empty reel, not attached to the empty reel, production shutdown, etc. Ingenious structure, neat and accurate movements, and short roll changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

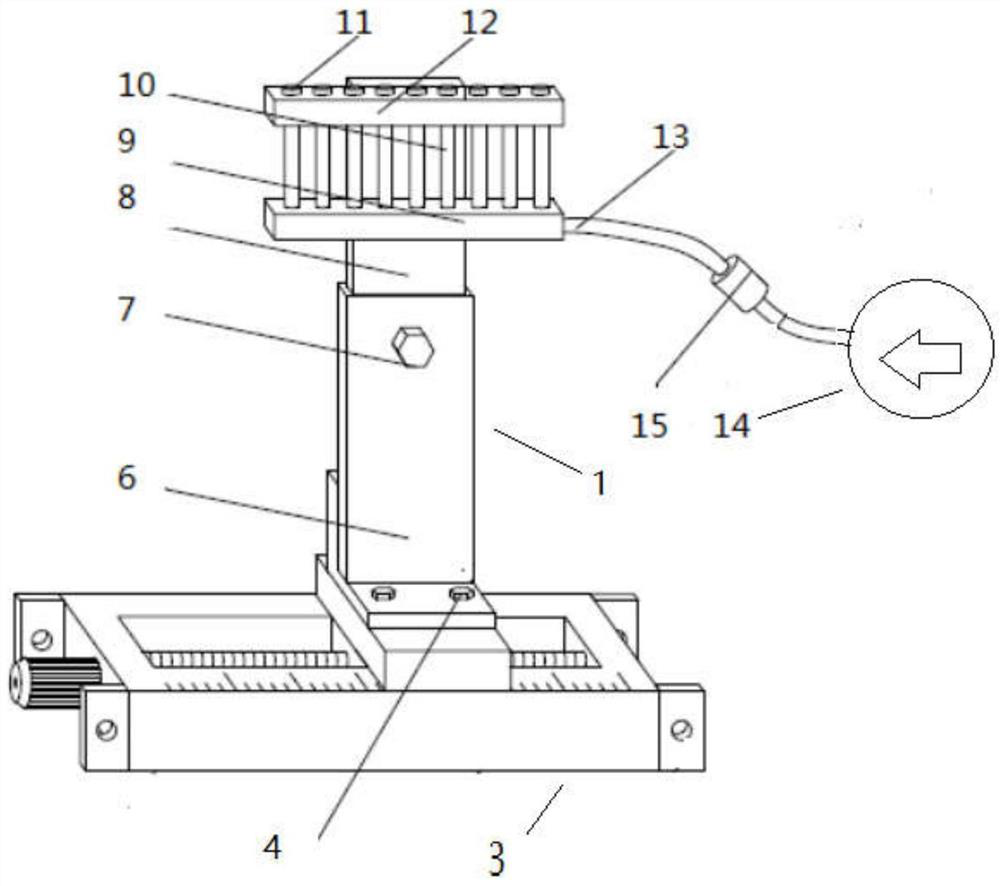

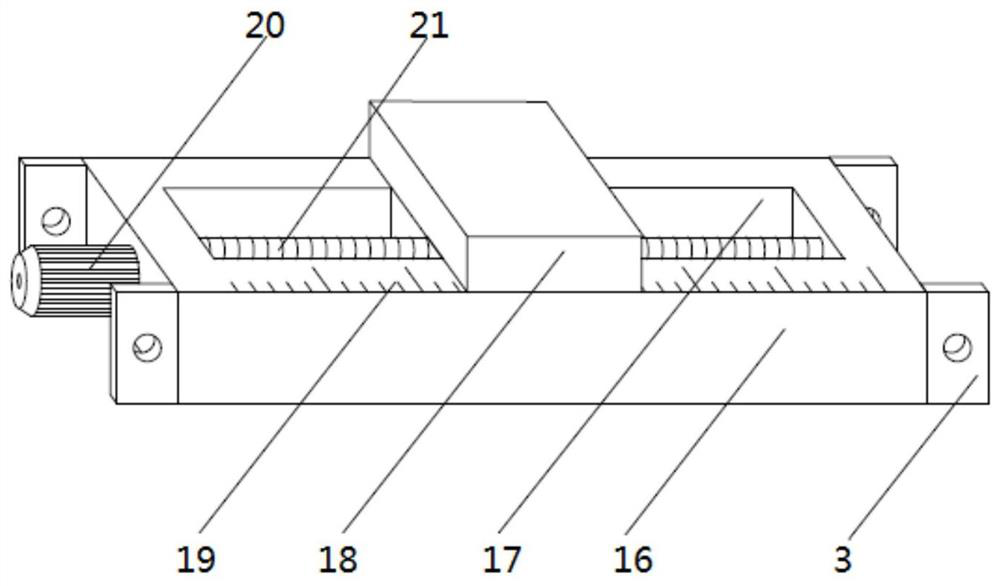

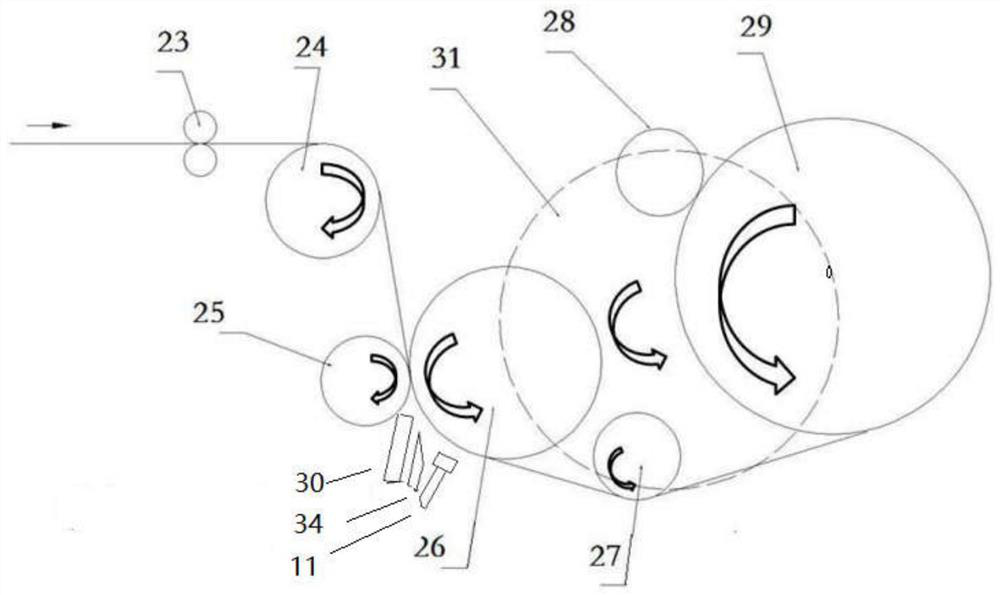

[0032] Referring to the accompanying drawings, the present invention includes an up and down position adjustment mechanism. The up and down position adjustment mechanism is fixed with a cover plate 6 through an L-shaped connecting block 4. The fastening knob 7 is fixed, the top of the telescopic plate 8 is fixed with a positioning plate 12 by bolts, and one side of the positioning plate 12 is equidistantly embedded with blowing nozzles 11, and the blowing nozzles 11 are respectively connected with the main air pipe 9 through the bronchus 10, One side of the main air pipe 9 is connected with the air outlet of the air compressor 14 through a connecting hose 13 . Electromagnetic valve 15 is housed on the pipeline that connects hose 13. The voltage sensor is used to detect whether the electrostatic adsorption rod is powered, and sends the signal to the input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com