Garbage can

A trash can and garbage technology, applied in the field of trash cans, can solve problems such as single function, easy to overdose, and unable to complete packaging, etc., to achieve the effect of simplifying the assembly structure, simplifying the operation steps, and improving the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

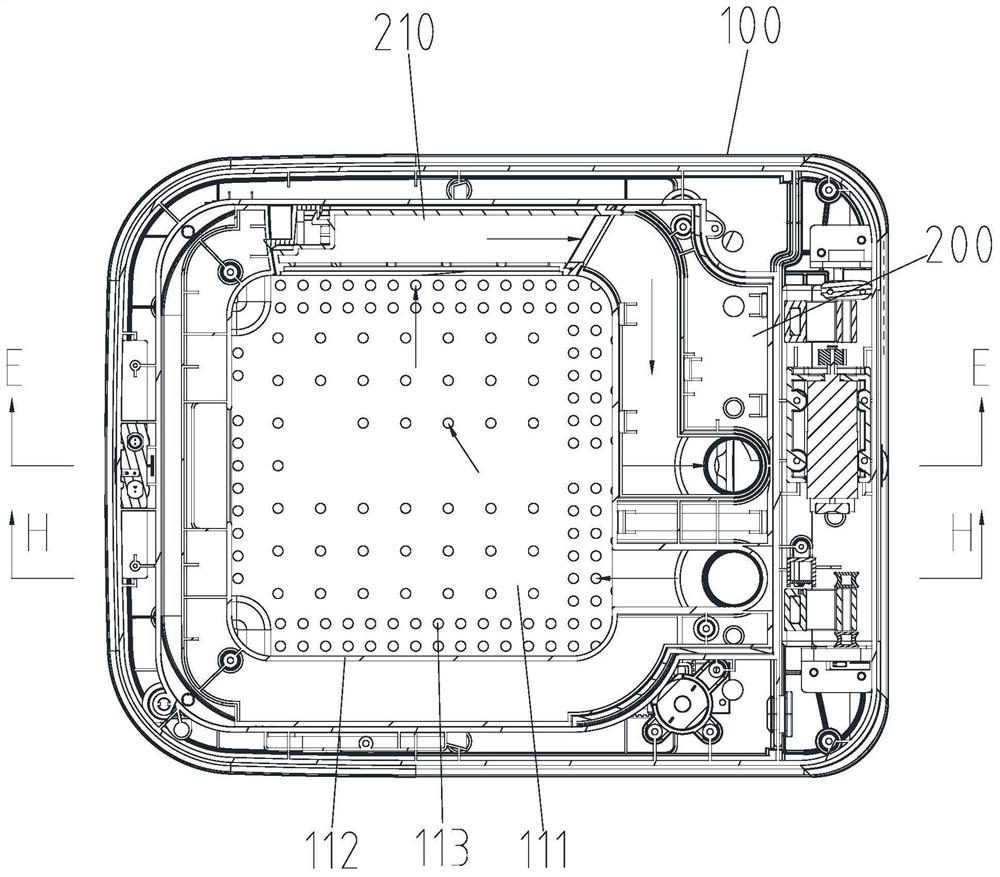

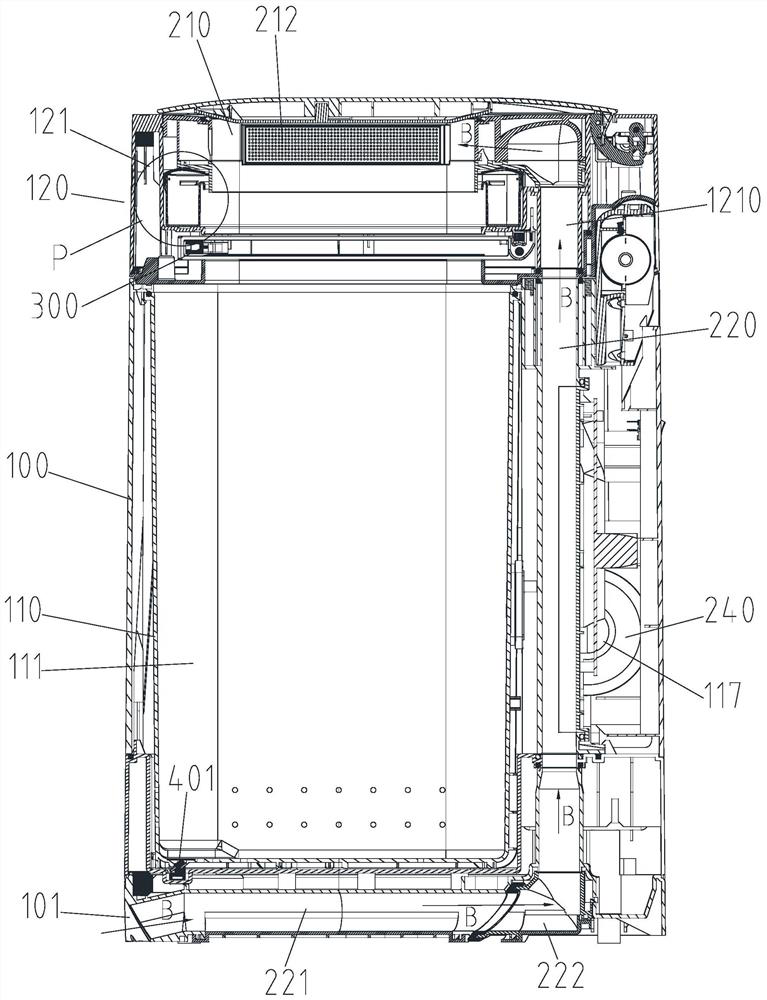

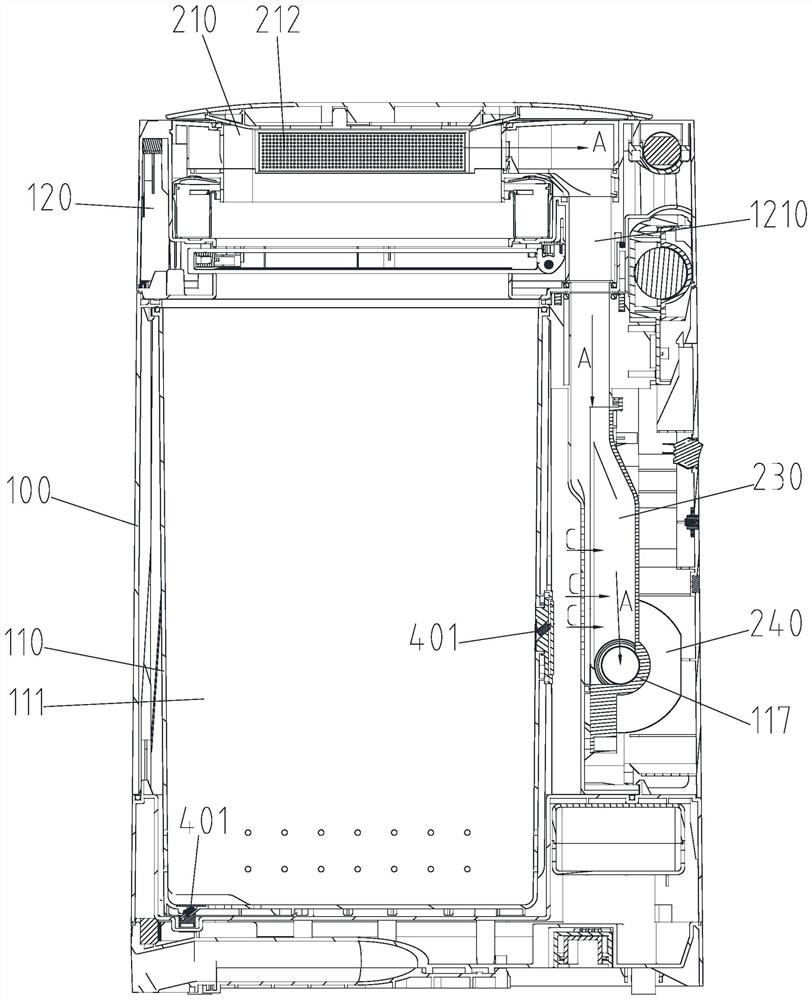

[0101] like Figure 1-3 As shown, the trash can of this embodiment mainly includes a bucket body 100, a dust collection system 200 and a packing system 300, wherein:

[0102] The barrel body 100 is provided with an inner cover 110 , and the upper portion of the barrel body 100 is provided with a barrel cover 120 . The middle of the inner cover 110 is hollow to form an accommodating cavity 111 , and the top surface of the accommodating cavity 111 is provided with an opening 112 for placing garbage bags. The inner cover 110 is also provided with an exhaust hole 113 for exhausting the air between the inner cover 110 and the garbage bags laid in it.

[0103] combine Figure 4 As shown, the barrel body 100 is further provided with a first groove 114-a and a second groove 114-b, the outer side of the first groove 114-a is provided with a first air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com