Mold making method of thermal forming plastic suction female mold and female mold

A technology of thermoforming and negative mold, which is applied to the molding method and the field of the female mold of thermoforming blister, which can solve the problems of reducing the service life of the mold, making it difficult to ensure the integrity of the blister, and failing to make reasonable use of negative pressure. Achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

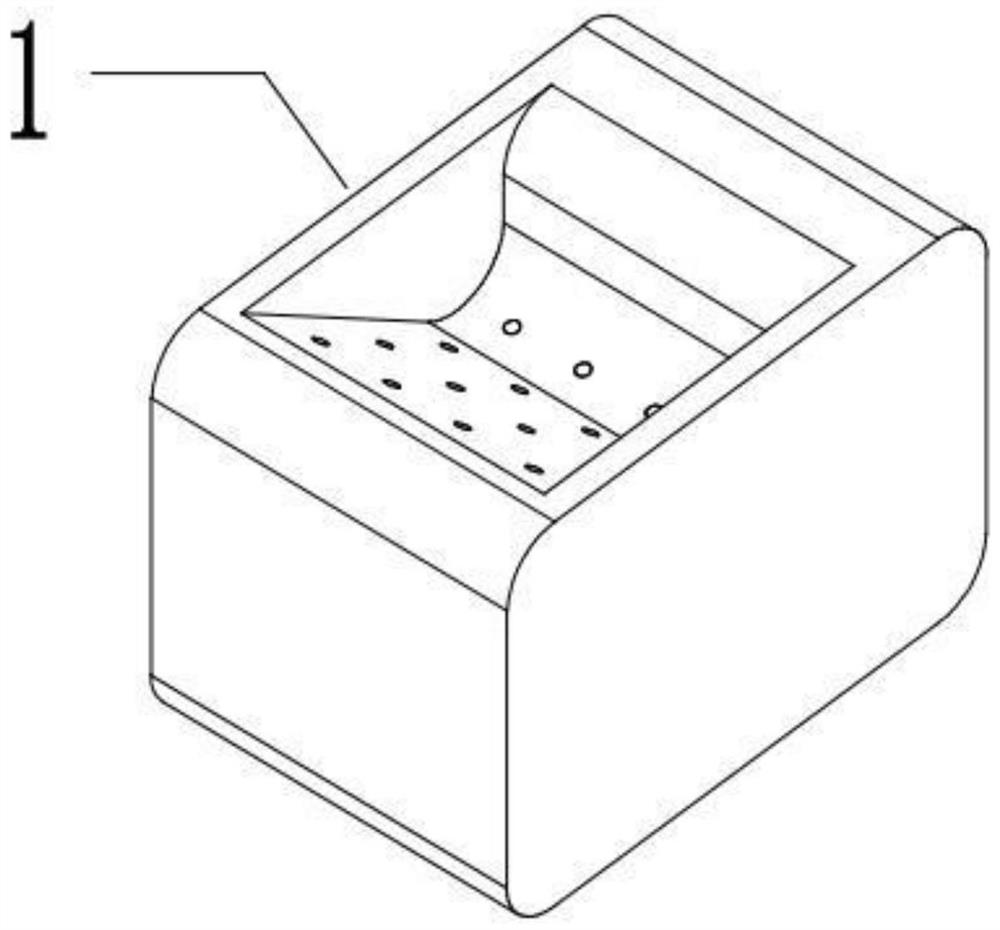

[0077] Such as Figure 1-Figure 9 Shown, a kind of molding method of thermoformed blister female mold comprises the following steps:

[0078] S1, 3D modeling to build the model data of mold body 1;

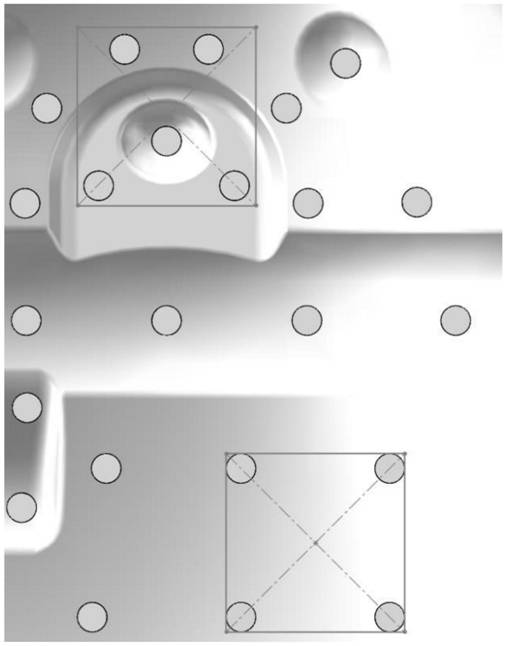

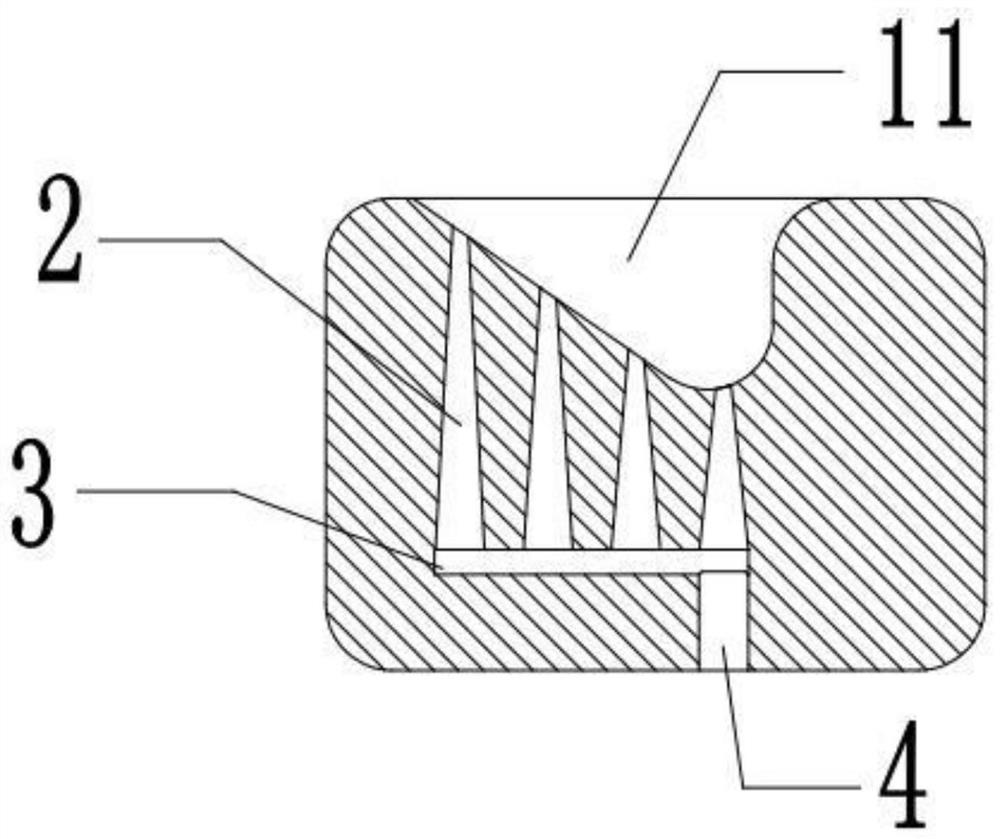

[0079] S2. In the model of the mold main body 1, construct the air extraction channel data formed by connecting multiple groups of air extraction holes 2, series holes 3 and total air outlet holes 4, wherein the air extraction holes 2 penetrate to the cavity 11 of the mold body 1, and the series holes The direction of 3 matches the shape of the bottom wall of the cavity 11, and the series holes 3 start from the total air outlet 4 according to the distance from the air inlet of the air extraction hole 2 to the top plane of the mold body 1, and connect multiple groups in series from far to near. The air extraction hole 2 and the total air outlet hole 4 pass through the main body of the mold 1;

[0080] S3. According to the above construction data, use 3D printing or machining to m...

Embodiment 2

[0110] Such as figure 1 and figure 2 As shown, the difference from Embodiment 1 is that, further, in step S3 of Embodiment 1 above, when using 3D printing to make a female mold,

[0111] 1) For the production of the air extraction hole 2, a draft angle of 0°-5° needs to be produced according to the length of the air extraction hole 2, and the minimum diameter d is greater than 2mm. Specifically, the draft angle of 0°-5° The drawing direction of the degree is the direction of gradually expanding from the bottom wall side of the cavity 11 to the bottom wall side of the mold main body 1;

[0112] 2) The cross-section of the serial hole 3 is set to be an equilateral triangle;

[0113] 3) The minimum wall thickness l of the mold main body 1 is greater than 3mm, and the internal filling rate of the mold main body 1 is 60%-90%, and it should be as compact as possible. Specifically, for a 3D printed female mold, the resistance of the female mold must The heat is not very good, so ...

Embodiment 3

[0115] Such as Figure 3-Figure 6 As shown, the difference from Embodiment 1 is that, further, in step S3 of Embodiment 1 above, the use of machining to make the female mold includes the following steps:

[0116] Step 1. Divide the mold base for the female mold into an upper mold 12 and a lower mold 13 according to the processing position of the serial hole 3 to be processed;

[0117] Step 2. In the upper mold 12, mill the cavity 11 of the mold body 1 according to the model data constructed in the step S1 of the first embodiment, and according to the model data constructed in the step S2 of the first embodiment, in the upper mold 12 Provide air extraction hole 2 on the top, meanwhile, according to the model data constructed in the step S2 of embodiment one, offer serial hole 3 and total air outlet hole 4 on lower mold 13;

[0118] Step 3: Clamp the upper mold 12 and the lower mold 13 processed in step 2 to form a female mold.

[0119] Specifically, the upper mold 12 mainly e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com