Heavy load automotive rear axle wheel side comprehensive experiment table

A test bench and bridge wheel technology, applied in the field of test benches, can solve the problems of non-compliance with lean production, ergonomics, low work efficiency, and high labor intensity of staff, and achieve novel design, low manufacturing cost, and on-site operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

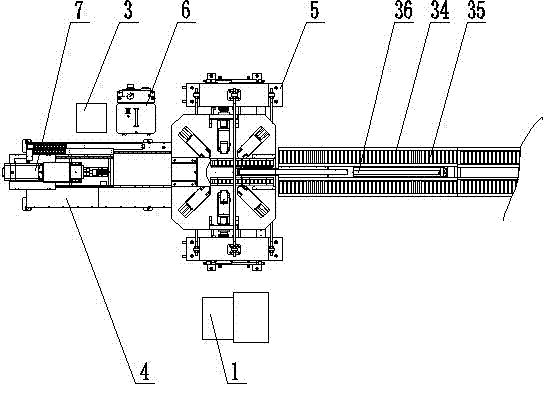

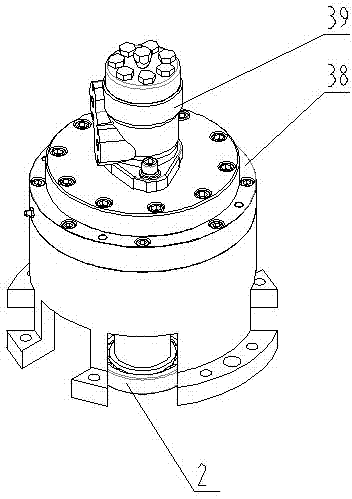

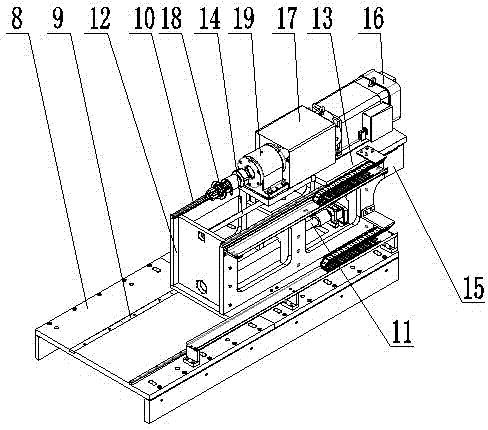

[0023] The heavy-duty vehicle rear axle wheel comprehensive test bench is composed of a foundation support 4, a program control cabinet 1, a hydraulic station 3, a transmission device, a workpiece turning device 5, an oil mist lubrication device 6 and a torque testing device 7. The foundation support 4 is T-shaped, and a workpiece turning device 5 is installed on one end of the foundation support 4 . The workpiece turning device 5 is composed of a support seat 20, a rotating shaft 21, a turning plate 22, a centering claw 23, a floating cylinder 24, a clamping claw 25, a swing cylinder 26, a transmission mechanism 27, a limit blocking plate 28, a locking cylinder 29 and The transmission rack 30 is formed, the support bases 20 are arranged symmetrically, and the flipping plate 22 is movably installed between the support bases 20 through the balance support plate 37 and the rotating shaft 21 .

[0024] The end of the rotating shaft 21 at the outer end of the support seat 20 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com