Two-step push type external expander of large-caliber seamless steel pipe and thermal expanding process for two-step push type external expander

A seamless steel pipe and large-diameter technology, applied in the field of stainless steel manufacturing, can solve the problems of serious environmental pollution, large loss of tools and molds, and many production processes, so as to achieve refined microstructure, increase the rate of finished products and qualifications, and reduce the time for changing specifications short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

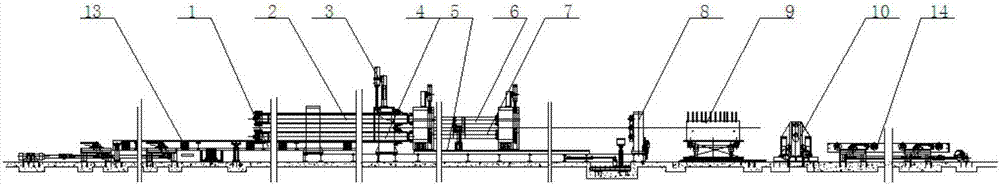

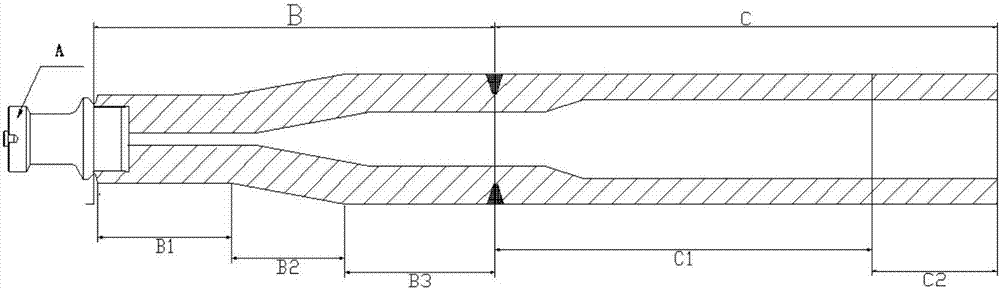

[0033] The present invention provides a two-step push-type thermal expansion machine for large-diameter seamless steel pipes, which includes a base 1 and a pull rod. A steel pipe to be pushed is provided over one end of the pull rod, and a pushing mandrel is provided at the other end of the pull rod. The base 1 is provided with The entrance roller table 13 for conveying steel pipes is provided with a hydraulic lifting gate 3 that can be lifted vertically. The hydraulic lifting gate 3 can be lowered to tighten and push the steel pipes to be horizontally transported to the intermediate frequency induction coil 9 .

[0034] The above-mentioned base 1 is provided with a main oil cylinder 2 for driving the above-mentioned lifting gate to move horizontally.

[0035] A movable push plate trolley 6 and a track 5 for driving steel pipes are also arranged between the inlet end of the intermediate frequency induction coil 9 and the main oil cylinder 2 .

[0036] The outlet end of the int...

Embodiment 2

[0043] The two-step push-type thermal expansion process for large-diameter seamless steel pipes is characterized in that the above-mentioned process steps are as follows:

[0044] The first step is to apply high temperature resistant lubricant evenly on the inner surface of the stainless steel pipe to be pushed;

[0045] The second step is to push the deformed section of the mandrel to be preheated in the intermediate frequency induction coil 9;

[0046] In the third step, after feeding and alignment, the stainless steel pipe to be pushed moves forward through the entrance roller table 13, and the stainless steel pipe to be pushed is inserted into the pull rod, and the main oil cylinder 2 advances to push the steel pipe through the hydraulic lift The ram 3 and the hydraulic lifting ram 3 descend against the steel pipe, and the main cylinder 2 continues to move forward, pushing the steel pipe on the pull rod to move in the direction of the intermediate frequency induction coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com