A pipe row preheating device

A technology of preheating device and tube row, which is applied in lighting and heating equipment, gas fuel burners, combustion methods, etc., can solve the problem of poor heating efficiency of pinhole fire tubes, uneven heating of metal tube walls, and large consumption of natural gas, etc. problems, to achieve the effect of improving product heating quality, improving energy utilization efficiency, and uniform and controllable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

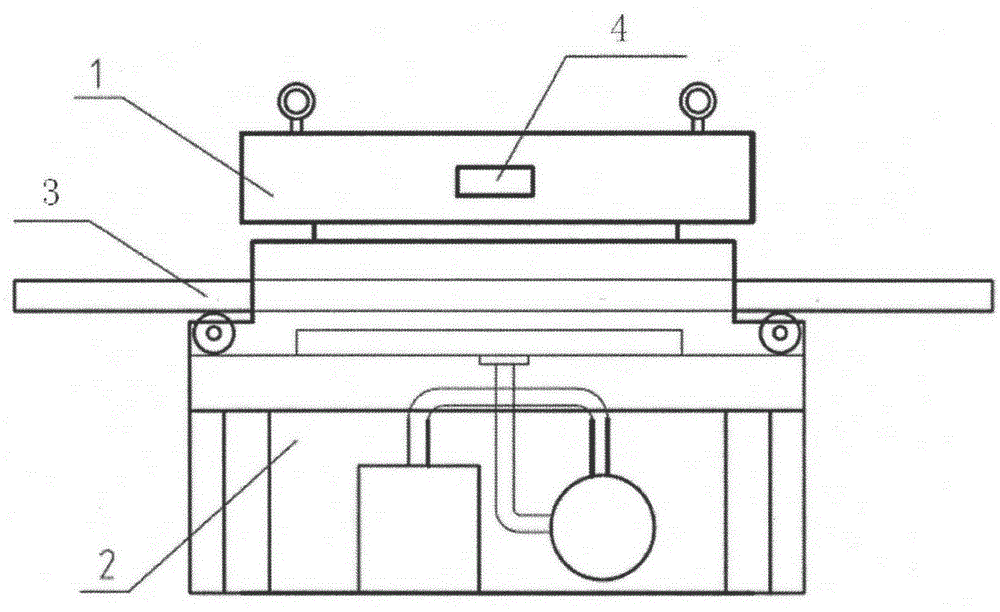

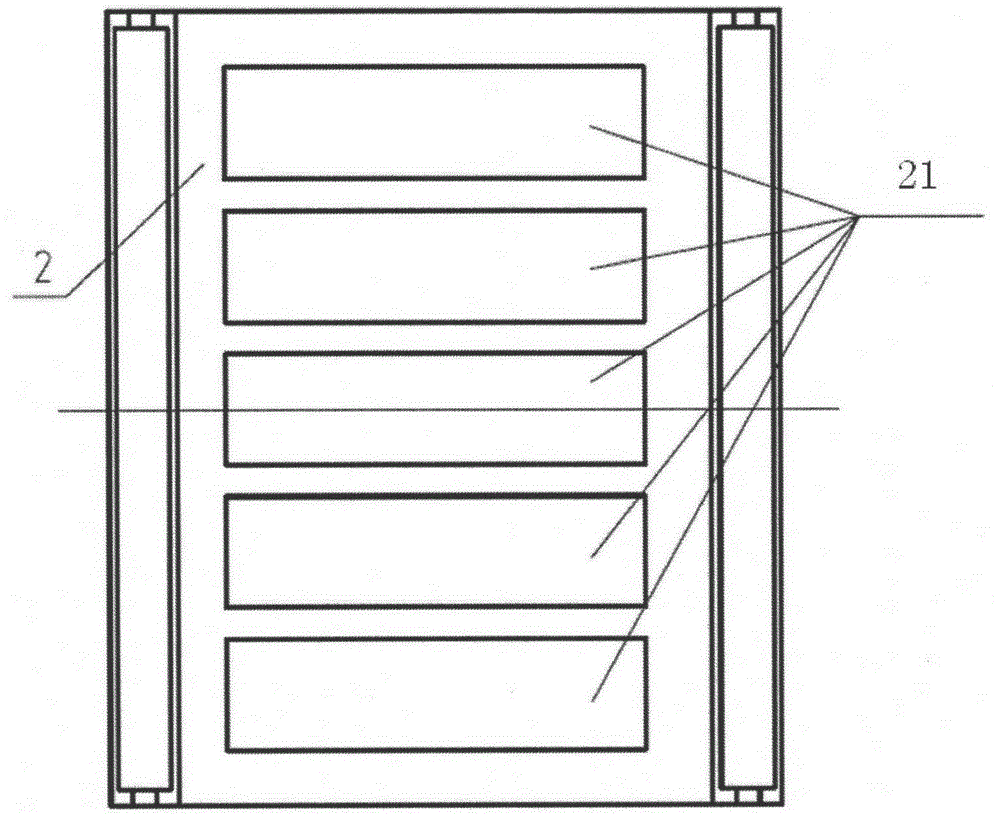

[0015] Such as figure 1 As shown, a pipe row preheating device disclosed in this embodiment includes a cover body 1, a heating platform 2 and an electric control unit. The cover body 1 is arranged above the heating platform 2, and the tube row 3 to be heated can pass through a The device is erected between the cover body 1 and the heating platform 2. In this embodiment, one roller is erected on the left and right sides of the upper surface of the heating platform 2, and the tube row 3 is erected on the two rollers. At the same time, both sides of the tube row 3 are closed by side plates, and a flame observation window 4 is opened in the cover body 1 to observe the heating condition of the tube row 3 , and heat insulating tiles are pasted on the inner wall of the cover body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com