Patents

Literature

31results about How to "Guaranteed uniform performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

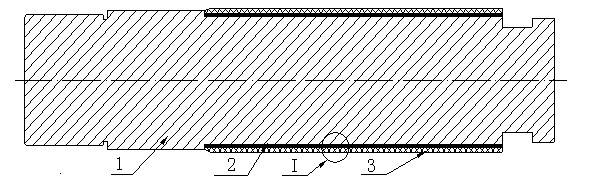

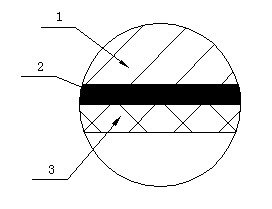

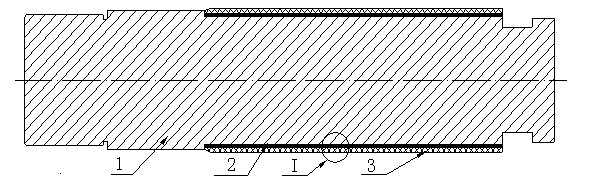

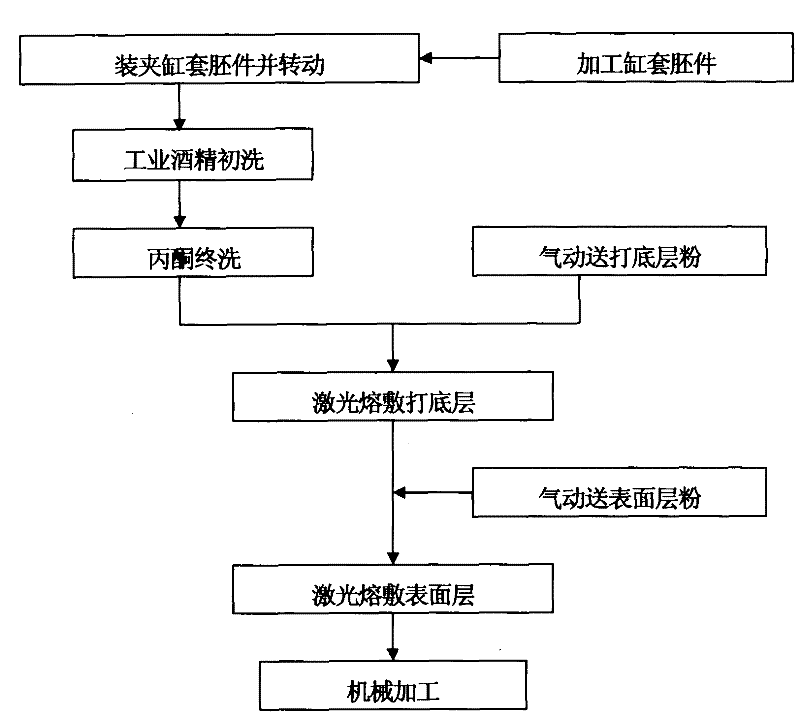

Compounding process of surface strengthening layer of piston rod

ActiveCN101994116AExtended service lifeGuaranteed mechanical propertiesPositive displacement pump componentsMetallic material coating processesForeign matterMartensitic stainless steel

The invention provides a compounding process of a surface strengthening layer of a piston rod, which is characterized by comprising the following steps: whasing oil stains and impurities on the working surface of the piston rod, sending 18-8 type austenitic stainless steel powder gas to the working surface of the piston rod, radiating with laser so as to clad stainless steel powder on the working surface of the piston rod and form a stainless steel cladding bottom layer with the thickness of 1-3mm, further sending 1Cr13 type martensitic stainless steel powder gas onto the bottom layer, and radiating with the laser so as to clad the stainless steel powder on the bottom layer of the working surface of the piston rod and form the stainless steel cladding strengthening layer with the thickness of 1-3mm.The compounding process can realize gradient compound strengthening, lead the piston rod of a hydraulic transmission oil cylinder to have longer service life and more balanced operation performances, and avoid the problems of galling of the working surface of the piston rod,leakage of hydraulic oil and the like during the use,caused by lack of cooling lubricating oil or entrance of foreign matters into the cylinder. The process has strong controllability of parameters and is convenient for processing and operation and convenient for industrial large-batch production.

Owner:云南志熔激光技术有限公司

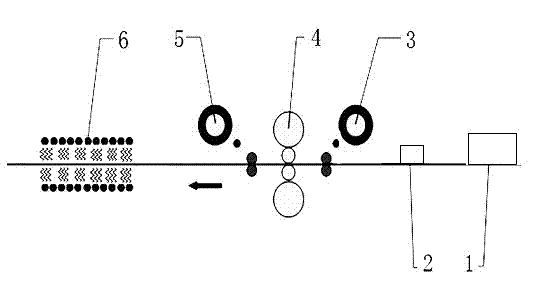

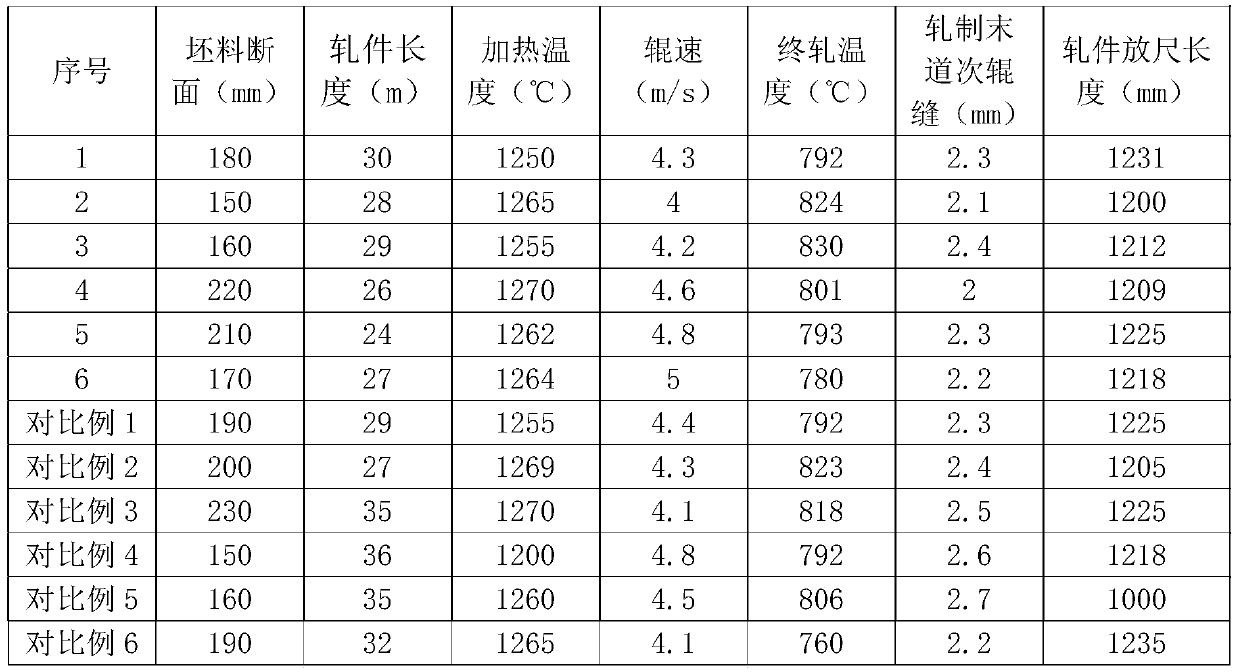

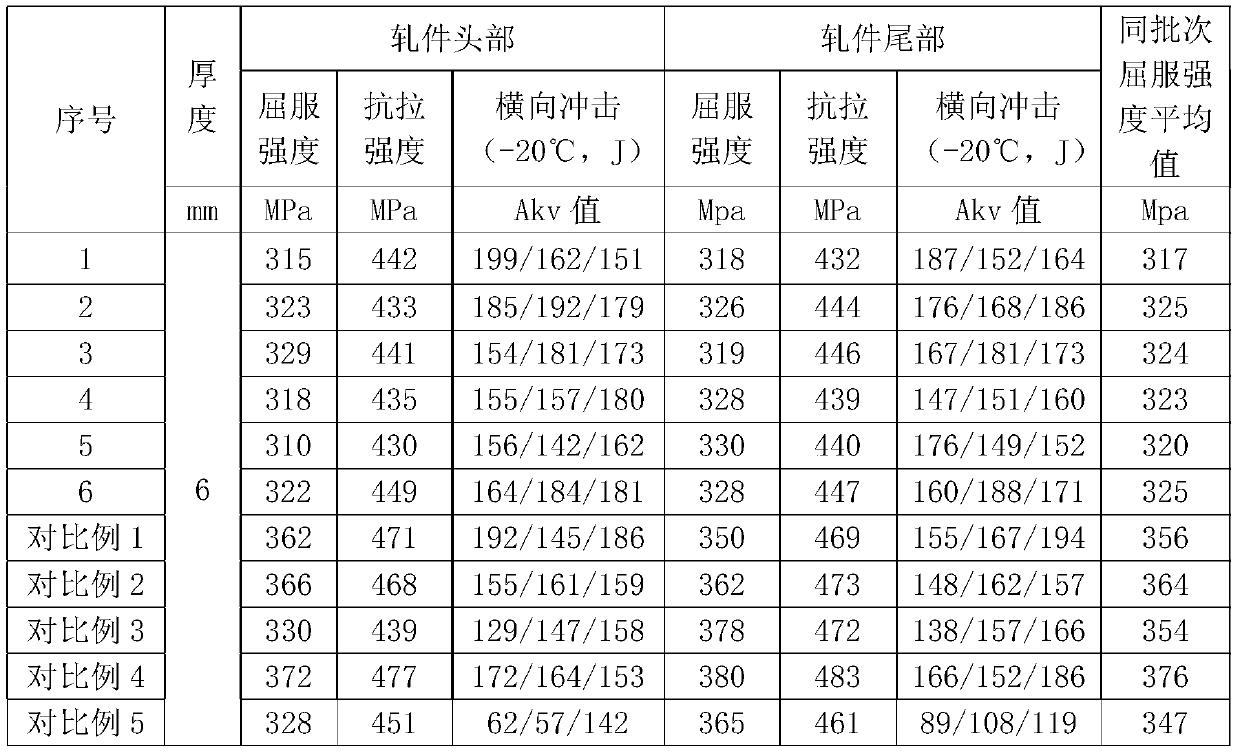

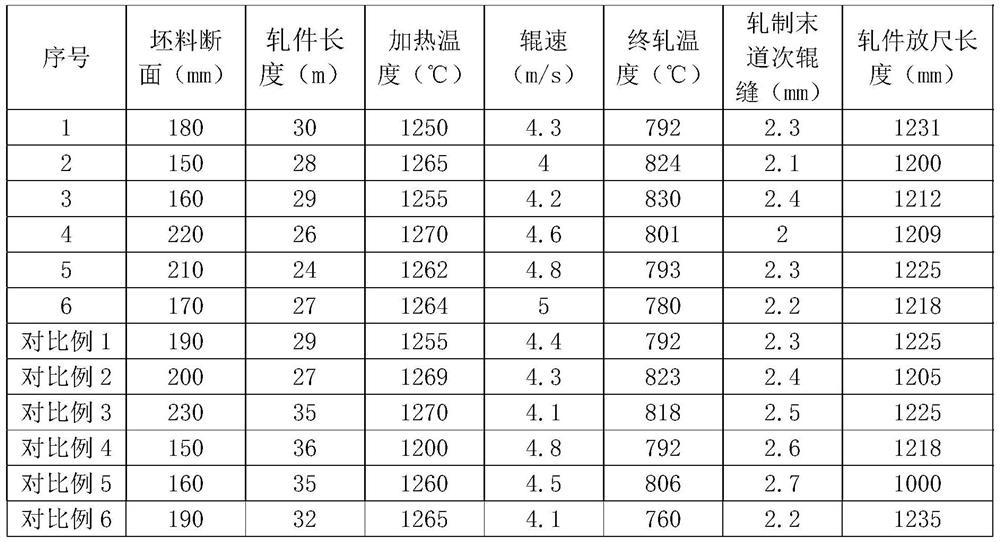

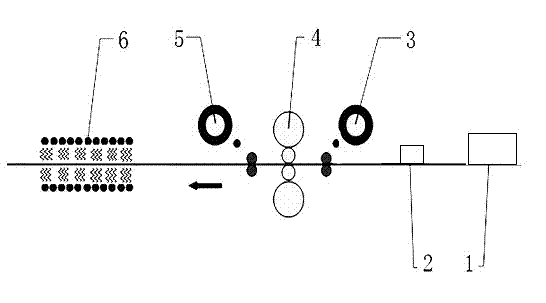

Control process for performances of steel plate during hot rolling and flat rolling process of single-stand steckel mill

ActiveCN102225432AGuaranteed uniform performanceSolve the problem of non-uniform longitudinal performanceTemperature control deviceMetal rolling arrangementsSheet steelStrip mill

The invention discloses a control process for performances of a steel plate during hot rolling and flat rolling process of a single-stand steckel mill, which is characterized in that the steel burning temperature at two ends of a heating furnace is 15-40 DEG C higher than that in the middle, the tail temperature of the billet is 10-25 DEG C higher than that at the head; on the procedure without adoption of the steckel mill for scale removal, an air purging system is started and no accumulated water is left on the surface during the rolling process; after a pyrometer detects that the temperature difference of a rolled piece is larger than 50 DEG C, the mill increases the steel throwing speed by an acceleration smaller than 0.02m / s<2>; after a pyrometer detects that the temperature difference of a rolled piece is larger than 30 DEG C, a laminar flow system automatically closes the last one to three groups of cooling water, so as to improve the temperature rise at the tail of the rolled piece and reduce the temperature rise difference of the rolled piece; and for a wide steel plate, a cooling system adopts edge shielding so as to remove temperature difference between the upper edge and the middle along the width direction. By adopting the process in the invention, the performance uniformity of the steel plate flatly rolled by the single-stand steckel mill can be ensured.

Owner:NANJING IRON & STEEL CO LTD

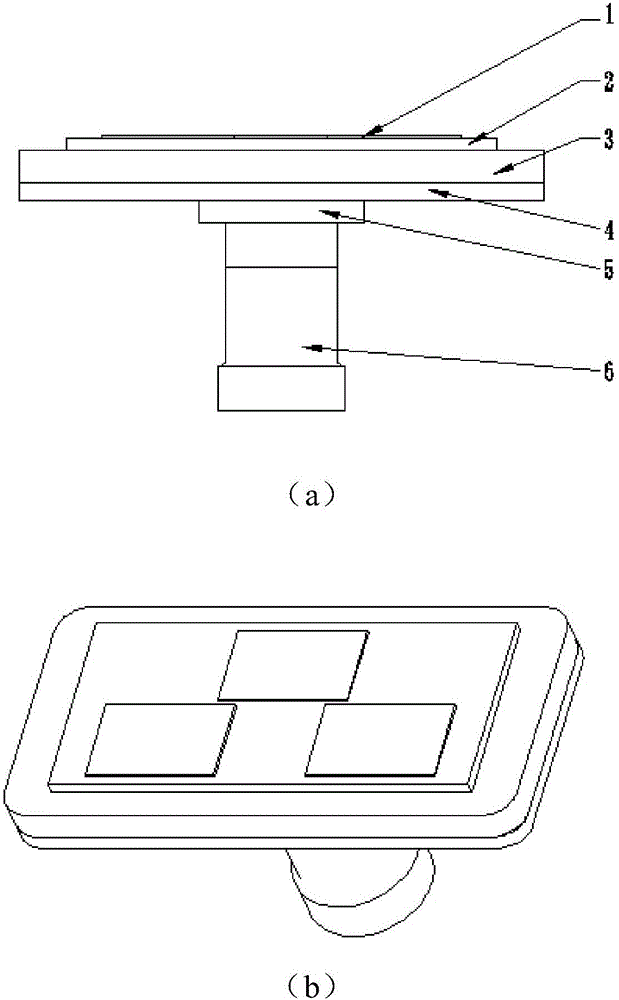

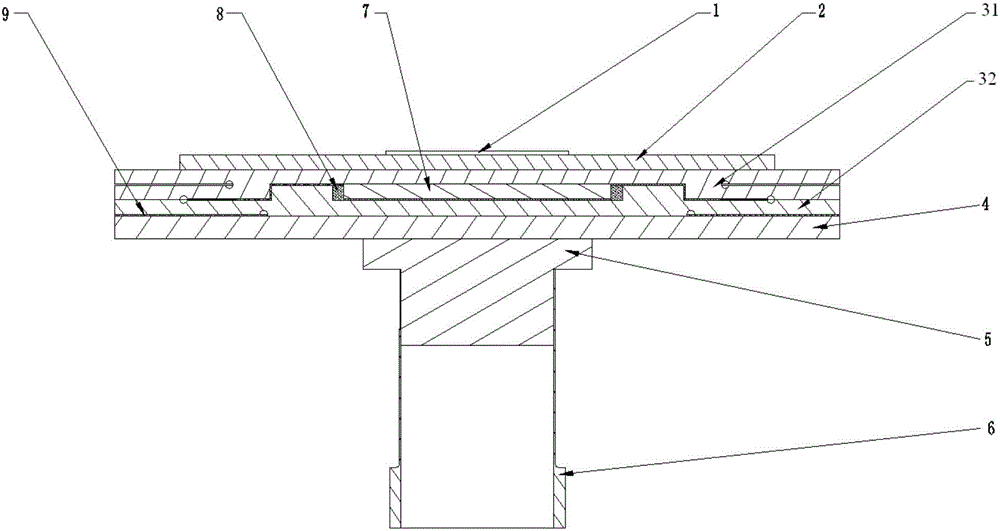

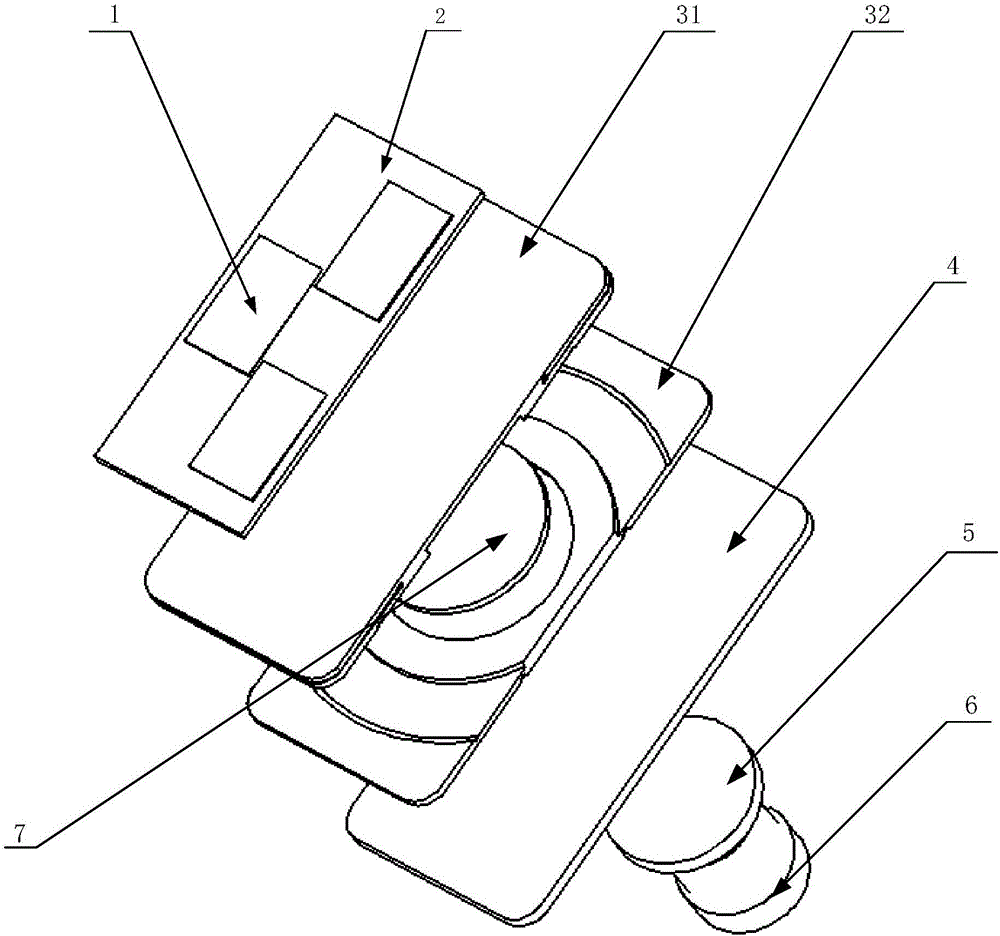

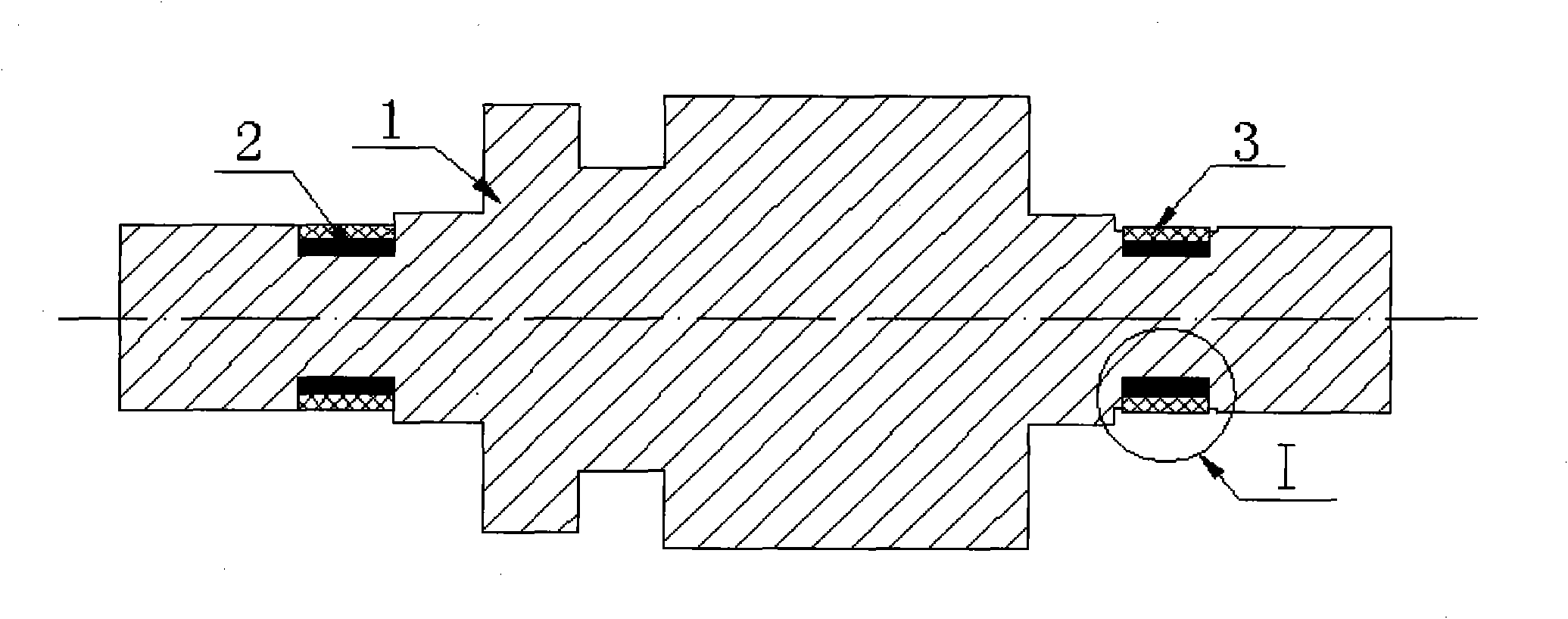

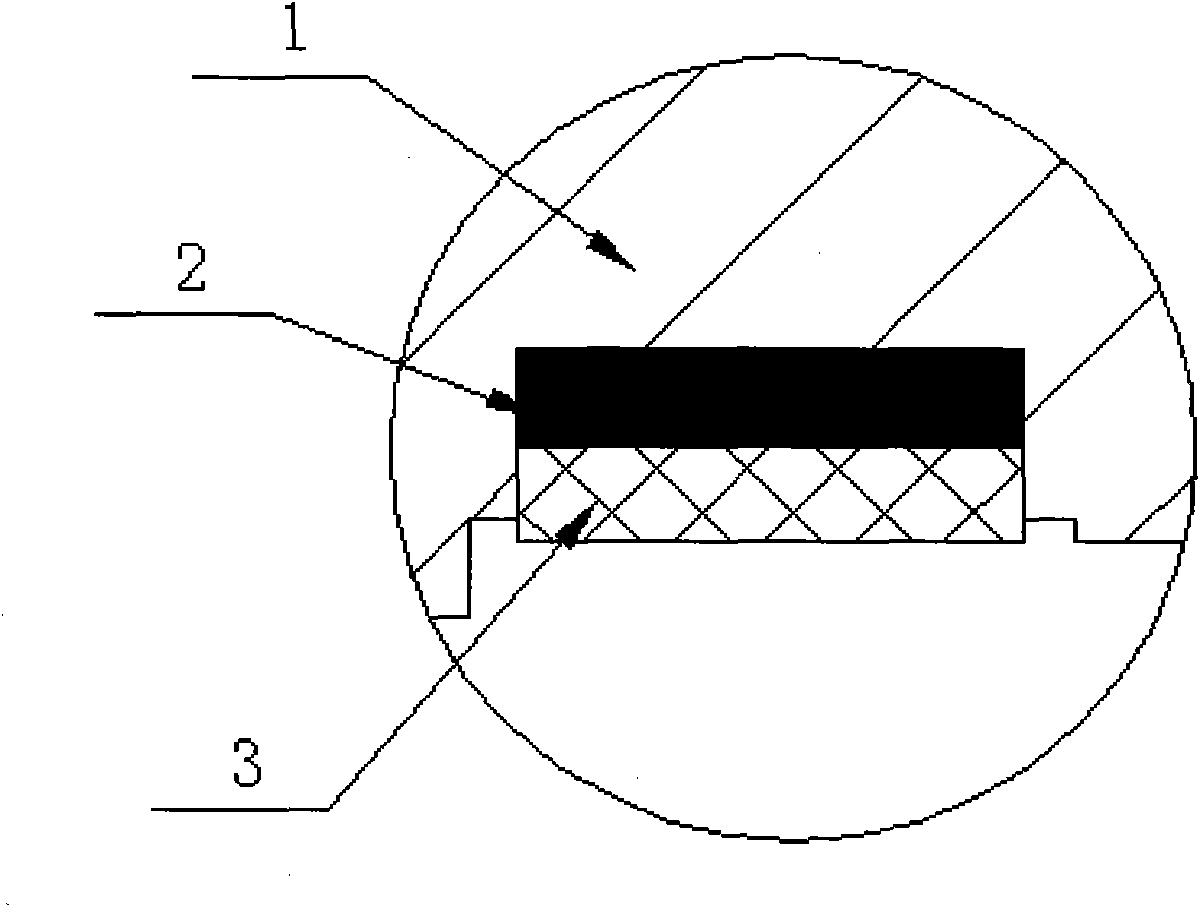

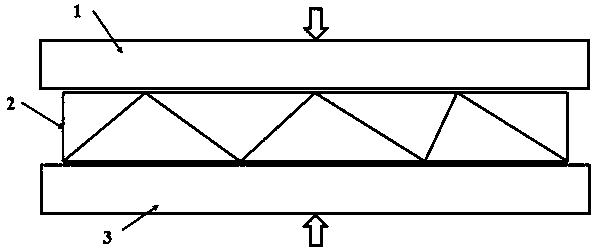

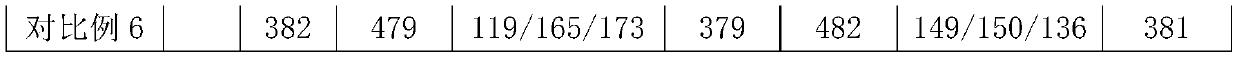

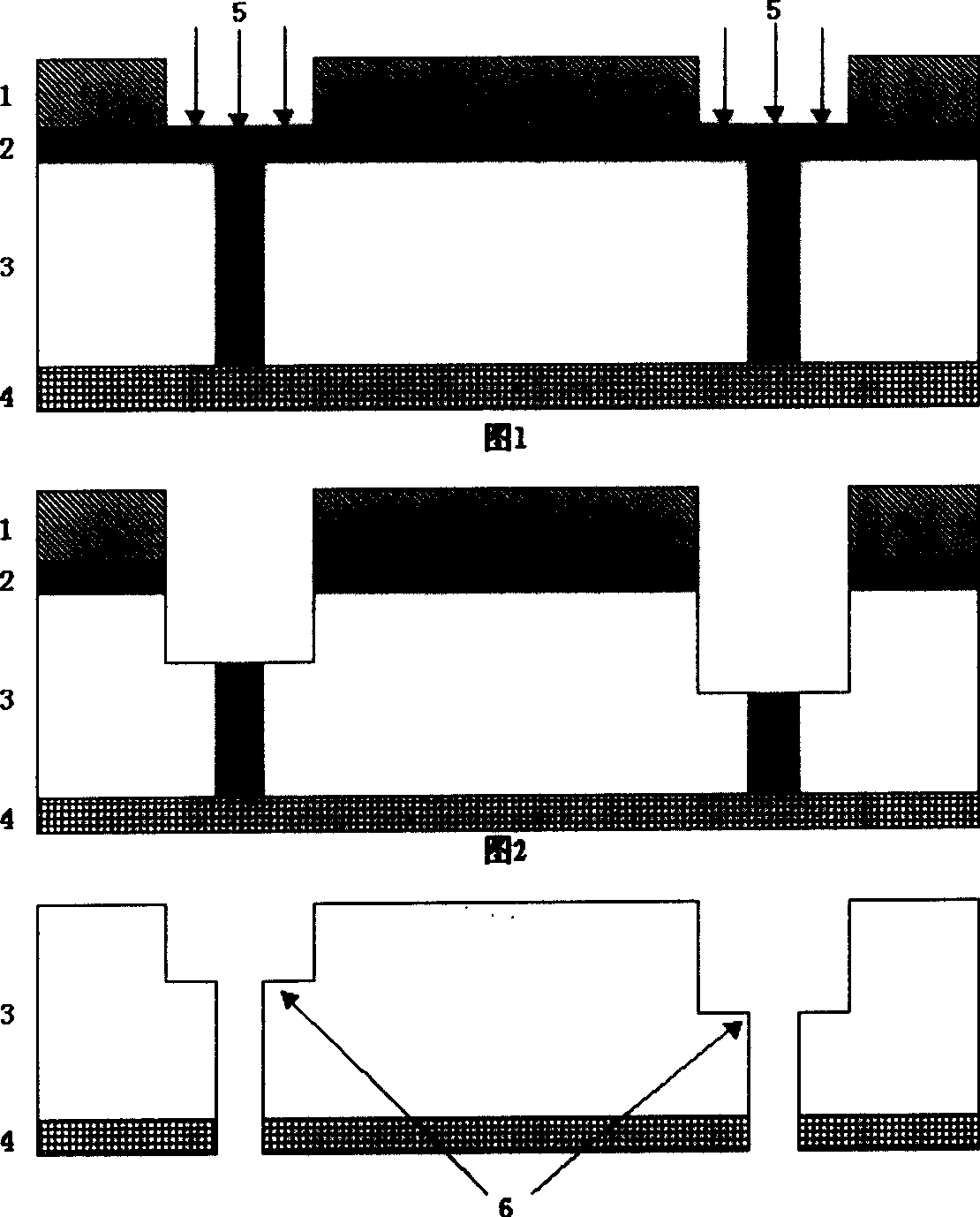

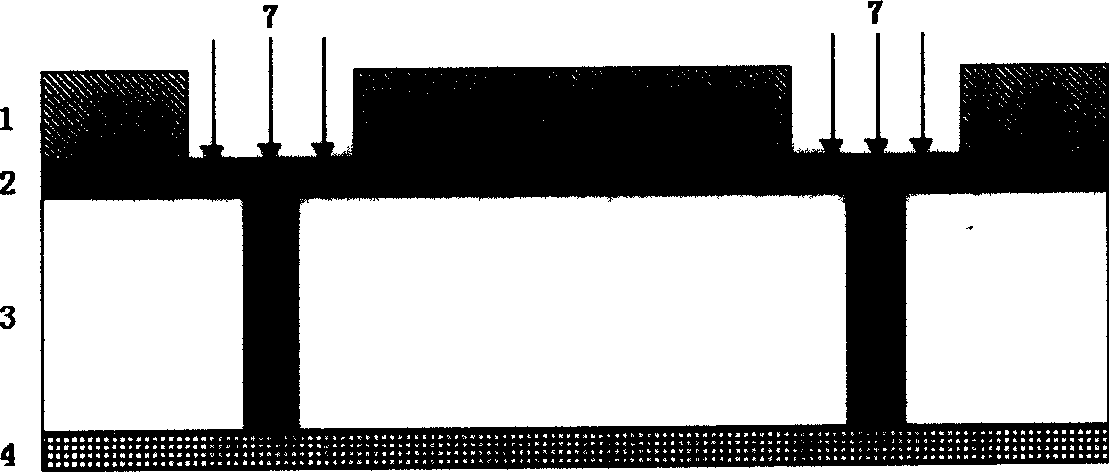

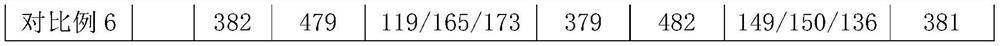

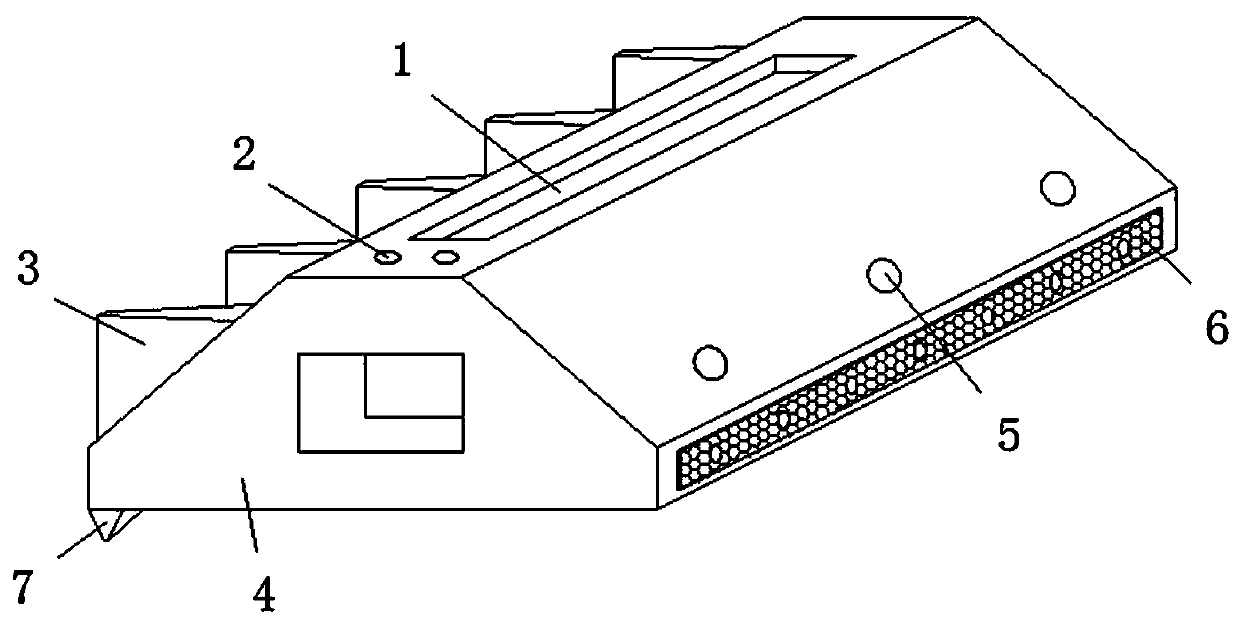

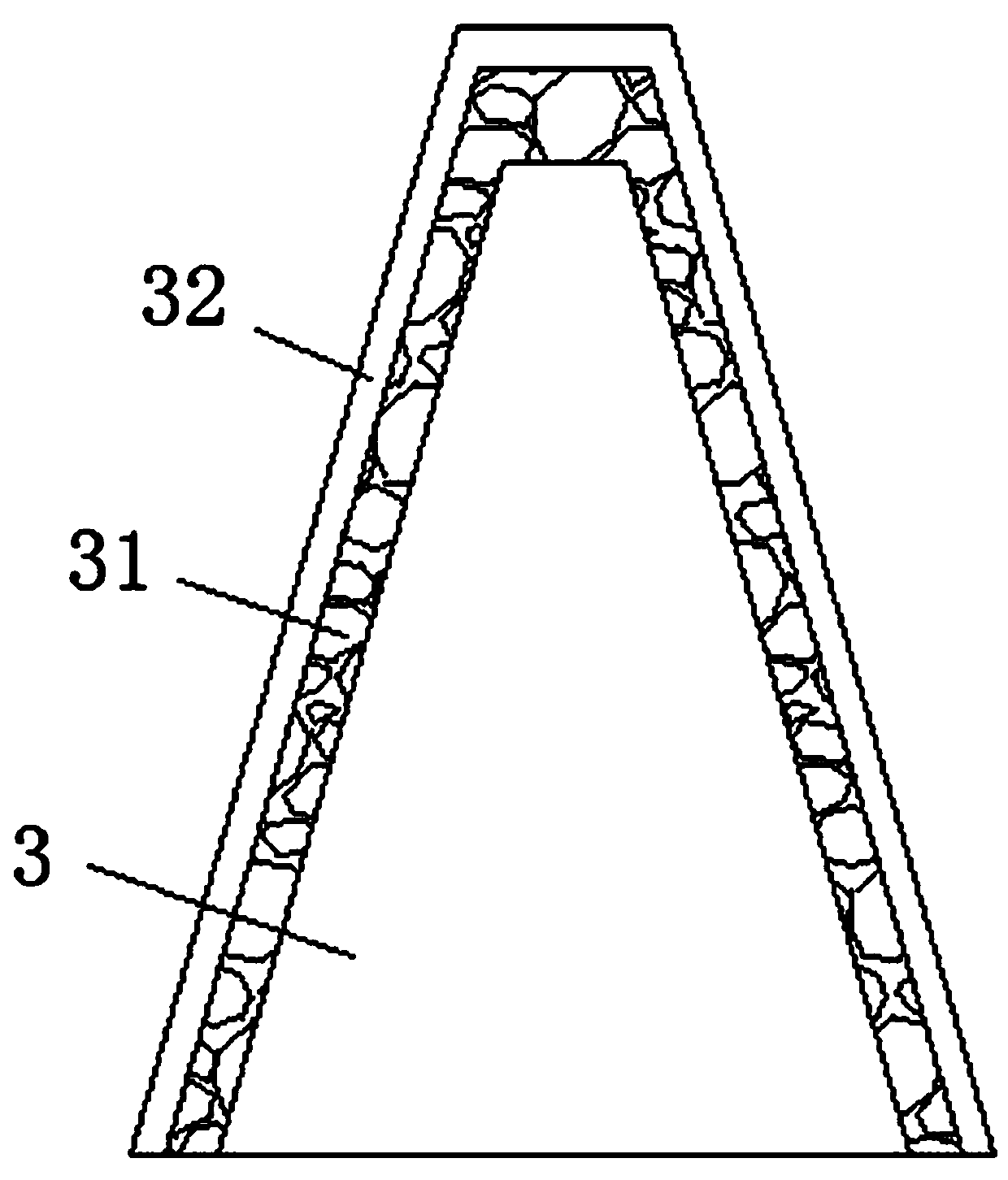

Large-scale infrared focal plane structure with thermal stress unloading capacity

ActiveCN106549067AReduce thermal stressReduce risk of sabotageSemiconductor devicesConvex structureThermal deformation

The invention relates to a large-scale infrared focal plane structure with thermal stress unloading capacity, which comprises a detector chip (1) and the like. The detector chip (1) is mounted on sapphire (2); one lateral surface of a first transitional substrate (31) is a plane, a ring-shaped groove is formed at the middle part of the other lateral surface of the first transitional substrate (31), and the sapphire (2) is adhered to the side of the plane of the first transitional substrate (31); one lateral surface of a second transitional substrate (32) is a plane, a ring-shaped convex structure is formed at the middle part of the other lateral surface of the second transitional substrate (32), the convex structure is abutted with the ring-shaped groove of the first transitional substrate (31) to form a cavity, and a sapphire compensation sheet (7) is mounted in the cavity and is adhered to the first transitional substrate (31); and the second transitional substrate (32) is mounted on a cold plate (4). According to the invention, by the stress unloading structure, a thermal stress and thermal deformation which are generated due to mismatching of thermal expansion coefficients of laminated materials are adsorbed, so that the thermal stress and thermal deformation of a large-scale infrared focal plane are effectively reduced, and reliability of a large-scale infrared focal plane device is improved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

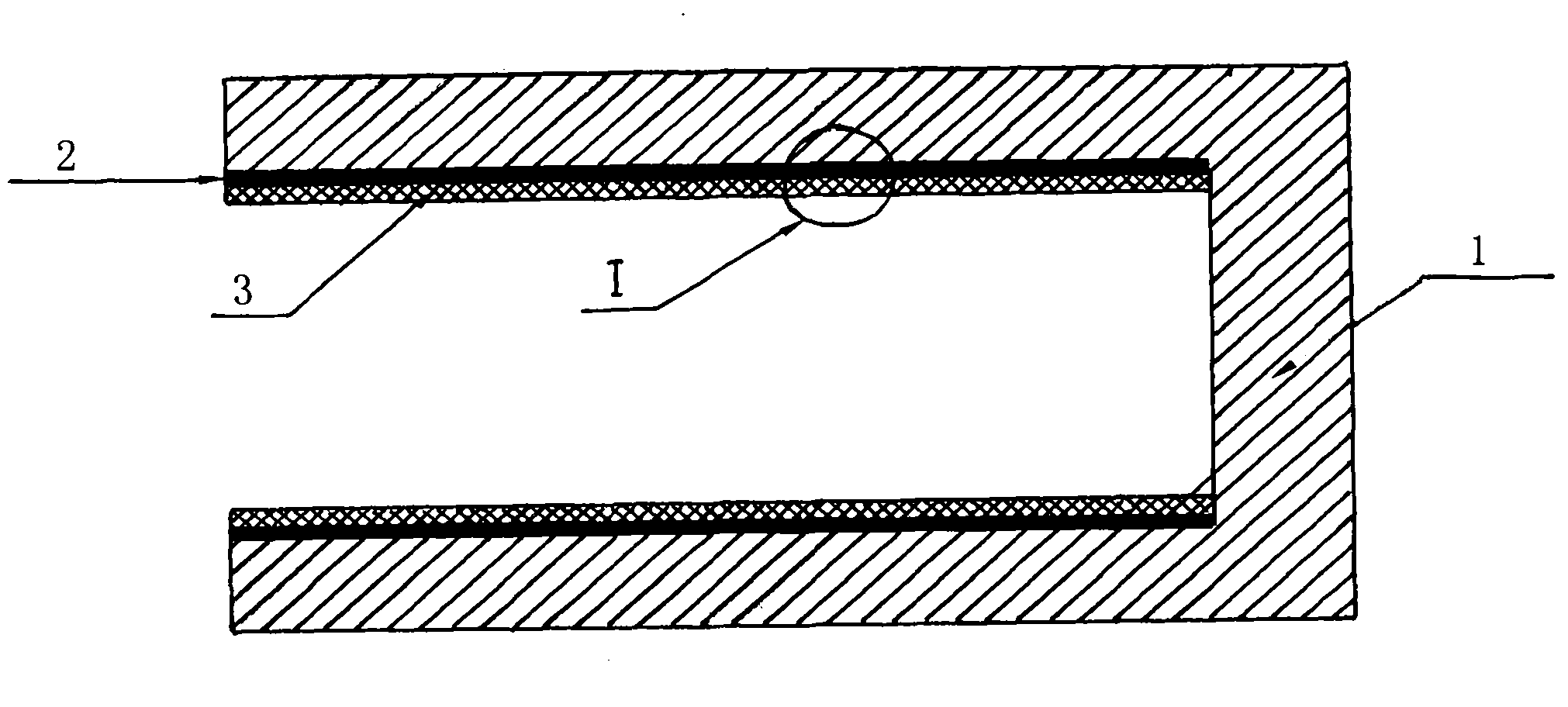

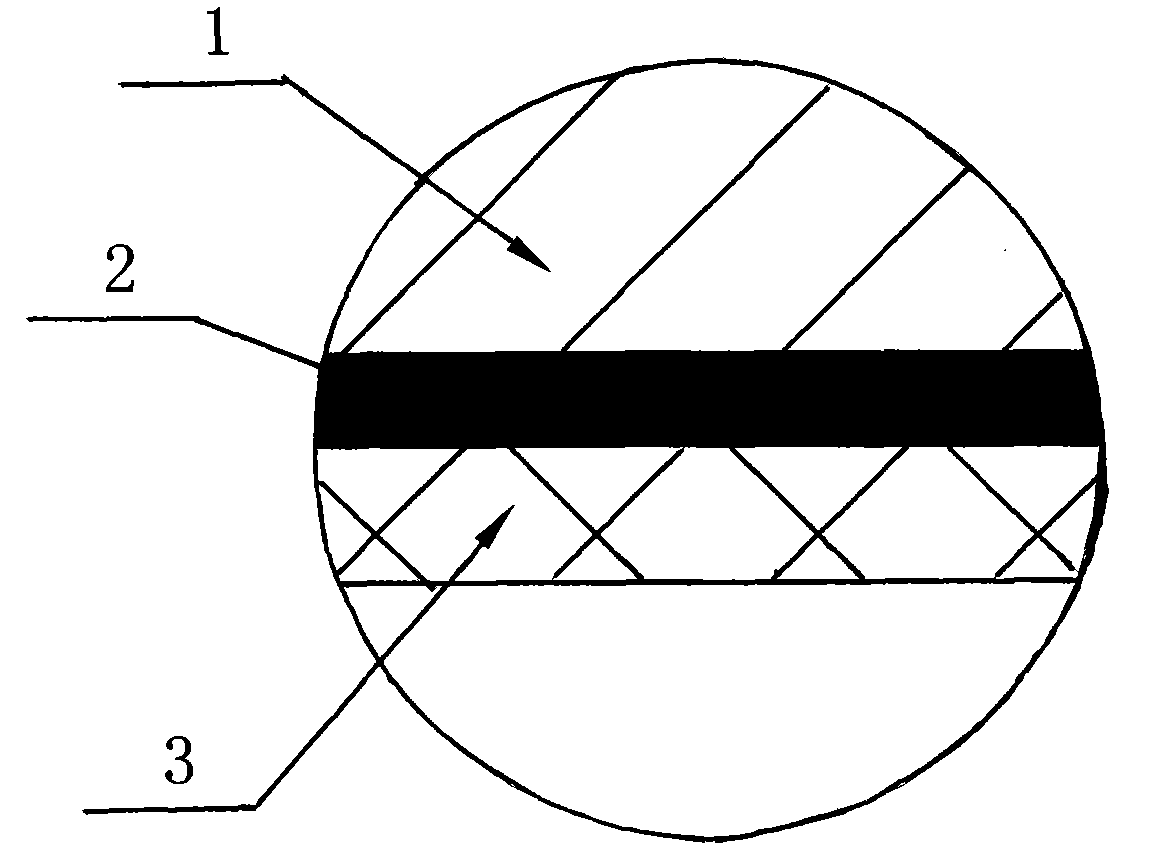

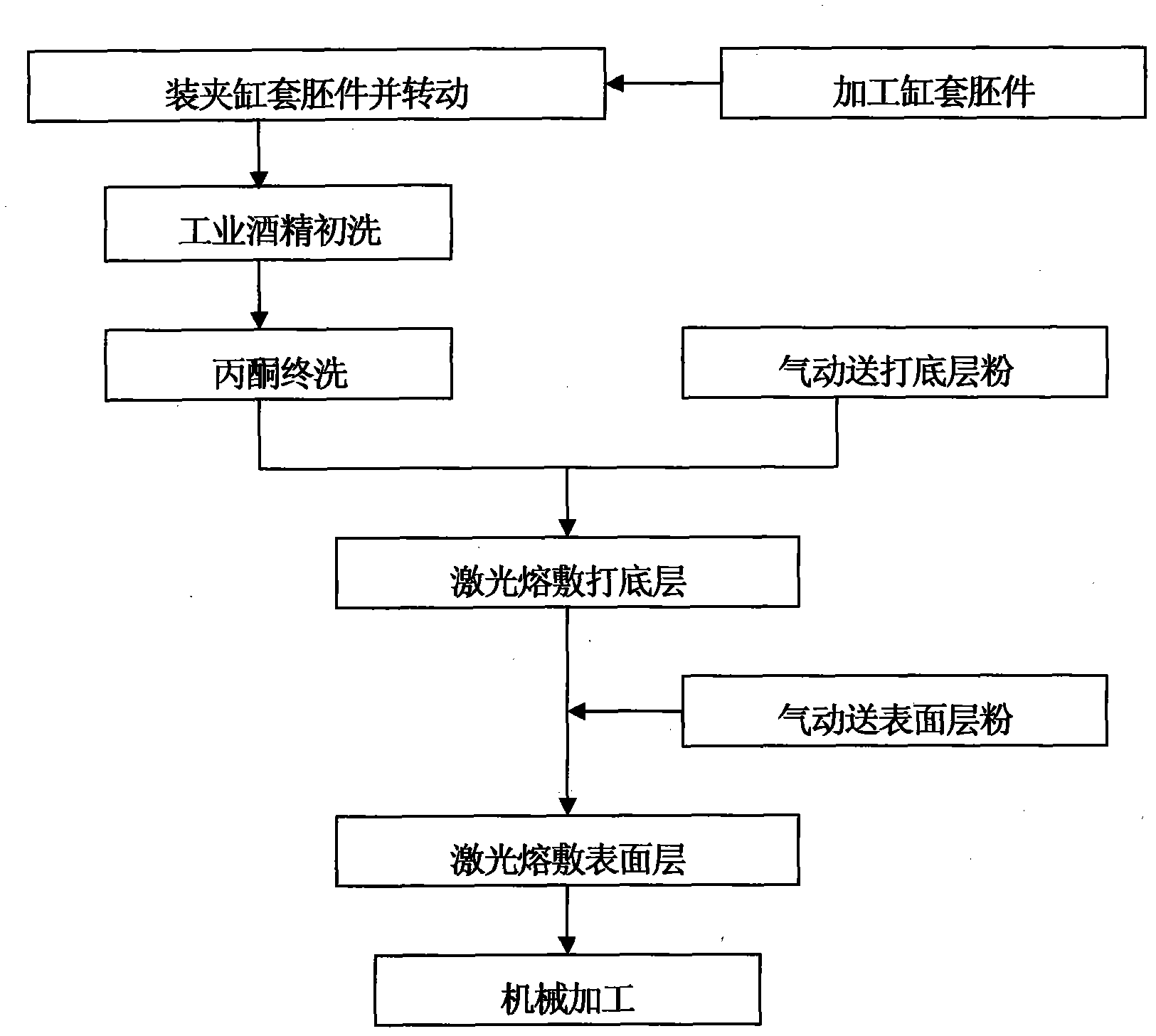

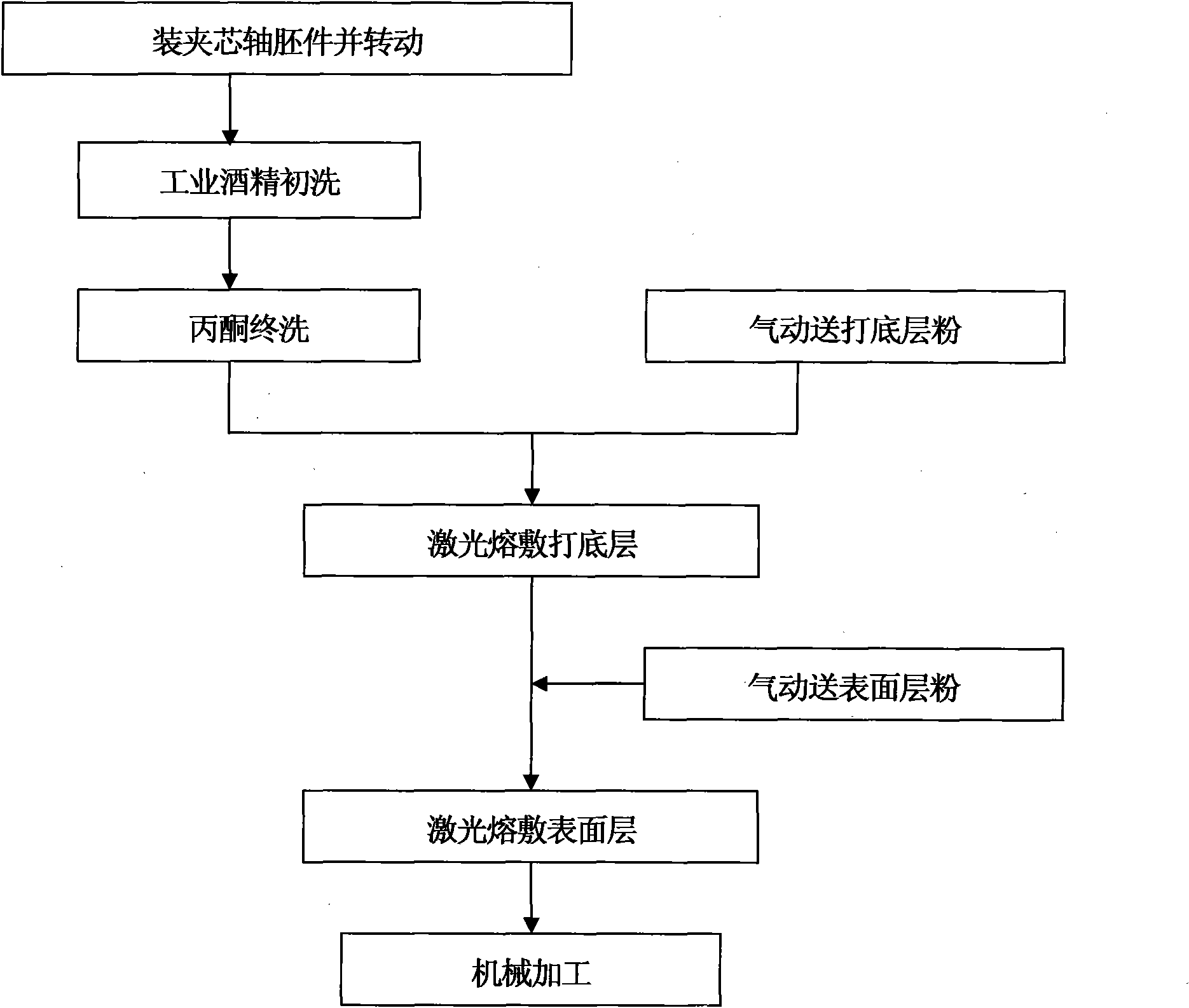

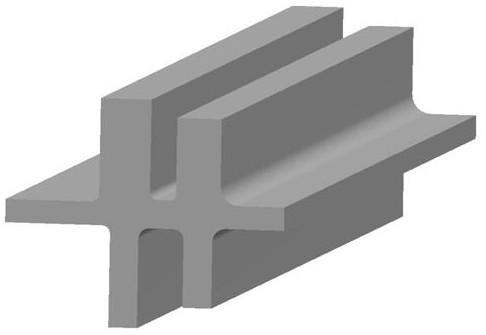

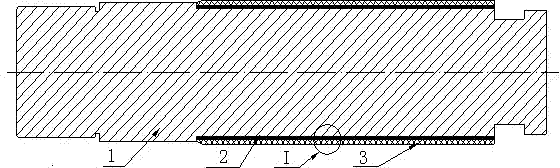

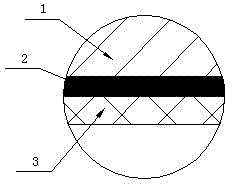

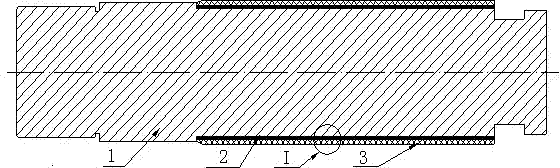

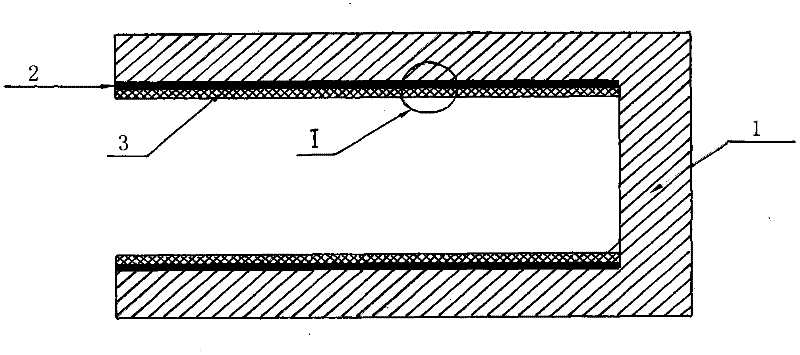

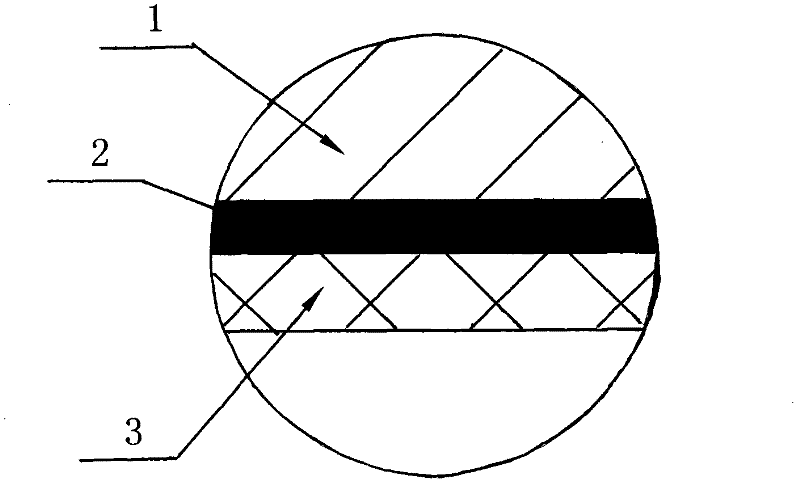

Manufacturing process of composite cylinder sleeve

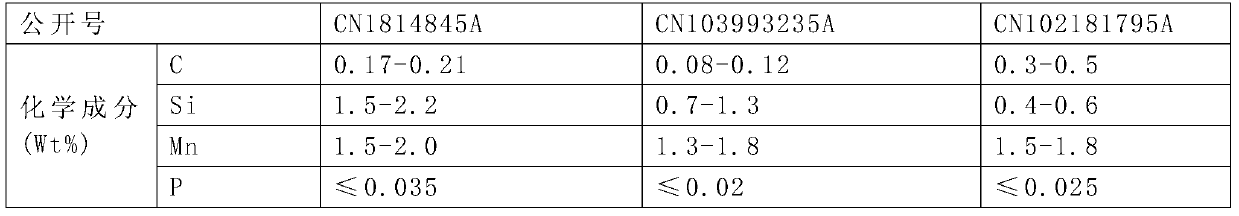

InactiveCN102069351ACost-effectiveImprove the bonding strength of the interfaceMetallic material coating processesCorrosion resistantAustenitic stainless steel

The invention discloses a manufacturing process of a composite cylinder sleeve. In the process, a layer of 18-8 type Austenitic stainless steel is firstly clad on a working surface of a medium carbon quenched and tempered steel or alloy steel cylinder sleeve to be used as a bond coat by a laser cladding technology, and then a layer of 1Cr13 type Martensitic stainless steel is clad to be used as a wear-resistant corrosion-resistant surface layer to realize gradient compounding and strengthening, so the cylinder sleeve of a hydraulic transmission oil cylinder has longer service life and more balanced operation performance, and the problems of cylinder sleeve surface galling, hydraulic oil leakage and the like caused by the frequent reciprocating motion of a piston rod when the working surface of the cylinder sleeve lacks cooling lubricating oil or foreign matters enter the cylinder are avoided. The manufacturing process disclosed by the invention has strong technological parameter controllability, is convenient to operate, and brings convenience industrialized mass production.

Owner:KUNMING UNIV OF SCI & TECH

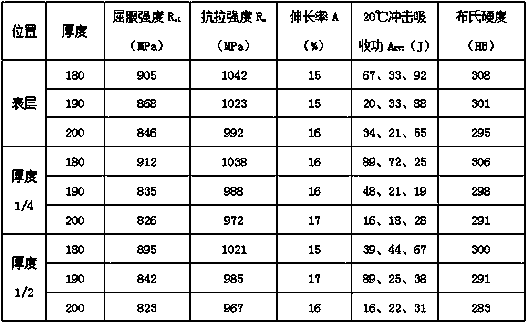

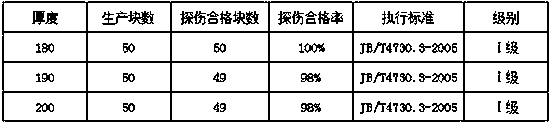

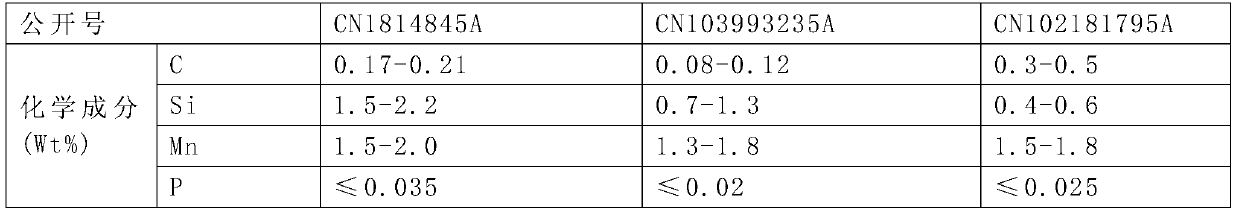

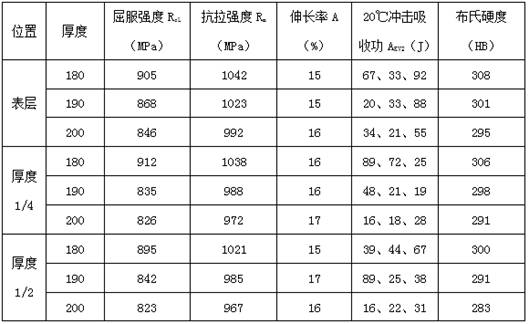

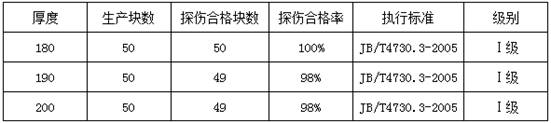

Alloy constructional steel 27SiMn with 180-200mm thickness and manufacturing technology thereof

ActiveCN109609840AImprove hardenabilityHigh strengthProcess efficiency improvementSmeltingHeat treated

The invention discloses alloy constructional steel 27SiMn with 180-200mm thickness and a manufacturing technology thereof. The alloy constructional steel 27SiMn is prepared from the chemical raw materials in percentage by mass: 0.27-0.30% of C, 1.2-1.4% of Si, 1.2-1.3% of Mn, no more than 0.030% of P, no more than 0.030% of S, 0.0008-0.001% of B, 0.020-0.030% of Ti, and the balance of Fe and residual elements. The manufacturing technology comprises the following steps of converter smelting, LF refining, VD vacuum degassing, die casting, heating, rolling, stacking cooling, and heat processing.The components of the alloy constructional steel 27SiMn are rationally designed, the manufacturing technology is improved, and parameters are accurately controlled, so that the alloy constructional steel 27SiMn with 180-200mm thickness and with a good combination property is obtained, and requirements of customers are better met.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

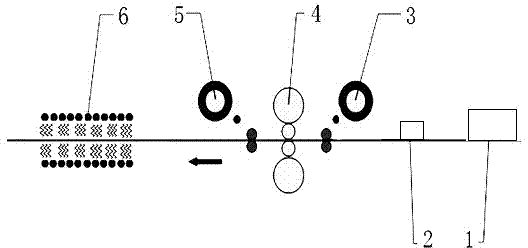

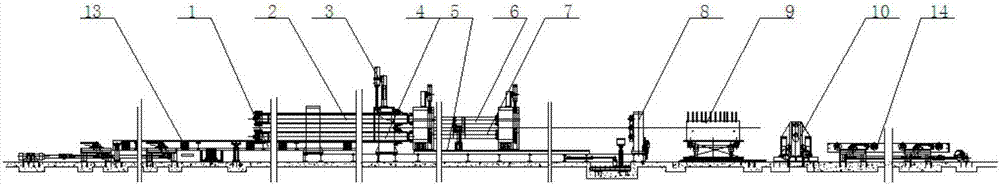

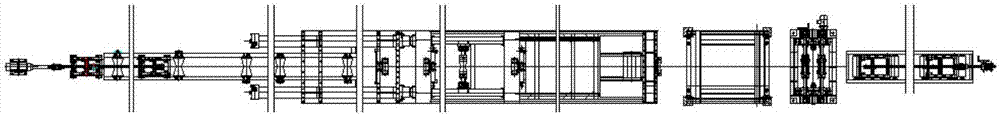

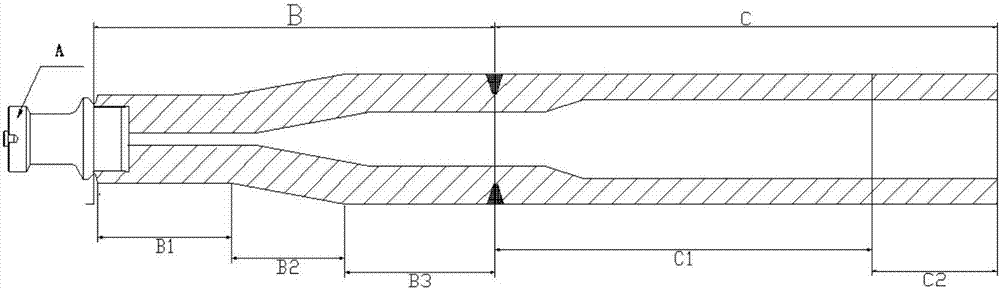

Two-step push type external expander of large-caliber seamless steel pipe and thermal expanding process for two-step push type external expander

InactiveCN106914554AFast and even controllable heatingUniform and controllable heatingShaping toolsMetal-working feeding devicesHydraulic cylinderMedium frequency

The invention discloses a two-step push type external expander of a large-caliber seamless steel pipe. The two-step push type external expander comprises a base and a drawbar, wherein a to-be-pushed steel tube sleeves outside one end of the drawbar; the other end of the drawbar is equipped with a pushing core rod; a feeding roller path for conveying the steel tube is arranged on the base; a hydraulic lifting gate plate capable of vertically lifting is arranged on the feeding roller path; and the hydraulic lifting gate plate can descend, jack and push the steel tube to horizontally convey to a medium-frequency induction heating coil. According to the two-step push type external expander disclosed by the invention, length of a hydraulic cylinder can be reduced nearly a half through two-step push, so that equipment manufacturing cost is reduced, length limitation of oil cylinder processing is solved from the process, raw materials are be quickly and uniformly heated in a controllable mode by the medium-frequency heating equipment, the raw materials can be pushed and deformed at constant speed, and performance uniformity of the tube body can be guaranteed. According to the thermal expander and the process thereof, the investment is less, the equipment is simple, the construction period is short, the product quality is good, the geometric accuracy is high, the yield is high, the energy consumption is low, and pollution is avoided.

Owner:浙江卓业能源装备有限公司

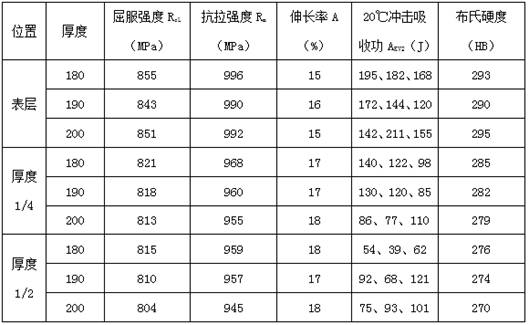

Bulletproof steel plate for armor and manufacturing method thereof

ActiveCN109930075AImprove plastic toughness indexGuaranteed performance uniformitySteel platesSheet steel

The invention provides a bulletproof steel plate for armor and a manufacturing method of the bulletproof steel plate. The bulletproof steel plate for the armor is prepared from, by weight, 0.25-0.38%of C, 0.20-0.40% of Si, 0.22-0.50% of Mn, 0.015% or less of P, 0.005% or less of S, 0.010-0.050% of Alt, 0.10-0.38% of Ni, 0.80-1.50% of Cr, 0.16-0.40% of Mo, 0.010-0.035% of Ti, 0.0050% or less of N,0.00022% or less of H and the balance Fe and inevitable impurities. The manufacturing method of the steel plate comprises a steel making work procedure, a steel rolling work produce and a heat treatment work procedure. The bulletproof steel plate for the armor improves the plastic toughness index while ensuring the strength of the steel plate. The manufacturing method of the bulletproof steel plate for the armor is reasonable in design, the advantages of each control process are fully exerted, the uniformity of the performance of the steel plate is guaranteed, the influence of residual internal stress of the steel plate is effectively eliminated, and the subsequent cutting, welding and other machining properties of the steel plate are improved.

Owner:贝斯山钢(山东)钢板有限公司

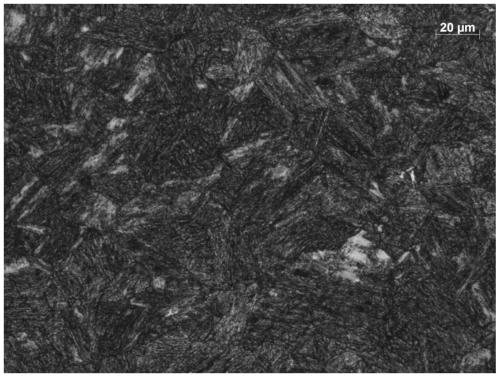

On-line quenched HB400-grade wear-resistant steel plate and preparation method thereof

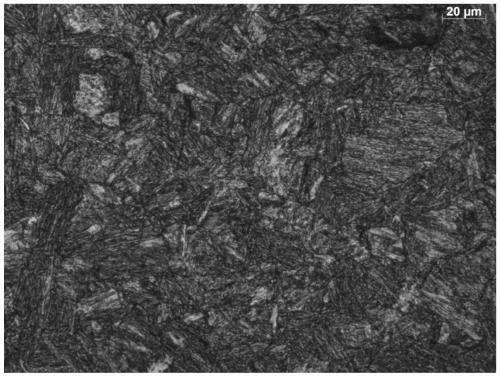

The invention relates to the technical field of high-strength wear-resistant steel plate preparation, in particular to an on-line quenched HB400-grade wear-resistant steel plate and a preparation method thereof. The steel plate comprises the following components of, in percentage by weight, 0.15%-0.18% of C, 0.30%-0.60% of Si, 0.22%-0.40% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.025%-0.050% of Alt, 0.10%-0.25% of Ni, 0.80%-1.00% of Cr, 0.15%-0.30% of Mo, 0.010%-0.030% of Ti, less than or equal to 0.0050% of N, less than or equal to 0.00015% of H, the balance Fe and trace impurities. The thickness of the steel plate is 8-20 mm. According to the preparation method, the manufactured wear-resistant steel plate is characterized in that the hardness value ofthe wear-resistant steel plate is 370 HBW-430 HBW, the tensile strength is 1250-1430 MPa, the elongation percentage (A50) ranges from 15% to 18%, the impact toughness value at 20 below zero is greater than or equal to 50J, excellent wear resistance is provided, meanwhile, excellent low-temperature impact toughness is provided, and wear-resistant steel plate is suitable for being used under severeworking conditions such as mining machinery and the like. In addition, different from the conventional off-line conditioning process, the wear-resistant steel plate manufactured by the method is produced by adopting an online quenching and off-line tempering process, the remarkable advantages of short production process and low manufacturing cost is realized.

Owner:贝斯山钢(山东)钢板有限公司

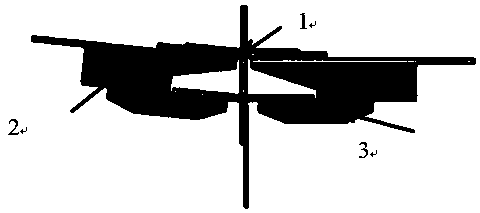

Laser cladding reinforcing process of motor central spindle

InactiveCN102071418AAchieve life extensionGuaranteed mechanical propertiesMetallic material coating processesHigh volume manufacturingWear resistant

The invention discloses a laser cladding reinforcing process of a motor central spindle. In the reinforcing process, a layer of 18-8 type austenitic stainless steel serving as a base coat is cladded by laser cladding technology at the bearing position of the central spindle, and then a layer of 1Cr13 type martensite stainless steel serving as a wear-resistant and corrosion-resistant surface layeris cladded, so that stepped reinforcement is realized, the service life of the motor central spindle is prolonged, operating performance is balanced, and using problems such as corrosion of the central spindle at the bearing position, shaft deviation caused by wear, roughing of a bush and the like are solved. In the process, parameter controllability is high, machining operation is convenient andindustrial batch production is convenient.

Owner:KUNMING UNIV OF SCI & TECH

7-series aluminum alloy profile used for civil aircraft first rib and preparation method thereof

InactiveCN111411273AGuaranteed performance uniformityReduce temperature and performance varianceIngot castingAluminium alloy

The invention discloses a 7-series aluminum alloy profile used for a civil aircraft first rib and a preparation method thereof and belongs to the field of manufacturing of aluminum alloy profiles usedfor a civil aircraft. The profile comprises the following substances including, by weight, smaller than 0.08% of Si, smaller than 0.10% of Fe, 2.1%-2.4% of Cu, 2.0%-2.2% of Mg, smaller than 0.05% ofMn, smaller than 0.02% of Cr, 7.8%-8.2% of Zn, 0.02%-0.06% of Ti, 0.08%-0.12% of Zr and the balance Al. According to the 7-series aluminum alloy profile used for the civil aircraft first rib and the preparation method thereof, to meet requirements for the performance of the aluminum alloy profile used for the civil aircraft first rib, an ingot casting step heating isothermal reverse extrusion technology, a combined tooling uniform stretching technology and the like are adopted, the uniformity of the performance of different portions of the profile is guaranteed, and the 7-series aluminum alloyprofile meeting the using requirements of the domestic civil aircraft first rib is produced.

Owner:SHANDONG NANSHAN ALUMINUM +1

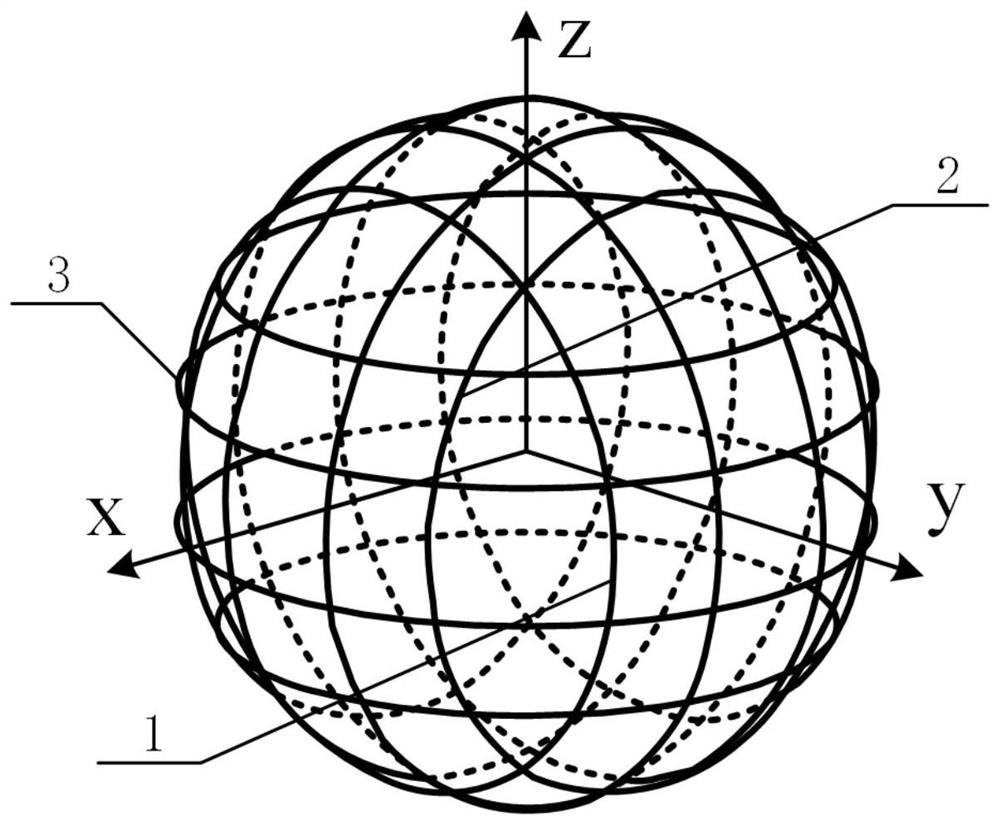

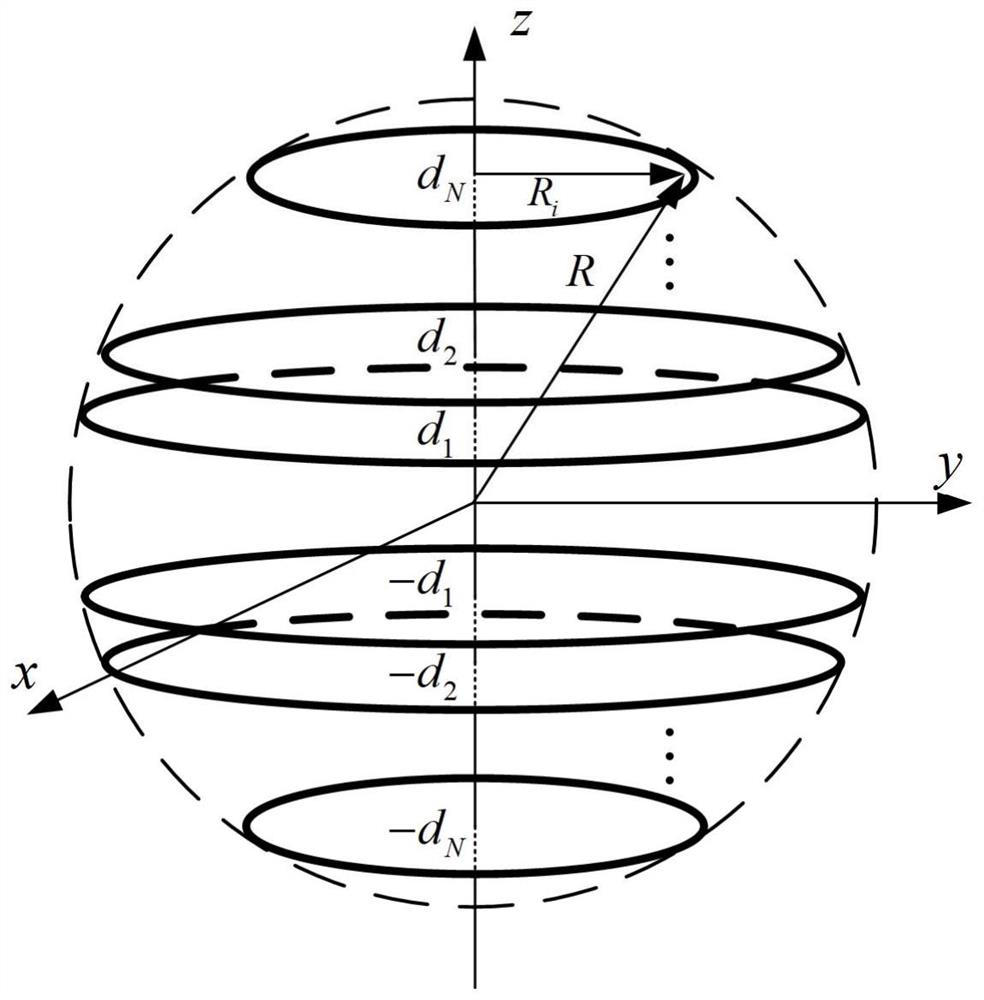

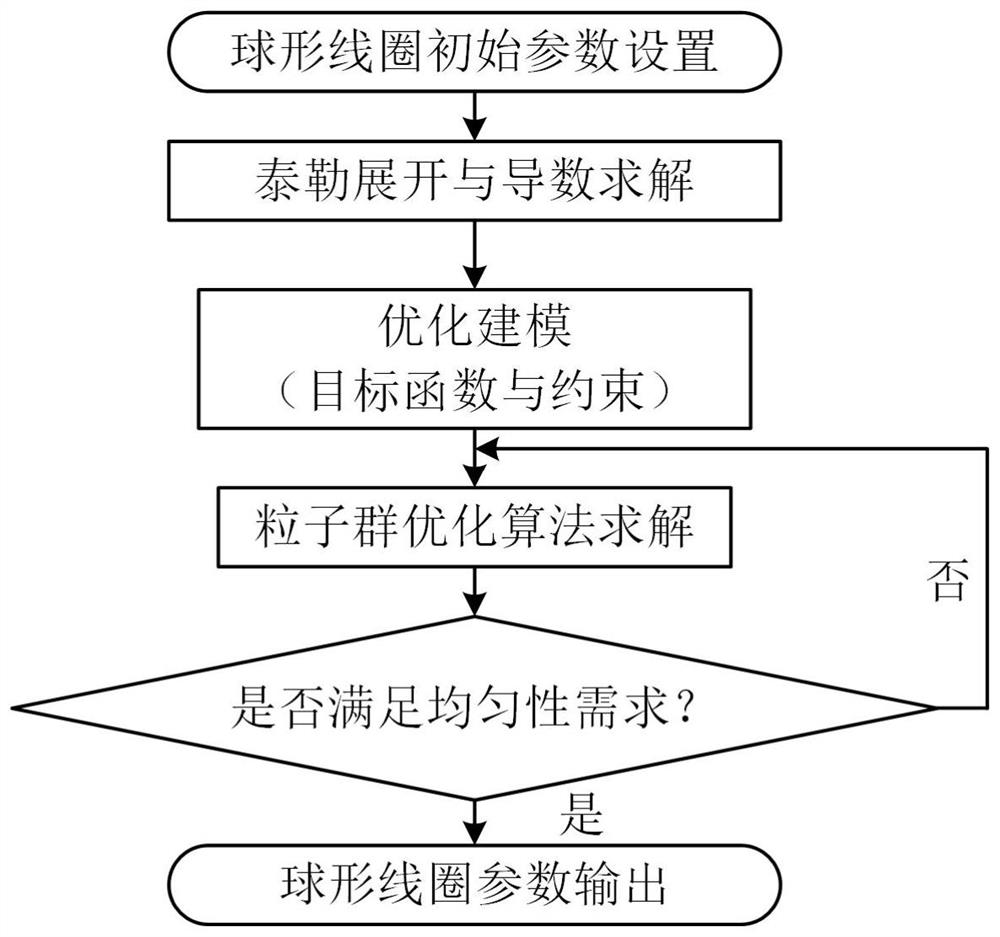

Spherical three-dimensional uniform magnetic field coil for SERF atomic magnetic field/inertial measurement sensor

InactiveCN112435837AReduce volumeGuaranteed uniform performanceTransformers/inductances coils/windings/connectionsNavigation by speed/acceleration measurementsMaterials scienceField coil

The invention discloses a spherical three-dimensional uniform magnetic field coil for an SERF atomic magnetic field / inertial measurement sensor. The spherical three-dimensional uniform magnetic fieldcoil is composed of three spherical coils which are identical in configuration and perpendicular to one another, wherein magnetic fields in the x direction, the y direction and the z direction are generated respectively, the defect that the length-diameter ratio in a cylindrical coil is too large can be overcome, the size of the magnetic field coil is reduced, and meanwhile it can be guaranteed that the uniform performance of the three-dimensional magnetic field is consistent.

Owner:BEIHANG UNIV

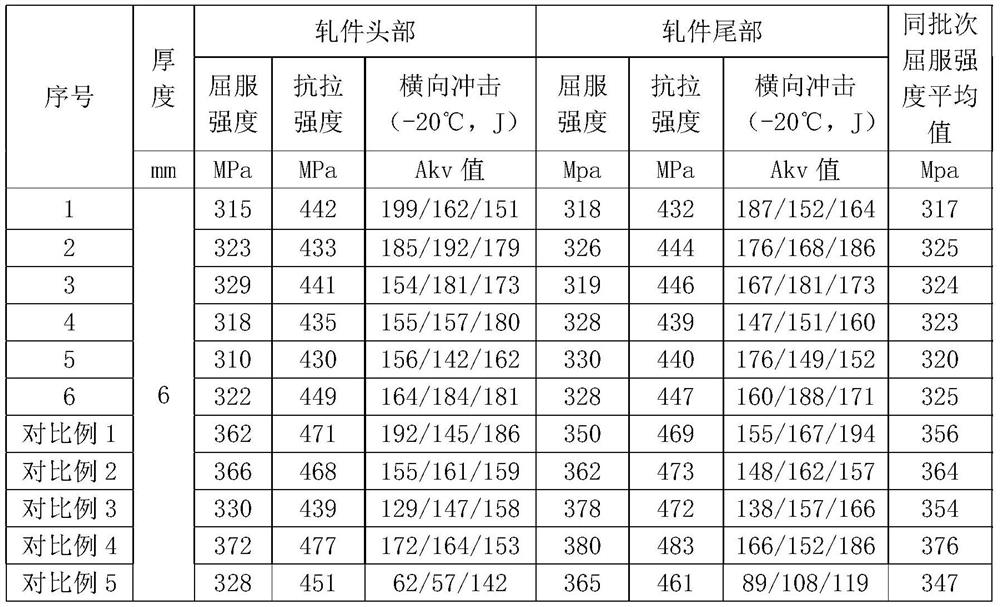

Steel for nuclear-power containment with thickness of 6 mm and manufacturing method of steel

ActiveCN111270153AEnsure yield strength stabilityTaking into account the radiation effectMetal rolling arrangementsNuclear physicsSteel plates

The invention discloses steel for nuclear-power containment with thickness of 6 mm and a manufacturing method of the steel. The low-C and low-Mn composition series design for the steel, extra alloyingcomponents are not added, and an irradiation effect is taken into consideration while yield strength stability is guaranteed. According to the manufacturing method, by means of optimization of blanktype, length of a rolled piece is effectively controlled in a rolling process, and larger temperature fluctuation caused by the too long rolled piece is avoided. With the adoption of superhigh-temperature heating mechanism, higher temperature for blanks is obtained during rolling, and higher final rolling temperature for a steel plate is guaranteed after the rolling is finished. By means of control for the rolling process, temperature drop in the process is reduced, and smaller temperature difference fluctuation of the head and the tail of the rolled piece is guaranteed. The length of the rolled piece is optimized and an area with poorer plate cut is cut off, and performance uniformity of a sampling position is ensured. The 6mm nuclear-power steel produced with the method has the advantages that yield strength is controlled stably, the toughness matching is excellent, and requirements for performance are met completely. The performance qualification rate of production reaches 94%, andthe steel is completely applicable to industrial mass production.

Owner:NANJING IRON & STEEL CO LTD

Method for removing sulfate radicals and hydrogen sulfate radicals when preparing sodium molybdate from molybdenum-containing waste catalyst through tertiary amine extraction method

InactiveCN110451563AGuaranteed uniform performanceTransportation and packagingSolid waste disposalKeroseneCompound (substance)

The invention relates to a method for removing sulfate radicals and hydrogen sulfate radicals when preparing sodium molybdate from a molybdenum-containing waste catalyst through a tertiary amine extraction method. The method comprises the following steps that alkalified oxidation roasting, water leaching filtration, phosphorous removal by a chemical precipitation method, tertiary amine and a kerosene solution are adopted to treat the molybdenum-containing waste catalyst under a faintly acid condition to extract a molybdenum-sodium hydroxide solution and re-extract and concentrate crystal sodium molybdate product. According to the method, a dilute sodium hydroxide solution is used for eluting a molybdenum-loaded organic phase, which can reduce the sulfate radicals of the molybdenum-loaded organic phase to 1.96 g / L from 10.82 g / L before elution with the elution rate of 81.88%. After the molybdenum-loaded organic phase is diluted through a dilute alkali liquor, an alkali liquor is used for reextraction to obtain a high-concentration sodium molybdate solution with Mo / SO4<2-> larger than 100 and SO4<2-> content less than 2g / L, and the crystal is concentrated to obtain the sodium molybdate product with the SO4<2-> less than or equal to 0.05%, which meets the requirements of industrial first-class products.

Owner:河北欣芮再生资源利用有限公司

Plasma etching method for eliminating organic substance using sulfur dioxide mixture gas

InactiveCN1632927AGuaranteed uniform performanceImprove flatnessSemiconductor/solid-state device manufacturingSubstance usePhysical chemistry

Owner:SHANGHAI HUA HONG GROUP +1

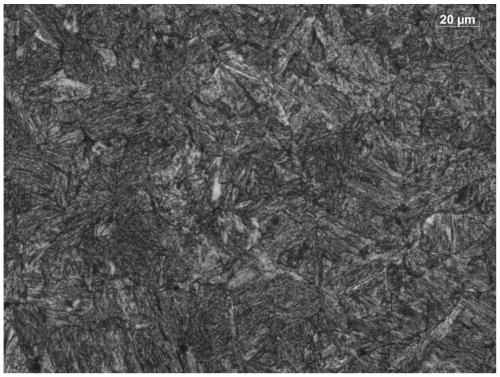

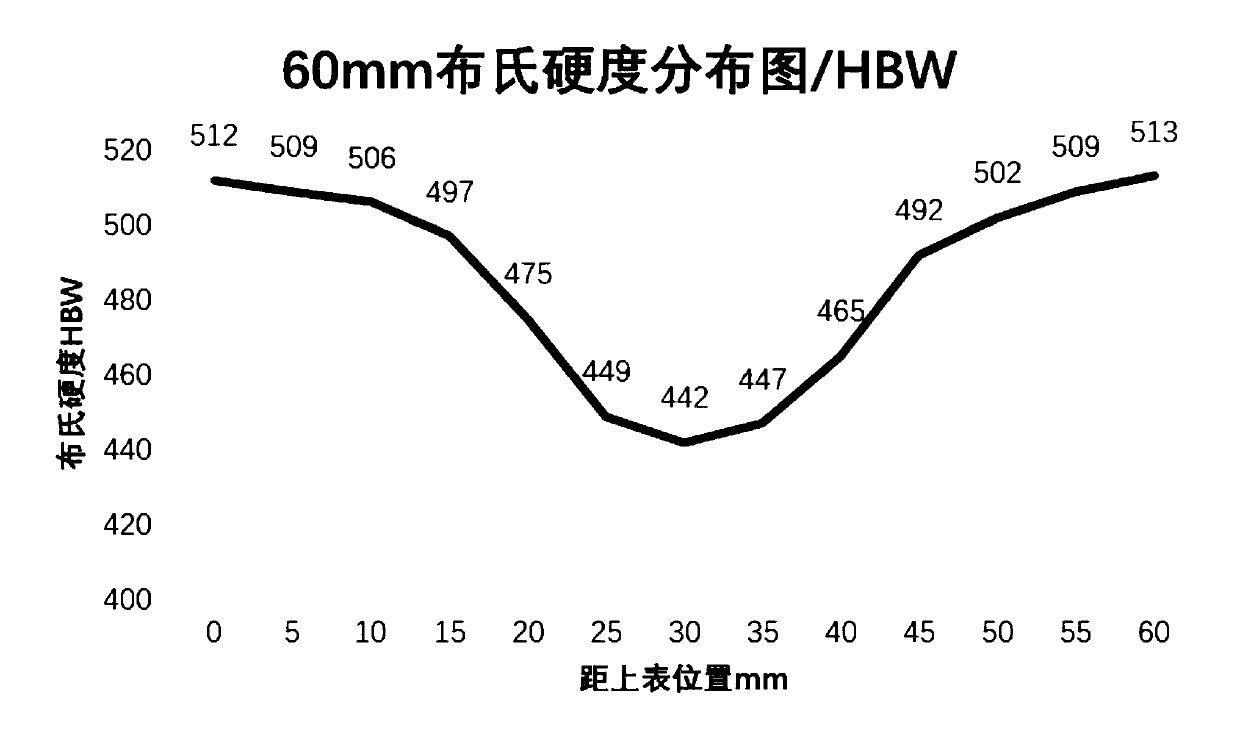

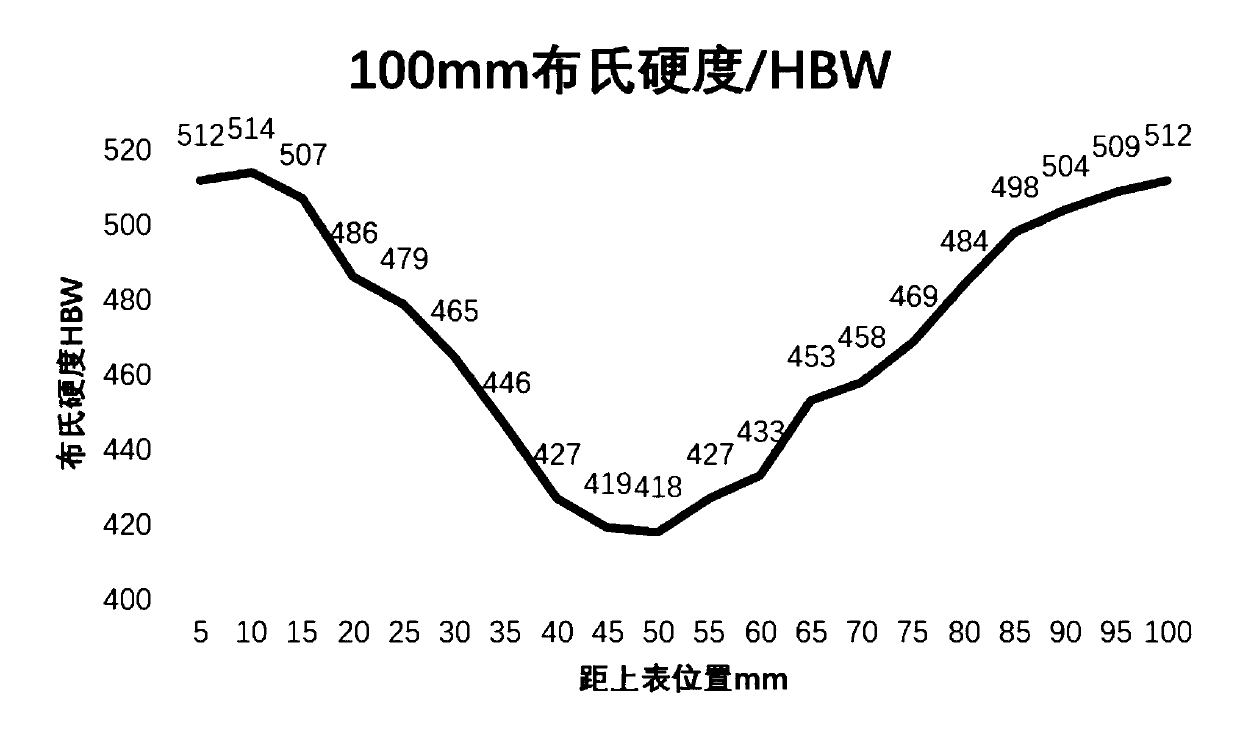

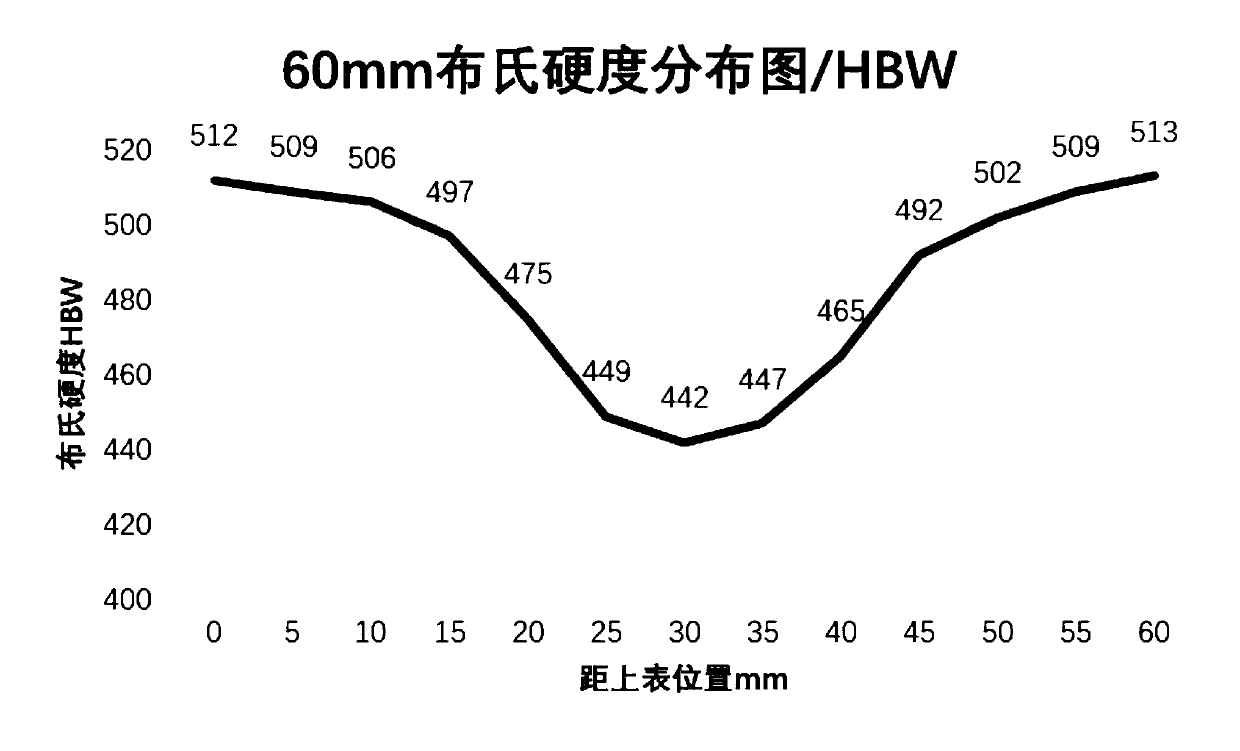

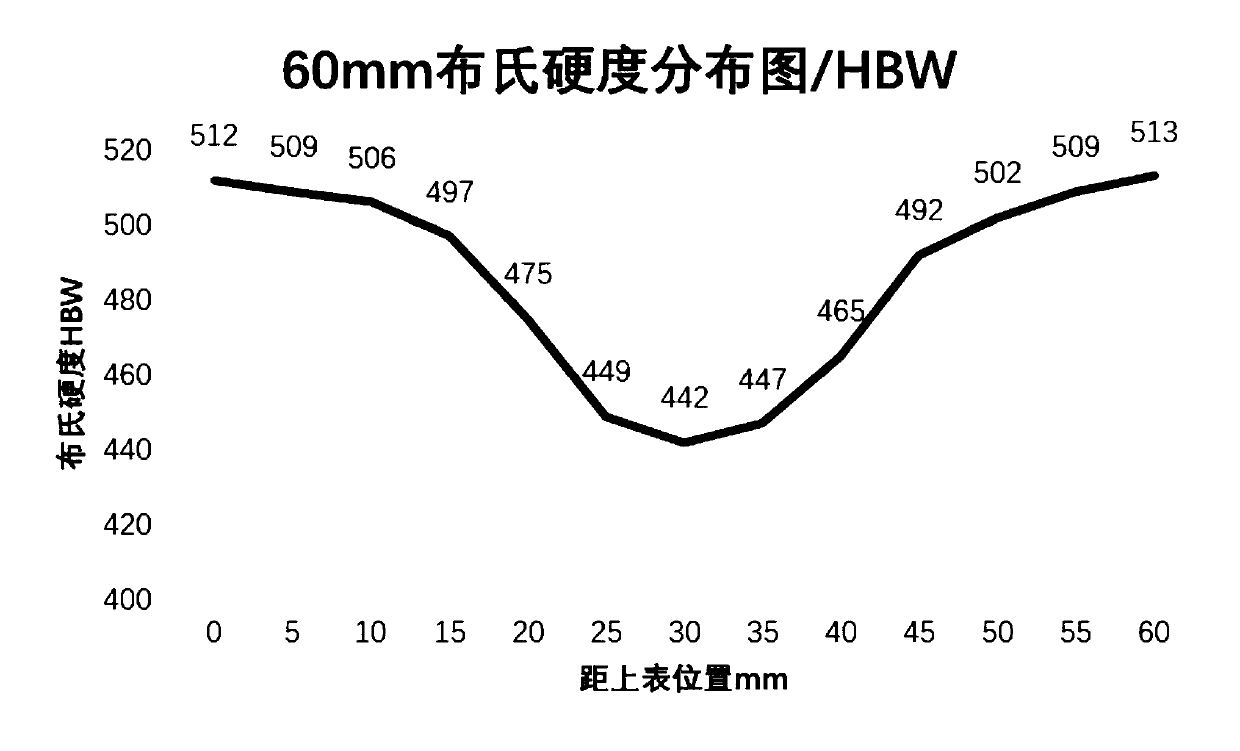

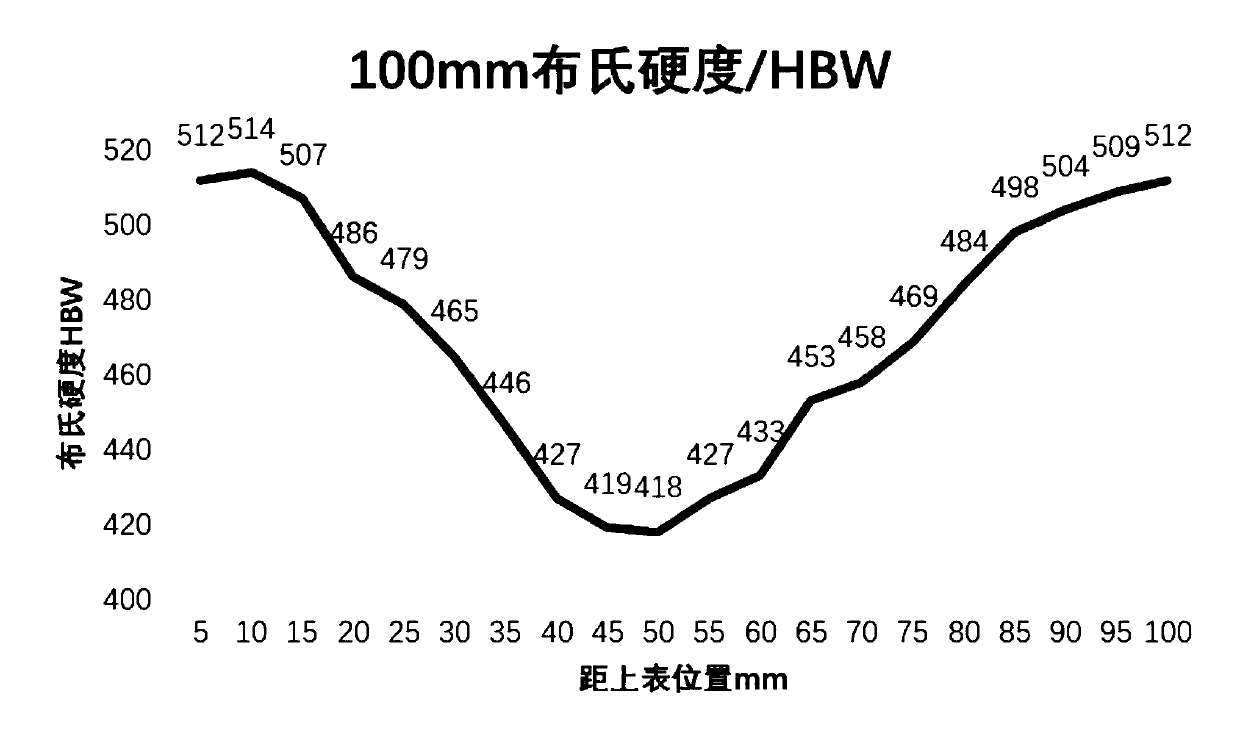

Super-thick high-hardenability HB500-grade wear-resistant steel plate and manufacturing method thereof

ActiveCN110042307AImprove hardenability indexGuaranteed performance uniformitySteel platesSheet steel

The invention provides a super-thick high-hardenability HB500-grade wear-resistant steel plate and a manufacturing method thereof. The thickness of the steel plate ranges from 60 mm to 100 mm, and thecomponents comprise the following components of C, Si, Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, Alt, Ni, Cr, Mo, Ti, less than or equal to 0.0050% of N, less than orequal to 0.00015% of H and the balance Fe and inevitable impurities. The manufacturing method of the wear-resistant steel plate comprises the steps of smelting, continuous casting blank slow cooling,forming rolling, quenching and tempering heat treatment. The manufacturing method of the wear-resistant steel plate has the advantages of being reasonable in design and easy to operate; and the steelplate obtained by using the preparation method has the advantages of being high in mechanical property uniformity and good in wear resistance.

Owner:贝斯山钢(山东)钢板有限公司

An extra-thick and high-hardenability HB500 wear-resistant steel plate and its manufacturing method

The invention provides a super-thick high-hardenability HB500-grade wear-resistant steel plate and a manufacturing method thereof. The thickness of the steel plate ranges from 60 mm to 100 mm, and thecomponents comprise the following components of C, Si, Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, Alt, Ni, Cr, Mo, Ti, less than or equal to 0.0050% of N, less than orequal to 0.00015% of H and the balance Fe and inevitable impurities. The manufacturing method of the wear-resistant steel plate comprises the steps of smelting, continuous casting blank slow cooling,forming rolling, quenching and tempering heat treatment. The manufacturing method of the wear-resistant steel plate has the advantages of being reasonable in design and easy to operate; and the steelplate obtained by using the preparation method has the advantages of being high in mechanical property uniformity and good in wear resistance.

Owner:贝斯山钢(山东)钢板有限公司

A 180-200mm thick alloy structural steel 27simn and its production process

ActiveCN109609840BImprove hardenabilityHigh strengthProcess efficiency improvementManufacturing technologyDie casting

The invention discloses alloy constructional steel 27SiMn with 180-200mm thickness and a manufacturing technology thereof. The alloy constructional steel 27SiMn is prepared from the chemical raw materials in percentage by mass: 0.27-0.30% of C, 1.2-1.4% of Si, 1.2-1.3% of Mn, no more than 0.030% of P, no more than 0.030% of S, 0.0008-0.001% of B, 0.020-0.030% of Ti, and the balance of Fe and residual elements. The manufacturing technology comprises the following steps of converter smelting, LF refining, VD vacuum degassing, die casting, heating, rolling, stacking cooling, and heat processing.The components of the alloy constructional steel 27SiMn are rationally designed, the manufacturing technology is improved, and parameters are accurately controlled, so that the alloy constructional steel 27SiMn with 180-200mm thickness and with a good combination property is obtained, and requirements of customers are better met.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

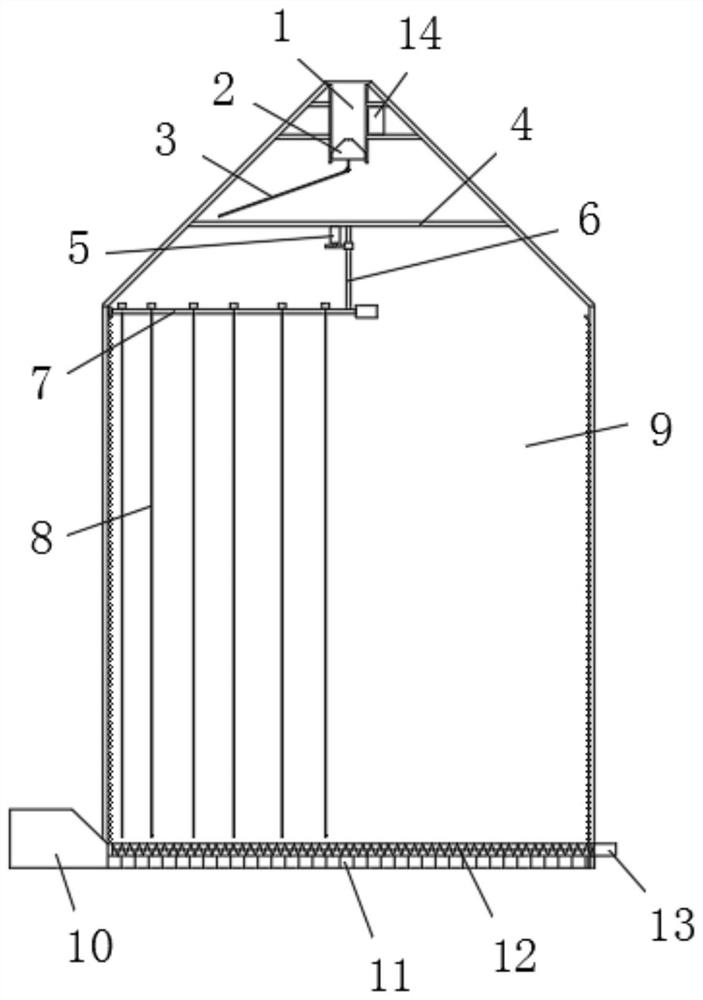

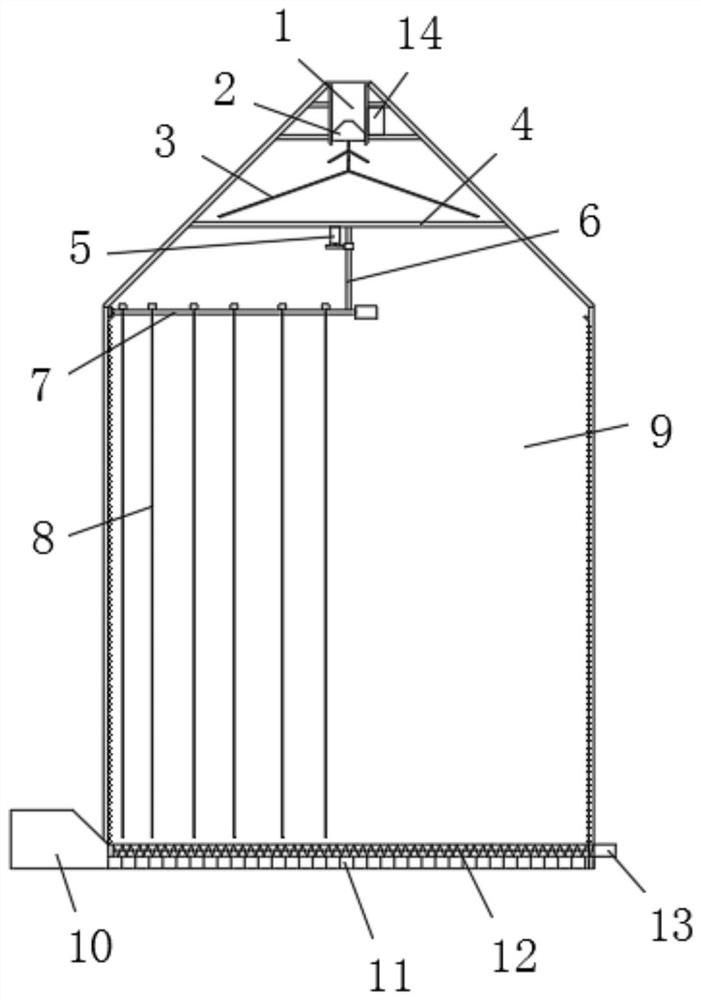

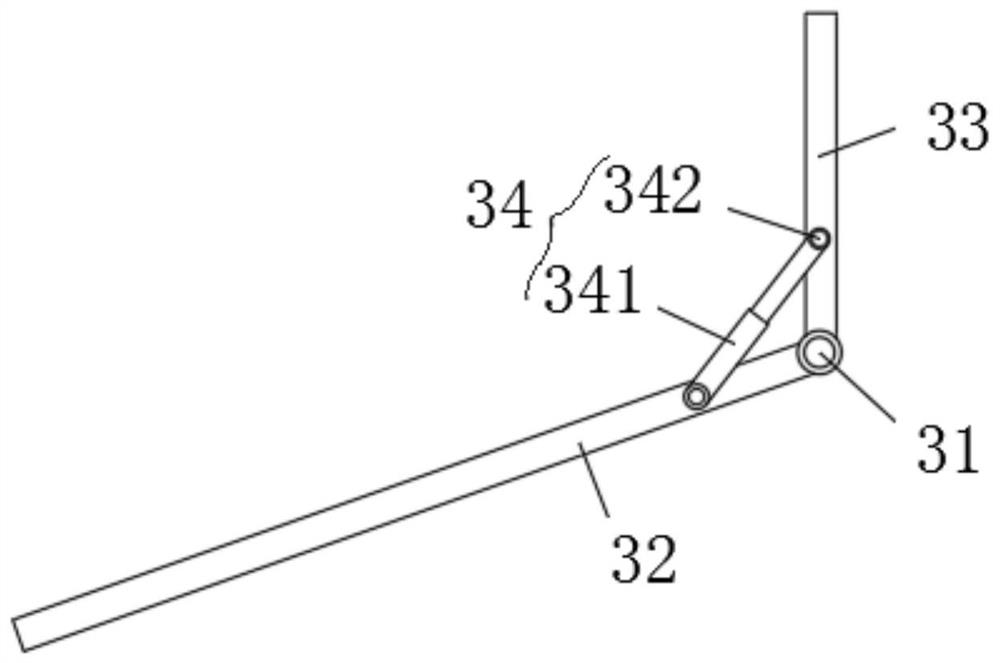

Novel intelligent granary system

PendingCN112696899AGuaranteed uniform performanceIncrease the relative gapDrying gas arrangementsDrying chambers/containersElectrical and Electronics engineeringMechanical engineering

The invention discloses a novel intelligent granary system. The novel intelligent granary system comprises a granary, wherein a spreading mechanism is connected to an unpowered rotor, and the spreading mechanism rotates in the central axial direction of the unpowered rotor to perform single-channel pitching annular spreading on grains, or rotates in the central axial direction of the unpowered rotor to perform multi-channel multi-point annular spreading on the grains; a mounting frame is arranged on the inner wall of the granary, and the mounting frame is connected with a hanging frame through a connecting shaft which is vertically arranged; a plurality of spiral stirring assemblies which are parallel to one another and drive the grains to be stirred from bottom to top are vertically arranged on the hanging frame; and a fan is arranged at one end of the bottom of the granary. According to the novel intelligent granary system disclosed by the invention, a granary flattening and stirring system can perform annular spreading operation on the grains falling into the granary through the arranged spreading mechanism, and the grains are more loose through the cooperation of the spiral stirring assemblies which rotate annularly, so that static pressure is reduced, the relative flow rate of flowing air entering the grains is increased, and the drying efficiency of the grains in the granary is improved.

Owner:白兴龙

Compounding process of surface strengthening layer of piston rod

ActiveCN101994116BExtended service lifeGuaranteed mechanical propertiesPositive displacement pump componentsMetallic material coating processesForeign matterMartensitic stainless steel

The invention provides a compounding process of a surface strengthening layer of a piston rod, which is characterized by comprising the following steps: whasing oil stains and impurities on the working surface of the piston rod, sending 18-8 type austenitic stainless steel powder gas to the working surface of the piston rod, radiating with laser so as to clad stainless steel powder on the workingsurface of the piston rod and form a stainless steel cladding bottom layer with the thickness of 1-3mm, further sending 1Cr13 type martensitic stainless steel powder gas onto the bottom layer, and radiating with the laser so as to clad the stainless steel powder on the bottom layer of the working surface of the piston rod and form the stainless steel cladding strengthening layer with the thickness of 1-3mm.The compounding process can realize gradient compound strengthening, lead the piston rod of a hydraulic transmission oil cylinder to have longer service life and more balanced operation performances, and avoid the problems of galling of the working surface of the piston rod,leakage of hydraulic oil and the like during the use,caused by lack of cooling lubricating oil or entrance of foreign matters into the cylinder. The process has strong controllability of parameters and is convenient for processing and operation and convenient for industrial large-batch production.

Owner:云南志熔激光技术有限公司

A kind of 6mm thick nuclear power containment steel and its manufacturing method

ActiveCN111270153BControl lengthIncrease temperatureMetal rolling arrangementsNuclear powerProcess engineering

The invention discloses a 6mm-thick nuclear power containment steel and a manufacturing method thereof. The steel adopts a low C and Mn component series design, does not add additional alloy components, and takes into account the radiation effect while ensuring the stability of the yield strength. The optimization of the material shape of the billet in the manufacturing method realizes the effective control of the length of the rolled piece during the rolling process, and avoids the large temperature fluctuation caused by the excessive length of the rolled piece. The ultra-high temperature heating system is adopted to ensure that the billet obtains a higher temperature during rolling, and to ensure that the steel plate has a higher final rolling temperature after the rolling is completed. The control of the rolling process reduces the temperature drop during the process and ensures that the fluctuation of the temperature difference between the head and the tail of the rolled piece is small. The length of the rolled piece is optimized and the area with poor plate shape is cut off to ensure the uniformity of the performance of the sampling position. The yield strength of the 6mm nuclear power steel produced by the method is stable, and the obtained performance is excellent in strength and toughness matching, which fully meets the performance requirements. The qualified rate of production performance reaches 94%, which is fully suitable for industrial batch production.

Owner:NANJING IRON & STEEL CO LTD

Prefabricated base of road or ridge temporary retaining wall

InactiveCN111364503AQuick Fit Connection OperationChange installation lengthArtificial islandsUnderwater structuresWater leakageArchitectural engineering

The invention discloses a prefabricated base of a road or bridge temporary retaining wall. The prefabricated base comprises a base body, a pouring groove is formed in the top of the base body, reinforcing ribs are poured at equal intervals on the inclined edge of one side of the base body, anchor rod holes are formed at equal intervals on the inclined edge of the other side of the base body, an assembling groove is formed in the outer wall of the vertical end of one side of the base body, an assembling block is arranged on the outer wall of the vertical end of the other side of the base body,and a water leakage hole transversely penetrates through the inside of the base body. The prefabricated base adopts a corresponding connection mode of the assembling block and the assembling groove, so that the prefabricated base can be quickly assembled and connected, the installation length of the prefabricated base can be freely and flexibly changed, the installation and fixing requirements ofdifferent types of retaining walls are met, the length of the retaining wall can be conveniently adjusted, meanwhile, the effects of buffering and pressure releasing can be achieved on a supporting soil body, and deformation and even fracture of the prefabricated base caused by excessive impact pressure are avoided.

Owner:SHANXI TRANSPORTATION SCI HIGHWAY SURVEY & DESIGN INST +1

A kind of al-zn-mg aluminum alloy medium-thick plate and preparation method thereof

The invention belongs to the technical fields of metal materials and processing thereof and discloses an Al-Zn-Mg aluminum alloy medium-thick plate and a preparation method thereof. The aluminum alloy medium-thick plate mainly comprises the following element components: 1.0-2.0 of Mg, 6.0-7.0 of Zn, less than or equal to 0.05 of Cu, less than or equal to 0.08 of Fe, less than or equal to 0.05 of Si, less than or equal to 0.05 of Cr, and the balance of Al and inevitable elements, wherein each inevitable element is less than 0.05 and the total amount of the inevitable elements is less than 0.15. The Al-Zn-Mg aluminum alloy medium-thick plate is prepared by adopting a hot rolling method, and the prepared aluminum alloy medium-thick plate has the thickness of 5-10mm and the surface hardness more than or equal to 150HV; meanwhile, plate surface is uniform, no blank mark is formed, and colour is uniform and close to natural colour of pure aluminum metal after anodic oxidation, so that the Al-Zn-Mg aluminum alloy medium-thick plate can be widely applied to IT appearance structural components.

Owner:广西南南铝加工有限公司

A kind of on-line quenching HB400 wear-resistant steel plate and preparation method

The invention relates to the technical field of high-strength wear-resistant steel plate preparation, in particular to an on-line quenched HB400-grade wear-resistant steel plate and a preparation method thereof. The steel plate comprises the following components of, in percentage by weight, 0.15%-0.18% of C, 0.30%-0.60% of Si, 0.22%-0.40% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.025%-0.050% of Alt, 0.10%-0.25% of Ni, 0.80%-1.00% of Cr, 0.15%-0.30% of Mo, 0.010%-0.030% of Ti, less than or equal to 0.0050% of N, less than or equal to 0.00015% of H, the balance Fe and trace impurities. The thickness of the steel plate is 8-20 mm. According to the preparation method, the manufactured wear-resistant steel plate is characterized in that the hardness value ofthe wear-resistant steel plate is 370 HBW-430 HBW, the tensile strength is 1250-1430 MPa, the elongation percentage (A50) ranges from 15% to 18%, the impact toughness value at 20 below zero is greater than or equal to 50J, excellent wear resistance is provided, meanwhile, excellent low-temperature impact toughness is provided, and wear-resistant steel plate is suitable for being used under severeworking conditions such as mining machinery and the like. In addition, different from the conventional off-line conditioning process, the wear-resistant steel plate manufactured by the method is produced by adopting an online quenching and off-line tempering process, the remarkable advantages of short production process and low manufacturing cost is realized.

Owner:贝斯山钢(山东)钢板有限公司

Control process for performances of steel plate during hot rolling and flat rolling process of single-stand steckel mill

ActiveCN102225432BGuaranteed uniform performanceSolve the problem of non-uniform longitudinal performanceTemperature control deviceMetal rolling arrangementsSheet steelStrip mill

Owner:NANJING IRON & STEEL CO LTD

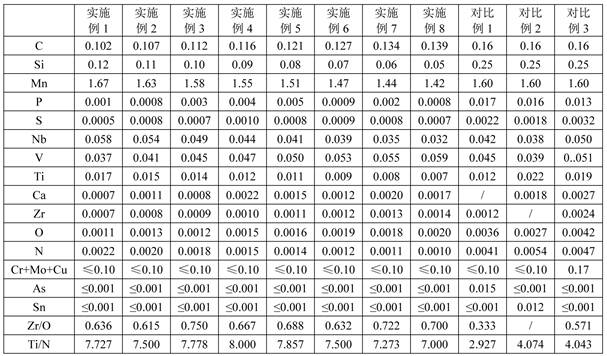

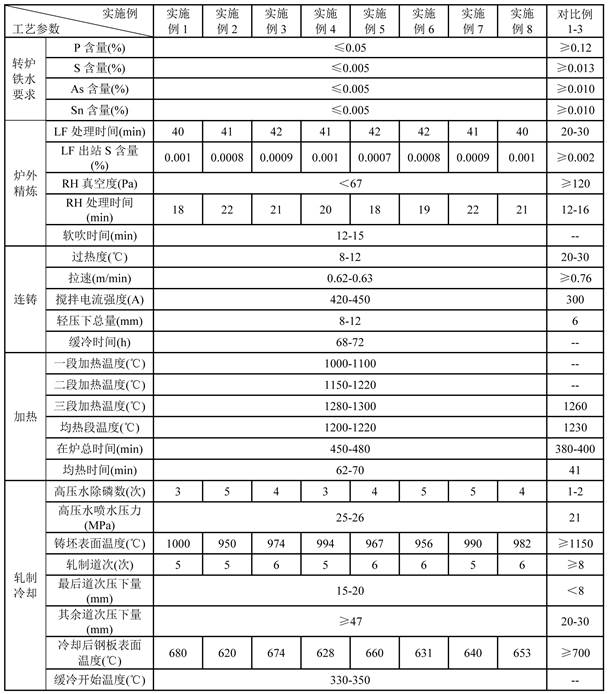

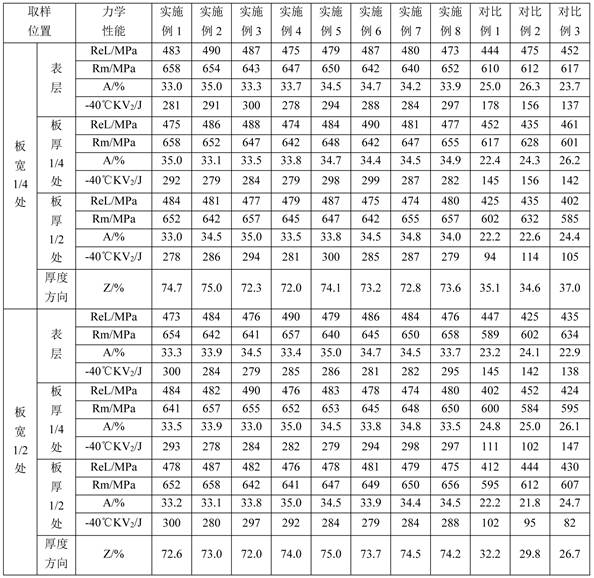

High-strength and high-toughness steel plate with uniform performance and excellent performance in thickness direction and production method of high-strength and high-toughness steel plate

ActiveCN114875330AFully austenitizedGuaranteed uniform performanceProcess efficiency improvementMetal rolling arrangementsPorosityToughness

The invention relates to a high strength and toughness steel plate with uniform performance and excellent performance in the thickness direction and a production method thereof, the steel plate comprises the following elements in percentage by mass: 0.102 to 0.139 percent of C, 0.05 to 0.12 percent of Si, 1.42 to 1.67 percent of Mn, less than or equal to 0.005 percent of P, less than or equal to 0.001 percent of S, 0.032 to 0.058 percent of Nb, 0.037 to 0.059 percent of V, 0.005 to 0.017 percent of Ti, 0.0007 to 0.0022 percent of Ca, 0.0007 to 0.0014 percent of Zr, (11 to 20) * 10 <-4 > percent of O, (10 to 22) * 10 <-4 > percent of N, less than or equal to 0.10 percent of Cu + Mo + Cr, less than or equal to 0.001 percent of As, less than or equal to 0.001 percent of Sn and the The thickness of the casting blank ranges from 360 mm to 380 mm, the center segregation of the casting blank is smaller than or equal to C1.0, the center porosity of the casting blank is smaller than or equal to 0.5, and the defects of cracks, bubbles, aluminum oxide and silicate inclusions and the like do not exist; the thickness of the finished steel plate ranges from 130 mm to 150 mm, ReL ranges from 473 MPa to 490 MPa, Rm ranges from 640 MPa to 658 MPa, A ranges from 33% to 35%, KV2 ranges from 278 J to 300 J at the temperature of-40 DEG C, Z in the thickness direction ranges from 72% to 75%, and the finished steel plate has high strength and toughness, excellent performance in the thickness direction and good performance uniformity.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Bulletproof steel plate for armor and manufacturing method thereof

ActiveCN109930075BGuaranteed StrengthImprove plastic toughness indexSteelmakingUltimate tensile strength

The invention provides a bulletproof steel plate for armor and a manufacturing method of the bulletproof steel plate. The bulletproof steel plate for the armor is prepared from, by weight, 0.25-0.38%of C, 0.20-0.40% of Si, 0.22-0.50% of Mn, 0.015% or less of P, 0.005% or less of S, 0.010-0.050% of Alt, 0.10-0.38% of Ni, 0.80-1.50% of Cr, 0.16-0.40% of Mo, 0.010-0.035% of Ti, 0.0050% or less of N,0.00022% or less of H and the balance Fe and inevitable impurities. The manufacturing method of the steel plate comprises a steel making work procedure, a steel rolling work produce and a heat treatment work procedure. The bulletproof steel plate for the armor improves the plastic toughness index while ensuring the strength of the steel plate. The manufacturing method of the bulletproof steel plate for the armor is reasonable in design, the advantages of each control process are fully exerted, the uniformity of the performance of the steel plate is guaranteed, the influence of residual internal stress of the steel plate is effectively eliminated, and the subsequent cutting, welding and other machining properties of the steel plate are improved.

Owner:贝斯山钢(山东)钢板有限公司

Manufacturing process of composite cylinder sleeve

InactiveCN102069351BAchieve life extensionGuaranteed mechanical propertiesMetallic material coating processesForeign matterMetallurgy

The invention discloses a manufacturing process of a composite cylinder sleeve. In the process, a layer of 18-8 type Austenitic stainless steel is firstly clad on a working surface of a medium carbon quenched and tempered steel or alloy steel cylinder sleeve to be used as a bond coat by a laser cladding technology, and then a layer of 1Cr13 type Martensitic stainless steel is clad to be used as awear-resistant corrosion-resistant surface layer to realize gradient compounding and strengthening, so the cylinder sleeve of a hydraulic transmission oil cylinder has longer service life and more balanced operation performance, and the problems of cylinder sleeve surface galling, hydraulic oil leakage and the like caused by the frequent reciprocating motion of a piston rod when the working surface of the cylinder sleeve lacks cooling lubricating oil or foreign matters enter the cylinder are avoided. The manufacturing process disclosed by the invention has strong technological parameter controllability, is convenient to operate, and brings convenience industrialized mass production.

Owner:KUNMING UNIV OF SCI & TECH

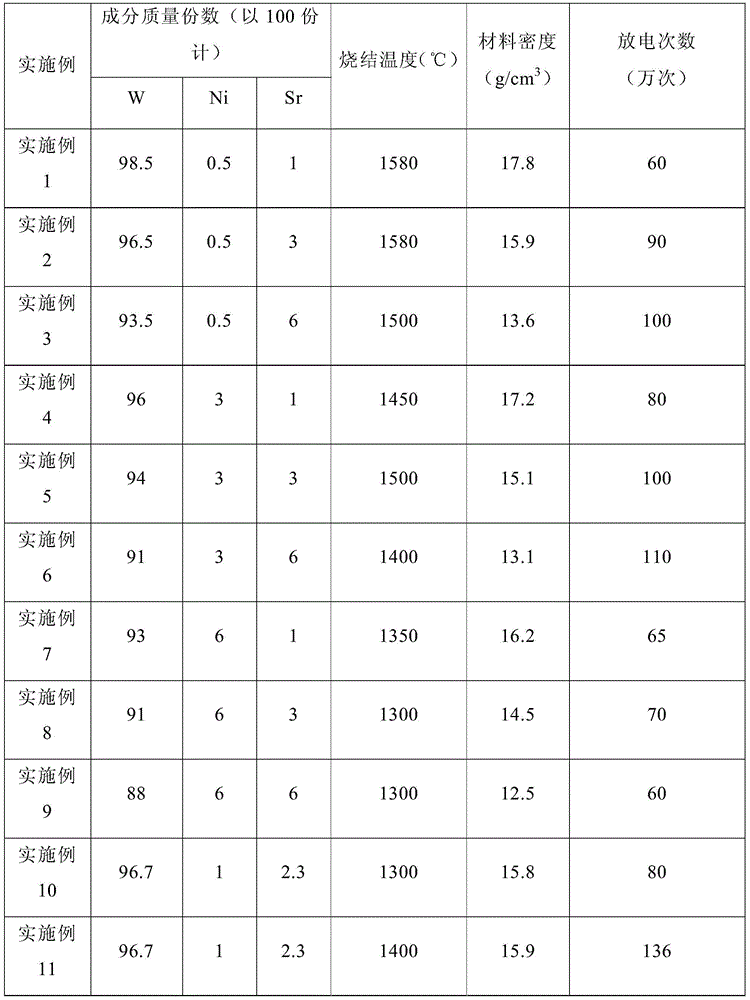

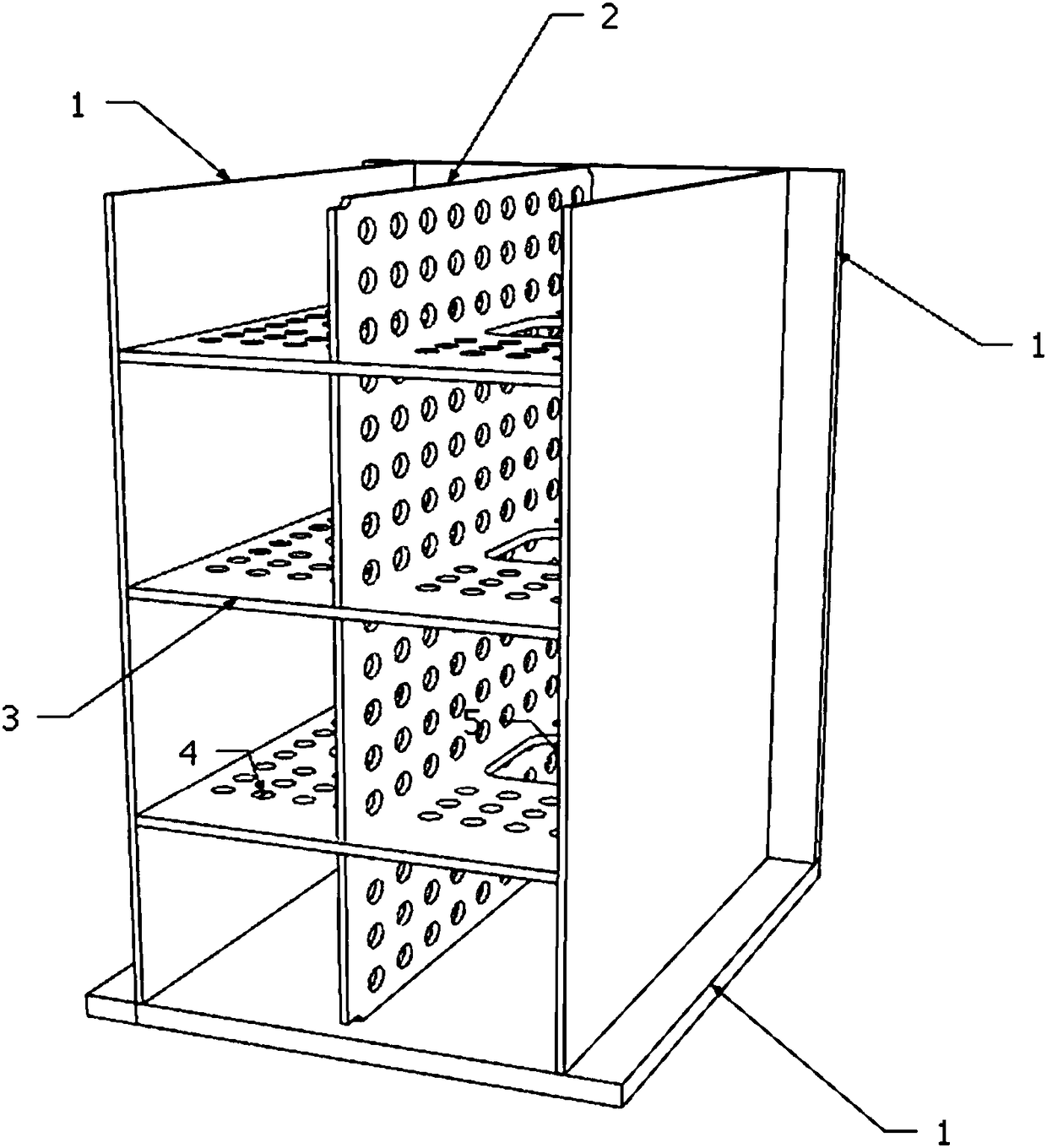

A kind of tungsten-based electrode material and preparation method thereof

Owner:ATTL (BEIJING) ADVANCED MATERIALS CO LTD +1

A kind of al-zn-mg aluminum alloy sheet and preparation method thereof

The invention belongs to the field of metal materials and machining technologies of the metal materials and discloses a manufacturing method of a Al-Zn-Mg aluminum alloy thin plate. The Al-Zn-Mg aluminum alloy thin plate mainly comprises the following elemental components of 1.0-3.8 of Mg, 5.0-8.0 of Zn, no more than 0.05 of Cu, no more than 0.08 of Fe, no more than 0.05 of Si, no more than 0.05 of Cr, 0.05-0.2 of Ni, 0.1-0.6 of Zr and the balance Al and inevitable elements, wherein each of the inevitable elements is smaller than 0.05, and the total amount of the inevitable elements is 0.15. The manufacturing method mainly adopts hot rolling, cold rolling, pretreatment, stamping and aging treatment; the thickness of the prepared aluminum alloy thin plate is 0.2-5 mm, and the prepared aluminum alloy thin plate has good finished product mechanical performance; and after anodizing, the surface of the plate is consistent, a bank mark and a bright streak are avoided, the color of the plateis uniform and close to the natural color of pure aluminum metal.

Owner:广西南南铝加工有限公司

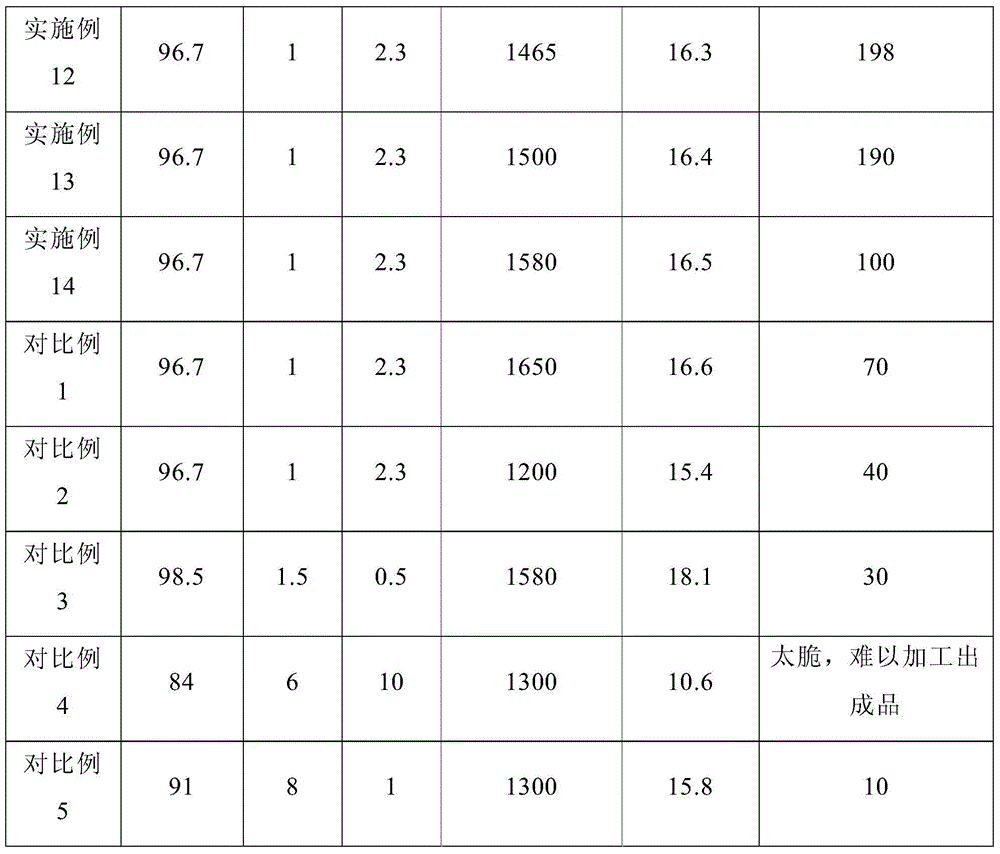

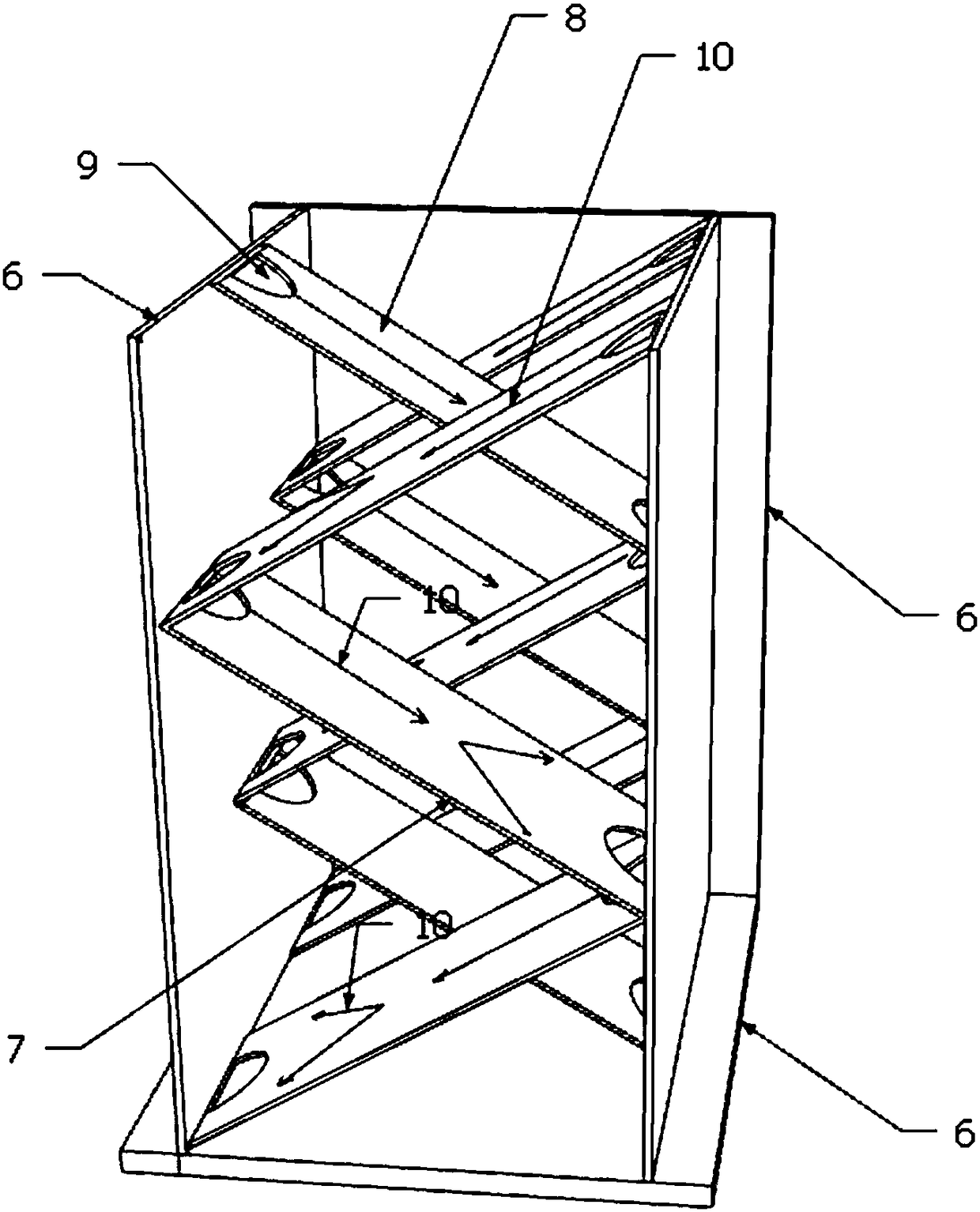

Steel-concrete composite beam structure applicable to self-compacting concrete pouring and design method

PendingCN108203921AAvoid uneven forcePrevent internal corrosionBridge structural detailsBridge materialsSelf-consolidating concreteBridge engineering

The invention provides a steel-concrete composite beam structure applicable to self-compacting concrete pouring and a design method, and belongs to the field of bridge engineering. The steel-concretecomposite beam structure applicable to self-compacting concrete pouring changes a square-grid mode of thinking adopted by a conventional steel structure design, and adopts oblique-crossing type stiffened plates and a cross arrangement mode instead. As a concrete flowing platform, the steel-concrete composite beam structure helps self-compacting concrete to reach the required position instead of directly pouring from a height by virtue of a pumping tube, so as to prevent concrete aggregates from splashing, to well avoid the separation of concrete ingredients and to facilitate the discharge of internal air, so that the steel-concrete composite beam structure is also applicable to other concrete pouring which is similarly affected by the construction space.

Owner:SICHUAN ROAD & BRIDGE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com