Laser cladding reinforcing process of motor central spindle

A technology of laser cladding and electric motor, which is applied in the coating process and coating of metal materials, can solve the problems of spare parts waste for shutdown and maintenance, increase loss cost, easy to be worn and corroded, and achieve dense and small solidified structure, high Interfacial bonding strength, the effect of ensuring the uniformity of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

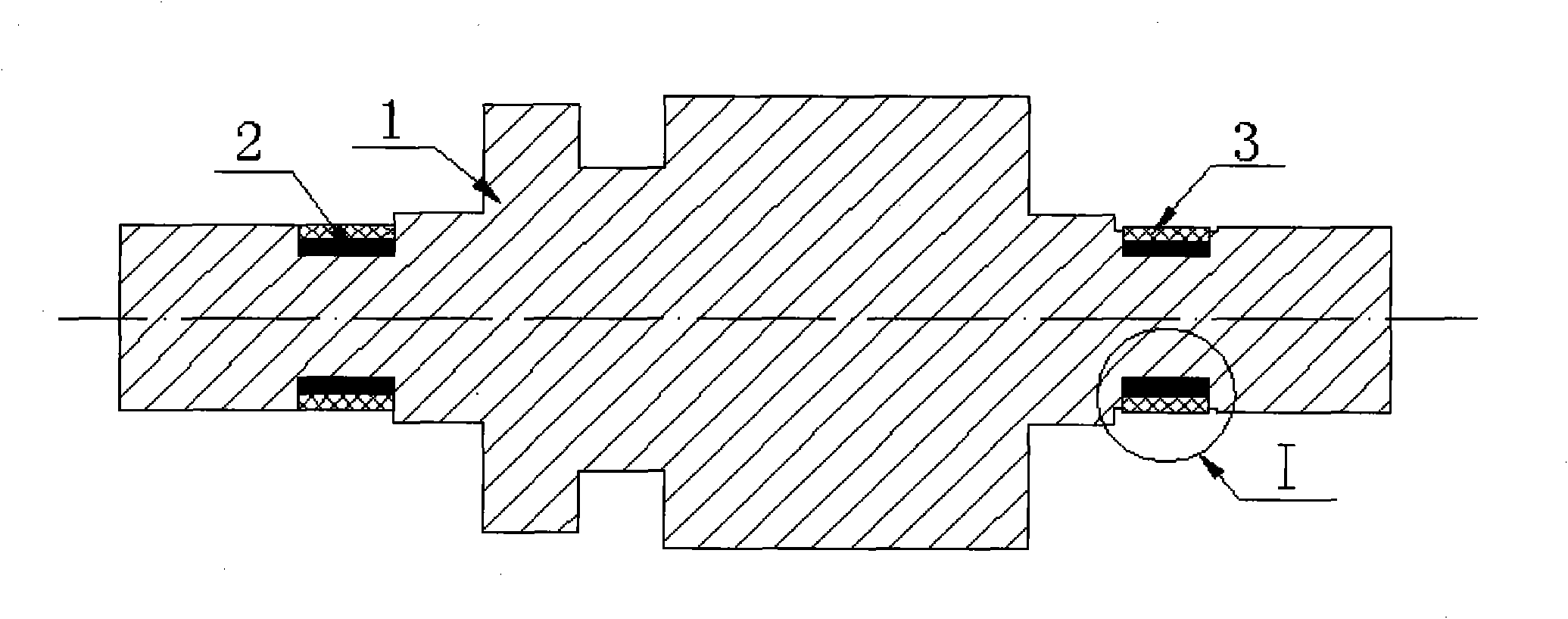

[0028] To prepare the mandrel of a 55KW AC motor with local gradient composite strengthening, the specific procedure is as follows.

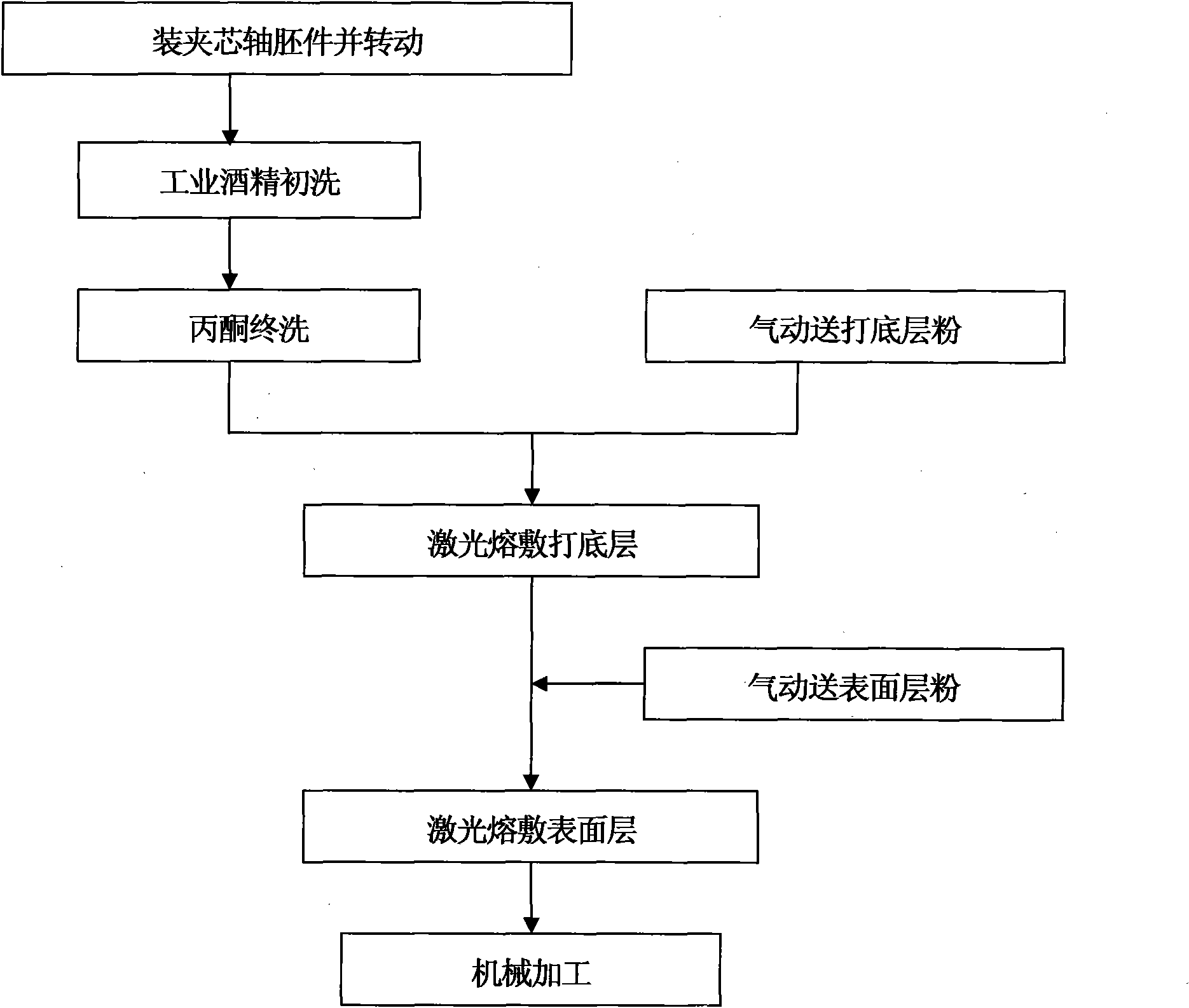

[0029] A. Install the motor core shaft blank (1) made of medium carbon quenched and tempered steel into the fixture, and rotate the fixture at a linear speed of 600mm / min;

[0030] B. Pour industrial alcohol on the bearing position of the mandrel for preliminary cleaning, and then pour acetone for final cleaning;

[0031] C. Turn on the argon pneumatic powder feeding device to deliver 18-8 austenitic stainless steel powder to the bearing position of the mandrel;

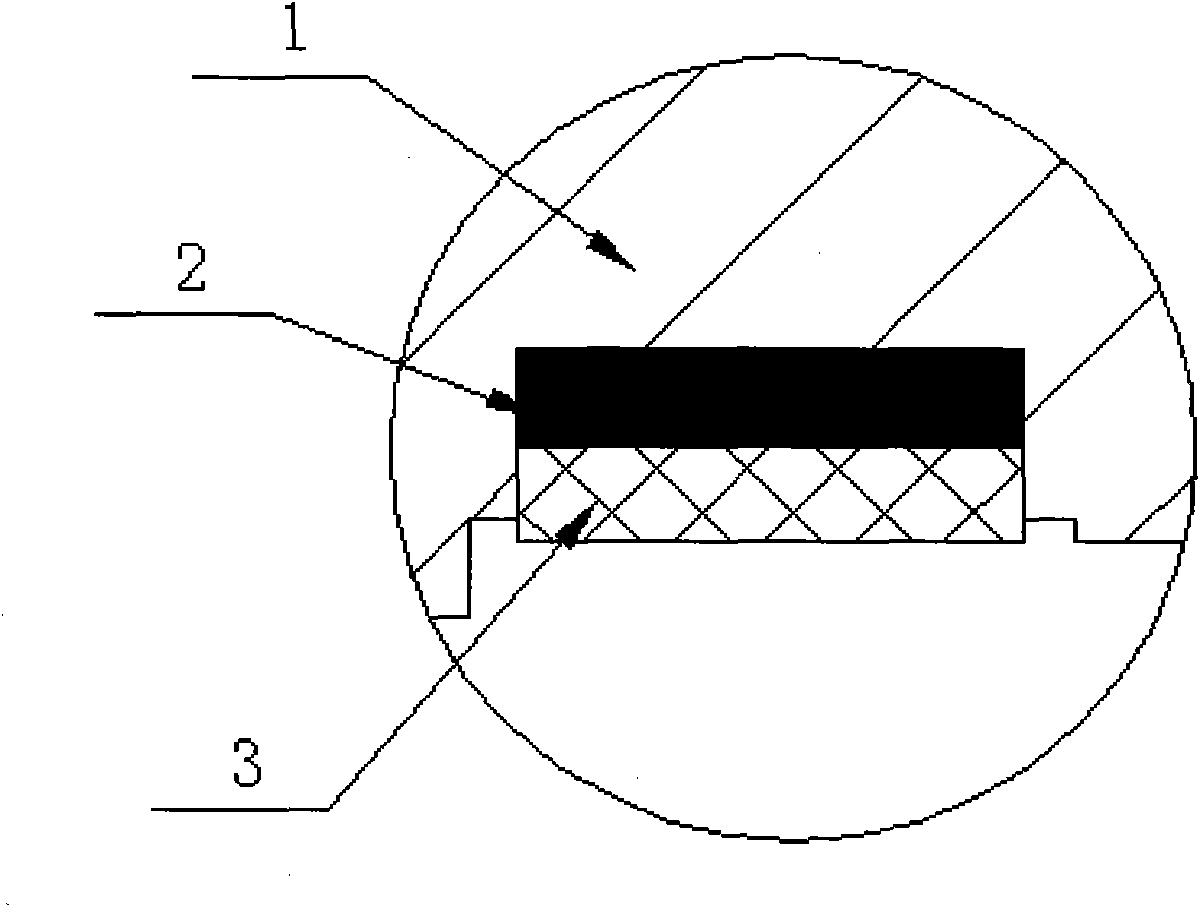

[0032] D. Irradiate the 18-8 type austenitic stainless powder with a power of 3.5KW and a bandwidth of 3mm to melt it, and deposit a layer with a thickness of 2mm (2);

[0033] E. Argon gas pneumatically transports 1Cr13 martensitic stainless steel powder to the bottom layer;

[0034] F, irradiating 1Cr13 type austenitic stainless steel powder with a power of 3.5KW and a bandwidth of...

Embodiment 2

[0037] Prepare pinch roll cylinder liners for hot rolling mills.

[0038] The preparation situation is basically the same as in Example 1, except that the particle size of the 18-8 type austenitic stainless steel powder used in the process C is 200 mesh, and the thickness of the bottom layer is 1mm; the 1Cr13 type Martensitic stainless steel powder used in the process E The particle size of bulk stainless steel powder is 200 orders, and the thickness of surface layer is 4mm; All the other situations are identical with embodiment 1.

Embodiment 3

[0040] Prepare pinch roll cylinder liners for hot rolling mills.

[0041] The preparation situation is basically the same as in Example 1, except that the particle size of the 18-8 type austenitic stainless steel powder used in the process C is 300 mesh, and the thickness of the bottom layer is 3mm; the 1Cr13 type Martensitic stainless steel powder used in the process E The particle size of bulk stainless steel powder is 300 orders, and the thickness of surface layer is 2mm; All the other situations are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com