Definite life extension method of key structural elements of in-service mechanical equipment under fatigue load

A technology of structural elements and fatigue loads, applied in the field of fatigue, can solve the problems of high test cost, low reliability, and lack of complete methods, etc., achieve significant economic and social benefits, improve calculation accuracy, and reduce fatigue test time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

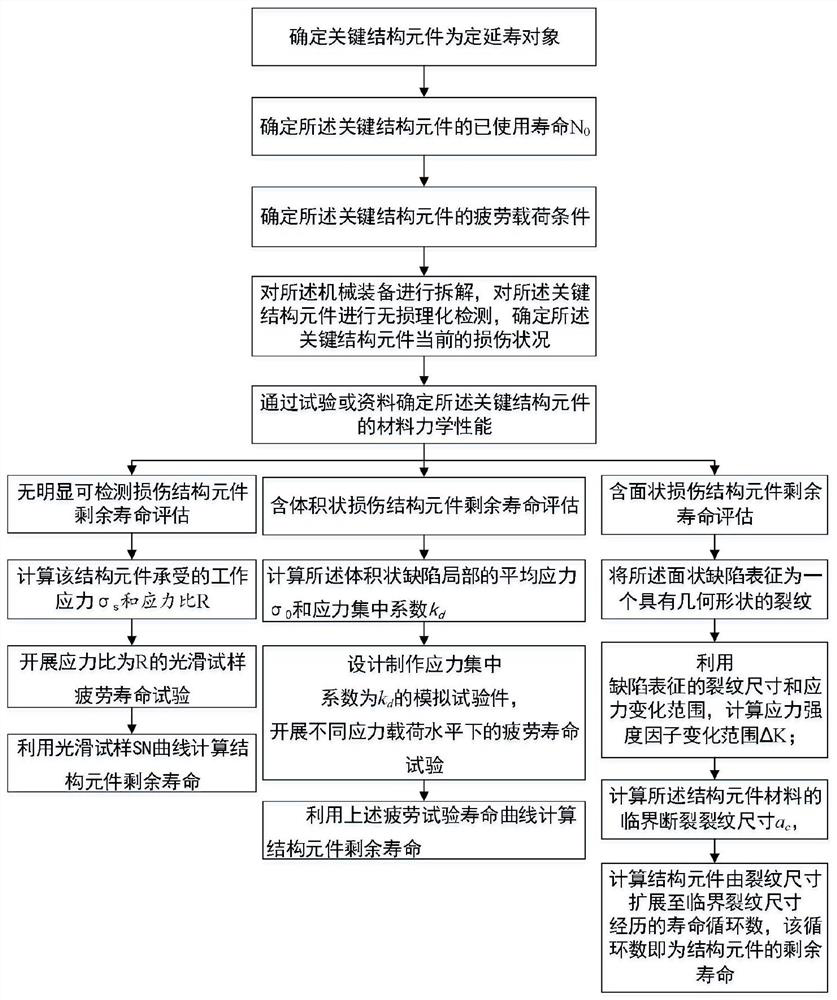

[0056] The embodiment of the present invention aims at the outer shell of the in-service mechanical equipment, and proposes a method for determining the life extension of the key structural elements of the in-service mechanical equipment under the fatigue load. The implementation process of the method is as follows figure 1 As shown, it includes the following steps:

[0057] S1. Analyze the structural elements according to the structural characteristics of the mechanical equipment, and select the key structural elements as the life extension objects;

[0058] S2. Collect the field use data of the mechanical equipment or collect the field use data of the same type of equipment, and determine the historical service life of the key structural elements N 0 ;

[0059] S3. Determine the fatigue loading conditions of the key structural elements;

[0060] S4. Dismantling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com