Metal material surface electromagnetic wave impact strengthening method

A metal material and impact strengthening technology, which is applied in the field of surface toughening modification and electromagnetic wave shock strengthening on the surface of metal materials, can solve problems such as poor stability of ultrasonic impact energy, uncontrollable defective rate of products, and damage to integrity. Improve the level of design and manufacturing, eliminate internal micro-defects, and promote the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] It is assumed that the metal material 5 is a Ti6Al4V casting plate, the absorption layer 3 is Al powder with uniform size, and the constraining layer 2 is SiC ceramic material.

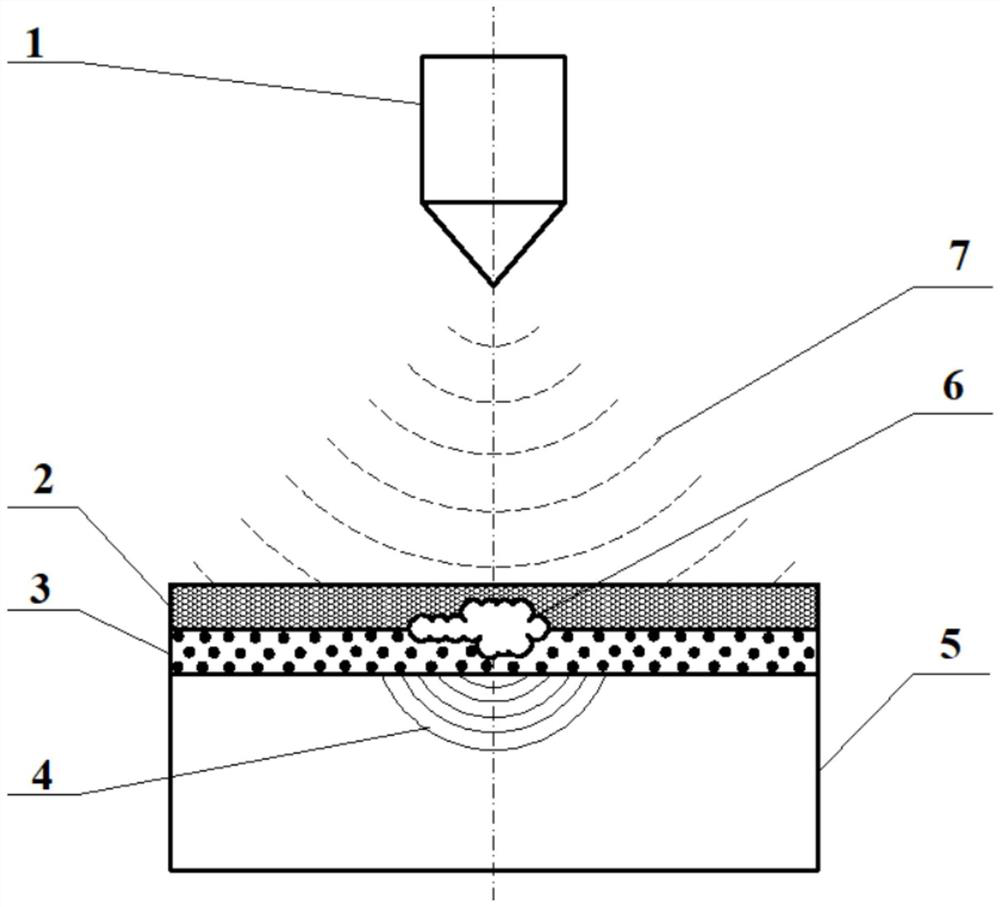

[0028] A metal material surface electromagnetic wave shock strengthening method, such as figure 1 shown, including the following steps:

[0029] Step 1: Screening the Al powder particles in the absorption layer 3, removing particles with too large or too small particle sizes, and measuring and screening the remaining Al powder particles with a particle size of about 0.5 μm;

[0030] Step 2: Set the output paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com