Method for continuous laser impacting micro particles to be melt-injected through injecting force formed by laser impacting work

A technology of micro-particles and laser shock, which is applied in the coating process of metal materials, coatings, etc., can solve problems such as constraints and difficulty in achieving micro-particle melting and injection, and achieve strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

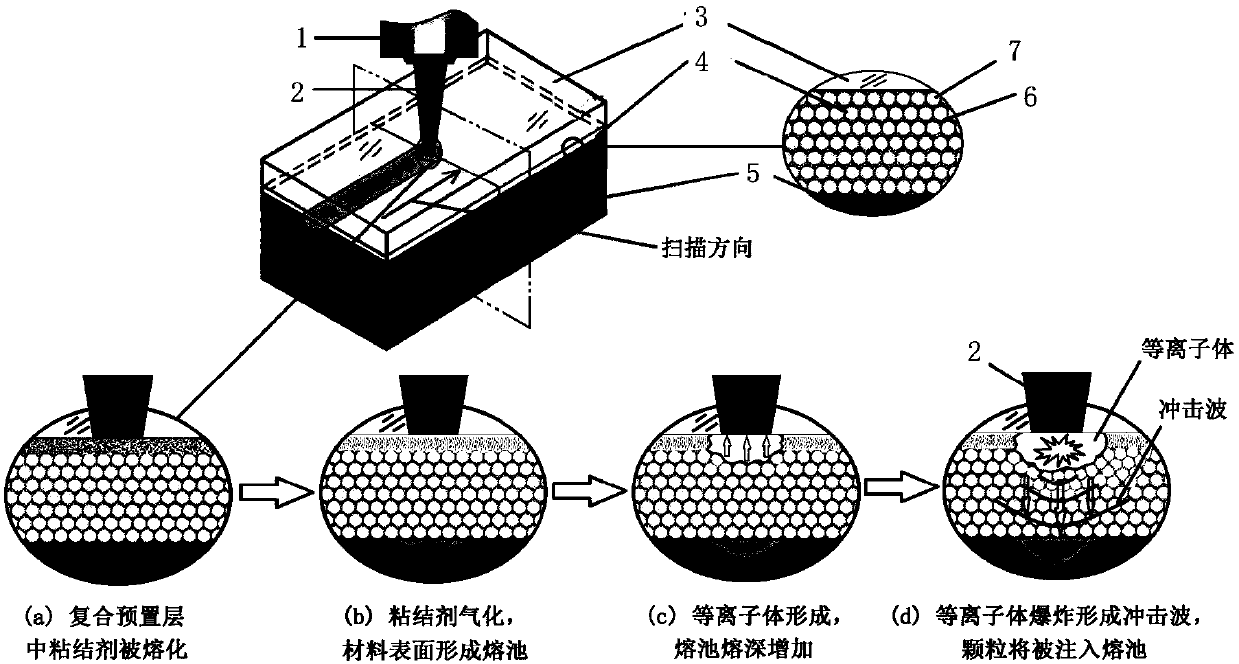

Method used

Image

Examples

Embodiment

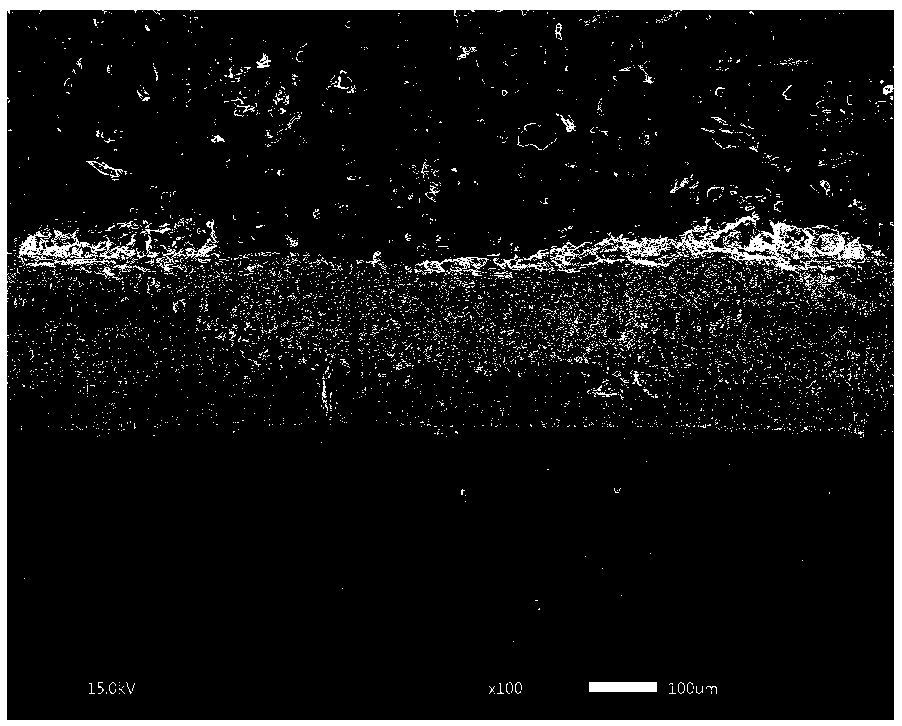

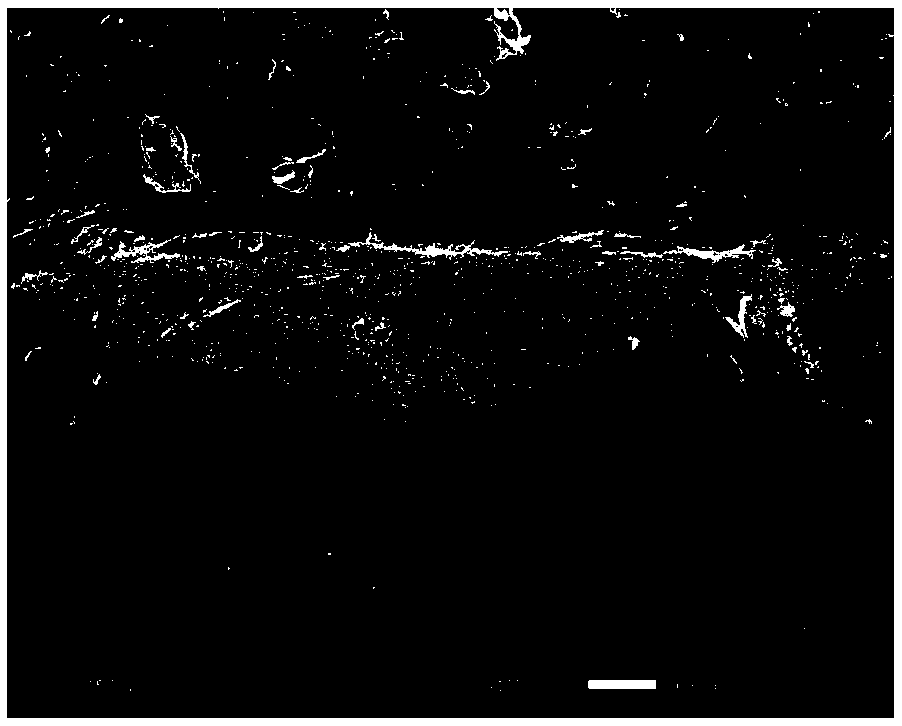

[0038] The material to be modified is an aluminum-silicon coating on the surface of a nickel-based superalloy (its melting point is about 1420°C), the binder is sodium chloride (its melting point is 891°C, its boiling point is 1413°C), and the fine particles to be melted are average Cerium oxide with a particle size of 1 μm (its melting point is 2397°C, when the particle size exceeds 100nm, its melting point basically does not decrease with the decrease of the particle size), the thickness of the composite pre-layer is 0.5mm; fiber laser is used in the melting process, The laser process parameters are 450W power, 1250mm / min scanning speed, 0.8mm spot diameter, and zero defocus; the constrained layer is covered with a coated quartz glass constrained layer on the composite preset layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com