Patents

Literature

36results about How to "Reduce aggregation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

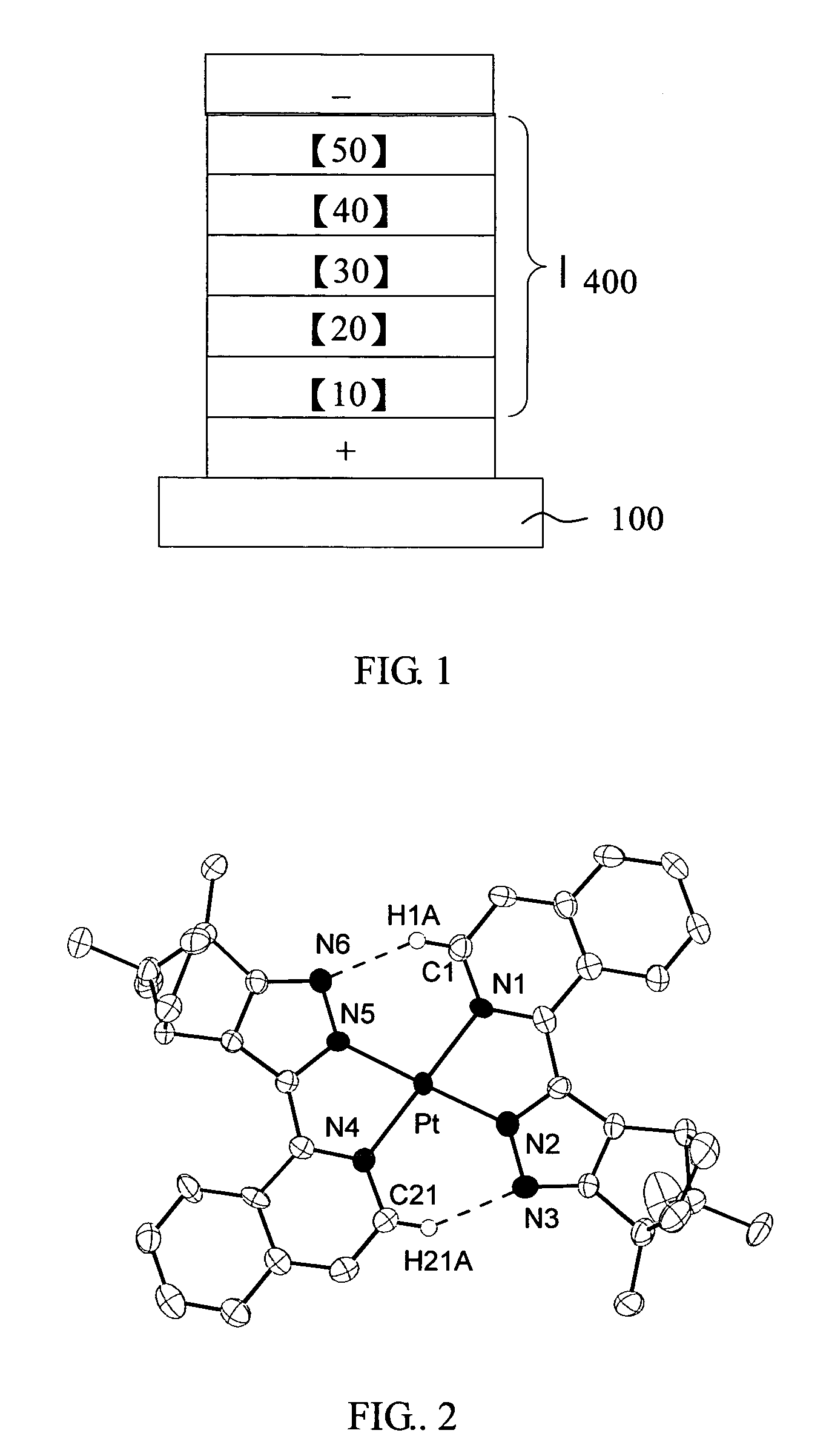

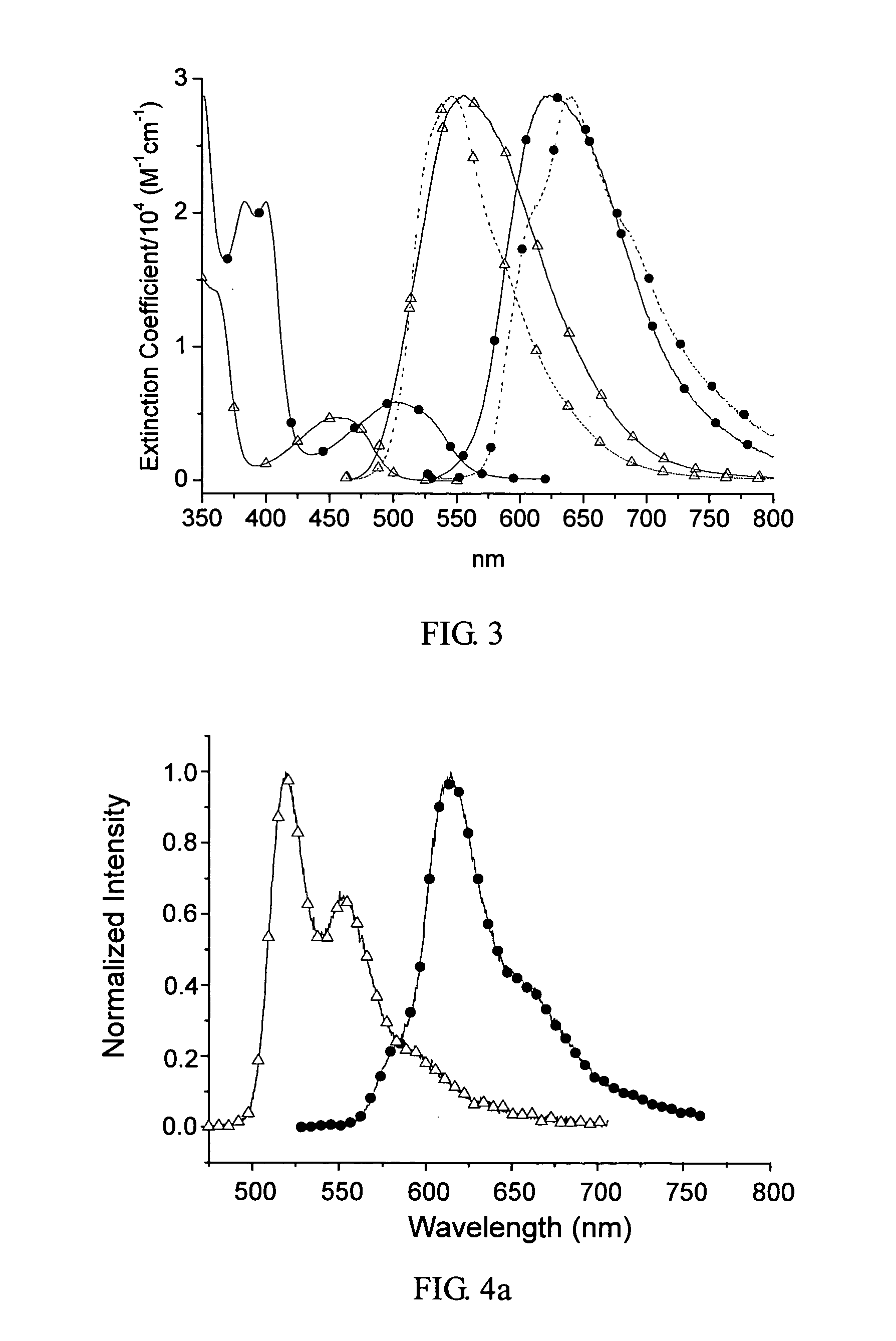

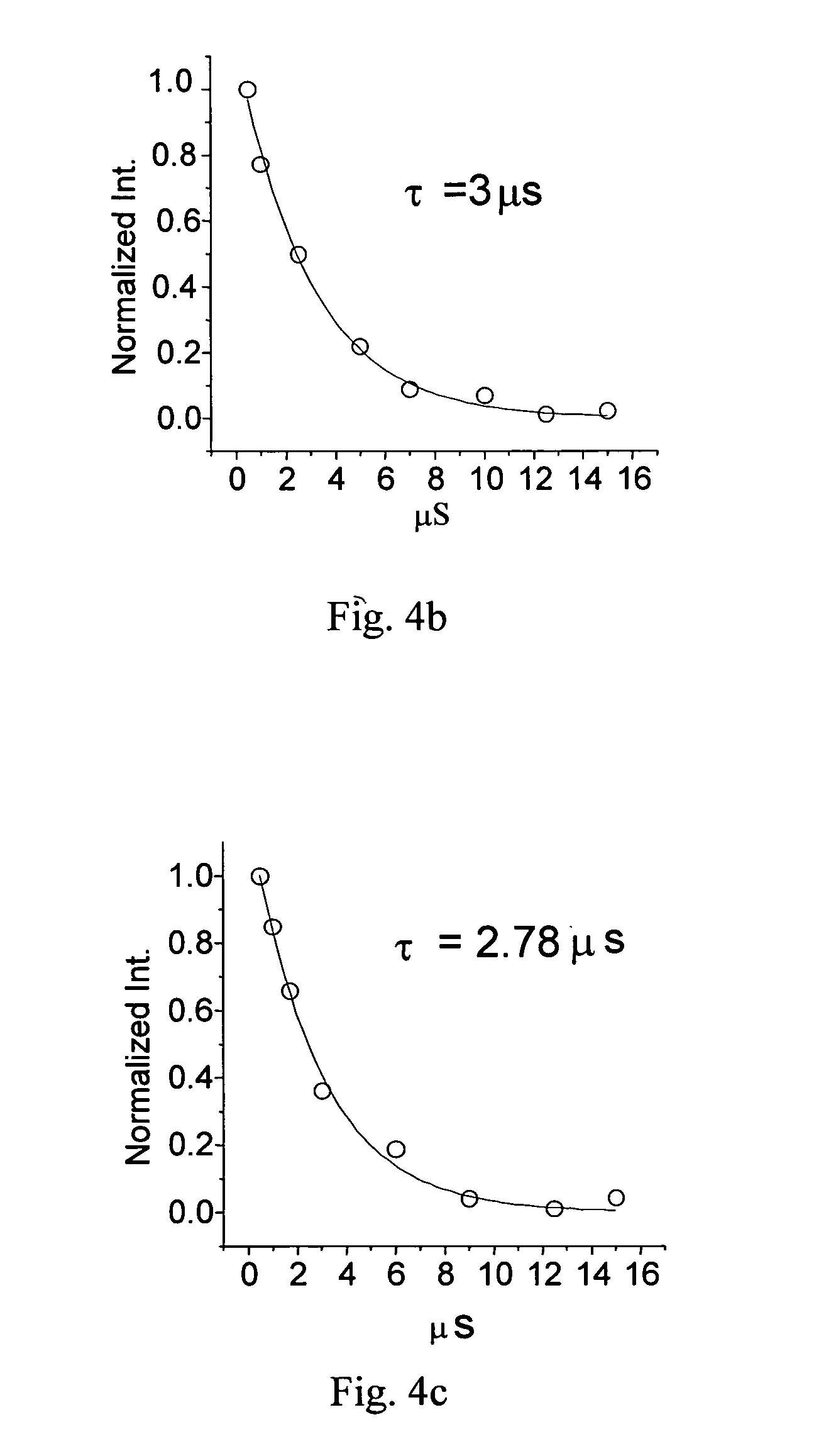

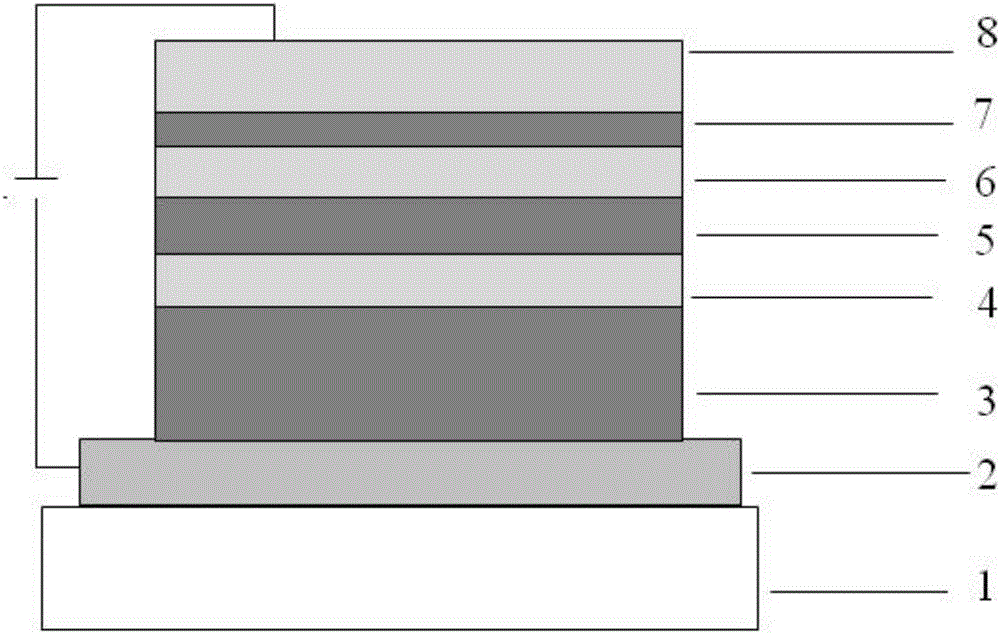

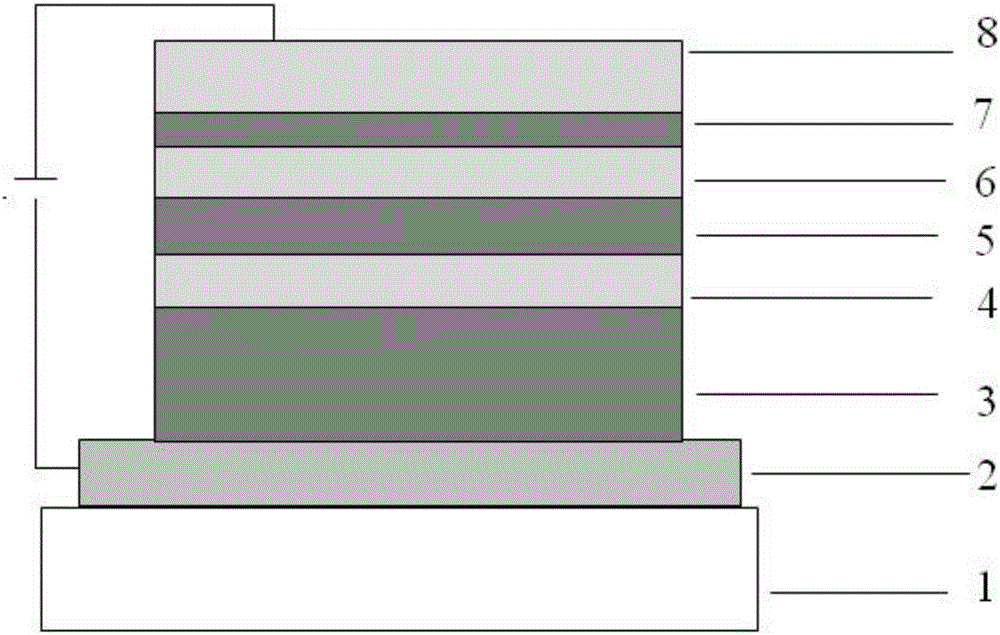

Pt complexes as phosphorescent emitters in the fabrication of organic light emitting diodes

ActiveUS7002013B1Inhibit aggregationReduction of phosphorescence radiative lifetimeGroup 4/14 element organic compoundsGroup 1/11 element organic compoundsLight-emitting diodeCoordination complex

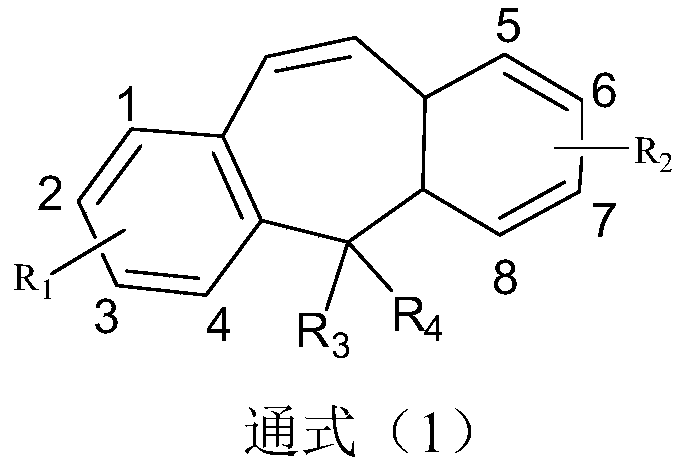

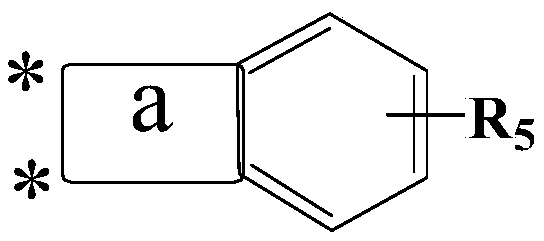

A series of Pt(II) complexes having the following formula are disclosed: X1 and X2 independently are C or N, X1 can also locate at another position of the hexagonal ring, when X1 is N;R1 is H, C1–C8 alkyl, or C1–C4 perfluoroalkyl, R2 is H, R1 and R2 together are C4–C8 alkylene, or R1 and R2 together are bridged carbocyclic C4–C12 alkylene, when X2 is C;R1 is H, C1–C8 alkyl, or C1–C4 perfluoroalkyl, and R2 is omitted, when X2 is N;R7 is H or methyl, and R8 is omitted, when X1 is N;R7 is H or methyl, R8 is H or methyl, or R7 and R8 together are when X1 is C.

Owner:SAMSUNG DISPLAY CO LTD

Method for reinforcing recycled concrete by using graphene oxide

The invention relates to a method for reinforcing recycled concrete by using graphene oxide. The method comprises the following steps: (1) preparing raw materials; (2) adding water into the graphene oxide to prepare dispersion liquid; (3) adding water into a water reducing agent to prepare a water reducing agent solution; (4) adding the dispersion liquid into the water reducing agent solution, stirring and then carrying out ultrasonic treatment for 15-20min to prepare a mixed solution; (5) screening recycled coarse aggregate, then mixing the screened material with fine sand and stirring, adding cement into the obtained mixture and stirring; (6) adding the mixed solution into the mixture under the condition of stirring, putting the product into a test mould after stirring, evenly vibrating on a vibration table, and then curing in a curing room. The method provided by the invention is reasonable in design and simple and convenient to operate; a rich lamellar structure of the graphene oxide contains a great deal of oxygen-containing active groups, so that growth points are provided for hydration products of the cement; a template effect for hydration of the concrete is achieved, and the mechanical properties and durability of the recycled concrete are improved.

Owner:宁夏赛马科进混凝土有限公司

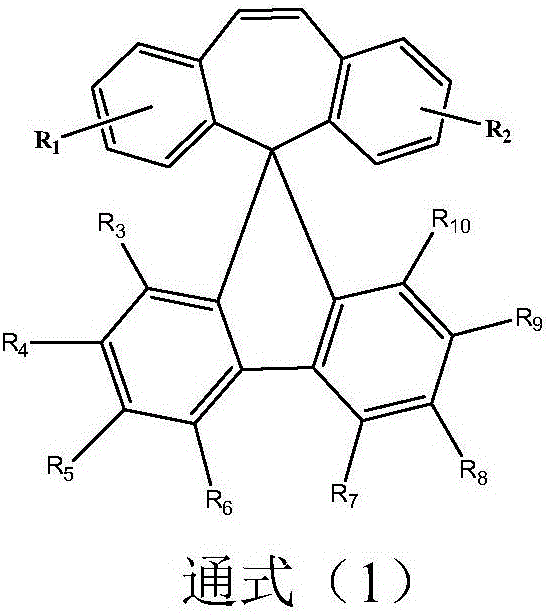

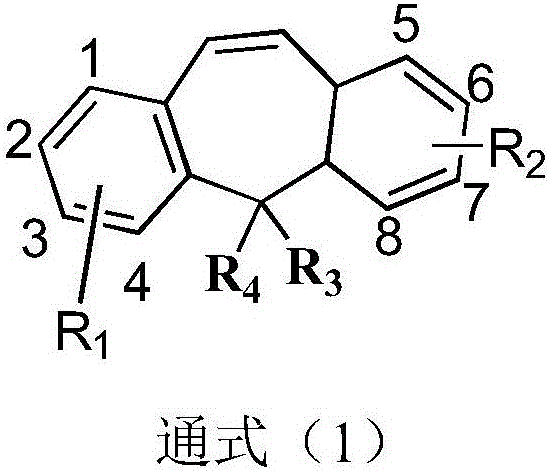

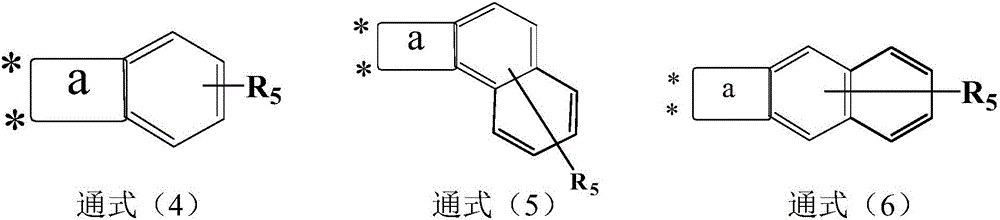

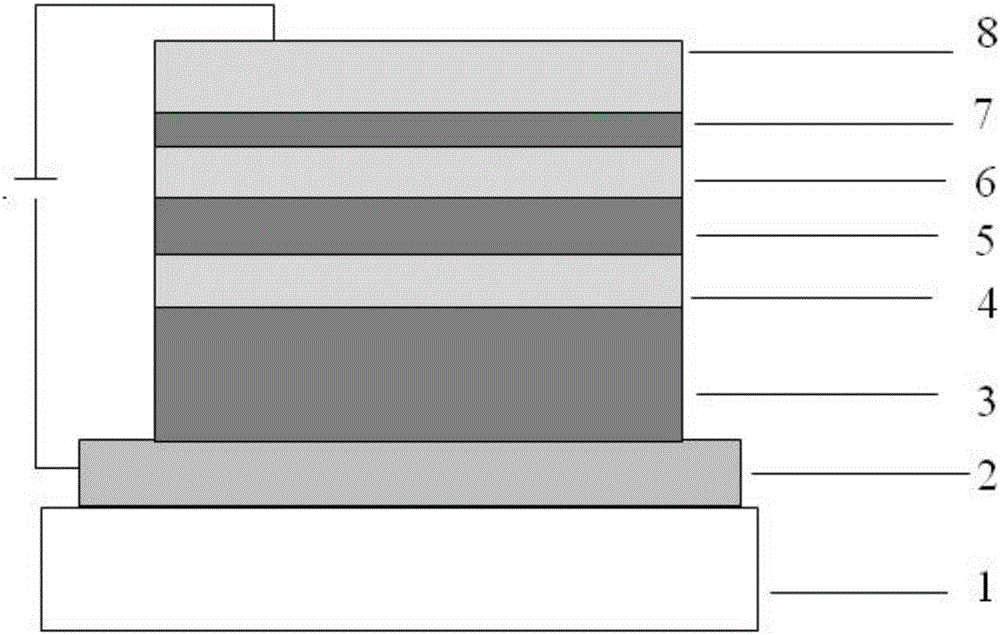

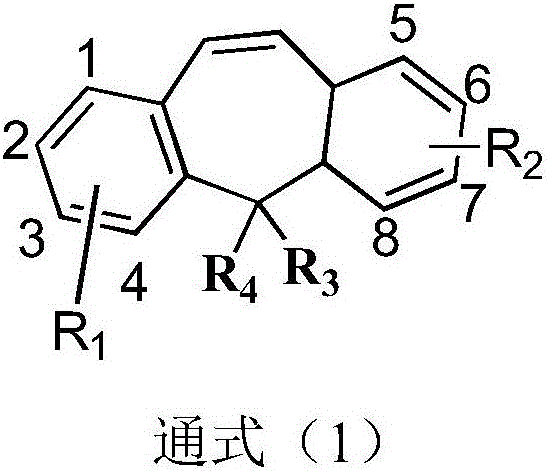

Organic electroluminescence compound and application thereof

InactiveCN106467469AImprove applicabilityImprove luminous efficiencyGroup 4/14 element organic compoundsSolid-state devicesQuantum efficiencyFluorescence

The invention discloses an organic electroluminescence compound and application thereof. The structural formula of the compound is as shown in the general formula (1). The material has good fluorescence quantum efficiency and electroluminescent efficiency, is easy to form an amorphous film, and has good heat stability. Thus, the material can be used as a luminescent layer main-body or a doping material in an organic electroluminescent device.

Owner:VALIANT CO LTD

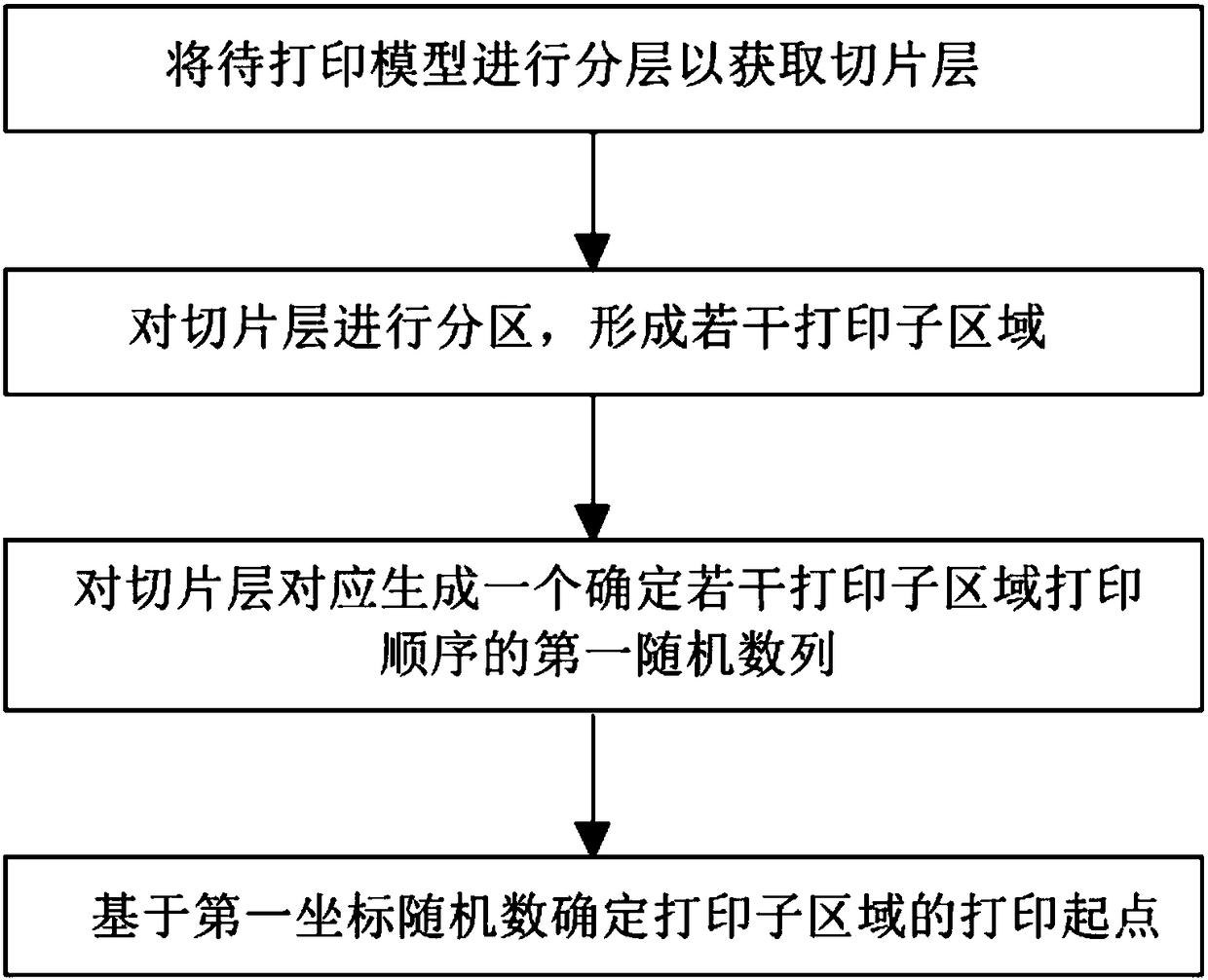

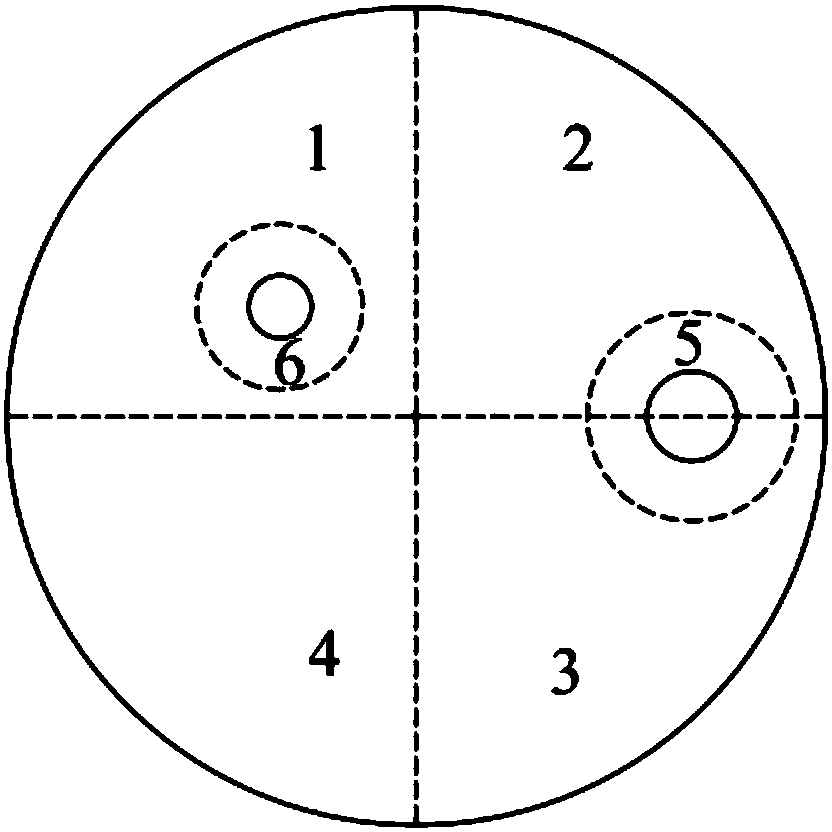

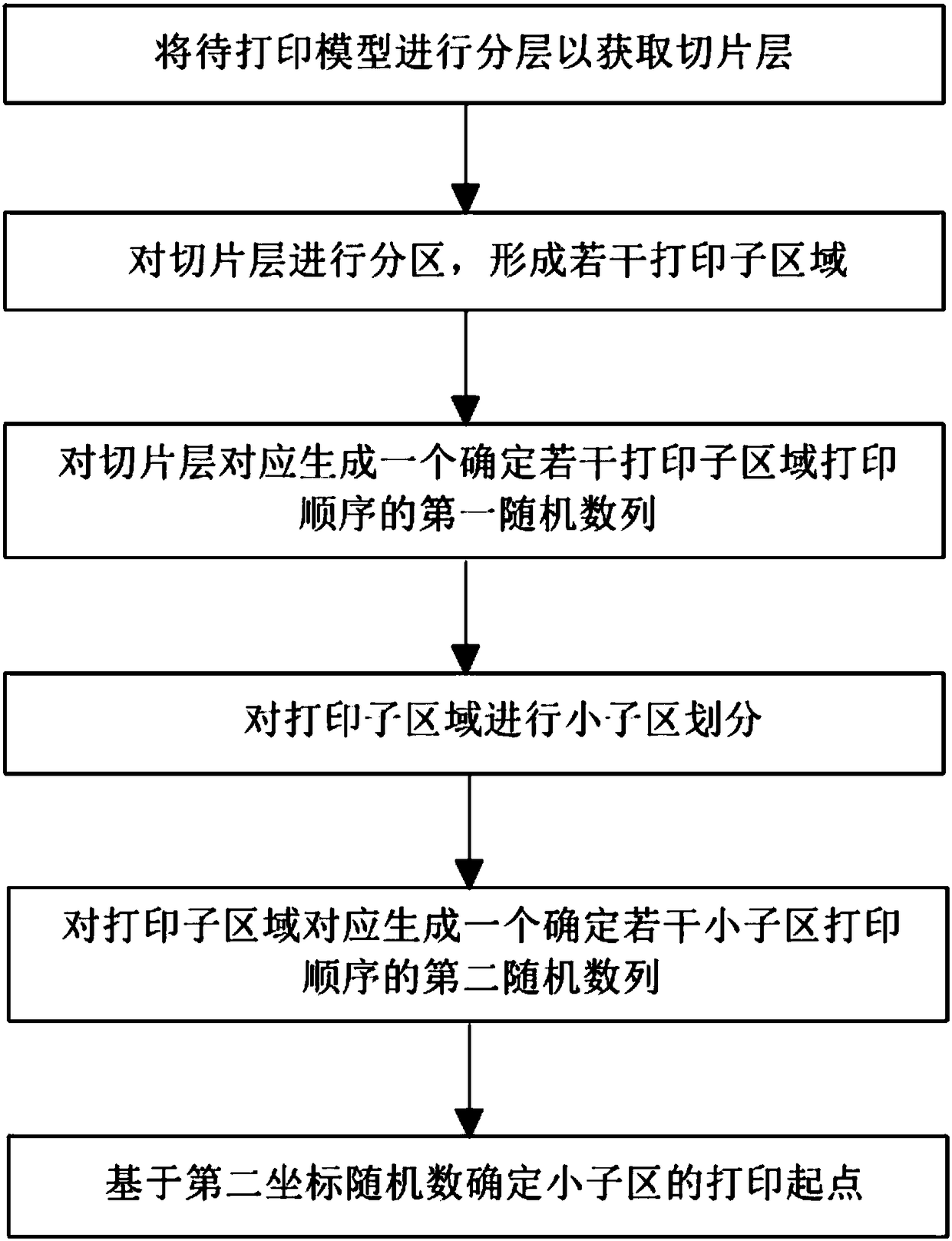

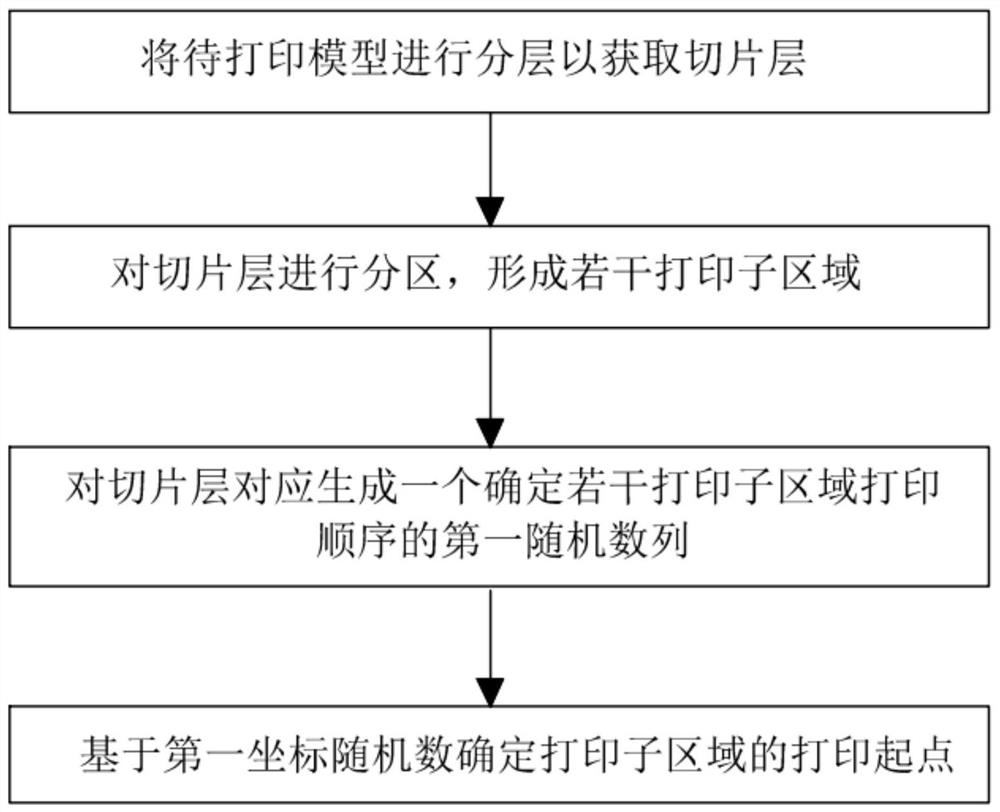

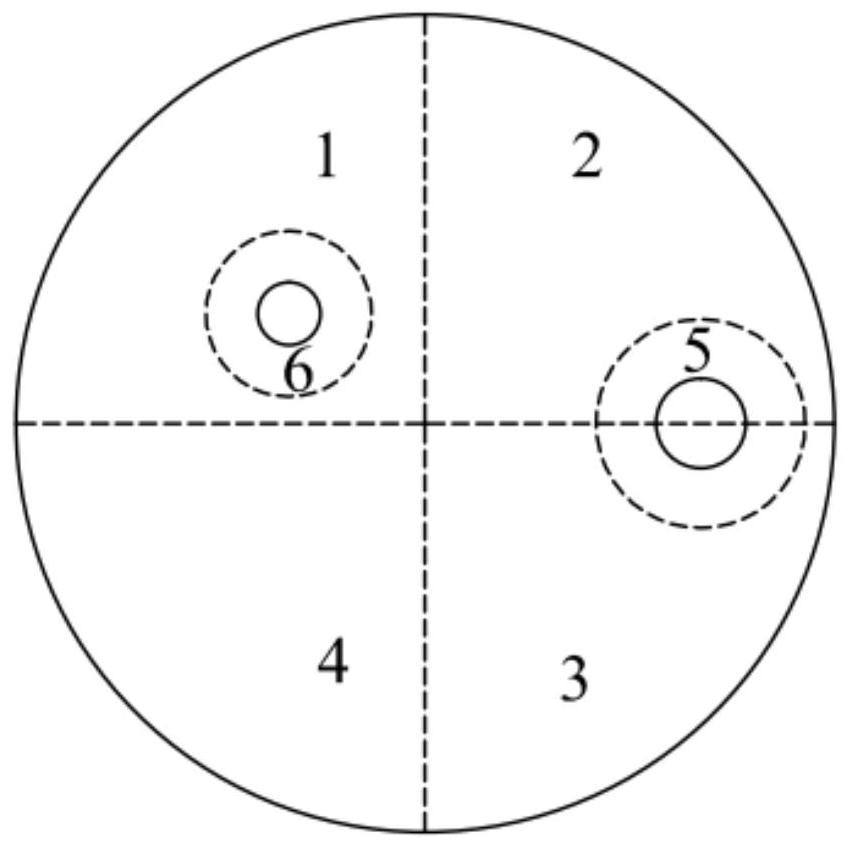

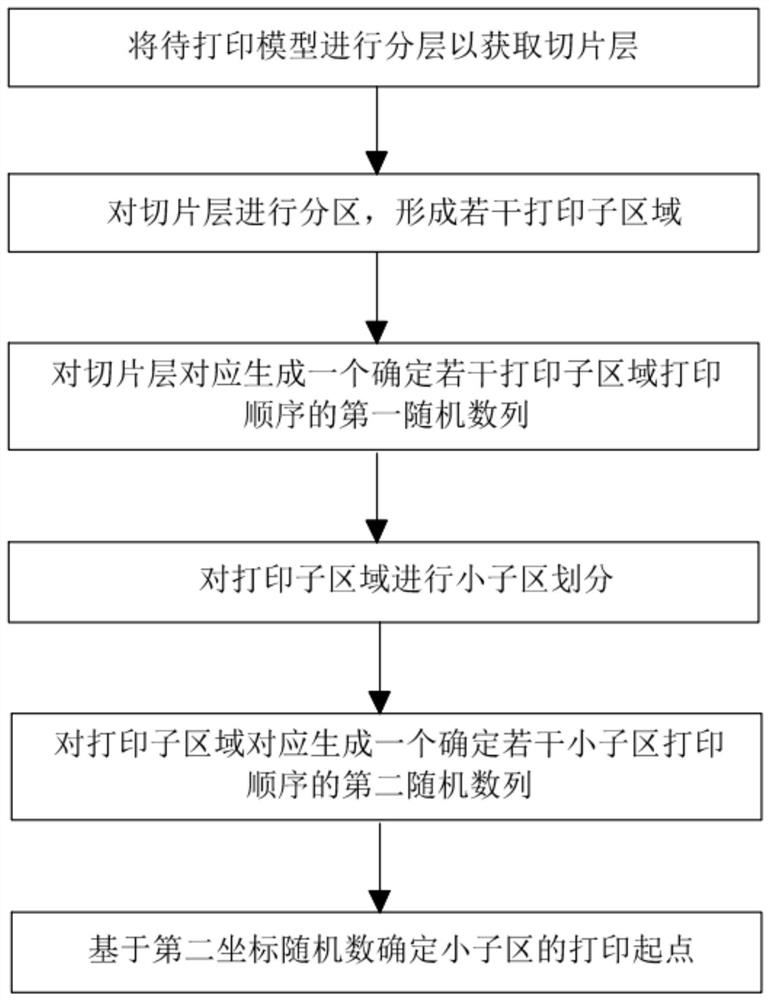

Printing path generation method of metal additive manufacturing

ActiveCN108326301AWith randomnessReduced shrinkage deformationAdditive manufacturing apparatusIncreasing energy efficiencyThermal deformationPath generation

The invention belongs to the technical field of 3D printing and particularly discloses a printing path generation method of metal additive manufacturing. The printing path generation method comprisesthe following steps that a model to be printed is layered so that section layers can be obtained; the section layers are partitioned, and a plurality of printing sub-regions are formed; a first randomnumber sequence determining the printing sequence of the multiple printing sub-regions is correspondingly generated for each section layer; and for the section layer, the printing sub-regions are sequentially printed according to the corresponding first random number sequence. According to the printing path generation method of the metal additive manufacturing, by means of the random distributionthought, the residual stress can be effectively reduced, the thermal deformation is reduced, and the surface quality and the size precision of parts are improved.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

Organic light emitting compound material and application thereof

InactiveCN106432158AImprove applicabilityImprove luminous efficiencySilicon organic compoundsGroup 5/15 element organic compoundsOrganic light emitting deviceChemical compound

The invention discloses an organic light emitting compound material and application of the organic light emitting compound material. The structural formula of the compound material is as shown in the general formula (1). The material can form an amorphous thin film easily, is high in heat stability and high in singlet state energy level, and is therefore can be used as a main material of a light emitting layer in an organic light-emitting device.

Owner:JIANGSU SUNERA TECH CO LTD

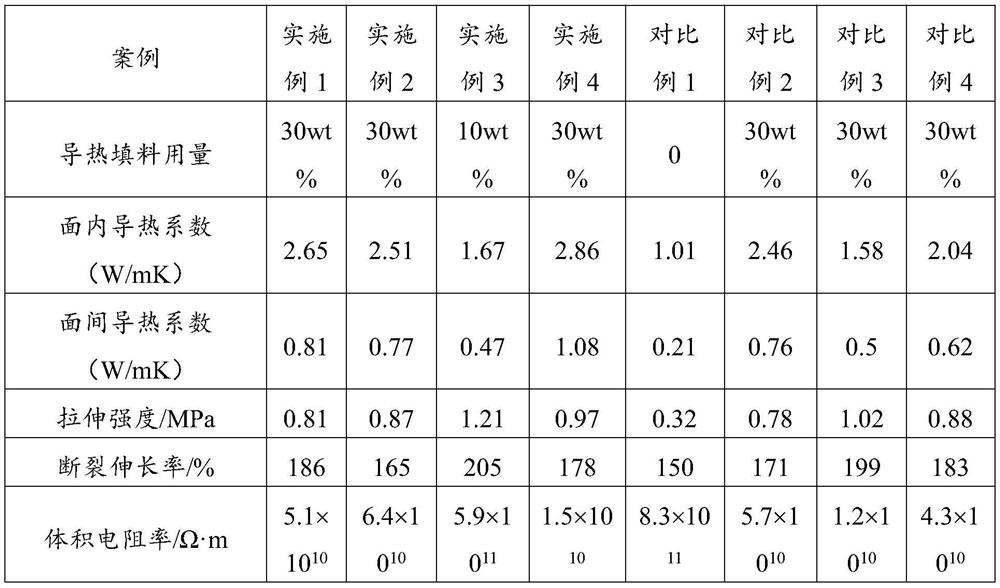

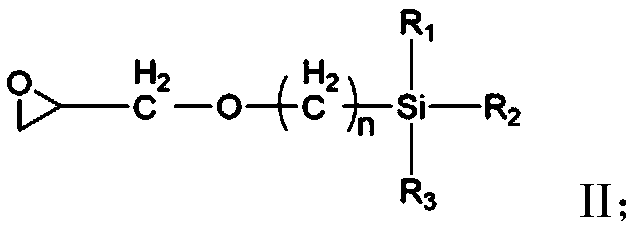

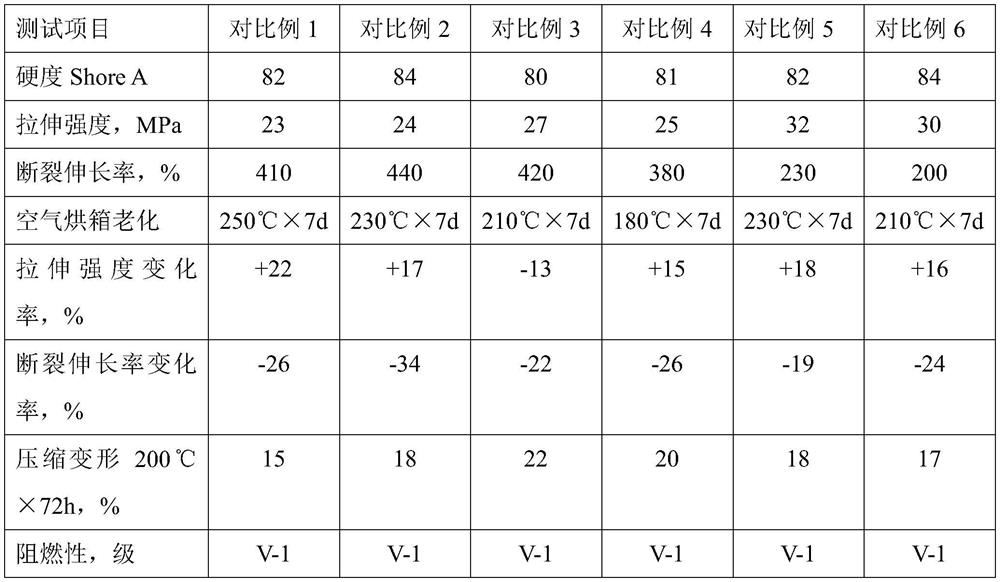

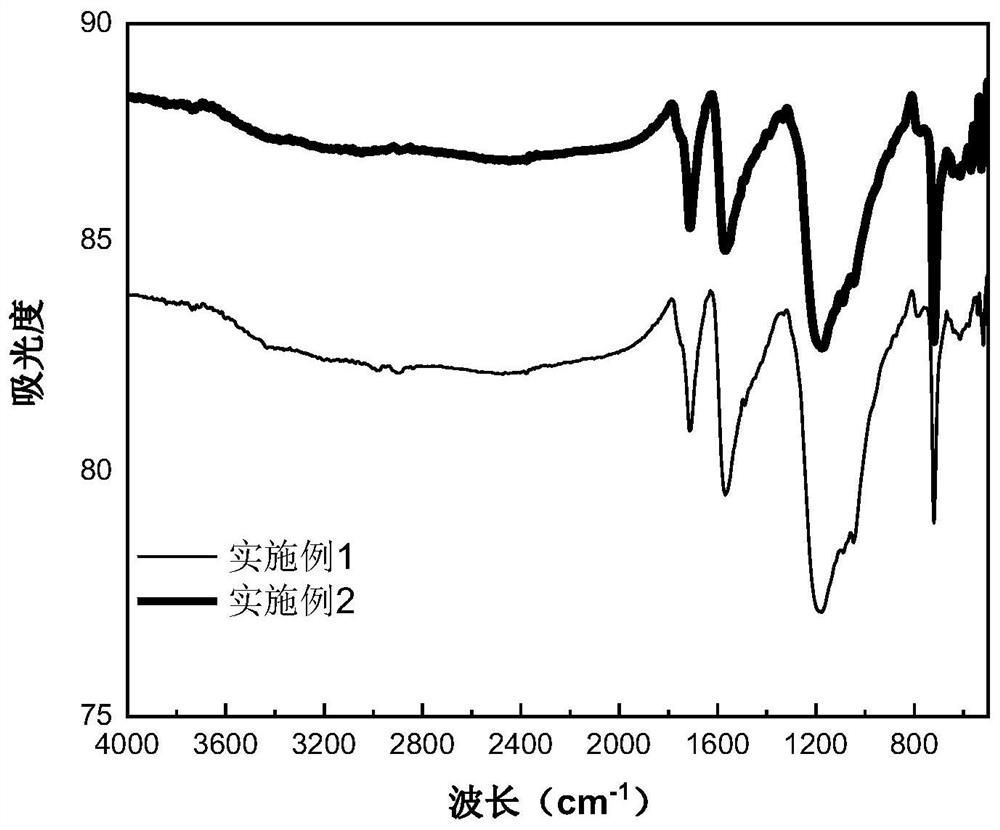

Heterostructure heat-conducting filler, preparation method and application thereof, silicone rubber heat-conducting insulating composite material and preparation method of same

PendingCN113087971ASignificant thermal anisotropyImprove filling efficiencyHeterojunctionPolymer science

The invention provides a heterostructure heat-conducting filler, a preparation method and application thereof, a silicone rubber heat-conducting insulating composite material and a preparation method thereof, and belongs to the technical field of heat-conducting insulating materials. gamma-glycidyl ether oxypropyl trimethoxy silane (GPTMS) and gamma-aminopropyl triethoxy silane (APTES) are adopted to carry out surface functional modification on boron nitride nanosheets and Al2O3 respectively, so that modified aluminum oxide is grafted to the surfaces of the modified boron nitride nanosheets, and the heat-conducting filler with a'point-surface 'heterostructure is obtained. Compared with a single boron nitride nanosheet layer and aluminum oxide particles, the heat-conducting filler with the point-surface heterostructure can increase the contact lap joint probability of the heat-conducting filler in a silicon rubber matrix, more heat-conducting channels or networks are formed, and the construction efficiency of the heat-conducting channels of the heat-conducting filler in the matrix is improved; therefore, the composite material with high heat-conducting property can be obtained when the use amount of the heat-conducting filler is low, and the mechanical property of the heat-conducting composite material is ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

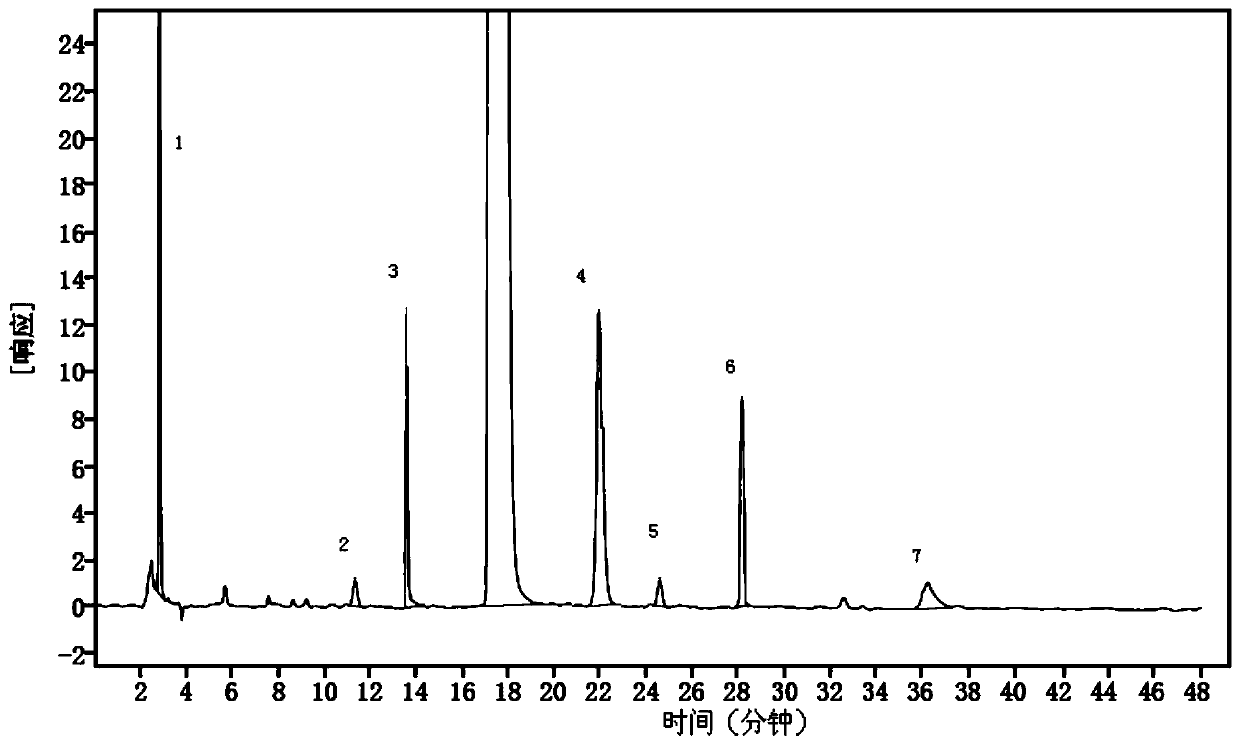

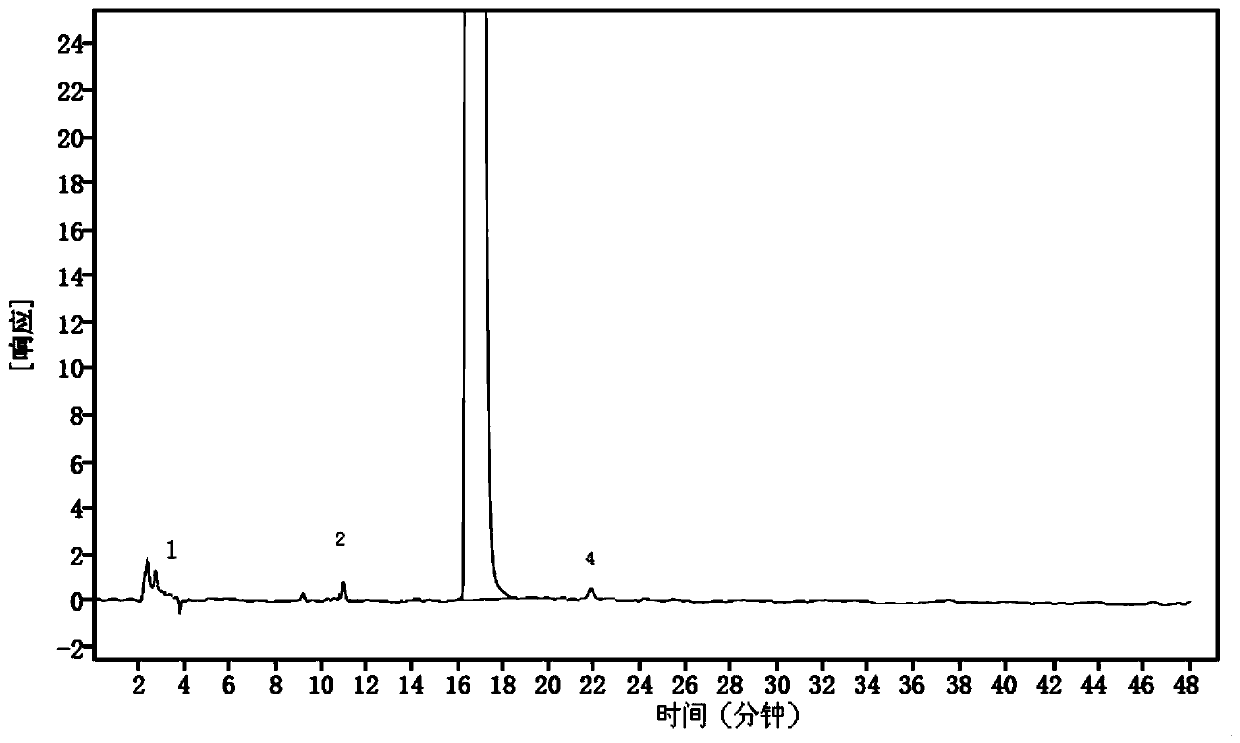

Ultrasonic composite acidic water extraction method for cordyceps polysaccharide and cordycepin in cordyceps militaris

PendingUS20220080333A1Enhance the destructive effectHigh dissolution rateSugar derivativesCultivating equipmentsLow frequency ultrasoundAcid water

Disclosed is an ultrasonic composite acidic water extraction method for a Cordyceps polysaccharide and cordycepin in Cordyceps militaris, which falls within the technical field of food processing. The method comprises: picking, washing, drying, pulverizing and degreasing Cordyceps militaris fruiting bodies to obtain a Cordyceps militaris dry powder; then immersing same in a prepared diluted hydrochloric acid solution to perform three cycles of ultra-low temperature freezing and microwave defrosting, and at the same time using low-frequency ultrasonic waves to carry out assisted stirring and extraction; then subjecting an extract to evaporation and concentration treatments; and finally, performing freeze-drying on the extract to collect a dry powder of a water extraction product. The amount of an additive used in the method meets domestic and foreign usage requirements of food additives, and the operation is simple, practical and uses a combination of chemical and physical methods, thereby saving time and being highly efficient.

Owner:JIANGNAN UNIV

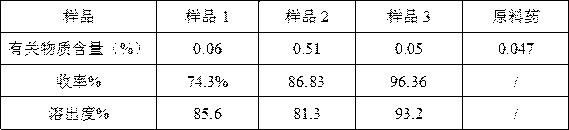

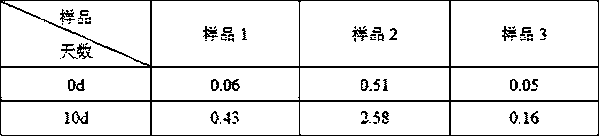

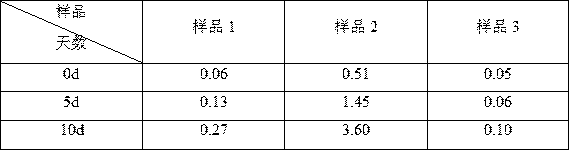

Preparation method of amlodipine besylate tablets

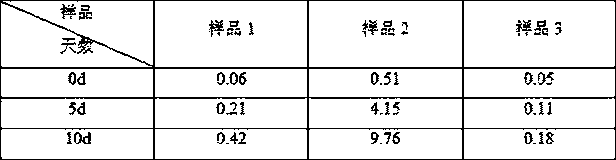

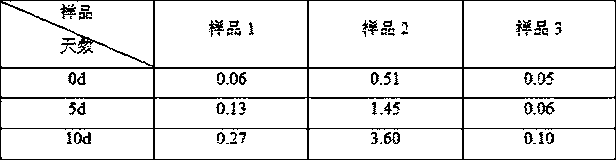

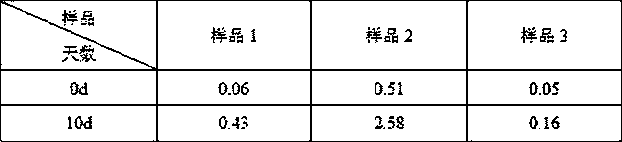

InactiveCN109953960AReduce adsorptionReduce aggregation effectOrganic active ingredientsInorganic non-active ingredientsAmlodipine besilateMixed materials

The invention relates to a preparation method of amlodipine besylate tablets. The preparation method is mainly used for solving the technical problems that existing products are low in yield and poorin dissolution rate. The technical scheme adopted by the invention lies in that the preparation method of amlodipine besylate tablets is characterized by comprising the steps of (1) firstly uniformlymixing amlodipine besylate with gum acacia to obtain a mixed material A; enabling microcrystalline cellulose and calcium phosphate dibasic anhydrous to dissolve in anhydrous ethanol, performing stirring, and then performing spray drying so as to obtain a mixed material B; placing the mixed material A, the mixed material B and magnesium stearate in a high-efficiency wet-method mixed granulating machine, and performing stirring to obtain a mixed material C; adding the mixed material C to a dry-method granulating machine, and screening out fine powder so as to obtain granules I; adding the granules I, magnesium stearate and sodium carboxymethyl starch to a three-dimensional movement mixing machine together, and performing mixing so as to obtain granules II; and tabletting the granules II so as to obtain the amlodipine besylate tablets. The amlodipine besylate tablets are mainly applied to the technical field of medicines.

Owner:HUNAN QIANJIN XIELI PHARMA CO LTD

Amlodipine besylate tablet and preparation method thereof

InactiveCN109953957AReduce adsorptionReduce aggregation effectOrganic active ingredientsInorganic non-active ingredientsHydrogen phosphateAmlodipine besilate

The invention relates to an amlodipine besylate tablet, and mainly solves the technical problems of low yield and poor dissolution rate of existing products. The key point of the technical solution isas follows: the amlodipine besylate tablet is characterized in that the amlodipine besylate tablet comprises amlodipine besylate, micro-powder silica gel, microcrystalline cellulose, anhydrous calcium hydrogen phosphate, magnesium stearate and sodium carboxymethyl starch. The amlodipine besylate tablet is mainly applied to the technical field of medicines.

Owner:HUNAN QIANJIN XIELI PHARMA CO LTD

Preparation method of high-performance special graphite

The invention discloses a preparation method of high-performance special graphite, and relates to the technical field of graphite preparation. The invention aims to solve the problems that raw material powder and asphalt are not uniformly mixed, kneaded and coated enough and the asphalt is excessive. The method comprises the following steps: grinding calcined petroleum coke, conducting screening to obtain ground calcined petroleum coke with different particle sizes, weighing a proper amount of raw material powder of each particle size, and carrying out uniform mixing; selecting medium-temperature coal pitch as a binder; preheating the raw material powder, melting the medium-temperature coal pitch, respectively spraying the raw material powder and the pitch through two nozzles, enabling the raw material powder to penetrate through a pitch spraying path and fall out of the end point of the pitch spraying path, enabling the surface of the raw material powder to be coated with the pitch, respectively collecting the redundant pitch and the raw material powder coated with the pitch, and carrying out cooling to obtain a paste material; and grinding, winnowing and briquetting the paste, and sequentially performing primary roasting, dipping, secondary roasting and graphitization to obtain a graphite product. According to the invention, the coating effect of the raw material powder and the pitch is good, product performance is excellent, and pitch consumption is reduced.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

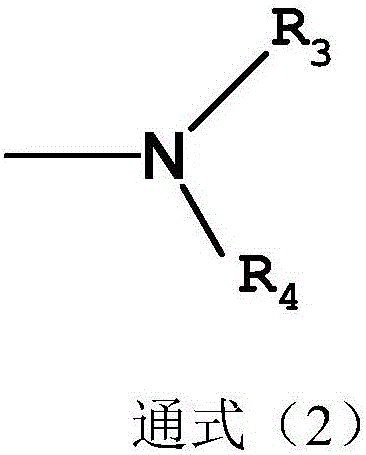

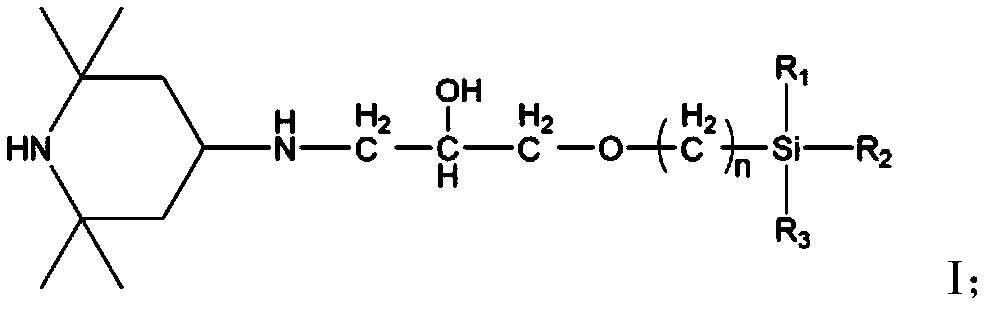

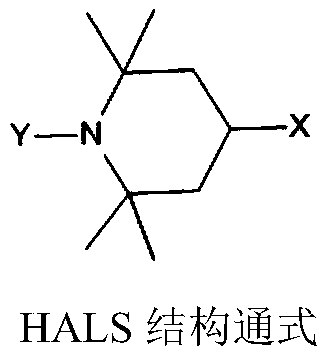

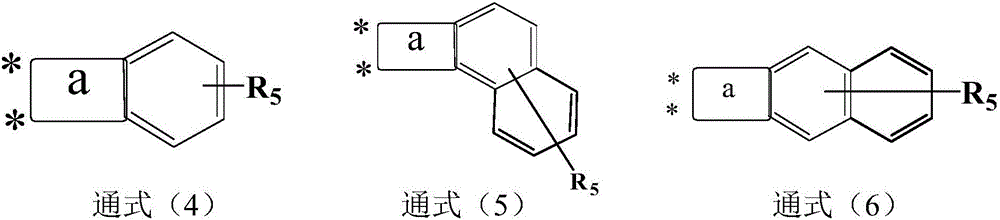

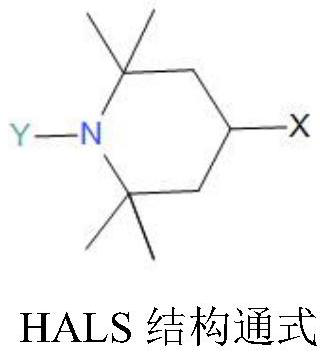

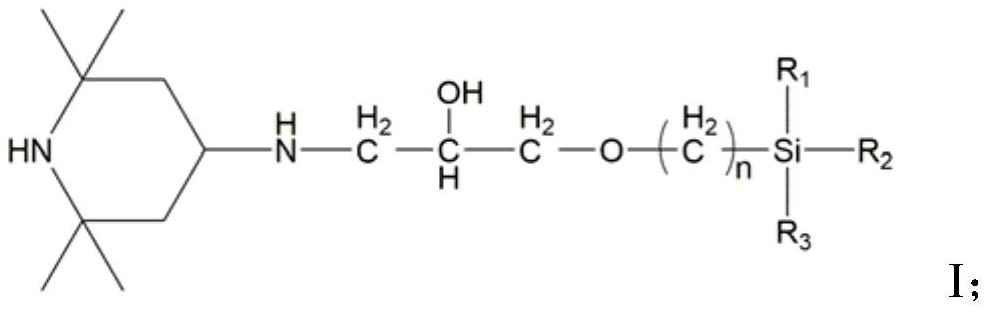

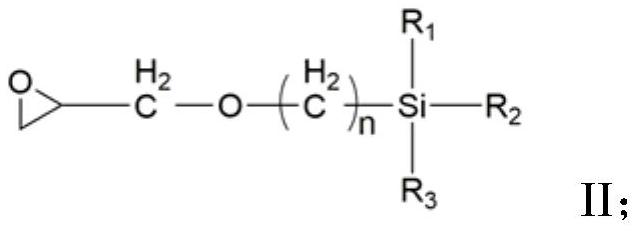

Light stabilizer and preparation method and application thereof

ActiveCN111100331AReactiveGood physical and mechanical propertiesGroup 4/14 element organic compoundsMonocomponent polyolefin artificial filamentPolymer chemistryInorganic filler

The invention discloses a light stabilizer. The light stabilizer has a structure as shown in the following formula I. In the formula I, R1, R2 and R3 are respectively and independently selected from one or two of alkyl or alkoxy, and n is an integer from 2 to 4. The light stabilizer has an improved light stabilizing effect, has a good dispersing effect on inorganic filler used together with the light stabilizer, and endows a plastic product using the light stabilizer with better physical and mechanical properties. The invention also discloses a preparation method and application of the light stabilizer.

Owner:宿迁联盛科技股份有限公司

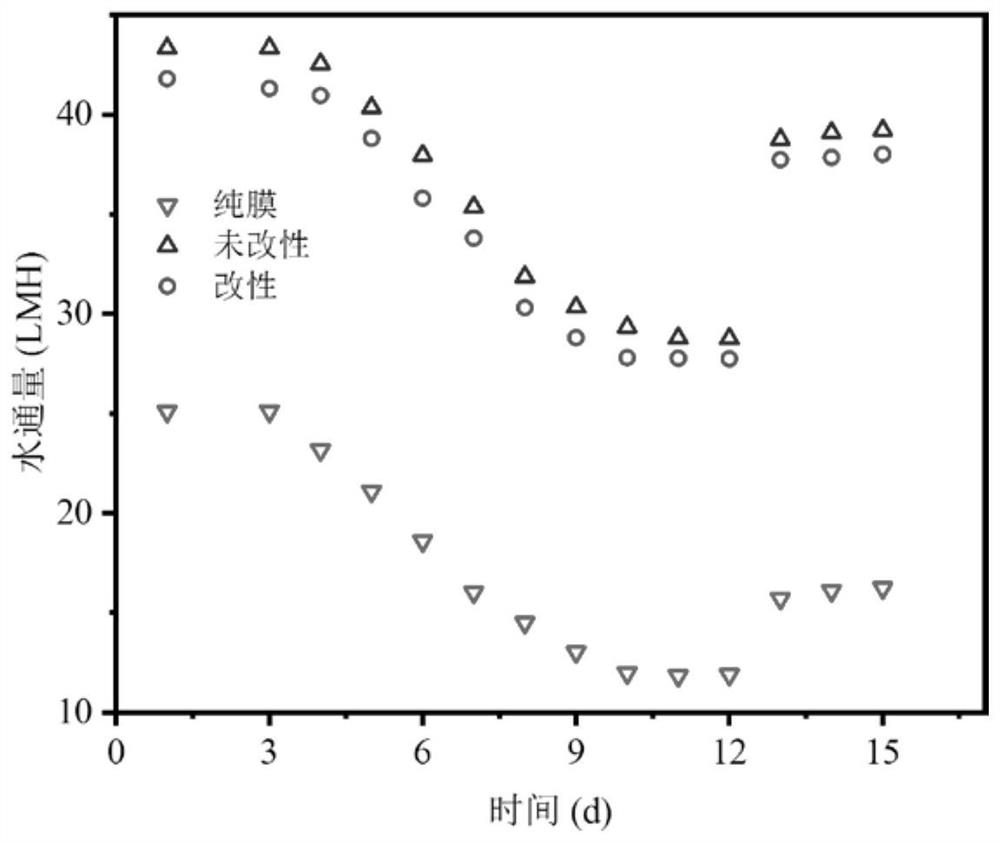

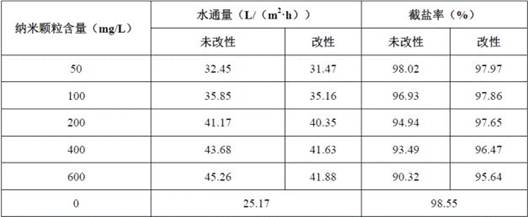

Reverse osmosis membrane and preparation method thereof

InactiveCN112237842AEasy to separateStrong antifoulingWater/sewage treatment bu osmosis/dialysisReverse osmosisNanoparticleReverse osmosis

The invention provides a reverse osmosis membrane. The reverse osmosis membrane comprises modified palygorskite nanoparticles, the reverse osmosis membrane comprises a porous support body layer and apolyamide layer, wherein the modified palygorskite nanoparticles are uniformly dispersed in the polyamide layer, and the modified palygorskite nanoparticles are modified by a silane coupling agent KH550. In the process of preparing the reverse osmosis membrane through interfacial polymerization reaction, the KH550 modified palygorskite nanoparticle doped reverse osmosis membrane has good separation performance and water flux capacity, and the membrane has strong antifouling property.

Owner:SHANDONG JIANZHU UNIV

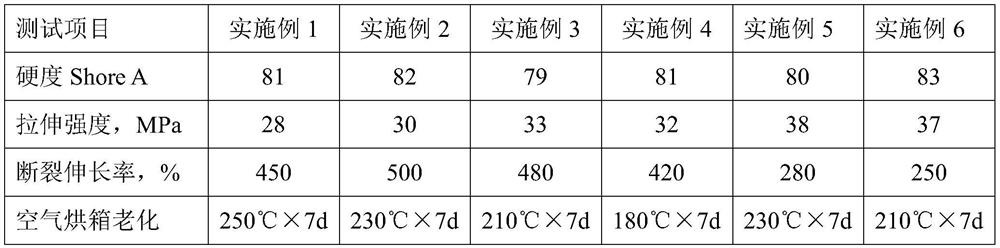

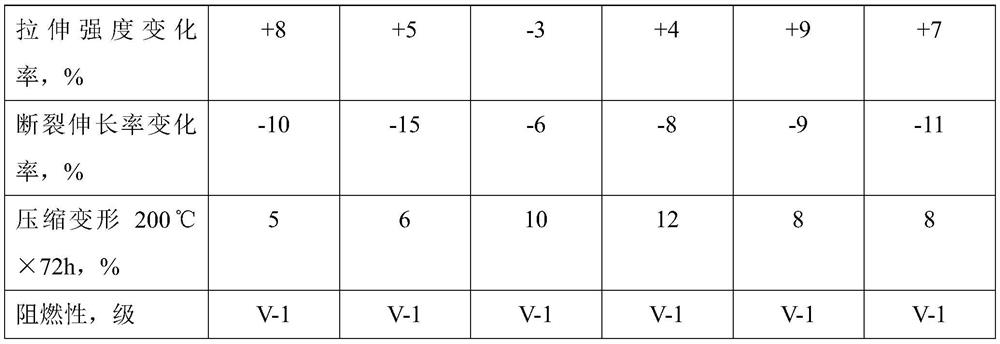

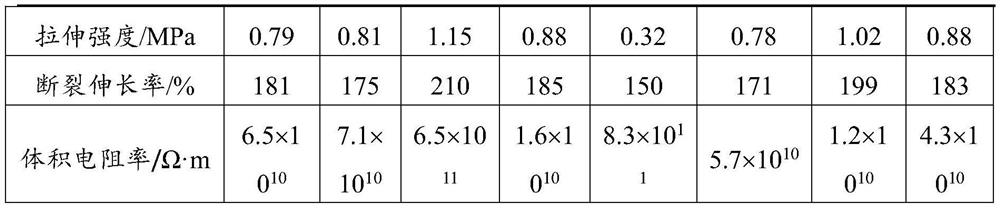

High-temperature-resistant low-compression-deformation flame-retardant thermoplastic elastomer and preparation method thereof

ActiveCN113583366AReduce aggregation effectSmall mechanical propertiesBulk chemical productionPolymer scienceRadiation resistant

The invention discloses a high-temperature-resistant low-compression-deformation flame-retardant thermoplastic elastomer which comprises the following raw materials in parts by mass: 20-60 parts of fluororesin, 45-100 parts of a flame-retardant fluororubber premix, 1-10 parts of a vulcanizing agent, 1-10 parts of a cross-linking agent, 3-10 parts of a lubricant, 1-3 parts of an antioxidant and 0-2 parts of an ultraviolet light initiator. The invention also discloses a preparation method of the high-temperature-resistant low-compression-deformation flame-retardant thermoplastic elastomer. The thermoplastic elastomer prepared by the invention not only has excellent chemical medium resistance and radiation resistance, but also has excellent properties of high temperature resistance, flame retardance and low compression deformation, and is suitable for being applied to harsh environments and high-temperature fields.

Owner:会通新材料(上海)有限公司

BNNS-coated Al2O3 heterostructure heat-conducting filler, preparation and application thereof, heat-conducting insulating composite material and preparation thereof

The invention provides a BNNS-coated Al2O3 heterostructure heat-conducting filler, preparation and application thereof, a heat-conducting insulating composite material and preparation thereof, and belongs to the technical field of heat-conducting insulating materials. Aluminum salt and boron nitride nanosheets are taken as raw materials, Al2O3 grows on the surface of BNNS in situ through a precipitation-high-temperature calcination method, the BNNS-coated Al2O3 heat conduction filler with a point-surface heterostructure is prepared, and compared with a single boron nitride nanosheet layer and Al2O3 particles, the heat-conducting filler BNNS-coated Al2O3 with a point-surface heterostructure can increase the contact lap joint probability of the heat-conducting filler in a silicone rubber matrix, more efficient heat-conducting passages or networks are formed, the construction efficiency of the heat-conducting passages of the heat-conducting filler in the matrix is improved, the heat-conducting property of the heat-conducting composite material is further improved, the composite material with high heat-conducting property can be obtained when the use amount of the heat-conducting filler is low, and the mechanical property of the heat-conducting composite material is ensured.

Owner:GUANGDONG SUQUN NEW MATERIAL CO LTD +1

Organic light-emitting material and application thereof

ActiveCN106431937AImprove applicabilityImprove luminous efficiencySilicon organic compoundsSolid-state devicesElectricityQuantum efficiency

The invention discloses an organic light-emitting material and application thereof. A structural formula of the light-emitting material is shown as a general formula (1). The material has good fluorescence quantum efficiency and electroluminescence efficiency and has good heat stability. Therefore, the material can be used as a light-emitting layer doped material in an organic electroluminescence device.

Owner:JIANGSU SUNERA TECH CO LTD

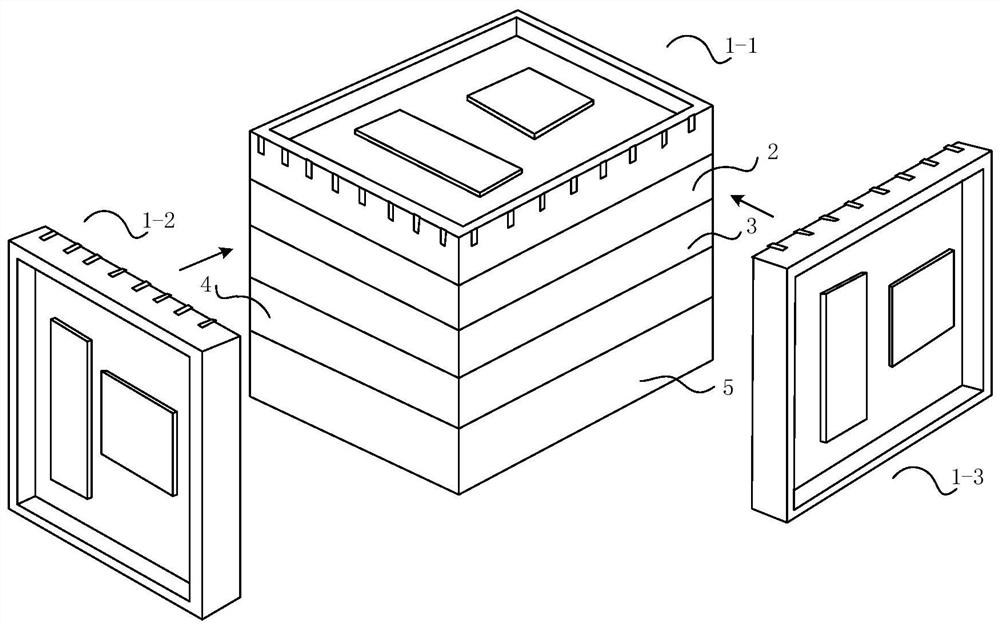

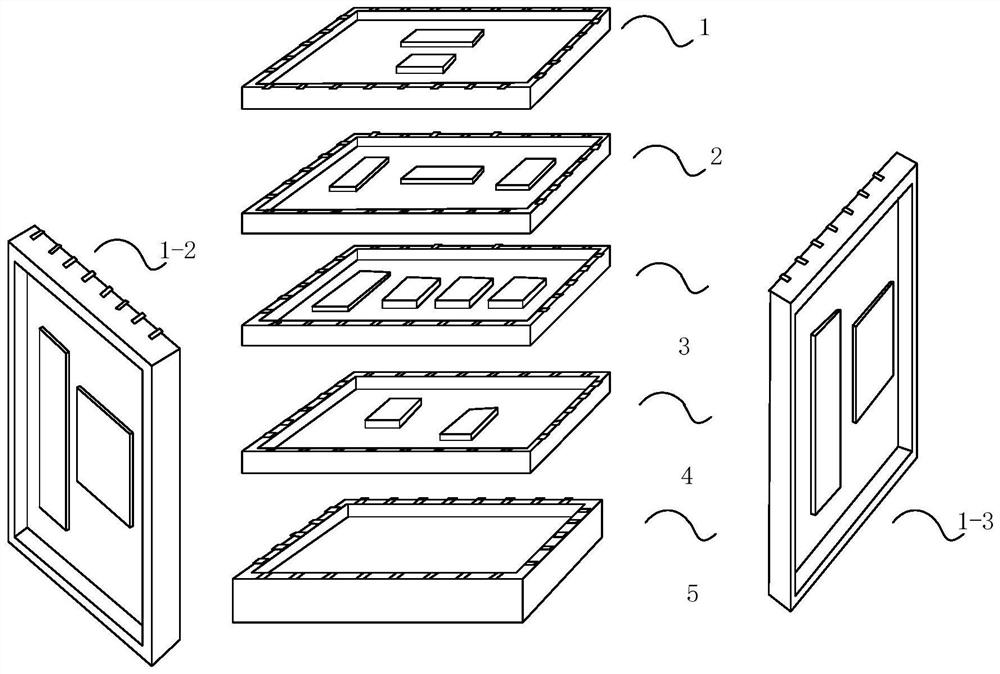

High-density integrated navigation, positioning and timing micro-device and its integration method

The present invention proposes a high-density integrated navigation, positioning and timing micro-device and its integration method, using the system architecture of four-layer assembly substrate, two side substrates and one bottom plate, adopting multilayer LTCC technology and ceramic thick film substrate technology to integrate each Similar functional chips are assembled on the substrate, using flexible baseband interconnection technology and solder ball technology to realize electrical signal connections between substrates, between substrates and bottom panels, and between substrates and side panels, and using three-dimensional high-density assembly technology to achieve three-dimensional high-precision assembly of multiple substrates. And the high-density integrated heat dissipation technology is used to realize the chip-level and package-level heat dissipation treatment of the three-dimensional chip stacking system, which effectively reduces the physical volume of the system and enhances the heat dissipation performance of the system.

Owner:INFORMATION SCI RES INST OF CETC

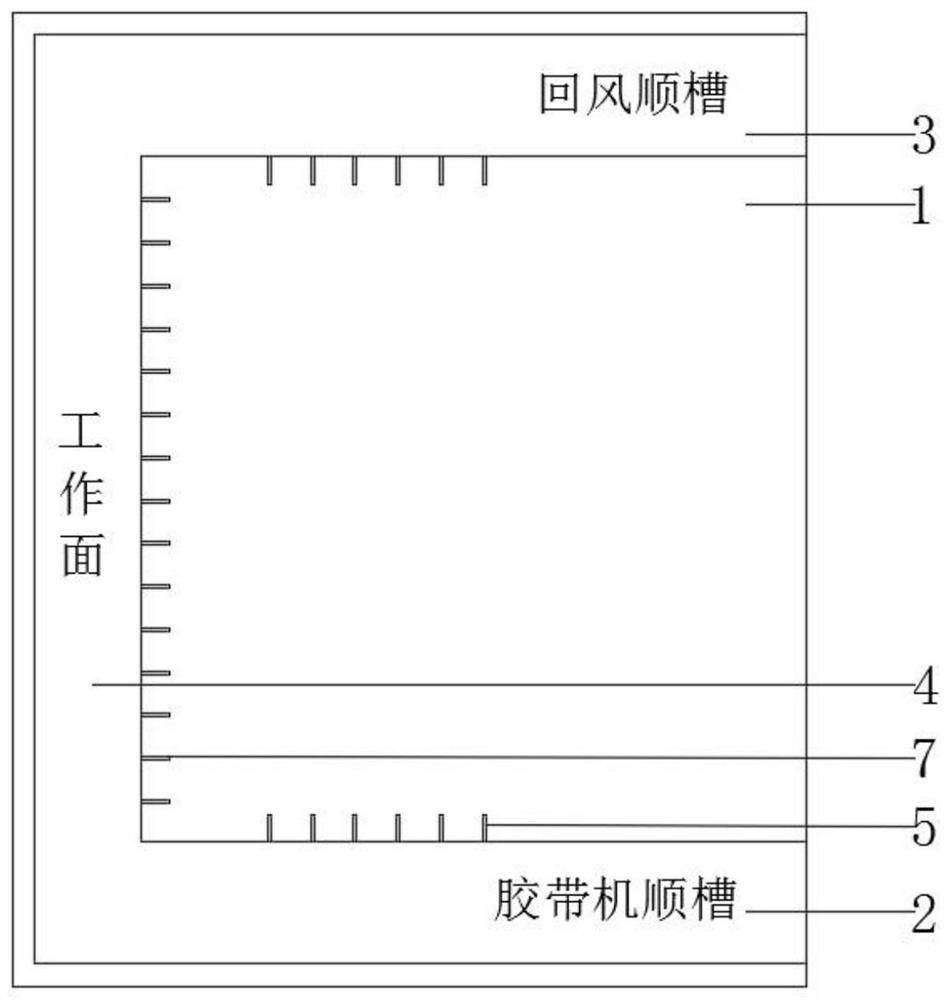

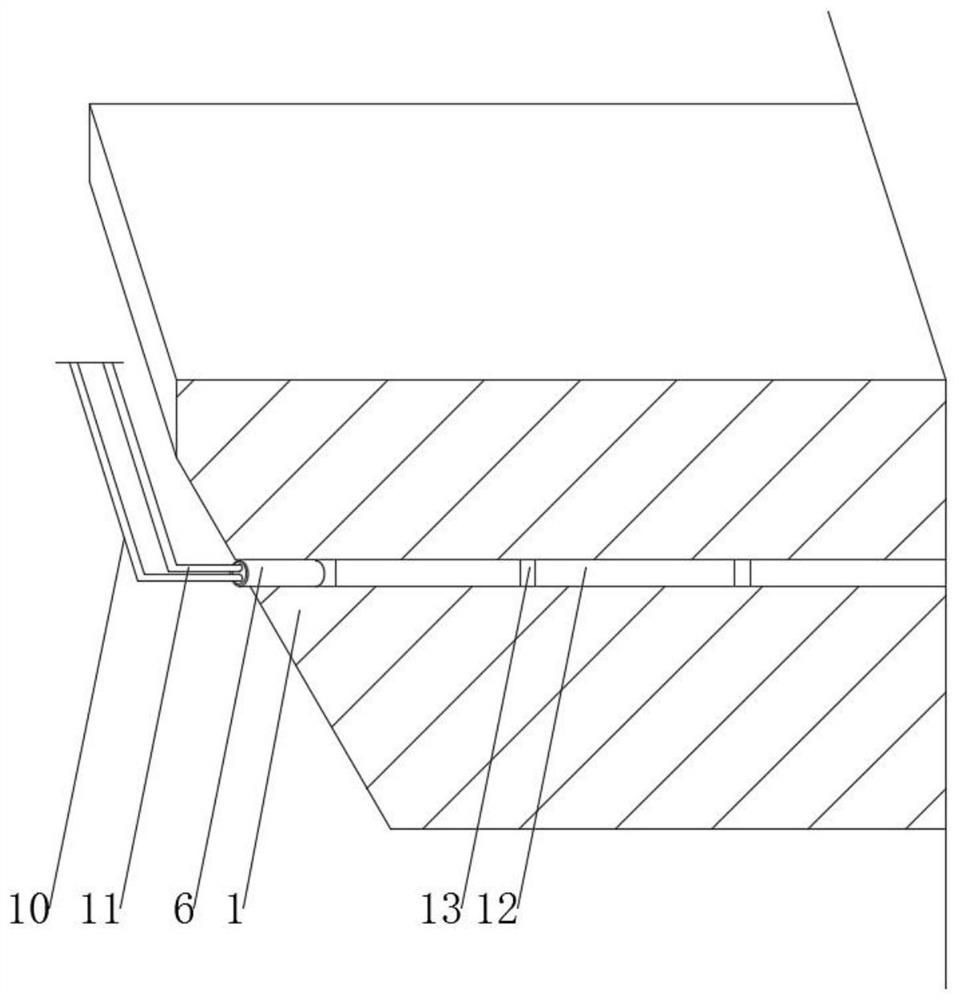

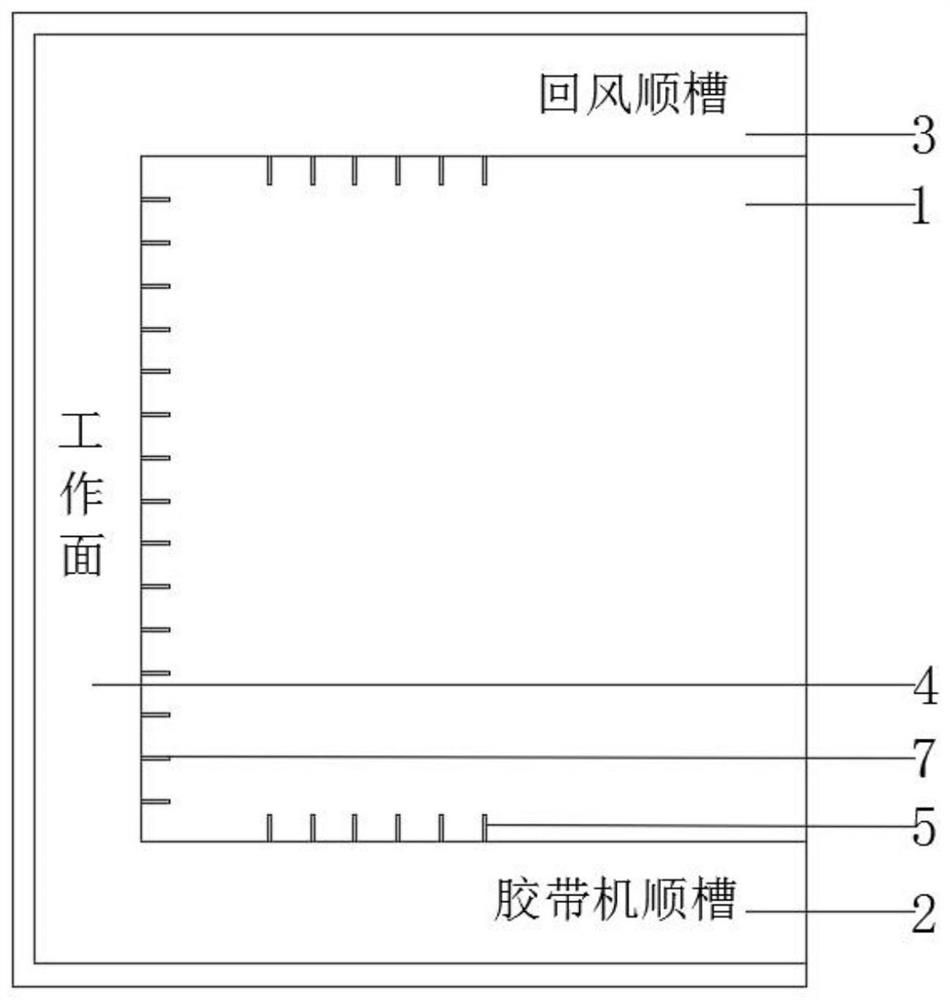

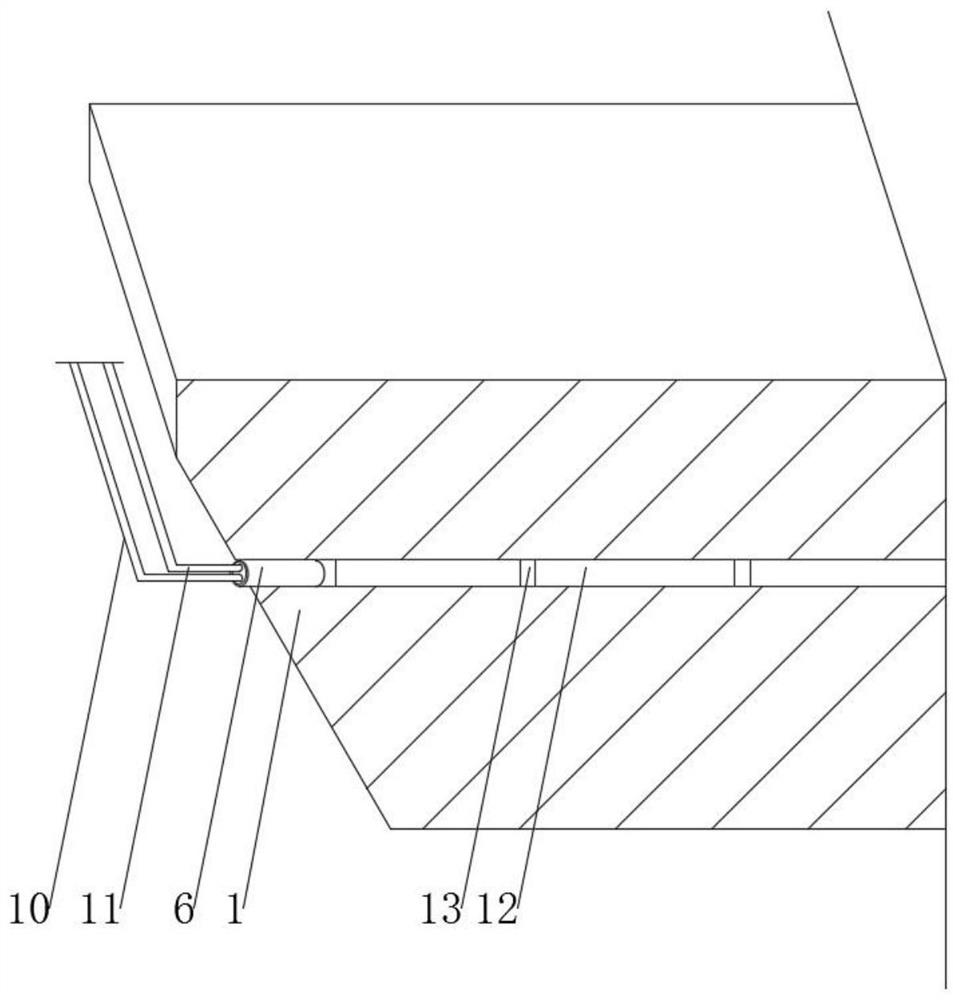

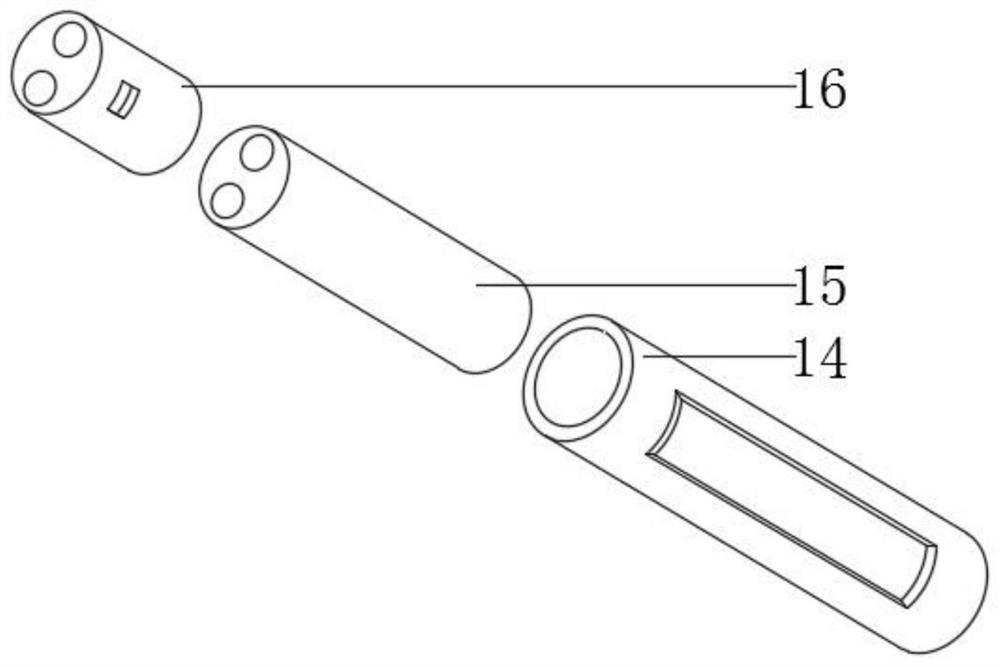

Dust-settling method of working face for layered and fully-mechanized coal mining of gently-declined thick coal seam by water injection under dynamic pressure

ActiveCN111794798AAvoid compaction effectReduce aggregation effectDust removalFire preventionMining engineeringMechanical engineering

The invention discloses a dust-settling method of a working face for layered and fully-mechanized coal mining of a gently-declined thick coal seam by water injection under dynamic pressure. The methodcomprises the following steps of drilling a sealing-tape machine crossheading and an air return crossheading in the two sides of the coal seam respectively, and getting through and connecting the tail ends of the sealing-tape machine crossheading and the air return crossheading to form the working face used for fully-mechanized coal mining; conducting drilling at intervals in the sealing-tape machine crossheading and the air return crossheading in the length direction of the sealing-tape machine crossheading and the air return crossheading to drill out spaced dynamic pressure holes I, and filling the dynamic pressure holes I with cut-off devices I used for sealing the radial direction of the dynamic pressure holes I; injecting safe gas in the dynamic pressure holes I through the cut-off devices I according to a predetermined exhaust rule, and then replacing hazardous gas in the dynamic pressure holes I with the safe gas through the cut-off devices I; using the safe gas to sufficientlyopen up the intervals according to the predetermined exhaust principle to avoid the situation that the hazardous gas drifts away, causing decompression and accompanying compaction effect; and meanwhile, the hazardous gas and safe gas are mixed to constantly and continuously dilute the concentration of the hazardous gas, and therefore, the aggregation effect of the hazardous gas is reduced to a great extent.

Owner:ANHUI UNIV OF SCI & TECH

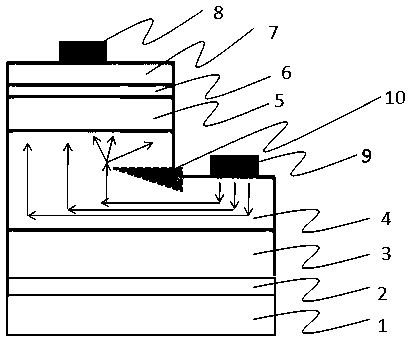

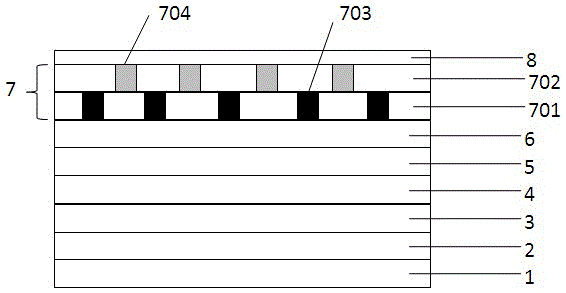

Light-emitting diode and method of making the same

ActiveCN105428483BUniform light outputReduce aggregation effectSemiconductor devicesLuminous intensityLight-emitting diode

The invention provides a diode structure design with uniform luminous intensity. An epitaxial wafer structure comprises a substrate, an N-type layer, a multi-quantum well active region and a P-type layer from bottom to top; preparation of a chip technology is carried out; a current adjusting structure is arranged at the position, close to an N electrode, in the N-type layer; a resistance value of a region at the position, close to the N electrode, in the N-type layer is increased by the current adjusting structure; the current carrier aggregation effect of the position close to the N electrode is reduced by controlling the summarized occupied volume and the transverse and longitudinal etching depths of the current adjusting structure in the N-type layer; relatively multiple current carriers flow to the position close to a P electrode; the number of electrons which flow to the position close to the P electrode in the N-type layer is increased; different positions of a same LED chip are relatively uniform in light-emitting; and meanwhile, the current carrier aggregation effect is relieved, so that the reliability of an LED is further improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

A method for dynamic pressure water injection and dust reduction in fully mechanized mining in layers with gently inclined thick coal seams

ActiveCN111794798BAvoid compaction effectReduce aggregation effectDust removalFire preventionEngineeringGas mixing

The invention discloses a method for dynamic pressure water injection and dust reduction on the working face of fully mechanized layered mining in a gently inclined thick coal seam, which comprises the following steps: respectively drilling out the belt machine along the groove and the return air along the groove according to the two sides of the coal seam, and putting the belt machine along the groove , The end of the air return chute is opened to connect to form a working face for comprehensive coal mining; holes are drilled at intervals in the belt conveyor chute and return air chute according to their length direction to drill the spaced dynamic pressure holes I, and Fill the dynamic pressure hole I with the interceptor I used to block the radial direction of the dynamic pressure hole I; according to the predetermined exhaust rules, inject safety gas into the dynamic pressure hole I through the interceptor I, and then pass through the interceptor I to release the safe gas Replace the dangerous gas in the dynamic pressure hole Ⅰ; according to the predetermined exhaust rules, the safety gas will fully open the gap to avoid the compaction effect caused by the pressure release after the dangerous gas is free; the dangerous gas and the safe gas are mixed to continuously and continuously Diluting its concentration greatly weakens the accumulation effect of dangerous gases.

Owner:ANHUI UNIV OF SCI & TECH

A method of using graphene oxide to strengthen recycled concrete

The invention relates to a method for reinforcing recycled concrete by using graphene oxide. The method comprises the following steps: (1) preparing raw materials; (2) adding water into the graphene oxide to prepare dispersion liquid; (3) adding water into a water reducing agent to prepare a water reducing agent solution; (4) adding the dispersion liquid into the water reducing agent solution, stirring and then carrying out ultrasonic treatment for 15-20min to prepare a mixed solution; (5) screening recycled coarse aggregate, then mixing the screened material with fine sand and stirring, adding cement into the obtained mixture and stirring; (6) adding the mixed solution into the mixture under the condition of stirring, putting the product into a test mould after stirring, evenly vibrating on a vibration table, and then curing in a curing room. The method provided by the invention is reasonable in design and simple and convenient to operate; a rich lamellar structure of the graphene oxide contains a great deal of oxygen-containing active groups, so that growth points are provided for hydration products of the cement; a template effect for hydration of the concrete is achieved, and the mechanical properties and durability of the recycled concrete are improved.

Owner:宁夏赛马科进混凝土有限公司

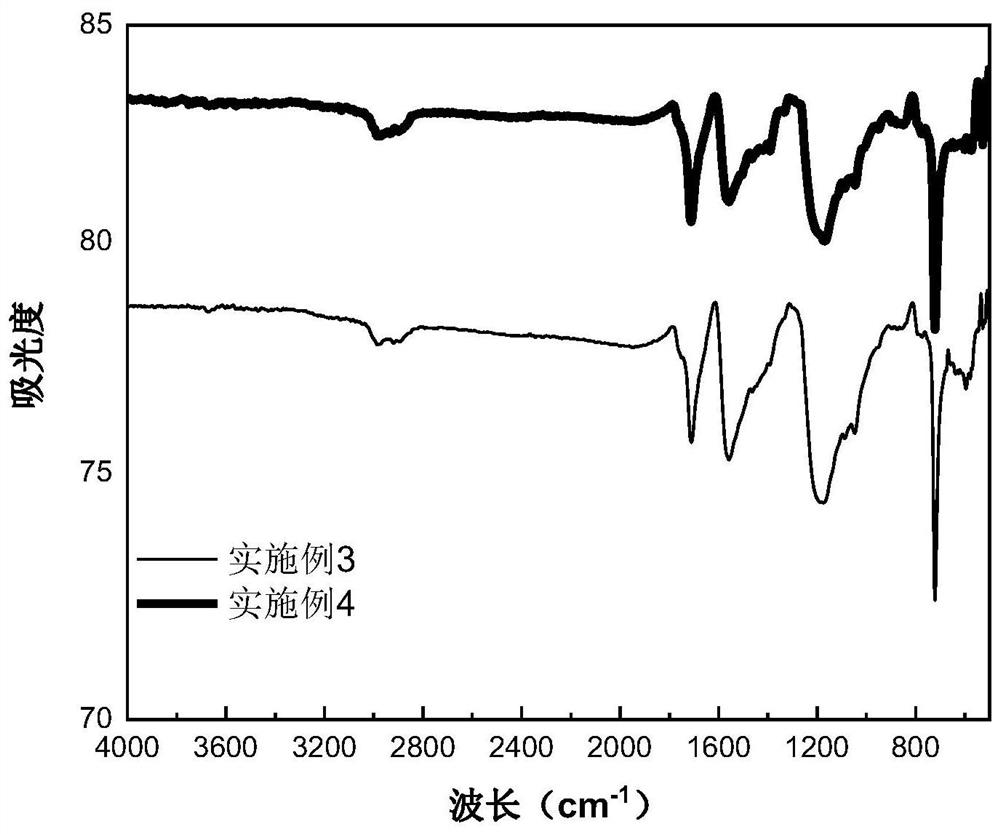

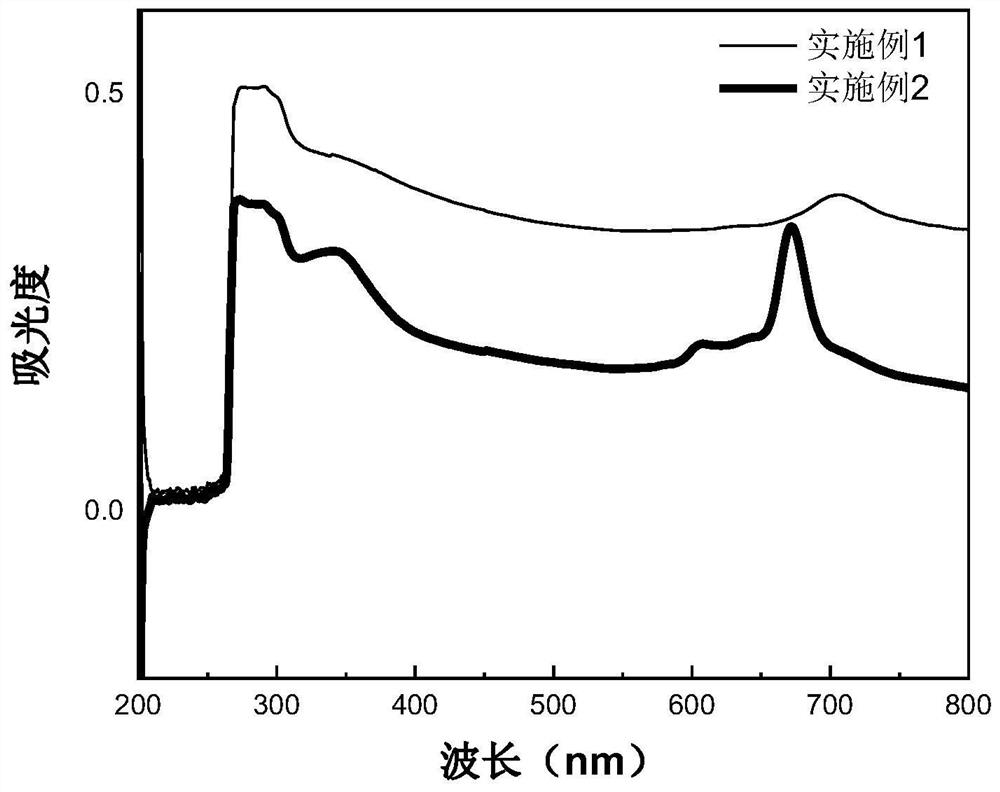

Functionalized graphene oxide-phthalocyanine nonlinear optical composite material as well as preparation method and application thereof

InactiveCN112142691AEasy to prepareApplicable protectionOrganic chemistry methodsNon-linear opticsElectron donorOptical limiting

The invention relates to a functionalized graphene oxide phthalocyanine nonlinear optical composite material as well as a preparation method and application thereof, belongs to the technical field ofnonlinear optical composite materials, overcomes the defects in the prior art, and obtains a functional material for effective optical limiting laser protection. The nonlinear optical composite material is formed by bonding phthalocyanine and functionalized graphene oxide, and the functionalized graphene oxide is one of asymmetric functionalized graphene oxide and symmetric functionalized grapheneoxide. The non-linear optical composite material forms an electron donor receptor system, is beneficial to rapid transfer of electrons, enables phthalocyanine and graphene oxide to have a synergisticeffect to show excellent three-order non-linear optical performance and stable performance, reduces the aggregation effect in an organic solvent, can be used as an optical limiting material, and is especially suitable for laser device protection.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

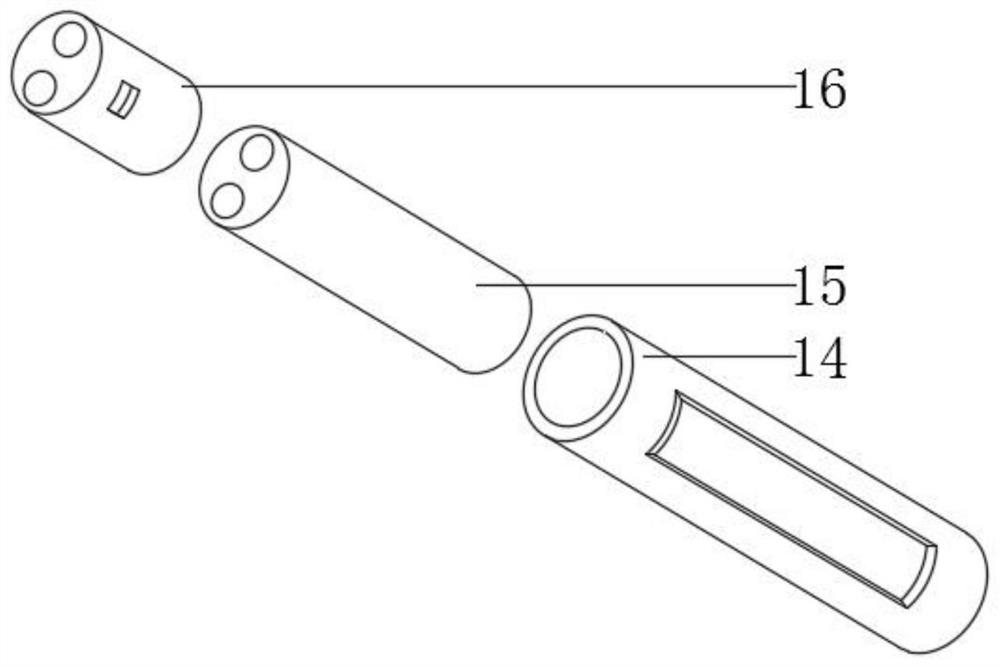

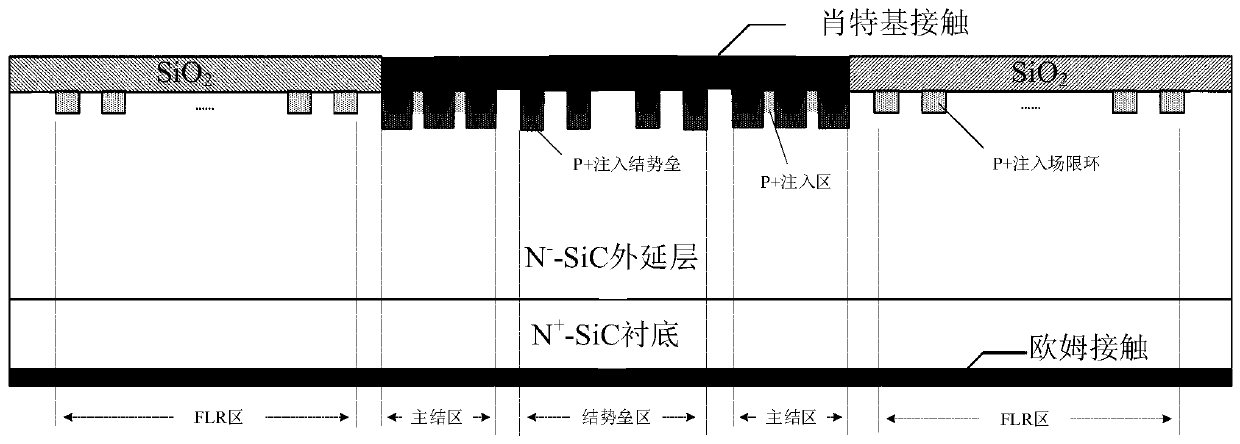

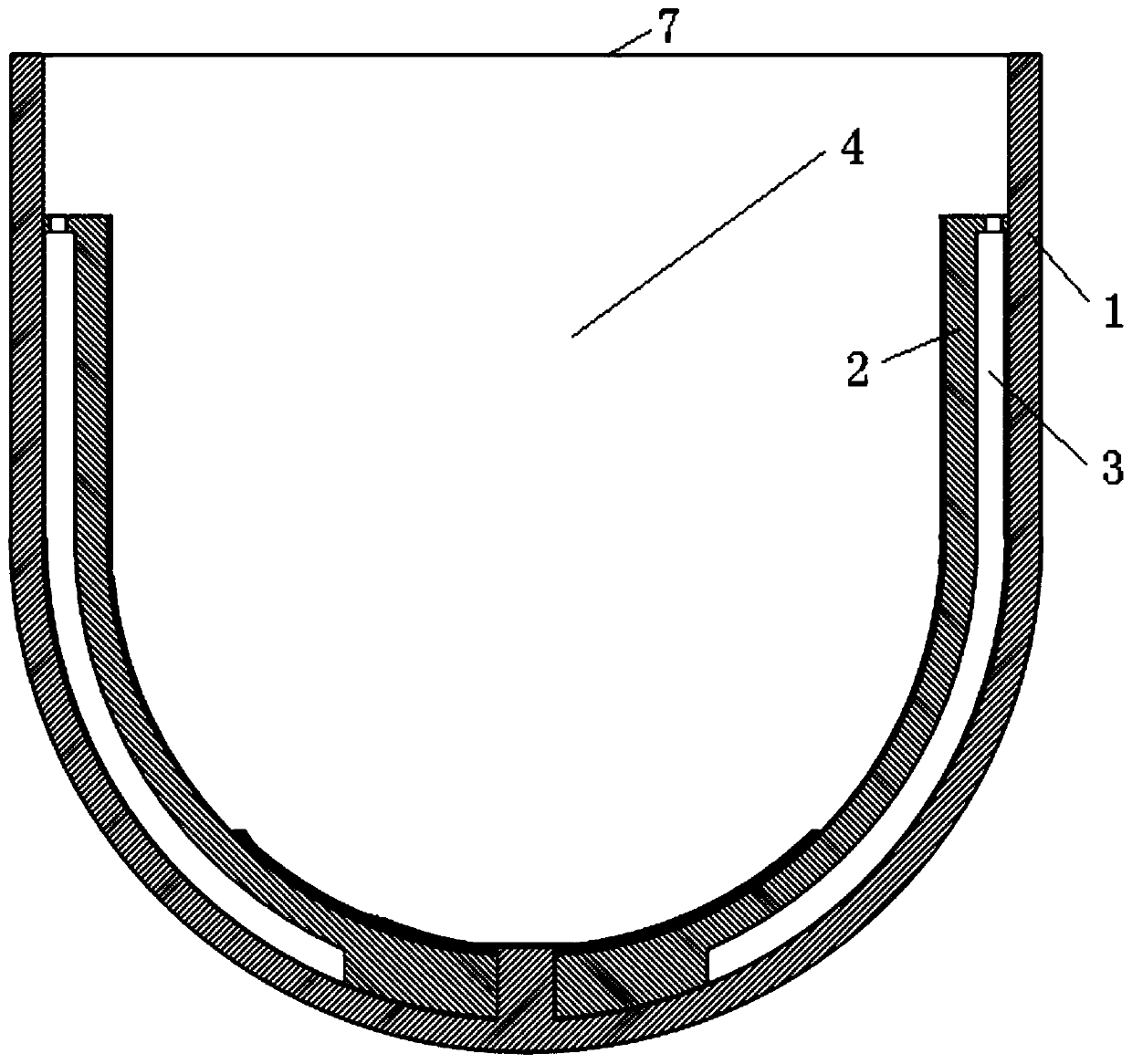

A trench junction barrier Schottky diode and its manufacturing method

ActiveCN107331616BReduce aggregation effectIncrease the main junction areaSemiconductor/solid-state device manufacturingSemiconductor devicesMetallic electrodeOhmic contact

The present invention provides a trench junction barrier Schottky diode and a manufacturing method thereof. The method comprises: the step 1, providing a substrate configured to manufacture a device, wherein an epitaxial layer is grown at the right side of the substrate; the step 2, manufacturing a field limiting ring area and a preparation main junction area on the epitaxial layer, wherein the preparation main junction area is configured to provide first ion implantation; the step 3, etching a junction barrier groove on the epitaxial layer except the field limiting ring area, wherein the main junction groove is etched at the preparation main junction area, and the junction barrier groove and the junction groove are subjected to second ion implantation; the step 4, manufacturing ohmic contact at the back of the substrate; the step 5, manufacturing a passivation layer and Schottky contact at the right side of the device; and the step 6, manufacturing a metal electrode at the right side of the device and performing passivation. The present invention further provides a trench junction barrier Schottky diode. The trench junction barrier Schottky diode and the manufacturing method thereof can reduce the main junction electric field aggregation effect while effectively shielding the Schottky surface electric field, vertically increase the main junction area and improve the pressure-resisting features.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

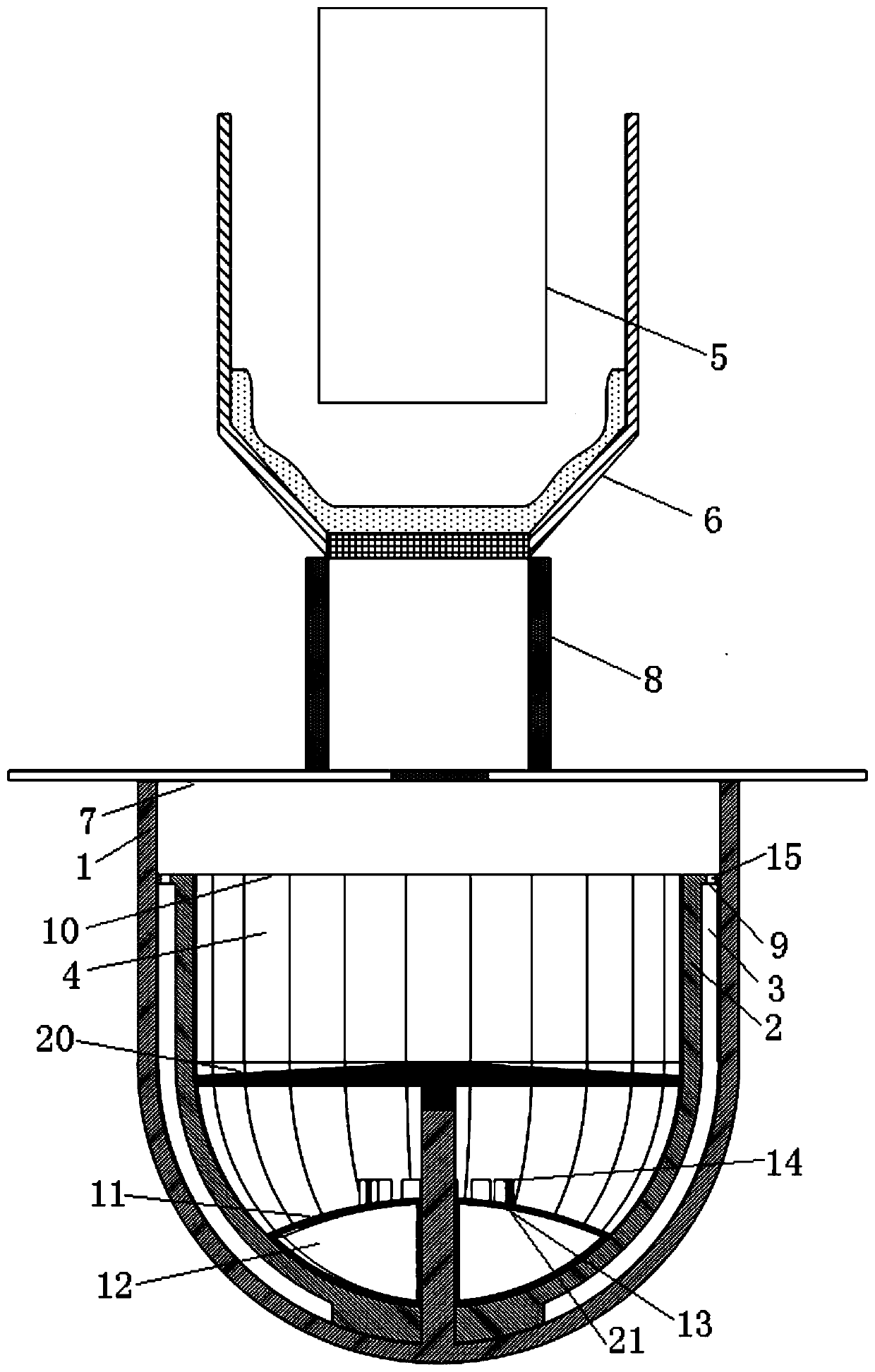

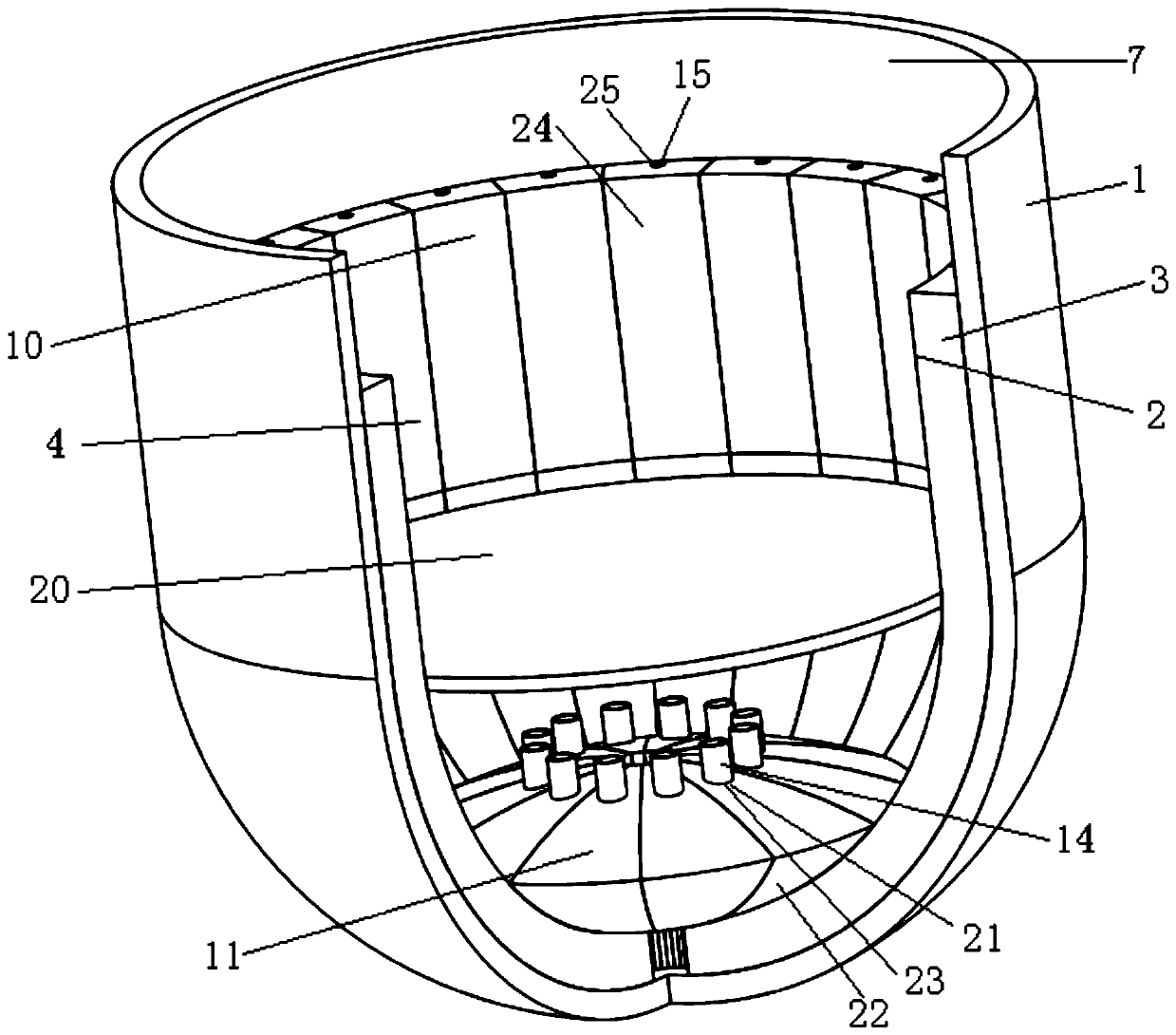

core melt trap

ActiveCN108550406BImprove cooling effectReduce aggregation effectNuclear energy generationEmergency protection arrangementsNuclear engineeringAtomic physics

The invention discloses a reactor core melt trapping device. The reactor core melt trapping device comprises a trapping cylinder having a crucible form and used for trapping a reactor core melt, the trapping cylinder is located below the pressure vessel of a reactor, the pressure vessel of the reactor is arranged in the reactor pit of the reactor, the bottom of the reactor pit of the reactor is connected with the opening of the trapping cylinder by a communication channel, the reactor core melt trapping device further comprises a first partition assembly, the first partition assembly divides the trapping cylinder into at least two trapping chambers which are sequentially sleeved from the outside to the inside, and the inlets of the trapping chambers are communicated with the opening of thetrapping cylinder. When severe nuclear accidents occur, the first partition assembly divides the trapping cylinder into the at least two trapping chambers which are sequentially sleeved from the outside to the inside, so the coolability of the melt is enhanced, the cooling efficiency of the melt is improved, the volume of the trapping device is effectively reduced, the melt is reduced in areas, the accident post-treatment of the reactor is greatly simplified, and the radiation dose received by workers is effectively reduced.

Owner:CHINA NUCLEAR POWER ENG CO LTD

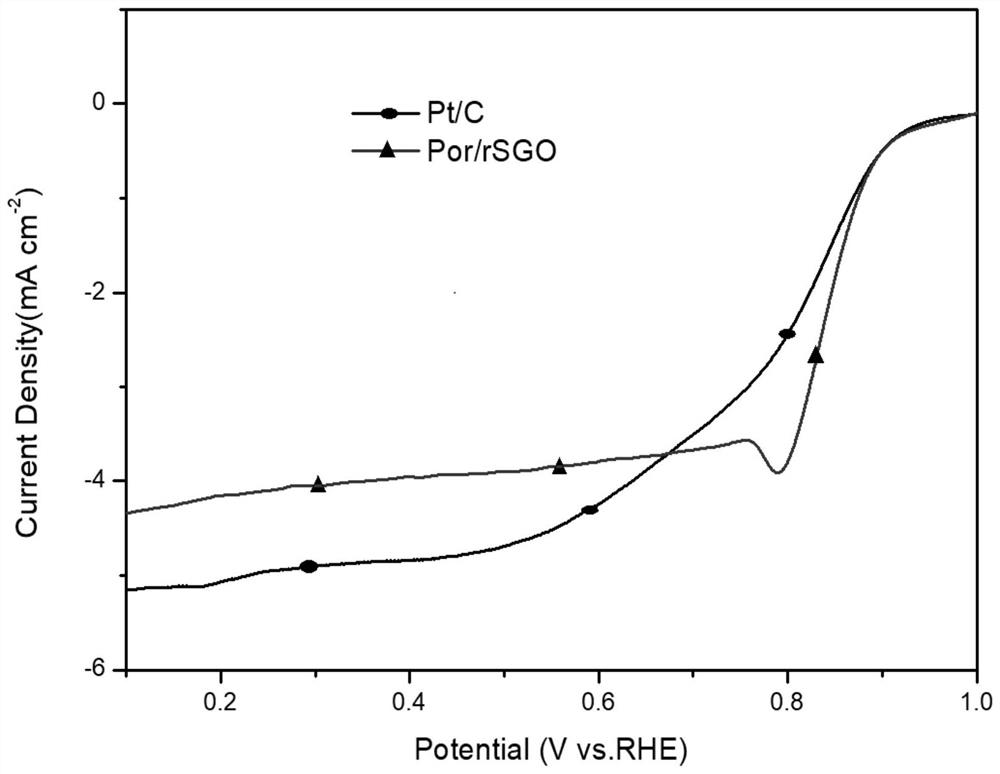

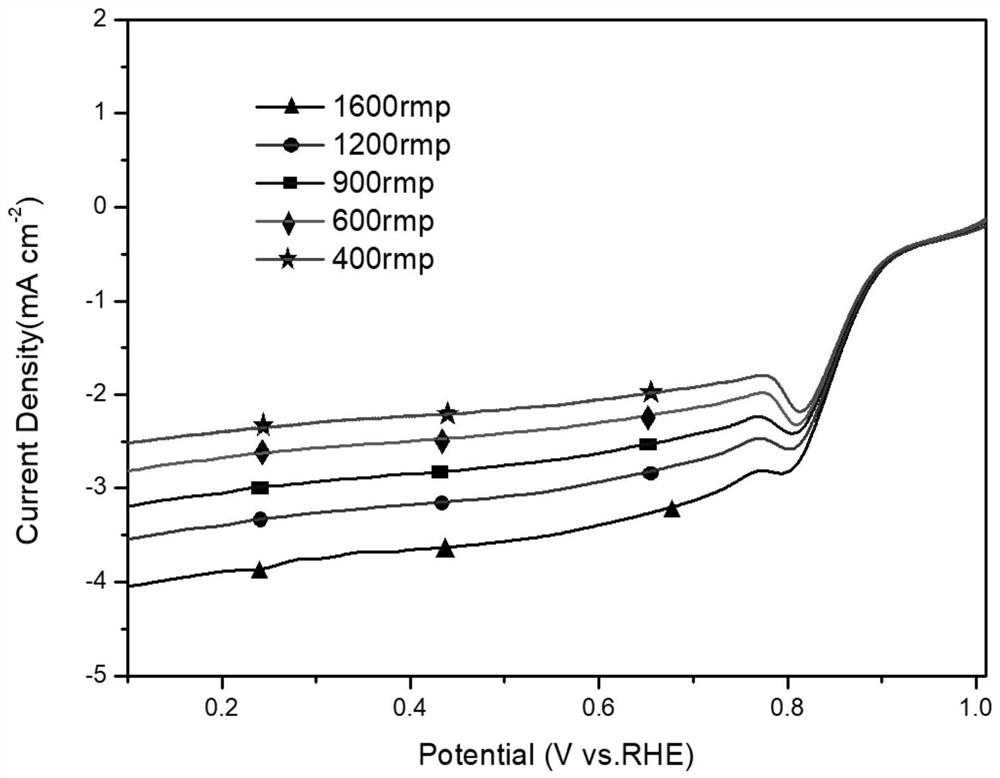

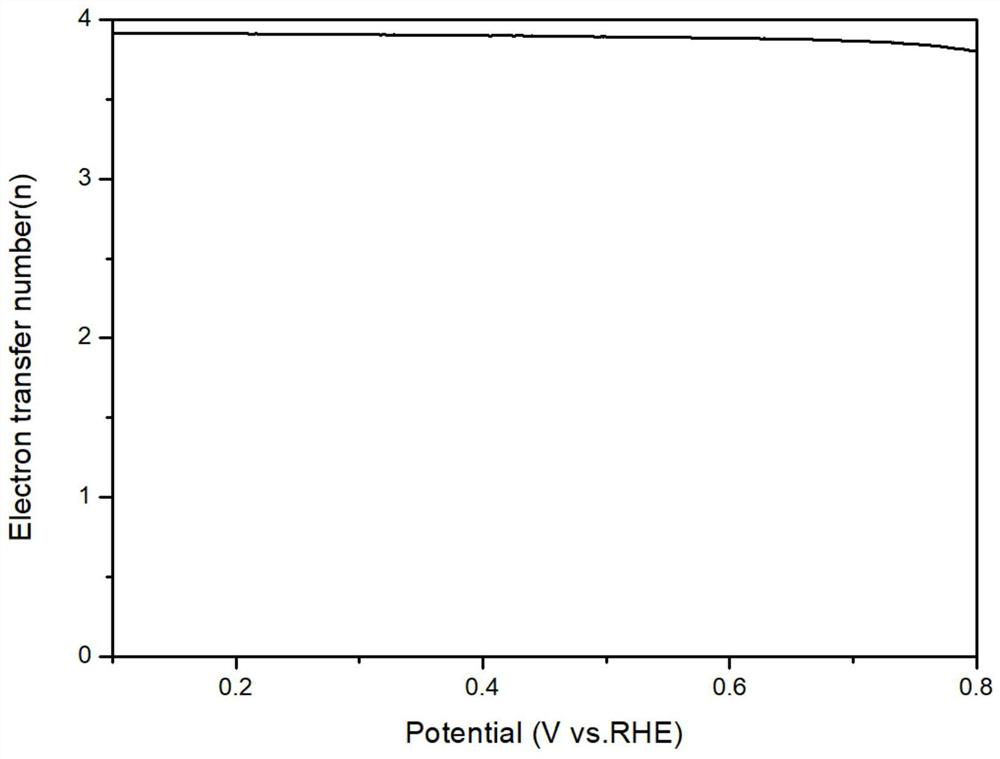

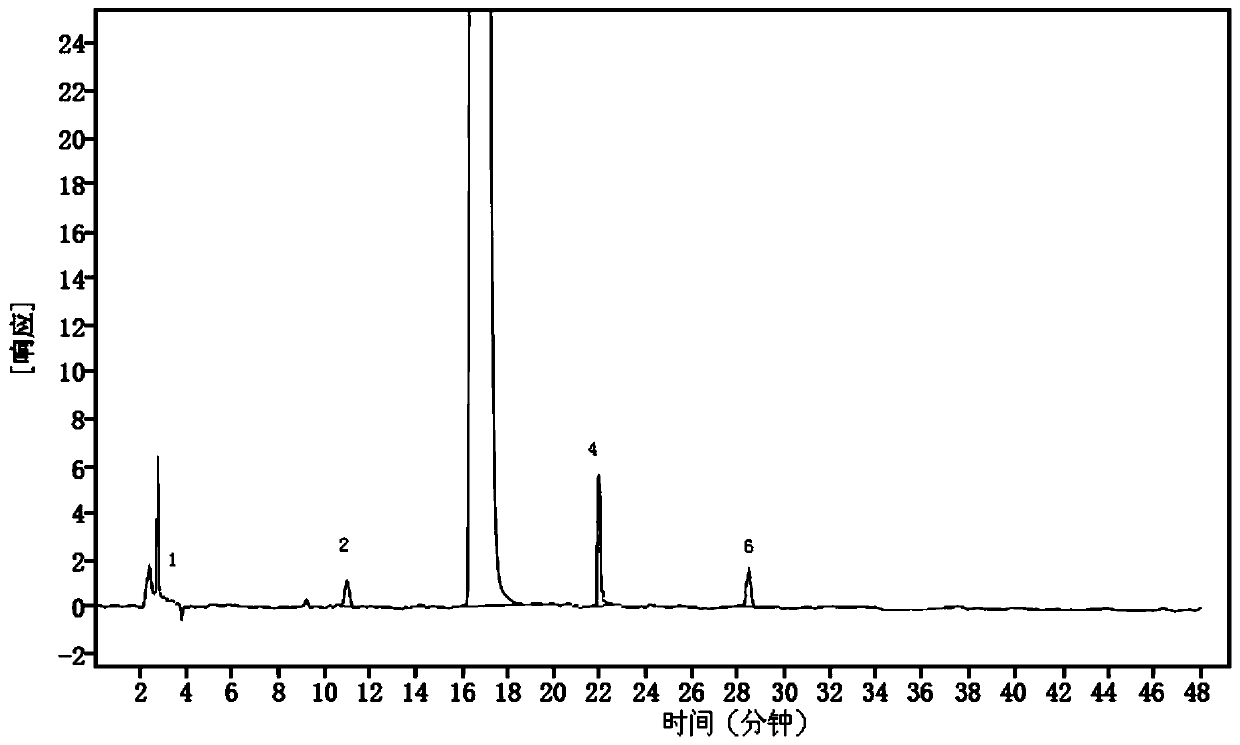

A kind of preparation method and application of functionalized graphene ORR catalyst

ActiveCN112242528BImprove conductivityHigh onset potentialFuel and primary cellsPositive electrodesPtru catalystElectrical battery

The invention discloses a preparation method and application of a functionalized graphene ORR catalyst. Including: S1 synthesis of graphene sulfide; S2 synthesis of alkyl branched modified graphene sulfide; S3 synthesis of metalloporphyrin; S4 synthesis of functionalized graphene ORR catalyst. Application: Functionalized graphene ORR catalysts for cathodic oxygen reduction reactions in metal-air batteries and dye batteries. The functionalized graphene ORR catalyst prepared by the invention has good electrical conductivity, high initial potential, effectively reduces the overpotential of oxygen reduction, and its catalytic performance can be comparable to that of commercial Pt / C. The catalyst is used to assemble the liquid electrolyte zinc-air Battery, the open circuit voltage, maximum power density and constant current discharge time of the battery are better than commercial Pt / C; the preparation method of the present invention is simple, the preparation cost is low, and the repeatability is good, which is beneficial to the development of new electrochemical catalysts and energy conversion and Storage devices have important theoretical and practical significance.

Owner:JIANGSU UNIV OF TECH

A kind of amlodipine besylate tablet and preparation method thereof

ActiveCN107951849BReduce adsorptionReduce aggregation effectOrganic active ingredientsPharmaceutical non-active ingredientsOrganosolvPhysical chemistry

Owner:HUNAN QIANJIN XIELI PHARMA CO LTD

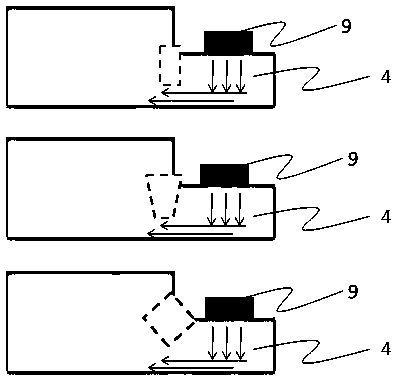

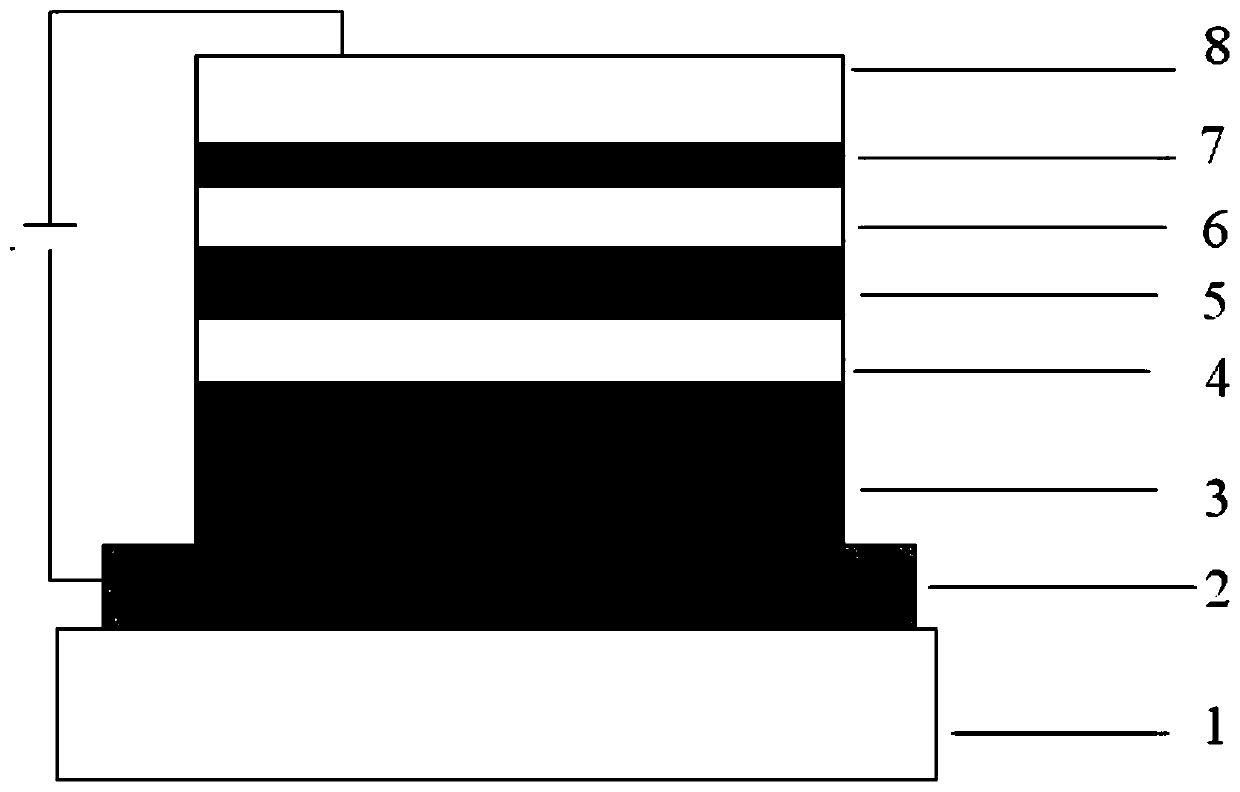

Light emitting diode and manufacturing method therefor

ActiveCN105742427AReduce carrier aggregation effectImprove light extraction efficiencySemiconductor devicesPower flowLight-emitting diode

The invention provides a light emitting diode and a manufacturing method therefor. The light emitting diode comprises an N type layer, a light emitting layer, a P type layer and a contact layer, wherein an insertion layer is designed between the P type layer and the contact layer; the insertion layer comprises an N<+> nitride layer and a P<+> nitride layer which are disjunctively distributed in a doping region; and the N<+> nitride layer and the P<+> nitride layer are not fully overlapped in the doping region in a perpendicular direction. Inclined tunneling junctions are formed by the N<+> nitride layer and the P<+> nitride layer disjunctively distributed in the doping region in the insertion layer, so that the current expansion is reinforced, and the luminance and reliability of the LED are improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

A kind of organic luminescent material and its application on oled

ActiveCN106432260BImprove applicabilityImprove luminous efficiencyGroup 4/14 element organic compoundsSolid-state devicesQuantum efficiencyFluorescence

The invention discloses an organic luminescent material and its application on OLED. The structural formula of the compound is shown in the general formula (1). The material has good fluorescence quantum efficiency and electroluminescent efficiency, and has good thermal stability, so the material can be used as a doping material for a light-emitting layer in an organic electroluminescent device.

Owner:JIANGSU SUNERA TECH CO LTD

Amlodipine besylate tablets

InactiveCN109953959AReduce adsorptionReduce aggregation effectOrganic active ingredientsInorganic non-active ingredientsCelluloseHydrogen phosphate

The invention relates to amlodipine besylate tablets. The amlodipine besylate tablets are mainly used for solving the technical problems that a conventional product is low in yield, poor in dissolution rate and the like. The technical scheme of the amlodipine besylate tablets is characterized in that the amlodipine besylate tablets comprise amlodipine besylate, micro powder silica gel, microlite cellulose, anhydrous calcium hydrogen phosphate, magnesium stearate and sodium carboxymethyl starch. The amlodipine besylate tablets are mainly used for the technical field of medicines.

Owner:HUNAN QIANJIN XIELI PHARMA CO LTD

A printing path generation method for metal additive manufacturing

ActiveCN108326301BWith randomnessReduced shrinkage deformationAdditive manufacturing apparatusIncreasing energy efficiencyThermal deformationProcess engineering

The invention belongs to the technical field of 3D printing, and specifically discloses a printing path generation method for metal additive manufacturing, which includes the following steps: layering the model to be printed to obtain a slice layer; partitioning the slice layer to form several printing sub-layers region; for the slice layer, generate a first random number sequence that determines the printing order of several print sub-areas; for each slice layer, the print sub-areas are sequentially sequenced according to the corresponding first random number sequence to print. The printing path generation method disclosed by the invention adopts the idea of random distribution, can effectively reduce residual stress, reduce thermal deformation, and improve the surface quality and dimensional accuracy of parts.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

A kind of light stabilizer and its preparation method and application

ActiveCN111100331BReactiveGood physical and mechanical propertiesGroup 4/14 element organic compoundsMonocomponent polyolefin artificial filamentPolymer scienceAlkoxy group

The invention discloses a light stabilizer, which has the structure shown in the following formula I: wherein, R 1 , R 2 , R 3 Each is independently selected from one or both of alkyl and alkoxy, and n is an integer of 2-4. The light stabilizer has an improved light stabilization effect, and at the same time, it has a good dispersing effect on the inorganic filler used together with it, and endows the plastic products using the light stabilizer with better physical and mechanical properties. The invention also discloses the preparation method and application of the light stabilizer.

Owner:宿迁联盛科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com